Professional Documents

Culture Documents

Joint Inspection Report Mechanical

Joint Inspection Report Mechanical

Uploaded by

Rohan SharmaCopyright:

Available Formats

You might also like

- Starbucks LTV Case StudyDocument8 pagesStarbucks LTV Case StudyThanh NhànNo ratings yet

- 400 MM Digital Clamp Meter Make-Kyoritsu Model-KEW SNAP 2009R, SL No-W8039512Document20 pages400 MM Digital Clamp Meter Make-Kyoritsu Model-KEW SNAP 2009R, SL No-W8039512Ashutosh MondalNo ratings yet

- API 6D Valve Inspection TestDocument2 pagesAPI 6D Valve Inspection Testsaffririzal4237No ratings yet

- Jha To Perform On-Site Verification For Glycol ReboilerDocument2 pagesJha To Perform On-Site Verification For Glycol ReboilerEdha AliNo ratings yet

- 001 Inspection - Report - INTEC (05 - 07102015) PDFDocument7 pages001 Inspection - Report - INTEC (05 - 07102015) PDFfitroh_hzNo ratings yet

- Trai Qa R 45 Process Audit - FormatDocument5 pagesTrai Qa R 45 Process Audit - FormatRS MANIKANDANNo ratings yet

- TA202 A Lecture 1: Tutor: Shantanu BhattacharyaDocument12 pagesTA202 A Lecture 1: Tutor: Shantanu BhattacharyaRajat JainNo ratings yet

- 019-RCFA Disposal Pump-14520a 1'' Inlet Line Repair On 4th November 2016Document3 pages019-RCFA Disposal Pump-14520a 1'' Inlet Line Repair On 4th November 2016Jinlong SuNo ratings yet

- Blank - Inspection Report FormatDocument7 pagesBlank - Inspection Report Formatabdullahshamsi57No ratings yet

- Ansi/Tia-942 Audit & Certification Services: Uptime InstituteDocument4 pagesAnsi/Tia-942 Audit & Certification Services: Uptime InstituteInsan ArdiansyahNo ratings yet

- 11RCFA-CPF2-HP Gas CompBDocument5 pages11RCFA-CPF2-HP Gas CompBJinlong SuNo ratings yet

- ECI Booking Form-V1.7 O# 90058401 PDFDocument2 pagesECI Booking Form-V1.7 O# 90058401 PDFdevNo ratings yet

- 4605 ER ProbeDocument3 pages4605 ER ProbeAimon JahangirNo ratings yet

- NL07T0583Document5 pagesNL07T0583roger.chyneNo ratings yet

- Equipment InspectionDocument8 pagesEquipment InspectionRakesh MenonNo ratings yet

- (KPCC) Sop - Gas BoosterDocument12 pages(KPCC) Sop - Gas BoosterWindy Nitaejun HorvejkulNo ratings yet

- Determining If A PSSR Is Needed: ModificationsDocument2 pagesDetermining If A PSSR Is Needed: ModificationsDave CNo ratings yet

- Nordic Group 2020Document116 pagesNordic Group 2020Ronald LengNo ratings yet

- JHA Dryer Hot CommissioningDocument5 pagesJHA Dryer Hot CommissioningJowel MercadoNo ratings yet

- Quotation: Escherichia ColiDocument3 pagesQuotation: Escherichia ColiayuNo ratings yet

- ELECTREX General CatalogueDocument52 pagesELECTREX General CatalogueO TottaNo ratings yet

- Katalog BurnerDocument48 pagesKatalog BurnerSyeikhabil AsshoqofiNo ratings yet

- SOP-LEE-01 Pengendalian Dokumen & Informasi (Rev 00)Document1 pageSOP-LEE-01 Pengendalian Dokumen & Informasi (Rev 00)FendiNo ratings yet

- Msds Cuso4Document3 pagesMsds Cuso4Muhammad EvanNo ratings yet

- Continental Industrial PDFDocument359 pagesContinental Industrial PDFDavidNo ratings yet

- Pelatihan K3LDocument13 pagesPelatihan K3Lyono DaryonoNo ratings yet

- Quotation - Cotation: Description Du Travail / Work DescriptionDocument1 pageQuotation - Cotation: Description Du Travail / Work DescriptionmkpqNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- Datasheet 4558CDocument2 pagesDatasheet 4558CJose Isabel Cordero LopezNo ratings yet

- 2021.12.12 - Pinched Finger (MTC) - Rantau - Zona 1Document1 page2021.12.12 - Pinched Finger (MTC) - Rantau - Zona 1BennyNo ratings yet

- ENV-SPV-DR-B-003 Fabrication Procedure-Rev - ADocument11 pagesENV-SPV-DR-B-003 Fabrication Procedure-Rev - AyoeyNo ratings yet

- PR-IMS-042 Chemical Management ProcedureDocument18 pagesPR-IMS-042 Chemical Management ProcedureBlister PatchNo ratings yet

- Cimolai Technology UtDocument12 pagesCimolai Technology UtWisthon GrimanNo ratings yet

- Blank - Inspection Report FormatDocument8 pagesBlank - Inspection Report Formatabdullahshamsi57No ratings yet

- Safety, Health & EnvironmentDocument60 pagesSafety, Health & EnvironmentGopalakrishnanNo ratings yet

- Pre-Shipment Inspection: Product PhotoDocument35 pagesPre-Shipment Inspection: Product Photo123456No ratings yet

- AM Series 45-200 D170 Rev D-W OM PDFDocument15 pagesAM Series 45-200 D170 Rev D-W OM PDFNestor SalasNo ratings yet

- ECOFOR For Cement Mill - A Dose of Dry MedicineDocument4 pagesECOFOR For Cement Mill - A Dose of Dry MedicineAntonNo ratings yet

- Methodology Tapping Methodology of WaterlineDocument15 pagesMethodology Tapping Methodology of WaterlineBryNo ratings yet

- Prose Dur QH Sse 2016Document198 pagesProse Dur QH Sse 2016danaokhtavianusNo ratings yet

- Sample Report AudioDocument33 pagesSample Report AudioraulNo ratings yet

- Operation Control - Powered and Hand Tools Procedure: Pt. Eskimo WieraperdanaDocument7 pagesOperation Control - Powered and Hand Tools Procedure: Pt. Eskimo WieraperdanadennisjuntakNo ratings yet

- Compro Russindo Group Tahun 2018 UpdateDocument44 pagesCompro Russindo Group Tahun 2018 UpdateElyza Farah FadhillahNo ratings yet

- Vscan ExtendDocument251 pagesVscan ExtendMohammed ShabanNo ratings yet

- 122 Triethylene GlycolDocument6 pages122 Triethylene Glycoleng20072007No ratings yet

- Hse Plan: W S Power SectorDocument130 pagesHse Plan: W S Power Sectorsurender bNo ratings yet

- Siemens Internship ReportDocument17 pagesSiemens Internship ReportmirfanbilalNo ratings yet

- 2 Rvs Training Profile Compressed (1) Din2Document22 pages2 Rvs Training Profile Compressed (1) Din2Ahmed shabanNo ratings yet

- Material Traceability ReporDocument2 pagesMaterial Traceability ReporDaengkulle Firmansyah PuteraNo ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: FacilityHelza RahmanniaNo ratings yet

- Noise Measurements, Standards and Control TechniquesDocument42 pagesNoise Measurements, Standards and Control TechniquesPrabhu PrasadNo ratings yet

- Radiography Permit: Al-Dur 2 Iwpp ProjectDocument1 pageRadiography Permit: Al-Dur 2 Iwpp ProjectJianping KeNo ratings yet

- Environment MP SoilDocument17 pagesEnvironment MP SoilRusihan HSE100% (1)

- Baticorrometro Polatrak Deepwater-Manual de OperacionDocument15 pagesBaticorrometro Polatrak Deepwater-Manual de OperacionemilidiverNo ratings yet

- (Datasheet Linterna Marina Carmanah M650) SelfContained - M650HDocument2 pages(Datasheet Linterna Marina Carmanah M650) SelfContained - M650Hahfuoahrf0384No ratings yet

- Danalyzer GC MAN 3 9000 744 700XA PDFDocument204 pagesDanalyzer GC MAN 3 9000 744 700XA PDFFercho MNo ratings yet

- 362-KMI-N2 Purging Into Station PipingDocument5 pages362-KMI-N2 Purging Into Station PipingNasrullah JanNo ratings yet

- RT Collimator Sentinel - Draft.compressedDocument2 pagesRT Collimator Sentinel - Draft.compressedEswaranNo ratings yet

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- RWNS 7Document2 pagesRWNS 7Rohan SharmaNo ratings yet

- RWNS - 70Document2 pagesRWNS - 70Rohan SharmaNo ratings yet

- Calibration Certificate Steel TapDocument3 pagesCalibration Certificate Steel TapRohan SharmaNo ratings yet

- Calibration Certificate U.T GaugeDocument1 pageCalibration Certificate U.T GaugeRohan SharmaNo ratings yet

- Calibration Certificate Dial VernierDocument2 pagesCalibration Certificate Dial VernierRohan SharmaNo ratings yet

- Hidayatullah National Law University Atal Nagar, ChhatisgarhDocument19 pagesHidayatullah National Law University Atal Nagar, ChhatisgarhPCLS HNLU ChapterNo ratings yet

- Wicaksana Overseas International Tbk-Dec 31 2022Document88 pagesWicaksana Overseas International Tbk-Dec 31 2022Jefri Formen PangaribuanNo ratings yet

- CH 12Document19 pagesCH 12Vandana GuptaNo ratings yet

- Partnership: Fundamentals Guarantee of ProfitsDocument12 pagesPartnership: Fundamentals Guarantee of ProfitsJoshua DevNo ratings yet

- Project of Business StudiesDocument12 pagesProject of Business StudiesVinit NishadNo ratings yet

- Market Failure With Public GoodsDocument29 pagesMarket Failure With Public GoodsJefainNo ratings yet

- Tax Invoice/Bill of Supply/Cash MemoDocument1 pageTax Invoice/Bill of Supply/Cash MemoCentralised NumberNo ratings yet

- Fiscal Policy Measures (4.3.3) CIE IGCSE Economics Revision Notes 2020 Save My ExamsDocument1 pageFiscal Policy Measures (4.3.3) CIE IGCSE Economics Revision Notes 2020 Save My Examseleftheriapetrou006No ratings yet

- Centenary Celebrations 05042022Document10 pagesCentenary Celebrations 05042022aditiNo ratings yet

- CPC Prc-3 Chap-1 NotesDocument14 pagesCPC Prc-3 Chap-1 NotesAhsan Rao0% (1)

- Nurmala Ahmar - STIE Perbanas Surabaya JMV Mulyadi - Universitas PancasilaDocument12 pagesNurmala Ahmar - STIE Perbanas Surabaya JMV Mulyadi - Universitas PancasilaHafidh NazmiNo ratings yet

- Contoh Laporan Arus KasDocument9 pagesContoh Laporan Arus KasPutri LestariNo ratings yet

- Practice Set: MerchandisingDocument2 pagesPractice Set: MerchandisingannegelieNo ratings yet

- Chessboards Price ListDocument6 pagesChessboards Price ListArandjel RodićNo ratings yet

- Fixed Income Group AssignmentDocument16 pagesFixed Income Group AssignmentHarshit Sekhar DassNo ratings yet

- Quality GurusDocument39 pagesQuality GurusShubham TiwariNo ratings yet

- Statsnotes 1Document140 pagesStatsnotes 1dcd80534No ratings yet

- CNC Problemset7Document2 pagesCNC Problemset7jibberish yoNo ratings yet

- College of Teacher Education: April Tivoli OmbayDocument3 pagesCollege of Teacher Education: April Tivoli OmbayMich ResueraNo ratings yet

- Probability and Nonprobability SamplingDocument7 pagesProbability and Nonprobability SamplingZemira BilogNo ratings yet

- ARVINDDocument1 pageARVINDprashant singhNo ratings yet

- Gcat21 Catalogo PetolDocument44 pagesGcat21 Catalogo Petoledinson piñerosNo ratings yet

- Accounting For GSTDocument30 pagesAccounting For GSTHarnitNo ratings yet

- Vol-1 - Appendix I.2 Axle Load Survey Data &a NalysisDocument2 pagesVol-1 - Appendix I.2 Axle Load Survey Data &a NalysisSudipThapaNo ratings yet

- SADC-RTGS Settlement Statistics and Indicators - December 2020Document9 pagesSADC-RTGS Settlement Statistics and Indicators - December 2020Kelvin ChisangaNo ratings yet

- 26 2829 01 Silicone Antifoams For Cleaning Products Manufacturing Selection GuideDocument2 pages26 2829 01 Silicone Antifoams For Cleaning Products Manufacturing Selection Guidelorejaz84071127No ratings yet

- SBI MaxGainDocument36 pagesSBI MaxGainRohit PandeyNo ratings yet

- Banking PresentationDocument8 pagesBanking PresentationGAGAN ANANDNo ratings yet

- Student Exam FormDocument4 pagesStudent Exam FormRaj Kumar TeotiaNo ratings yet

Joint Inspection Report Mechanical

Joint Inspection Report Mechanical

Uploaded by

Rohan SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Joint Inspection Report Mechanical

Joint Inspection Report Mechanical

Uploaded by

Rohan SharmaCopyright:

Available Formats

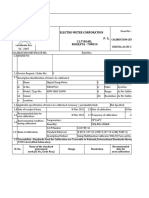

Joint Inspection Report

00090- FRAME FOR DEFLECTOR ROLL ASSY

NO 2 & 3(DEGREASING) 95465, 95477, 96074, 96140,

Item Name: 00100- FRAME FOR DIPPED DEFLETOR ROLL Inspection Call No. 96142, 96144, 96894 & 96897

NO 3 & 4 ASSY (ECL)

00070- ENTRY SEAL ROLL REMOVAL RIG ASSY

00090, 00100,

00170,00160,00200,00120,

Tata Steel PO No : 2300059935 Dtd 15/07/2022 SAP Line Item No :

00130 & 00220

602040108A1 R4, 602040507A1 R5,

602040119A1 R4, 602040115A1 R4,

PO Qty & Offered Qty: 8 No, 2 No, 2 No, 1 No, 2 No, 1 No, 1 No, 3 No. Approved Drg. No : 602040515A1 R4, 602040015A1 R4,

602040019A1 R4, 602040519A1 R4

Vendor as per PO : HEAVY ENGINEERING Sub Vendor: NIL

WORKSHOP(H02M),REWA

Tick relevant boxes & attach all backup reports

1. Final inspection

Witness/Review of test R W Witness/Review of test R W Witness/Review of test R W

2. Stage inspection 7.Internal Inspection

1.WPS/PQR/WPQ 14.Assembly Check

Report

15.Temparature

3. Other 2.Calibration Reports 8.Heat Treatment Record

Rise/Vibration/ Noise

16.Mechanical/Chemical

Check for Approved Documents 3.Material Test Certificate 9.LPT/DPT

Tests

1.PO SAP Description Check

4. Visual/Dimensions 10.MP Test 17.Hardness

2.Approved Drg.Datasheet & P&ID 11. LeakageTest

Diagram 4.Performance Test 18. Other

(Hydro/Pneumatic/waterfill)

3.Approved QAP & TDC 5.No load Run Test 1Ultrasonic Test 19. Movement Check

4. Other 6.Balancing Test 13.Function Test 20. Paint DFT check

S. No Non-compliance(s) To be attended by Vendor / Observations / Inprovements & rectifications Target Date Given by

Vendor

1. QAP Clause No 3 (a) Visual and weld size checked and witnessed as per drawing on 20% offered Lower

Support & Upper Support, Frame Motor Side, Defector Roll Frame, Frame support for Dipped Defetor, Frame

for Dipped Defector Roll, Support for Dipped Defector Roll, Support for Defector Roll & Frame for Defector

Roll and found in order and accepted.

2. QAP Clause No 3 (b). DP test for surface defects of fillet weld checked and witnessed on 20% offered Lower

Support & Upper Support, Frame Motor Side, Defector Roll Frame, Frame support for Dipped Defetor, Frame

for Dipped Defector Roll, Support for Dipped Defector Roll, Support for Defector Roll & Frame for Defector

Roll and no significant indication was observed and accepted.

3. QAP Clause no 3 (c) UT test on full penetraion joint- Not Applicable

4. QAP Clause No. 5 (a). Visual and Dimensional checked and witnessed on Lower Support & Upper Support,

Frame Motor Side, Defector Roll Frame, Frame support for Dipped Defetor, Frame for Dipped Defector Roll,

Support for Dipped Defector Roll, Support for Defector Roll & Frame for Defector Roll and found in order and

accepted

5. QAP Clause No. 5 (b). Completion of all operations/stages before painting checked and verified as per

drawing on offered Lower Support & Upper Support, Frame Motor Side, Defector Roll Frame, Frame support

for Dipped Defetor, Frame for Dipped Defector Roll, Support for Dipped Defector Roll, Support for Defector

Roll & Frame for Defector Roll and found in order and accepted.

6. Offered PO item No. 00090- FRAME FOR DEFLECTOR ROLL ASSY NO 2 & 3(DEGREASING) Slotted hole to be

aligned in one line and smooth, to be rectified. Compliance report submitted and other dimensions

checked as per drawing and found within tolerance.

00100- FRAME FOR DIPPED DEFLETOR ROLL NO 3 & 4 ASSY (ECL). Machining Completed Compliance

report submitted.

Note-Add additional page if required.

Page 1 of 1

Joint Inspection Report

7. Job Identification No- Drawing No, Mark No & Qty punched by hard punch checked and verifed and found in

order.

8. QAP Clause No. 1(b). MTCs reviewed and found inorder.

9. QAP Clause No. 2(a). WPS/PQR/WPQ reviewed and found in order.

10. Calibration Status of measuring instruments used in inspection verified and found valid calibration. Equipment

suitability and condition checked and found satisfactory at the time of inspection.

Decision:

Yes, see remarks

Compliance above Yes Yes

Reinspection Released for next

No Required No process No

Manufacturer/Sub Vendor’s

TSL’s Inspection Personnal’s Signature Signature With Stamp: Date: 21/03/2023

with Stamp: Main Contractor’sInspection & 22/03/2023

Personnal’s Signature with Stamp:

Place:

For details of offered item, Reference document, Calibration details and attendance details please refer continaution sheet.

MATERIAL / SUBJECT OF INSPECTION ITEM / TAG QTY

QTY

(Indicate if separate material list is provided in Nr / Material Offered for

As per P/O

attachment) Code inspection

NA 1 SET 1 SET

PO ITEM NO 00090- FRAME FOR DEFLECTOR ROLL ASSY NO 2 & 3

1 SET 1 SET

PO ITEM NO 00100- FRAME FOR DIPPED DEFLECTOR ROLL NO 3 NA

&4

1 SET 1 SET

PO ITEM NO 00170- FRAME SUPPORT FOR DEF ROLL NO 2 & 3 NA

DRIVE ASSY DEGREASING

1 SET 1 SET

PO ITEM NO 00160- FRAME SUPPORT FOR DEF ROLL NO 2 & 3 NA

DRIVE ASSY DEGREASING

PO ITEM NO 00200- FRAME FOR DIPPED ROLL DEF. ROLL NO 3 & 4 1 SET

NA 1 SET

DRIVE ASSY

PO ITEM NO 00120- SUPPORT FOR DIPPED DEF. ROLL No 1 DRIVE 1 SET

NA 1 SET

ASSY

PO ITEM NO 00130- SUPPORT FOR DIPPED DEF. ROLL No 1 DRIVE 1 SET

NA 1 SET

ASSY

PO ITEM NO 00220- FRAME FOR DEFLECTOR ROLL NO 4 , 5 & 6 1 SET

NA 1 SET

DRIVE ASSY

Note-Add additional page if required.

Page 1 of 1

Joint Inspection Report

REFERENCE DOCUMENTATION:

(Indicate if separate document list is provided in attachment)

Approval

Title Reference n° Rev. Approved by Date

status

PO 2300059935 0 Approved TSL 15/07/2022

QAP HEW/TATA Steel/01 0 Approved TSL 11/08/2022

GAD 602040108A1 R4, 602040507A1 R5, 602040119A1 R4,

Approved TSL

602040115A1 R4, 602040515A1 R4, 602040015A1 R4,

602040019A1 R4, 602040519A1 R4

Procedures NA NA NA NA NA

Tech. Spec. NA NA NA NA NA

MEASURING & TESTING EQUIPMENT USED

(Indicate if separate equipment list is provided in attachment)

Equipment Type Equipment Identity n° Last Calibration Date Expiry Date

Measuring Tape 0-5 Mtr KVN-21 28/01/2023 27/01/2024

Measuring Tape 0-30 Mtr MT-08 23/01/2023 22/01/2024

Vernier Caliper-0-300 MM 0044880 23/01/2023 22/01/2024

Weld Gauge 269/WG-03 23/01/2023 22/01/2024

Bevel Angle Protector CR2032 28/01/2023 27/01/2024

Note-Add additional page if required.

Page 1 of 1

Joint Inspection Report

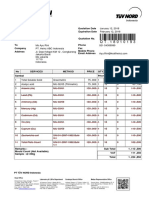

BV File No IND.K.4.21.0144 ZIG No: 12111391

BV Client TATA STEEL Limited

Vendor: Heavy Engineering Workshop, Rewa (M. P. )

Contracting Centre: BV-KOLKATA Performing Centre: BV Bhopal

Actual KMs

Surveyor’s name

Date of

Inspection Place

Manday/ Travelled If

visit

Vist Insp. Place >

100KM.

21/03/2023

Rajesh Sharma Heavy Engineering Workshop, Rewa 1130 KM

& 02 Days

(M.P.) (To & Fro)

22/03/2023

(Rajesh Sharma) (Mr. Anil Kumar Pandey) (7024113929)

Surveyor Name & Signature Client/Vendor/Mfg/Supplier -Sign/Stamp

DIGITAL PICTURE

Note-Add additional page if required.

Page 1 of 1

Joint Inspection Report

Description: Material offered for inspection Description: Material offered for inspection

Description: Dimension Check Description: Dimension Check

Description: Dimension Check Description: Dimension Check

Description: Dimension Check Description: Hard Punch Marking Check

Note-Add additional page if required.

Page 1 of 1

Joint Inspection Report

Description: Material Offered for inspection Description: Material Offered for inspection

Description: Dimension Check Description: Dimension Check

Description: Dimension Check Description: Dimension Check

Description: Dimension Check Description: Dimension Check

Description: Hard stamp for Identification purpose Description: Material Offered for inspection

Note-Add additional page if required.

Page 1 of 1

Joint Inspection Report

Description: Dimension Check Description: Dimension Check

Description: Dimension Check Description: Dimension Check

Description: Dimension Check Description: Dimension Check

Description: Dimension Check Description: DP Test Check

Description: DP Test Check Description: Weld size check

Note-Add additional page if required.

Page 1 of 1

Joint Inspection Report

Description: Weld size check Description: Hard stamp for Identification purpose

ATTACHMENTS

Item Attachment Name Total Pages Description

1 Annexure-4, Annexure- 4

5, Annexure-7 &

Annexure-8

2 Dimension Report 4

3 DP Report 4

4 Weld Visual Report 4

5 MTCs 14

6 WPS/PQR/WPQ 13

7 Calibration Report 5

Note-Add additional page if required.

Page 1 of 1

You might also like

- Starbucks LTV Case StudyDocument8 pagesStarbucks LTV Case StudyThanh NhànNo ratings yet

- 400 MM Digital Clamp Meter Make-Kyoritsu Model-KEW SNAP 2009R, SL No-W8039512Document20 pages400 MM Digital Clamp Meter Make-Kyoritsu Model-KEW SNAP 2009R, SL No-W8039512Ashutosh MondalNo ratings yet

- API 6D Valve Inspection TestDocument2 pagesAPI 6D Valve Inspection Testsaffririzal4237No ratings yet

- Jha To Perform On-Site Verification For Glycol ReboilerDocument2 pagesJha To Perform On-Site Verification For Glycol ReboilerEdha AliNo ratings yet

- 001 Inspection - Report - INTEC (05 - 07102015) PDFDocument7 pages001 Inspection - Report - INTEC (05 - 07102015) PDFfitroh_hzNo ratings yet

- Trai Qa R 45 Process Audit - FormatDocument5 pagesTrai Qa R 45 Process Audit - FormatRS MANIKANDANNo ratings yet

- TA202 A Lecture 1: Tutor: Shantanu BhattacharyaDocument12 pagesTA202 A Lecture 1: Tutor: Shantanu BhattacharyaRajat JainNo ratings yet

- 019-RCFA Disposal Pump-14520a 1'' Inlet Line Repair On 4th November 2016Document3 pages019-RCFA Disposal Pump-14520a 1'' Inlet Line Repair On 4th November 2016Jinlong SuNo ratings yet

- Blank - Inspection Report FormatDocument7 pagesBlank - Inspection Report Formatabdullahshamsi57No ratings yet

- Ansi/Tia-942 Audit & Certification Services: Uptime InstituteDocument4 pagesAnsi/Tia-942 Audit & Certification Services: Uptime InstituteInsan ArdiansyahNo ratings yet

- 11RCFA-CPF2-HP Gas CompBDocument5 pages11RCFA-CPF2-HP Gas CompBJinlong SuNo ratings yet

- ECI Booking Form-V1.7 O# 90058401 PDFDocument2 pagesECI Booking Form-V1.7 O# 90058401 PDFdevNo ratings yet

- 4605 ER ProbeDocument3 pages4605 ER ProbeAimon JahangirNo ratings yet

- NL07T0583Document5 pagesNL07T0583roger.chyneNo ratings yet

- Equipment InspectionDocument8 pagesEquipment InspectionRakesh MenonNo ratings yet

- (KPCC) Sop - Gas BoosterDocument12 pages(KPCC) Sop - Gas BoosterWindy Nitaejun HorvejkulNo ratings yet

- Determining If A PSSR Is Needed: ModificationsDocument2 pagesDetermining If A PSSR Is Needed: ModificationsDave CNo ratings yet

- Nordic Group 2020Document116 pagesNordic Group 2020Ronald LengNo ratings yet

- JHA Dryer Hot CommissioningDocument5 pagesJHA Dryer Hot CommissioningJowel MercadoNo ratings yet

- Quotation: Escherichia ColiDocument3 pagesQuotation: Escherichia ColiayuNo ratings yet

- ELECTREX General CatalogueDocument52 pagesELECTREX General CatalogueO TottaNo ratings yet

- Katalog BurnerDocument48 pagesKatalog BurnerSyeikhabil AsshoqofiNo ratings yet

- SOP-LEE-01 Pengendalian Dokumen & Informasi (Rev 00)Document1 pageSOP-LEE-01 Pengendalian Dokumen & Informasi (Rev 00)FendiNo ratings yet

- Msds Cuso4Document3 pagesMsds Cuso4Muhammad EvanNo ratings yet

- Continental Industrial PDFDocument359 pagesContinental Industrial PDFDavidNo ratings yet

- Pelatihan K3LDocument13 pagesPelatihan K3Lyono DaryonoNo ratings yet

- Quotation - Cotation: Description Du Travail / Work DescriptionDocument1 pageQuotation - Cotation: Description Du Travail / Work DescriptionmkpqNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- Datasheet 4558CDocument2 pagesDatasheet 4558CJose Isabel Cordero LopezNo ratings yet

- 2021.12.12 - Pinched Finger (MTC) - Rantau - Zona 1Document1 page2021.12.12 - Pinched Finger (MTC) - Rantau - Zona 1BennyNo ratings yet

- ENV-SPV-DR-B-003 Fabrication Procedure-Rev - ADocument11 pagesENV-SPV-DR-B-003 Fabrication Procedure-Rev - AyoeyNo ratings yet

- PR-IMS-042 Chemical Management ProcedureDocument18 pagesPR-IMS-042 Chemical Management ProcedureBlister PatchNo ratings yet

- Cimolai Technology UtDocument12 pagesCimolai Technology UtWisthon GrimanNo ratings yet

- Blank - Inspection Report FormatDocument8 pagesBlank - Inspection Report Formatabdullahshamsi57No ratings yet

- Safety, Health & EnvironmentDocument60 pagesSafety, Health & EnvironmentGopalakrishnanNo ratings yet

- Pre-Shipment Inspection: Product PhotoDocument35 pagesPre-Shipment Inspection: Product Photo123456No ratings yet

- AM Series 45-200 D170 Rev D-W OM PDFDocument15 pagesAM Series 45-200 D170 Rev D-W OM PDFNestor SalasNo ratings yet

- ECOFOR For Cement Mill - A Dose of Dry MedicineDocument4 pagesECOFOR For Cement Mill - A Dose of Dry MedicineAntonNo ratings yet

- Methodology Tapping Methodology of WaterlineDocument15 pagesMethodology Tapping Methodology of WaterlineBryNo ratings yet

- Prose Dur QH Sse 2016Document198 pagesProse Dur QH Sse 2016danaokhtavianusNo ratings yet

- Sample Report AudioDocument33 pagesSample Report AudioraulNo ratings yet

- Operation Control - Powered and Hand Tools Procedure: Pt. Eskimo WieraperdanaDocument7 pagesOperation Control - Powered and Hand Tools Procedure: Pt. Eskimo WieraperdanadennisjuntakNo ratings yet

- Compro Russindo Group Tahun 2018 UpdateDocument44 pagesCompro Russindo Group Tahun 2018 UpdateElyza Farah FadhillahNo ratings yet

- Vscan ExtendDocument251 pagesVscan ExtendMohammed ShabanNo ratings yet

- 122 Triethylene GlycolDocument6 pages122 Triethylene Glycoleng20072007No ratings yet

- Hse Plan: W S Power SectorDocument130 pagesHse Plan: W S Power Sectorsurender bNo ratings yet

- Siemens Internship ReportDocument17 pagesSiemens Internship ReportmirfanbilalNo ratings yet

- 2 Rvs Training Profile Compressed (1) Din2Document22 pages2 Rvs Training Profile Compressed (1) Din2Ahmed shabanNo ratings yet

- Material Traceability ReporDocument2 pagesMaterial Traceability ReporDaengkulle Firmansyah PuteraNo ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: FacilityHelza RahmanniaNo ratings yet

- Noise Measurements, Standards and Control TechniquesDocument42 pagesNoise Measurements, Standards and Control TechniquesPrabhu PrasadNo ratings yet

- Radiography Permit: Al-Dur 2 Iwpp ProjectDocument1 pageRadiography Permit: Al-Dur 2 Iwpp ProjectJianping KeNo ratings yet

- Environment MP SoilDocument17 pagesEnvironment MP SoilRusihan HSE100% (1)

- Baticorrometro Polatrak Deepwater-Manual de OperacionDocument15 pagesBaticorrometro Polatrak Deepwater-Manual de OperacionemilidiverNo ratings yet

- (Datasheet Linterna Marina Carmanah M650) SelfContained - M650HDocument2 pages(Datasheet Linterna Marina Carmanah M650) SelfContained - M650Hahfuoahrf0384No ratings yet

- Danalyzer GC MAN 3 9000 744 700XA PDFDocument204 pagesDanalyzer GC MAN 3 9000 744 700XA PDFFercho MNo ratings yet

- 362-KMI-N2 Purging Into Station PipingDocument5 pages362-KMI-N2 Purging Into Station PipingNasrullah JanNo ratings yet

- RT Collimator Sentinel - Draft.compressedDocument2 pagesRT Collimator Sentinel - Draft.compressedEswaranNo ratings yet

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- RWNS 7Document2 pagesRWNS 7Rohan SharmaNo ratings yet

- RWNS - 70Document2 pagesRWNS - 70Rohan SharmaNo ratings yet

- Calibration Certificate Steel TapDocument3 pagesCalibration Certificate Steel TapRohan SharmaNo ratings yet

- Calibration Certificate U.T GaugeDocument1 pageCalibration Certificate U.T GaugeRohan SharmaNo ratings yet

- Calibration Certificate Dial VernierDocument2 pagesCalibration Certificate Dial VernierRohan SharmaNo ratings yet

- Hidayatullah National Law University Atal Nagar, ChhatisgarhDocument19 pagesHidayatullah National Law University Atal Nagar, ChhatisgarhPCLS HNLU ChapterNo ratings yet

- Wicaksana Overseas International Tbk-Dec 31 2022Document88 pagesWicaksana Overseas International Tbk-Dec 31 2022Jefri Formen PangaribuanNo ratings yet

- CH 12Document19 pagesCH 12Vandana GuptaNo ratings yet

- Partnership: Fundamentals Guarantee of ProfitsDocument12 pagesPartnership: Fundamentals Guarantee of ProfitsJoshua DevNo ratings yet

- Project of Business StudiesDocument12 pagesProject of Business StudiesVinit NishadNo ratings yet

- Market Failure With Public GoodsDocument29 pagesMarket Failure With Public GoodsJefainNo ratings yet

- Tax Invoice/Bill of Supply/Cash MemoDocument1 pageTax Invoice/Bill of Supply/Cash MemoCentralised NumberNo ratings yet

- Fiscal Policy Measures (4.3.3) CIE IGCSE Economics Revision Notes 2020 Save My ExamsDocument1 pageFiscal Policy Measures (4.3.3) CIE IGCSE Economics Revision Notes 2020 Save My Examseleftheriapetrou006No ratings yet

- Centenary Celebrations 05042022Document10 pagesCentenary Celebrations 05042022aditiNo ratings yet

- CPC Prc-3 Chap-1 NotesDocument14 pagesCPC Prc-3 Chap-1 NotesAhsan Rao0% (1)

- Nurmala Ahmar - STIE Perbanas Surabaya JMV Mulyadi - Universitas PancasilaDocument12 pagesNurmala Ahmar - STIE Perbanas Surabaya JMV Mulyadi - Universitas PancasilaHafidh NazmiNo ratings yet

- Contoh Laporan Arus KasDocument9 pagesContoh Laporan Arus KasPutri LestariNo ratings yet

- Practice Set: MerchandisingDocument2 pagesPractice Set: MerchandisingannegelieNo ratings yet

- Chessboards Price ListDocument6 pagesChessboards Price ListArandjel RodićNo ratings yet

- Fixed Income Group AssignmentDocument16 pagesFixed Income Group AssignmentHarshit Sekhar DassNo ratings yet

- Quality GurusDocument39 pagesQuality GurusShubham TiwariNo ratings yet

- Statsnotes 1Document140 pagesStatsnotes 1dcd80534No ratings yet

- CNC Problemset7Document2 pagesCNC Problemset7jibberish yoNo ratings yet

- College of Teacher Education: April Tivoli OmbayDocument3 pagesCollege of Teacher Education: April Tivoli OmbayMich ResueraNo ratings yet

- Probability and Nonprobability SamplingDocument7 pagesProbability and Nonprobability SamplingZemira BilogNo ratings yet

- ARVINDDocument1 pageARVINDprashant singhNo ratings yet

- Gcat21 Catalogo PetolDocument44 pagesGcat21 Catalogo Petoledinson piñerosNo ratings yet

- Accounting For GSTDocument30 pagesAccounting For GSTHarnitNo ratings yet

- Vol-1 - Appendix I.2 Axle Load Survey Data &a NalysisDocument2 pagesVol-1 - Appendix I.2 Axle Load Survey Data &a NalysisSudipThapaNo ratings yet

- SADC-RTGS Settlement Statistics and Indicators - December 2020Document9 pagesSADC-RTGS Settlement Statistics and Indicators - December 2020Kelvin ChisangaNo ratings yet

- 26 2829 01 Silicone Antifoams For Cleaning Products Manufacturing Selection GuideDocument2 pages26 2829 01 Silicone Antifoams For Cleaning Products Manufacturing Selection Guidelorejaz84071127No ratings yet

- SBI MaxGainDocument36 pagesSBI MaxGainRohit PandeyNo ratings yet

- Banking PresentationDocument8 pagesBanking PresentationGAGAN ANANDNo ratings yet

- Student Exam FormDocument4 pagesStudent Exam FormRaj Kumar TeotiaNo ratings yet