Professional Documents

Culture Documents

PM6 LEGACY Express PID Controller QSG 07-21-20

PM6 LEGACY Express PID Controller QSG 07-21-20

Uploaded by

kamran ashrafCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PM6 LEGACY Express PID Controller QSG 07-21-20

PM6 LEGACY Express PID Controller QSG 07-21-20

Uploaded by

kamran ashrafCopyright:

Available Formats

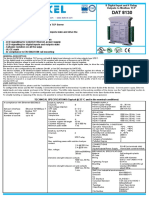

1 - MOUNT TO PANEL NOTE: Mounting requires ?? ??

2 - CONNECT THE SENSOR INPUT

QUICK START access to the back of the panel.

GUIDE 1. Make the panel cutout using the Connect your sensor as

measurements in figure 1.

44.96 to 45.47 mm indicated in the diagram for

PM6 LEGACY EXPRESS TM 2. Remove the green terminal (1.77 to 1.79 in.) your sensor input. Figure

connectors and the mounting collar 4 is an example illustrating

assembly. the connection shown for a

44.96 to 45.47 mm

PID CONTROLLER 3. Insert the controller into the panel (1.77 to 1.79 in.) Thermocouple.

cutout from the front.

4. Orient the collar base so the flat side

for configurations: faces front and the screw openings

PM6 C _ _ _ -_ AAAH_ _ Thermocouple

are on the sides (see figure 2), then

NOTE: Express Only slide the base over the back of the

controller.

Figure 1

– S1

5. Slide the mounting bracket over the Figure 2

+ R1

controller with the screws aligned to

the collar base. Push the bracket gently but

firmly until the hooks snap into the slots in the Figure 4: Thermocouple Wiring Example

case.

6. Tighten the two #6-19 x 1.5 in. screws with a

Process Voltage: 0 to 10V@ 20kΩ Platinum 100Ω

Phillips screwdriver until the device is flush to

Process Current: 0 to 20 mA @ 100Ω 20Ω max. loop lead resistance

the panel (3 to 4 in-lbs torque).

7. Reinstall the terminal connectors to their

T1 + T1

S2

T1

original locations. (Or first connect field wiring

as indicated in this guide and then reinstall the

T1

connectors). – S1 – S1 S3

S1 S1

S3

For assistance contact Watlow: www.watlow.com

1-800-WATLOW2 (1-800-928-5692)

+ R1 R1

S1

R1 S1 R1

wintechsupport@watlow.com

volts amperes 2-wire 3-wire

Document No. 10-41691 - Part No. 2126-4397 June 30, 2020 Figure 3

3 - WIRE OUTPUT 1 Refer to the wiring diagram for your configuration code

and connect to the slots indicated. 4 - WIRE OUTPUT 2 5 - CONNECT POWER 6- CE DECLARATION OF CONFORMITY

Declaration of Conformity - Series EZ-ZONE® PM

PM6_ _ C _ - _ _ _ _ H _ _: Switched DC or Open Collector PM6_ _ _ J - _ _ _ _ H _ _: 5A Form A Relay WATLOW Electric Manufacturing Company

1241 Bundy Blvd. Winona, MN 55987 USA

Declares that the following product meets the essential requirements of the following European Union Directives by using

Internal Circuit Normally Open the relevant standards show below to indicate compliance.

Open Collector Designation: Series EZ-ZONE® PM (Panel Mount)

Common

X1

Model Numbers: PM (3, 6, 8, 9 or 4)(Any Letter or number)(1, 2, 3 or 4)(A, C, E, F or K) (A, C,

– Power Supply +

L2 AC

H, J or K) – (Any letter or number)(Any letter or number)(A, C, E, F or K)(A, C,

–

Load Classification:

H, J or K) (Any three letters or numbers)

Temperature control, Installation Category II, Pollution degree 2, IP65

W1

Rated Voltage and Frequency: 100 to 240 V~ (ac 50/60 Hz) or 15 to 36 V dc/ 24 V~ac 50/60 Hz

+

– Load

K2

Rated Power Consumption: 10 VA maximum PM3, PM6 Models.

14 VA maximum PM8, PM9, PM4 Models

24V(dc) 2014/30/EU Electromagnetic Compatibility Directive

Y1

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC

+ Load –

Internal Circuit Common

requirements (Industrial Immunity, Class B Emissions).

+

IEC 61000-4-2:2008 Electrostatic discharge immunity

IEC 61000-4-3:2007 +A1/2008, Radiated, radio-frequency electromagnetic field immunity 10V/M 80–1000 MHz, 3 V/M

Switched DC A2/2010

IEC 61000-4-4:2012

1.4–2.7 GHz

Electrical fast-transient / burst immunity

IEC 61000-4-5:2014 +A1/2017 Surge immunity

IEC 61000-4-6:2013 + Immunity to conducted disturbances induced by radio-frequency fields

Corrigendum 2015

IEC 61000-4-11:2004 + A1/2017 Voltage dips, short interruptions and voltage variations immunity

EN 61000-3-2:2014 Limits for harmonic current emissions for equipment ≤ 16 Amps per phase

PM6_ _ _ C - _ _ _ _H_ _: Switched DC

EN 61000-3-31:2013 + A1/2017 Voltage fluctuations and flicker ≤ 16 Amps per phase

SEMI F47-0812 Specification for semiconductor sag immunity Figure R1-1

PM6_ _ E _ - _ _ _ _ H _ _: 5A Form C Relay For mechanical relay loads, cycle time may need to be extended up to 160 seconds to meet flicker requirements

1

depending on load switched and source impedance.

Figure 5: Switched DC Output Wiring 2014/35/EU Low-Voltage Directive

5A @240 V(ac) or 30 V (dc) Common

EN 61010-1:2010 2

2 Compliance

Safety Requirements of electrical equipment for measurement, control and

laboratory use. Part 1: General requirements

with 3rd Edition requirements with use of external surge suppressor installed on 230 Vac~ power line units.

Recommend minimum 1000 V peak to maximum 2000 V peak, 70 joules or better part be used.

Internal Circuit Compliant with 2011/65/EU RoHS2 Directive Per 2012/19/EU W.E.E.E Directive

Normally –

W2

Please Recycle Properly. Models PM(4, 8 or 9)E contain a type BR1225 coin cell battery which shall be

Open recycled at end of life per 2006/66/EC Battery Directive as amended by 2013/56/EU Directive.

Load

Models PM6XXXX – (B, E, F, G, H, J, K)XXXXXX where (X = any letter or number allowed above)

24V(dc)

Include Bluetooth® wireless technology and have been reviewed to the following additional requirements.

L1 2014/53/EU Radio Equipment Directive (RED)

Y2 Load

EN 61010-1:2010 Safety Requirements of electrical equipment for measurement, control and laboratory use.

Part 1: General requirements

K1 AC + Connect the power source for your

EN 61326-1:2013

Covering the essential requirements of article 3.1(a) or Directive 2014/53/EU

Electrical equipment for measurement, control and laboratory use – EMC requirements

Common (Industrial Immunity, Class A Emissions).

J1

CAUTION: This equipment not intended for use in residential environments and may not provide

configuration code:

adequate protection to radio reception in such environments.

PM6_ _ F _ - _ _ _ _ H_ _: Universal Process Internal Circuit EN 301 489-1 V2.1.1 ElectroMagnetic Compatibility (EMC) standard for radio equipment and services; Part 1: Common

Load

technical requirements; Harmonized Standard covering the essential requirements of article

PM6 _ [1,2,3,4] _ _ - _ _ _ _ _ _ _

3.1(b) of Directive 2014/53/EU and the essential requirements of article 6 of Directive 2014/30/EU

Normally EN 301 489-17 V3.1.1 ElectroMagnetic Compatibility (EMC) standard for radio equipment and services; Part 17:

Closed

Specific conditions for Broadband Data Transmission Systems; Harmonized Standard covering

0 to 20 mA: 800 Ω max. load EN 300 328 V1.9.1

the essential requirements of article 3.1(b) of Directive 2014/53/EU

Electromagnetic compatibility and Radio spectrum Matters (ERM); Wideband transmission

systems; Data transmission equipment operating in the 2,4 GHz ISM band and using wide band

0 to 10V: 1kΩ min. load modulation techniques; Harmonized EN covering the essential requirements of article 3.2 of the

R&TTE Directive

Internal Circuit

PM6_ _ _ H - _ _ _ _H_ _: No-Arc Relay 1 or 2:120-240 V (ac) EN 300 328 V2.1.1

NVLAP Test Report 10928545H-A

Additional Receiver blocking test for to cover requirements for 2014/53/EU.

NVLAP Test Report 11649468H-E

Voltage Load or Current Load Normally Open 3 or 4: 24 V (ac or dc)

F1

Contains Module FCC ID: VPYLBZY Part 15C 2.

Contains Module IC: 772C-LBZY RSS 210

–

L2 AC

Output Power: Frequency Range 2402.0 - 2480.0

+

0 to 10 V G1 Load Load Output Power 0.001 Watts Antenna gain: -0.6 dBi PCB antenna

+ H1

4 to 20mA Load

K2 CAUTION

Doug Kuchta

Name of Authorized Representative

Winona, Minnesota, USA

Place of Issue

Internal Circuit Common

Director of Operations May 2018

Do not connect high voltage to a controller that

requires low voltage. Signature of Authorized Representative

8 - INTRODUCTION TO KEYPAD & MENU BASICS ‰‰ 9 - SET UP THE INPUT

7 - KEYPAD OVERVIEW

Zone Display:

Indictes the controller Upper Display: Temperature Units Menu and Keypad Basics Start from Home.

addess when using In the Operations Menu, Indicator Lights:

communications.

[1] to [9] = zones 1

displays the process

value, otherwise dis-

Indicates whether the

temperature is dis-

Setting

Parameter

PV NOTE: You must read and understand the role of each key on

your controller keypad before proceeding.

Press + for 6 seconds

to 9 plays the value of the played in Fahrenheit SP to enter Setup Menu.

parameter in the lower or Celsius. See Panel 7 - Keyboard Overview.

[A] = zone 10 display. Set Up Menu Operations Menu Must be level 5 to make

Output Activity: These instructions are not inclusive. This Quick Start Guide

[b] = zone 11

Number lights

indicate activity

[`loC] Lockout Menu

[`SEn] Sensor Type [`AUt] Autotune (QSG) is meant to be a quick reference guide. It will show you ‰ to changes.

[C] = zone 12 of outputs 1 [`Lin] Linearization [`C;M] Control Mode how to navigate to frequently used areas of your controller. As

[d] = zone 13 ° and 2. [``t;C] Thermistor Curve

‰ [`h;pb] Heat Proportional Band an example, settings process outputs are not documented in

[E] = zone 14 If Thermocouple select ( ).

[F] = zone 15

° Communications [``r;r] Resistance Range [`C;pb] Cool Proportional Band

this QSG. Refer to the User Manual for more detailed instruc-

% Activity: [`deC] Decimal [``ti] Time Integral

[h] = zone 16 Flashes when ‰ tions. NOTE: These diagrams might vary depending on the

Z [`C_F] Display Units [``td] Time Derivative

another device is

Lower Display: O

N communicating [`r;lo] Range Low [o;tb1] Time Base

Controller programming. ‰ to

Indicates the set E with this con- [`r;hi] Range High [o;tb2] Time Base

point or output troller. [`fn1] Function Output 1 [`A;lo] Alarm Low Set Point Introduction to the Set Up & Operating Menus Select thermocouple type.

power value during Up and Down [`o;ty] Output Type (J, K is letter H or T is letter t)

operation or the Arrow Keys: [`A;hi] Alarm High Set Point Upon power up, the display will default

In the Operations [`fn2] Function Output 2 [`i;Ca] Calibratin Offset

parameter whose to the home page in the Operations

Menu, adjusts [`h;ag] Heat Algorithm

PV

value appears in

the upper display. FN the set point in

the lower dis-

[`h;sC] Hysteresis (Heat & Cool)

Menu. The upper red row displays the

SP

OR Return Home.

play. In the other [`C;Ag] Cool Algorithm process value (PV). The lower green

pages, changes [`A;ty] Alarm Type row displays the set point (SP).

the upper dis- OR

play to a higher

[`A;hy] Alarm Hysteresis

Operations Menu

Function Key: or lower value,

or changes a

[`A;lg] Alarm Logic

[`A;lA] Alarm Latching

To enter the Operations Menu, press to return to Home Press + for 6 seconds to

This key will toggle the con-

parameter selec- Page. Press the green advance key ‰ to scroll through enter Setup Menu.

Infinity Key:

trol mode between the cur-

rent value of the C.M prompt Clears and silences tion.

[`A;bl] Alarm Blocking

[`A;si] Alarm Silencing the various prompts found in the Operations Menu. Press ‰ to Must be level 5 to make changes.

(Off, MAn, AUto) and Manual alarms, press to back up Advance Key:

one level, or press and Advances through [A;dsp] Alarm Display the Infinity key at any point within the Operations Menu to

when the Function Key is hold for two seconds to parameter [``rp] Ramp Action

pushed and held for return to the Home Page. Use Arrow Keys to increment

return to the Operations prompts. [`r;rt] Ramp Rate

3 seconds. Menu. or decrement settings or change selection. If rtd 100 ohm select rtd.

[`s;lo] Scale Low

[`s;hi] Scale High

Set Up Menu

For assistance contact Watlow: www.watlow.com To enter the Setup Menu press to return to Home Page. Press both Arrow Keys

[o;hi1] Power Scale High Output 1 Return Home

+1-(507)-494-5656 [o;hi2] Power Scale High Output 2 for 6 seconds. Press green Advance Key ‰ to scroll through to the prompt of

wintechsupport@watlow.com [`Ad;s] Zone Address

choice. Use Arrow Keys to increment or decrement settings or change selection.

http://www.watlow.com/downloads/en/manuals/pmpmi.pdf [btth] Bluetooth

Scan for full manual. At any point within the Setup Menu, push the Infinity Key to return to the Home Page.

13. - LOOP CONTROL MODE/ 14- AUTOTUNE THE

10 - SET UP OUTPUTS FOR HEAT, COOL AND ALARM 11 - SET UP AN ALARM 12 - SET ALARM SET POINTS

LOOP SET POINT CONTROL LOOP

Start From Home. Start from Home. Set Loop Control Mode

Start from Start from

Press + for 6 Start from

seconds to enter

‰ to Home. Press +

for ‰ to Home. Start from ‰to Home.

Setup Menu. Must be 6 seconds to enter Enter degrees. to Home.

If heat or cool

Setup Menu. ‰

level 5 to make changes. >= 20 if mechanical No/yes.

‰ to relay. Select time ‰ to Must be level 5 to make Select low set

Select Auto

changes. point. (- for dev Enter degrees.

base output 1. Tune. (Returns

alarm type). Ensure that

Heat, Cool, Alarm, or Off. to no when

‰to Advance to to CM is set to completed).

Select function output 1. If heat or cool

Process, deviation.

‰ Auto

(See Fn 2 for output 2). >= 20 if mechanical Select type, enter.

‰ to relay. Select time to

Enter degrees. Return Home.

base output 2. ‰ Select high set Return Home.

Advance to Adjust Loop Set Point

PID, on/off, none. point.

Return Home. Enter degees.

Select heat control method. Return Home.

Select Hysteresis.

Tuning in progress

‰ to to Enter degrees.

If on/off enter degrees.

‰ Select set point.

Select at switching Alarm active

hysteresis. Close, open.

Select logic.

‰ to Non-latching,

to latching.

Advance to PID, on/off, none. ‰ Alternates

Select cool control method. Select latching.

If on/off, enter degrees. Select Alternates

cool switching hysteresis.

‰ to Return Home

Return Home.

For other alarm settings see

the user manual.

You might also like

- Update 61000-3-6 05TD0540Document22 pagesUpdate 61000-3-6 05TD0540Kiki TataNo ratings yet

- PM PLUS Quick Start Guide Rev A1Document2 pagesPM PLUS Quick Start Guide Rev A1JorgeNo ratings yet

- Series Border Installation GuideDocument1 pageSeries Border Installation GuideSpenNo ratings yet

- Control Board Kit 30072-451-86ADocument8 pagesControl Board Kit 30072-451-86AEdwin RinconNo ratings yet

- Staco 1010 Transformer Series Owners ManualDocument6 pagesStaco 1010 Transformer Series Owners ManualdonsterthemonsterNo ratings yet

- Pentax p3 p30Document16 pagesPentax p3 p30MartinNo ratings yet

- Delphi Lockout Placard Template W Instruction v2Document26 pagesDelphi Lockout Placard Template W Instruction v2Andre Santos SantosNo ratings yet

- Operating/Safety Instructions Consignes de Fonctionnement/sécurité Instrucciones de Funcionamiento y SeguridadDocument16 pagesOperating/Safety Instructions Consignes de Fonctionnement/sécurité Instrucciones de Funcionamiento y SeguridadrgueznoeNo ratings yet

- CR3A Network - Installation InstructionsDocument12 pagesCR3A Network - Installation InstructionsMin Jiat PANGNo ratings yet

- Electronics Workshop 2 Manual - Thames & KosmosDocument14 pagesElectronics Workshop 2 Manual - Thames & KosmosLaurent BovayNo ratings yet

- ManualDocument20 pagesManualHosein AlaviNo ratings yet

- InstallingDocument11 pagesInstallingMatthewNo ratings yet

- 5100 Users Guide PDFDocument87 pages5100 Users Guide PDFAugusto BlancoNo ratings yet

- Antena TV ShakespeareDocument4 pagesAntena TV ShakespearenachoborjasNo ratings yet

- Manual - Sm-T4.5r-Motor-Install 20150606Document20 pagesManual - Sm-T4.5r-Motor-Install 20150606aboediartoNo ratings yet

- Drager Narkomed 4 Installation of Ultrasonic Flow SensorDocument13 pagesDrager Narkomed 4 Installation of Ultrasonic Flow Sensorsamlu71No ratings yet

- Advance CR BF Manual 1308-1 eDocument2 pagesAdvance CR BF Manual 1308-1 ehikmah jevie yusriNo ratings yet

- Mi 9654 TDocument3 pagesMi 9654 Tamir barekatiNo ratings yet

- Fm10002a Nv3.5 Nv10 Cooling ModDocument9 pagesFm10002a Nv3.5 Nv10 Cooling ModBG JluisNo ratings yet

- Application Notes: P-I Servoamplifier G122-829A001Document6 pagesApplication Notes: P-I Servoamplifier G122-829A001rimmer boyNo ratings yet

- Installation SRVDocument6 pagesInstallation SRVTuan Anh NguyenNo ratings yet

- SR-1600 Shelf User's Manual: Telecom / DatacomDocument16 pagesSR-1600 Shelf User's Manual: Telecom / DatacomDr.Ahmed GhareebNo ratings yet

- Close Side Setting Sensor SB-96BDocument4 pagesClose Side Setting Sensor SB-96Bjuanandres_martinezNo ratings yet

- GRP300Document13 pagesGRP300Jehan Ducret0% (1)

- Assembling Method - Type Ø22: Operating Part Contact PartDocument1 pageAssembling Method - Type Ø22: Operating Part Contact PartHJMNo ratings yet

- Pa7300 Quickstart Fan App r1Document9 pagesPa7300 Quickstart Fan App r1Electrónica Melendez FazzNo ratings yet

- Meter of Network Parameters Nd20 Type: User'S ManualDocument35 pagesMeter of Network Parameters Nd20 Type: User'S Manualशिवकृष्णतेजा कावूरिNo ratings yet

- Installation Manual: Rosenberger Asia Pacific Electronic Co., LTDDocument4 pagesInstallation Manual: Rosenberger Asia Pacific Electronic Co., LTDTinh DongNo ratings yet

- Installation: U-Match Series DC Inverter Service ManualDocument22 pagesInstallation: U-Match Series DC Inverter Service ManualEricNo ratings yet

- 0455a PDFDocument2 pages0455a PDFBernardo Roman MaciasNo ratings yet

- Square Duct Board Installation ManualDocument4 pagesSquare Duct Board Installation ManualApurv GoyalNo ratings yet

- Index: Service ManualDocument20 pagesIndex: Service ManualGianluca MasalaNo ratings yet

- Technical Manual T2K - RevDocument32 pagesTechnical Manual T2K - RevEng Peter TabboNo ratings yet

- SV-600, SV-610, SV-620: Instruction ManualDocument39 pagesSV-600, SV-610, SV-620: Instruction ManualHristo Stoichkov Rosmel RicraNo ratings yet

- Minivator 1000 Series Installation Manual PDFDocument36 pagesMinivator 1000 Series Installation Manual PDFSergio PNo ratings yet

- Technical Manual & Parts List: ModelDocument24 pagesTechnical Manual & Parts List: ModeljamelNo ratings yet

- Rack Installation Guide-DA240Document8 pagesRack Installation Guide-DA240Fabricio RiverNo ratings yet

- PV Grid Tie Inverter: User ManualDocument19 pagesPV Grid Tie Inverter: User ManualTiako Daniel N'DRINo ratings yet

- Control Panel: Installation and User's Manual Installasjon Og Brukermanual InstallationsanleitungDocument16 pagesControl Panel: Installation and User's Manual Installasjon Og Brukermanual InstallationsanleitungAsep TatangNo ratings yet

- Manual - Service - PB560 - English (148-160)Document13 pagesManual - Service - PB560 - English (148-160)STEPHANY VANESSA LOMBANA ROJASNo ratings yet

- Operation and Instruction Manual: 7. Technical Characteristics of The MeterDocument4 pagesOperation and Instruction Manual: 7. Technical Characteristics of The MeterAbhijeet Narayanbhai VareNo ratings yet

- Application: Focus 3 "M" Contactor F3M112 & F3M224 Instruction SheetDocument7 pagesApplication: Focus 3 "M" Contactor F3M112 & F3M224 Instruction SheetLuis MorenoNo ratings yet

- Boom Extend/Retract Cables Genie S105Document3 pagesBoom Extend/Retract Cables Genie S105Vagif RzayevNo ratings yet

- Onda AngledDocument6 pagesOnda AngledPatricio PintoNo ratings yet

- Aalborg OC Boiler - PART 2 PDFDocument328 pagesAalborg OC Boiler - PART 2 PDFPhạm Quốc ToànNo ratings yet

- JVC KS - FX772R Service ManualDocument35 pagesJVC KS - FX772R Service ManualPaula KaNo ratings yet

- Canonet GIII 17Document4 pagesCanonet GIII 17Jose Paulo Martins NarcisoNo ratings yet

- DAPZ - AR 2010-10c 756075g1Document4 pagesDAPZ - AR 2010-10c 756075g1Richardson de Souza CavalcanteNo ratings yet

- NTB02 083Document4 pagesNTB02 083PMNo ratings yet

- Tm 481a维修手册Document50 pagesTm 481a维修手册byd5jcdzxtNo ratings yet

- DEH-2850MP DEH-1850: Downloaded From Manuals Search EngineDocument5 pagesDEH-2850MP DEH-1850: Downloaded From Manuals Search EngineMeland SacNo ratings yet

- Yamaha Ydre Moric To Curtis 1268 Conversion: Installation InstructionsDocument5 pagesYamaha Ydre Moric To Curtis 1268 Conversion: Installation Instructionsmg victorNo ratings yet

- Instructions: Headlamp Visor KitDocument2 pagesInstructions: Headlamp Visor KitPaco JonesNo ratings yet

- KX TC1400Document48 pagesKX TC1400Anonymous Lfgk6vygNo ratings yet

- DISC-O-FLEX COUPLING Installations& InstructionsDocument14 pagesDISC-O-FLEX COUPLING Installations& InstructionsbederinadmlNo ratings yet

- Boost Valve Kit: Toyota/Lexus U140E, U140F, U240E, U241EDocument1 pageBoost Valve Kit: Toyota/Lexus U140E, U140F, U240E, U241EossoskiNo ratings yet

- GenII Main Rotor Sikorsky S76 Pushrod 1.00Document23 pagesGenII Main Rotor Sikorsky S76 Pushrod 1.00agripinaluzmilaaNo ratings yet

- 24kv - 630amp - Instruction Inc SubconnectorDocument5 pages24kv - 630amp - Instruction Inc SubconnectorHendry LuaseNo ratings yet

- Sk330-Sk350lc-8 Gauge Controller PinDocument2 pagesSk330-Sk350lc-8 Gauge Controller PinPHÁT NGUYỄN THẾ100% (1)

- Baby Lock Pro BL8800 ServiceDocument20 pagesBaby Lock Pro BL8800 ServiceiliiexpugnansNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- EcoStruxure Power Monitoring Expert 8.2 - PSWSANCZZSPEZZDocument2 pagesEcoStruxure Power Monitoring Expert 8.2 - PSWSANCZZSPEZZkamran ashrafNo ratings yet

- As 127307 Iv3 Um C22GB WW GB 2042 3 PDFDocument448 pagesAs 127307 Iv3 Um C22GB WW GB 2042 3 PDFkamran ashrafNo ratings yet

- Harmony Electromechanical Relays - RSB1A120EDDocument6 pagesHarmony Electromechanical Relays - RSB1A120EDkamran ashrafNo ratings yet

- Modbus TCP Digital Io Dat8130Document2 pagesModbus TCP Digital Io Dat8130kamran ashrafNo ratings yet

- SER205 16 AMIBearingsInc. 2DSalesDrawing 04 08 2023Document1 pageSER205 16 AMIBearingsInc. 2DSalesDrawing 04 08 2023kamran ashrafNo ratings yet

- Sist en 61000 3 2 2006 A1 2009Document8 pagesSist en 61000 3 2 2006 A1 2009L K YuNo ratings yet

- Ac Tech Smvector Drive User ManualDocument62 pagesAc Tech Smvector Drive User ManualANo ratings yet

- An Improved Valley-Fill Passive Power-Factor-CorrectionDocument8 pagesAn Improved Valley-Fill Passive Power-Factor-Correctionpdseetharam009No ratings yet

- Protect Transformer Assets: Serveron TM3Document6 pagesProtect Transformer Assets: Serveron TM3xiaomiNo ratings yet

- Mentor MP Short Form Guide English Issue 8Document133 pagesMentor MP Short Form Guide English Issue 8SAYAKNo ratings yet

- Lenze SMV ManualDocument50 pagesLenze SMV Manualcairo.1834566No ratings yet

- Evc Drive User Manual en Us 160814Document142 pagesEvc Drive User Manual en Us 160814Coil98No ratings yet

- Unidrive m100Document100 pagesUnidrive m100Kharla SotoNo ratings yet

- Electronic TransformersDocument32 pagesElectronic TransformersKhaled RabeaNo ratings yet

- Eyelite Catalogue 2018-V1Document24 pagesEyelite Catalogue 2018-V1Linh TrọngNo ratings yet

- CISPR Guide 2019Document25 pagesCISPR Guide 2019daudmmvgNo ratings yet

- Resources Leaflets - Din Rail Power SupplyDocument8 pagesResources Leaflets - Din Rail Power SupplyMEHDINo ratings yet

- Electronic Timer - Series Micon 225: Multi Function Timer Multi Function Timer With 1 Instant & 1 Delayed C/ODocument2 pagesElectronic Timer - Series Micon 225: Multi Function Timer Multi Function Timer With 1 Instant & 1 Delayed C/ORohit chavanNo ratings yet

- Saeco Incanto - 52Document20 pagesSaeco Incanto - 52Gheorghe CimpoeruNo ratings yet

- Resolucion Acreditación BACLDocument31 pagesResolucion Acreditación BACLramicaleNo ratings yet

- Exterior Lighting-Rev05Document15 pagesExterior Lighting-Rev05Mohamed HamedNo ratings yet

- ABL7REDocument16 pagesABL7REeehassaanNo ratings yet

- EU Declaration of Conformity: 2014/53/EU 2009/125/EC and Amendments 1194/2012 and AmendmentsDocument3 pagesEU Declaration of Conformity: 2014/53/EU 2009/125/EC and Amendments 1194/2012 and AmendmentsEduard George UngureanuNo ratings yet

- Roborock Robotic Vacuum Cleaner Manual: Please Read This Manual Carefully Before Using The Product and Store It ProperlyDocument20 pagesRoborock Robotic Vacuum Cleaner Manual: Please Read This Manual Carefully Before Using The Product and Store It ProperlyErik VagenNo ratings yet

- Managing Harmonic GuidelineDocument37 pagesManaging Harmonic GuidelineAli AkbarNo ratings yet

- CE-EMC Test ReportDocument97 pagesCE-EMC Test ReportDuy ChuNo ratings yet

- ABB Technical Guide BookDocument226 pagesABB Technical Guide BookORK BUNSOKRAKMUNYNo ratings yet

- Technical Guide - HALOTRONIC For Low-Voltage Halogen LampsDocument25 pagesTechnical Guide - HALOTRONIC For Low-Voltage Halogen LampsjustjudgeNo ratings yet

- En 50438 2013-BSDocument70 pagesEn 50438 2013-BSMario BreškiNo ratings yet

- Analysis of Harmonic Current Emissions in Voltages Below The PresentedDocument4 pagesAnalysis of Harmonic Current Emissions in Voltages Below The PresentedDiepMiuDiepMiuNo ratings yet

- Form C: Type Test Verification ReportDocument10 pagesForm C: Type Test Verification ReportMadhushan DassanayakeNo ratings yet

- Schneider - Medidor de Energía Ion Catálogo-Pm2000 - Plsed310053en - WebDocument53 pagesSchneider - Medidor de Energía Ion Catálogo-Pm2000 - Plsed310053en - WebpeterNo ratings yet

- CPC100 Manual PDFDocument32 pagesCPC100 Manual PDFAnonymous wx4I4YQONo ratings yet

- SERVERON - Brochure TM1 (2014)Document6 pagesSERVERON - Brochure TM1 (2014)Marco GourdetNo ratings yet