Professional Documents

Culture Documents

Approval Document ASSET DOC LOC 953

Approval Document ASSET DOC LOC 953

Uploaded by

andy_ramblaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approval Document ASSET DOC LOC 953

Approval Document ASSET DOC LOC 953

Uploaded by

andy_ramblaCopyright:

Available Formats

S IFI

AS

WL 7156

CL

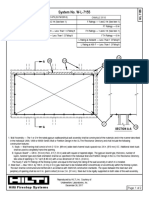

System No. W-L-7156

ED

C US

ANSI/UL1479 (ASTM E814) CAN/ULC S115

Classified by

Underwriters Laboratories, Inc. F Ratings — 1 and 2 Hr (See Item 1) F Ratings — 1 and 2 Hr (See Item 1)

to UL 1479 and CAN/ULC-S115

T Rating — 0, 1 and 2 Hr (See Item 4C) FT Rating — 0, 1, and 2 Hr (See Item 4C)

FH Ratings — 1 and 2 Hr (See Item 1)

FTH Rating — 0, 1, and 2 Hr (See Item 4C)

1A

4A

4C A 4A 4B 3 3

4B

2

4C 1B

A SECTION A-A

1. Wall Assembly — The 1 or 2 hr fire-rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner specified in

the individual U300, U400, V400 or W400 Series Wall and Partition Designs in the UL Fire Resistance Directory and shall include the following

construction features:

A. Studs — Wall framing shall consist of either wood studs or steel channel studs. Wood studs to consist of nom 2 by 4 in. (51 by 102 mm)

lumber spaced max 16 in. (406 mm) OC. Steel studs to be min 3-1/2 in. (89 mm) wide and spaced max 24 in. (610 mm) OC. Additional

framing members shall be used to completely frame around opening.

B. Gypsum Board* — Min 5/8 in. (16 mm) thick, 4 ft (1.2 m) wide with square or tapered edges. The gypsum board type, thickness, number of

layers and orientation shall be as specified in the individual Wall and Partition Design. Max size of opening is 210 sq in. (1355 cm2) with a

max width of 14-1/2 in. (368 mm) for wood studs. Max size of opening is 76.2 sq ft. (7 m2) with a max width of 105-1/2 in. (2.7 m) for steel

studs.

The hourly F and FH Ratings of the firestop system are equal to the hourly fire rating of the wall in which it is installed.

2. Steel Duct — Max 100 by 100 in. (2.5 by 2.5 m) steel duct to be installed within the framed opening. The duct shall be constructed and reinforced

in accordance with SMACNA construction standards. Steel duct to be rigidly supported on both sides of wall assembly.

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

August 22, 2018

Hilti Firestop Systems Page: 1 of 2

WL 7156

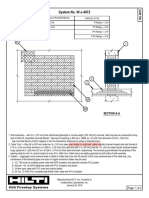

System No. W-L-7156

3. Batts and Blankets* — Nom 1-1/2 or 2 in. (38 or 51 mm) thick glass fiber batt or blanket (min 3/4 pcf or 12 kg/m3) jacketed on the outside with a

foil-scrim-kraft facing. Longitudinal and transverse joints sealed with aluminum foil tape. During the installation of the fill material, the batt or

blanket shall be compressed minimum 50% such that the annular space within the firestop system shall be min 1/2 in. (13 mm) to max 3-1/2 in.

(89 mm); refer to the table below.

See Batts and Blankets (BKNV) category in the Building Materials Directory for names of manufacturers. Any batt or blanket meeting the above

specifications and bearing the UL Classification Marking with a Flame Spread Index of 25 or less and a Smoke Developed Index 50 or less

may be used.

4. Firestop System — The firestop system shall consist of the following:

A. Packing Material — Min 3-5/8 (92 mm) or 4-7/8 in. (124 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into

opening as a permanent form for 1 or 2 hr fire-rated walls, respectively. Packing material to be recessed from both surfaces of wall to

accommodate the required thickness of fill material.

B. Fill, Void or Cavity Material* — Sealant — Min 5/8 in. (16 mm) thickness of fill material applied within annulus, flush with both surfaces of wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — FS-ONE MAX Intumescent Sealant

C. Steel Retaining Angles — Min No. 16 gauge (0.059 in. or 1.5 mm) galv steel angles sized to lap steel duct a min of 2 in. 51 mm) and lap wall

surfaces a min of 1 in. (25 mm). Angles attached to steel duct on both sides of wall with min No. 10 steel sheet metal screws spaced a max of

1 in. (25 mm) from each end of steel duct and spaced a max of 6 in. (152 mm) OC. When max duct dimension does not exceed 48 in. (122

cm) and duct area does not exceed 1300 in2 (8387 cm2), angles may be min No. 18 gauge galv steel. Angles attached to steel duct on both

sides of wall with min No. 10 by 1/2 in. (13 mm) long steel sheet metal screws located a max of 1 in. (25 mm) from each end of steel duct and

spaced a max of 6 in. (152 mm) OC. In addition, see table below for additional conditions and options regarding retaining angles.

Max Packing

Angle (Item

Max Duct Duct Insulation Annular Material

4C) T-Rating Hr

Dimension Thickness Thickness Space (Item 4A)

Required

(Item 3) Required

1/4 in. min to

**24 in. (610 24 ga or 1-1/2 in. (38

1 in. max (6 No No 0

mm) heavier mm)

to 25 mm)

25 in. (635 1/4 in. min to

1 and 2

mm) wide by 24 ga or 2 in. (51 3-1/2 in.

Yes No (Same as

45 in. (1143 heavier mm) max (6 to 89

wall rating)

mm) high mm)

** Indicates that when max 1-1/2 in. (38 mm) thick insulation is used, steel angles are optional for those sides of the duct that do not exceed the

dimension specified.

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

August 22, 2018

Hilti Firestop Systems Page: 2 of 2

You might also like

- Unit 4 Assignment 2 PXS TEMPLATEDocument4 pagesUnit 4 Assignment 2 PXS TEMPLATEAnNo ratings yet

- BILSTEIN - WNB-881-E (Long) - 1 CleanlinessDocument27 pagesBILSTEIN - WNB-881-E (Long) - 1 CleanlinessRoberto AlvarezNo ratings yet

- Esr 1042Document0 pagesEsr 1042murdicksNo ratings yet

- Cosmetology Portfolio: Jaimie R. FortinDocument34 pagesCosmetology Portfolio: Jaimie R. FortinJaimie FantasticNo ratings yet

- Schizophreniform DisorderDocument16 pagesSchizophreniform Disorderfeva55No ratings yet

- Readworks - From One To ManyDocument5 pagesReadworks - From One To ManyPilar Andrea MarquezNo ratings yet

- Holti System No. C-AJ-8143Document3 pagesHolti System No. C-AJ-8143S. Priscila Castillo V.No ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- Approval Document ASSET DOC LOC 709Document2 pagesApproval Document ASSET DOC LOC 709fazil yoosufNo ratings yet

- Approval Document ASSET DOC LOC 716Document2 pagesApproval Document ASSET DOC LOC 716fazil yoosufNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- Approval Document ASSET DOC LOC 939Document2 pagesApproval Document ASSET DOC LOC 939andy_ramblaNo ratings yet

- Hilti Insulated Metal Pipe Through Drywall PDFDocument2 pagesHilti Insulated Metal Pipe Through Drywall PDFShaun LopezNo ratings yet

- Ul HWD 0209Document2 pagesUl HWD 0209jlledwinestebanNo ratings yet

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlNo ratings yet

- W-L-1054 Pipe Through Gyp Board AssemblyDocument2 pagesW-L-1054 Pipe Through Gyp Board AssemblyJason StelleNo ratings yet

- Fire Sealant C-AJ-4054Document1 pageFire Sealant C-AJ-4054Ezhil AnandNo ratings yet

- HILTI - Approval-document-ASSET-DOC-LOC-722Document1 pageHILTI - Approval-document-ASSET-DOC-LOC-722david messierNo ratings yet

- Max 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyDocument2 pagesMax 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyvikaspisalNo ratings yet

- System No. C-AJ-2898Document2 pagesSystem No. C-AJ-2898darwish.hiltiNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- Caj 4107Document2 pagesCaj 4107Jorge OropezaNo ratings yet

- System No. C-AJ-2342: F Rating - 3 HR T Rating - 0 HR W Rating - Class 1 (See Item 3B)Document2 pagesSystem No. C-AJ-2342: F Rating - 3 HR T Rating - 0 HR W Rating - Class 1 (See Item 3B)darwish.hiltiNo ratings yet

- W L 1176Document1 pageW L 1176shama093No ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj8113 - DLDocument4 pagesSystem PDF Files - 1. UL and cUL Systems - Caj8113 - DLEmanuel PastlNo ratings yet

- C Aj 2586 PDFDocument1 pageC Aj 2586 PDFEmanuel PastlNo ratings yet

- Approval Document ASSET DOC LOC 257Document3 pagesApproval Document ASSET DOC LOC 257Omar DDCNo ratings yet

- Design No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263Document3 pagesDesign No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263EngTamerNo ratings yet

- Fundamentals of Shaped ChargesDocument111 pagesFundamentals of Shaped ChargesJaggerNo ratings yet

- BXUV.P725 - UL Product IqDocument13 pagesBXUV.P725 - UL Product IqRalph Ian MalabananNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- Iso 8457 2 1989 en FR PDFDocument6 pagesIso 8457 2 1989 en FR PDFMada TetoNo ratings yet

- Iso 8458 2 1989Document8 pagesIso 8458 2 1989Sumit bidwaiNo ratings yet

- Part A: Basic Information: Ref: Current Spec. NoDocument17 pagesPart A: Basic Information: Ref: Current Spec. NoAbhey DograNo ratings yet

- TF100 17D Rynglok Tube Repair SystemDocument8 pagesTF100 17D Rynglok Tube Repair SystemAnup DahalNo ratings yet

- WL7223Document1 pageWL7223Juvenal GutierrezNo ratings yet

- Approval Document ASSET DOC LOC 145Document2 pagesApproval Document ASSET DOC LOC 145Amir IqbalNo ratings yet

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- 10 kVA - Technical Specifications and GTP of DTRsDocument45 pages10 kVA - Technical Specifications and GTP of DTRsNirav ShahNo ratings yet

- Sistema UL HWD0079 Junta 2 Hrs DrywallDocument2 pagesSistema UL HWD0079 Junta 2 Hrs DrywallRaul Fernando Villarreal VargasNo ratings yet

- T Proc Notices Notices 040 K Notice Doc 35289 253020834Document8 pagesT Proc Notices Notices 040 K Notice Doc 35289 253020834billy chrisNo ratings yet

- BIS Hume PipeDocument7 pagesBIS Hume PipeShiv Pratap SinghNo ratings yet

- Technical Data: Model VFC Foam ChambersDocument8 pagesTechnical Data: Model VFC Foam Chambersrusli bahtiarNo ratings yet

- ASTM B333 Ni-Mo PlateDocument5 pagesASTM B333 Ni-Mo PlateElankumaran PeriakaruppanNo ratings yet

- Astm A820 A820m 22Document4 pagesAstm A820 A820m 22ashutoshkhurana15258No ratings yet

- Stopping StuffDocument28 pagesStopping StuffaNo ratings yet

- 357 Series Control Valves: Bulletin 51.2:357Document10 pages357 Series Control Valves: Bulletin 51.2:357Djebali MouradNo ratings yet

- Astm b160Document6 pagesAstm b160Kevin Almeida100% (1)

- A252Document7 pagesA252Luz DuarteNo ratings yet

- Prestressed Concrete I Beam - Design ExampleDocument67 pagesPrestressed Concrete I Beam - Design ExampleNOEL RODRIGUEZ100% (1)

- Design No. D759: October 31, 2003Document9 pagesDesign No. D759: October 31, 2003souravrobinNo ratings yet

- F 987 - 93 - Rjk4ny1sruq - PDFDocument6 pagesF 987 - 93 - Rjk4ny1sruq - PDFRománBarciaVazquezNo ratings yet

- Part Number: 811280: Issue 3Document7 pagesPart Number: 811280: Issue 3Francisco Alejandro Ibanez DextreNo ratings yet

- Astm B163 PDFDocument12 pagesAstm B163 PDFSuellen FerreiraNo ratings yet

- Technical Specification - FilterDocument15 pagesTechnical Specification - FilterMurli RamchandranNo ratings yet

- Check The Source To Verify That This Is The Current Version Before UseDocument18 pagesCheck The Source To Verify That This Is The Current Version Before UseLuis CrespoNo ratings yet

- Approval Document ASSET DOC LOC 99Document1 pageApproval Document ASSET DOC LOC 99Amir IqbalNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFEmanuel PastlNo ratings yet

- Nickel Rod and Bar: Standard Specification ForDocument6 pagesNickel Rod and Bar: Standard Specification FormahfuzNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Narrow Band-Pass Filters for Low Frequency Applications: Evaluation of Eight Electronics Filter Design TopologiesFrom EverandNarrow Band-Pass Filters for Low Frequency Applications: Evaluation of Eight Electronics Filter Design TopologiesNo ratings yet

- Thyssenkrupp Traffic AnalysisDocument12 pagesThyssenkrupp Traffic Analysisandy_ramblaNo ratings yet

- Approval Document ASSET DOC LOC 939Document2 pagesApproval Document ASSET DOC LOC 939andy_ramblaNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- Road BlockersDocument4 pagesRoad Blockersandy_ramblaNo ratings yet

- Schematics and Light Details-Aviation LightsDocument23 pagesSchematics and Light Details-Aviation Lightsandy_ramblaNo ratings yet

- Security Conditions and Requirements of The Services of Money and Precious Materials TransportationDocument16 pagesSecurity Conditions and Requirements of The Services of Money and Precious Materials Transportationandy_ramblaNo ratings yet

- Normal 628cbcbec046cDocument241 pagesNormal 628cbcbec046candy_ramblaNo ratings yet

- Puddle Flange 2011Document12 pagesPuddle Flange 2011andy_ramblaNo ratings yet

- Kadar Protein Terlarut Dalam Albumin Ikan Gabus (Channa Striata Dan Channa Micropeltes) Asal BogorDocument9 pagesKadar Protein Terlarut Dalam Albumin Ikan Gabus (Channa Striata Dan Channa Micropeltes) Asal BogorAnkaranaRenvaNo ratings yet

- Volcanic EruptionDocument2 pagesVolcanic EruptionAhmad NursidikNo ratings yet

- Poa UkDocument4 pagesPoa Ukbelu22adlNo ratings yet

- Best and Worst Paying University DegreesDocument5 pagesBest and Worst Paying University Degreesrajronson6938No ratings yet

- Parker Hose & Fittings (2014-08)Document488 pagesParker Hose & Fittings (2014-08)BrianNo ratings yet

- Choosing Wisely Recommendations PDFDocument244 pagesChoosing Wisely Recommendations PDFFelipe Bernardelli MarquesNo ratings yet

- The Effect of Abuse Among Children in Conflict With The Law in Bahay Pag-AsaDocument13 pagesThe Effect of Abuse Among Children in Conflict With The Law in Bahay Pag-AsaMarlone Clint CamilonNo ratings yet

- STS PrelimsDocument9 pagesSTS PrelimsKatrina PeñaNo ratings yet

- Steve F. Carlisle,: Professional SummaryDocument5 pagesSteve F. Carlisle,: Professional SummaryRickey StokesNo ratings yet

- Research Proposal - Matthew WengrowichDocument17 pagesResearch Proposal - Matthew Wengrowichapi-311840545100% (1)

- Approach To Neonatal HyperbilirubinemiaDocument34 pagesApproach To Neonatal HyperbilirubinemiaNilesh HatzadeNo ratings yet

- Reducing Work Related Psychological Ill Health and Sickness AbsenceDocument15 pagesReducing Work Related Psychological Ill Health and Sickness AbsenceBM2062119PDPP Pang Kuok WeiNo ratings yet

- CHEM 203 Introductory Chemical Techniques: Exp. 3: Determination of An Equilibrium ConstantDocument4 pagesCHEM 203 Introductory Chemical Techniques: Exp. 3: Determination of An Equilibrium ConstantCarl-Etienne ChaayaNo ratings yet

- Magazine AnnounceDocument36 pagesMagazine AnnounceRonaldo Rodrigues de OliveiraNo ratings yet

- DSP Glucose OxidaseDocument1 pageDSP Glucose OxidaseJowanna BurceNo ratings yet

- Muscle Energy Model 9-30-08.coryDocument4 pagesMuscle Energy Model 9-30-08.coryWilliam BlairNo ratings yet

- UK DynaSand C0209Document2 pagesUK DynaSand C0209Mee DepoNo ratings yet

- 10 - Guidelines For IOR and EORDocument35 pages10 - Guidelines For IOR and EORAndre Yudhistira100% (1)

- 4-Adrienne Adams, New York City CouncilDocument2 pages4-Adrienne Adams, New York City CouncilCapitol PressroomNo ratings yet

- Pharmacology of AntidepressantsDocument28 pagesPharmacology of Antidepressantsحيدر كريم سعيد حمزهNo ratings yet

- F 27414 3Document216 pagesF 27414 3VinothKumarDhananjayanNo ratings yet

- Responsibility AccountingDocument4 pagesResponsibility AccountingEllise FreniereNo ratings yet

- 150 de Thi Hoc Sinh Gioi Tieng Anh Lop 6 Kem Dap AnDocument58 pages150 de Thi Hoc Sinh Gioi Tieng Anh Lop 6 Kem Dap AnChung Thuỷ NguyễnNo ratings yet

- Re48050 2010-08Document96 pagesRe48050 2010-08Cesar SanchezNo ratings yet

- Ppt-Sugarcane Bagasse AshDocument27 pagesPpt-Sugarcane Bagasse AshHegdeVenugopalNo ratings yet

- Trans-Savi-Med2-Lec 28-Introduction-to-Infectious-Diseases-1st-SemesterDocument7 pagesTrans-Savi-Med2-Lec 28-Introduction-to-Infectious-Diseases-1st-SemesterAdrian CaballesNo ratings yet