Professional Documents

Culture Documents

08 Segmented Lubrication Pinions PDF

08 Segmented Lubrication Pinions PDF

Uploaded by

Sugiharto RichardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

08 Segmented Lubrication Pinions PDF

08 Segmented Lubrication Pinions PDF

Uploaded by

Sugiharto RichardCopyright:

Available Formats

Special Lubrication Systems

Lubrication pinions for gears

Segmented lubrication pinions

Description

The segmented lubrication pinions consist of

alternating laminated shims made of plastic. Hence

the number of outlets is increased and a very

variable grading of gear heights is reached.

Lubrication pinions

In order to optimize lubrication, designs with

integrated proximity switches are used to adjust the

number of lubrication cycles via the number of

revolutions.

Function

Lubricant is delivered via a grease pump into the Technical data

center drilling of the pinions shaft. The drilling must

Module: 12 / 16

exactly be orientated towards the center of the

Height: depends on application

lubricated gear so that lubricant always comes out of

at module 12: min. height 26 mm,

the tooth flank during the meshing.

further in steps of 9 mm

Lubricant flows from the center drilling of the shaft

at module 16: min. height 22 mm,

through the channel of the lubricant outlet of the

further in steps of 6 mm

pinion and is evenly applied on the flank of the gear.

Profile displacement: + 0,38 mm

Design: in disk construction

No. of teeth: 8

Lubricant: greases up to NLGI-cl. 2

Operating temperature: -20 to 70 °C

Connection: variable

Material: gear - aluminium, plastic

Retainer retainer, shaft - steel

Center drilling

Lubricant channel

Lubricant

Outlet surface

state: 01.16EN

Lubrication pinion

Gear

08-1-20-01

1090200398

© BEKA 2016 All rights reserved! Subject to alterations!

BAIER + KÖPPEL GmbH + CO BEETHOVENSTR.

BAIER + KÖPPEL14GmbH

TEL.:

+ CO+49

KG9241

BEETHOVENSTR.

729-0 WEB: www.beka-lube.de

14 POSTFACH 1320

D-91257 PEGNITZ FAX: +49 9241D-91257

729-50 PEGNITZ

E-MAIL: beka@beka-lube.de

D-91253 PEGNITZ X TEL.: +49 9241 729-0

FAX: +49 9241 729-50

WEB: www.beka-lube.de

Contents

E-MAIL: beka@beka-lube.de

Special Lubrication Systems

Lubrication pinions for gears

Segmented lubrication pinions

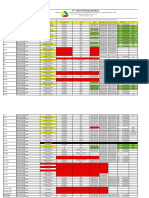

Example Lubrication pinion for existing modules and

Connection, height of lubrication pinion and the heights

retainer version are variable. Module Height Drawing**

(mm)

12 98 FAZ05167_00

Module 12

12 107 FAZ05167_01

Ø 129,12 129,5

Lubrication pinions

Ø 96 20 98

lubri. direction 16 88 FAZ05032_00

16 82 FAZ05032_01*

16 82 FAZ05032_02

16 82 FAZ05032_03*

16 106 right FAZ05032_04

16 106 left FAZ05032_05

16 82 FAZ05032_06

16 82 FAZ05032_07

180

16 82 FAZ05032_08

150

pressure connect. 16 82 FAZ05032_09

M10x1 16 142 FAZ05032_10

55

10

16 136 FAZ05032_11

16 136 FAZ05032_12

15

12

16 118 FAZ05032_13

retainer 10

60

16 124 FAZ05032_14

16 112 FAZ05032_15

16 148 FAZ05032_16

16 112 FAZ05032_17

Module 16

Ø 172,16 110 * Lubrication pinion with proximity switch; the

Ø 128 22 88 31,5 proximity switch can be completed at any

lubrication direction lubrication pinion acc. to customers request.

**We are pleased to send you our drawings with

exact connection dimensions and order details on

demand.

180

150

55

10

swivelling joint

plug-type connection

pipe-Ø 6

15

state: 01.16EN

retainer 12 10

60

08-1-20-02

1090200398

Subject to alterations! © BEKA 2016 All rights reserved!

BAIER

BAIER++KÖPPEL

KÖPPELGmbH

GmbH++CO

COKG BEETHOVENSTR. 14 TEL.:

POSTFACH

+49 9241

1320

729-0 TEL.:

WEB: +49

www.beka-lube.de

9241 729-0 WEB: www.beka-lube.de

D-91257 PEGNITZ FAX:

D-91253

+49 PEGNITZ

9241 729-50 FAX:

E-MAIL:

+49 9241

beka@beka-lube.de

729-50 E-MAIL: beka@beka-lube.de X Contents

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- User Guide Black WidowDocument3 pagesUser Guide Black WidowIrving Zuriel Rivera Mondragon0% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Electronically Controlled Brake System (EBS)Document18 pagesElectronically Controlled Brake System (EBS)Sherzad Chem100% (4)

- Evolution of Computer Cooling Systems FINALDocument30 pagesEvolution of Computer Cooling Systems FINALAvinash Menon0% (1)

- 08 Spray Nozzles Chain Lubrication PDFDocument2 pages08 Spray Nozzles Chain Lubrication PDFSugiharto RichardNo ratings yet

- 09 Beka Xmatic Controller S ControllingDocument2 pages09 Beka Xmatic Controller S ControllingSugiharto RichardNo ratings yet

- 08 PU-lubrication Pinion For Gearings PDFDocument4 pages08 PU-lubrication Pinion For Gearings PDFSugiharto RichardNo ratings yet

- 09 GIGA-multitronic ControllingDocument30 pages09 GIGA-multitronic ControllingSugiharto RichardNo ratings yet

- 09 EP-tronic ControllingDocument8 pages09 EP-tronic ControllingSugiharto RichardNo ratings yet

- 09 ISU3 ControllingDocument2 pages09 ISU3 ControllingSugiharto RichardNo ratings yet

- 09 GIGA-tronic ControllingDocument8 pages09 GIGA-tronic ControllingSugiharto RichardNo ratings yet

- 09 Pressure SwitchDocument6 pages09 Pressure SwitchSugiharto Richard100% (1)

- IRITS 1016 204 en Lubrication CatalogDocument36 pagesIRITS 1016 204 en Lubrication CatalogSugiharto RichardNo ratings yet

- Price Als & Afs Jomon UpdateDocument4 pagesPrice Als & Afs Jomon UpdateSugiharto RichardNo ratings yet

- Original Operating and Assembly Manual: PFP - UDocument16 pagesOriginal Operating and Assembly Manual: PFP - USugiharto RichardNo ratings yet

- Field Assembly Instruction: Hydraulic ExcavatorDocument288 pagesField Assembly Instruction: Hydraulic ExcavatorSugiharto RichardNo ratings yet

- Central Lubrication Pump PICO: ... A Product of BEKADocument10 pagesCentral Lubrication Pump PICO: ... A Product of BEKASugiharto RichardNo ratings yet

- Domestic Production and Foreign Trade The American Capital Position Re-ExaminedDocument23 pagesDomestic Production and Foreign Trade The American Capital Position Re-ExaminedKevin Mcdonald100% (2)

- Janda 400V PDFDocument11 pagesJanda 400V PDFJoel BrasilBorgesNo ratings yet

- Ji 2008 JB00 K NNLC 000 0001 PDFDocument41 pagesJi 2008 JB00 K NNLC 000 0001 PDFHamza ChemmamNo ratings yet

- (RSC PAPERBACKS) G. Scott - Polymers and The Environment-Royal Society of Chemistry (2003)Document148 pages(RSC PAPERBACKS) G. Scott - Polymers and The Environment-Royal Society of Chemistry (2003)nimraNo ratings yet

- Experiment No. 8: Specific Heat of MetalsDocument2 pagesExperiment No. 8: Specific Heat of MetalsTiny100% (1)

- Process Design CalcDocument9 pagesProcess Design Calckiran raghukiranNo ratings yet

- C 150 - 04Document8 pagesC 150 - 04Ariana PetersonNo ratings yet

- Tc-Carbomer 340 MsdsDocument4 pagesTc-Carbomer 340 MsdstopguitarNo ratings yet

- 5-Corrective Maintenance FahuDocument2 pages5-Corrective Maintenance FahuUmair LiaqatNo ratings yet

- TD CTC 997 PuDocument2 pagesTD CTC 997 PuMeliany SariNo ratings yet

- Making of Stamped Batik by Machined Batik Stamp Pattern Made From Hand Made Design Batik ImageDocument4 pagesMaking of Stamped Batik by Machined Batik Stamp Pattern Made From Hand Made Design Batik ImageIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Peoples Steel Mills LTDDocument19 pagesPeoples Steel Mills LTDalmasNo ratings yet

- Housekeeping's Cleaning Responsibilities in Front-Of-The-House Areas of The HotelDocument5 pagesHousekeeping's Cleaning Responsibilities in Front-Of-The-House Areas of The HotelThandar Swe ZinNo ratings yet

- M105 93to9Document21 pagesM105 93to9Ravi RanjanNo ratings yet

- Handbook Parting Off 2009 enDocument44 pagesHandbook Parting Off 2009 enGilberto ManhattanNo ratings yet

- Doors and Wall Partitions 2021 2022 It en Glas Italia 0 Cat150e611fDocument289 pagesDoors and Wall Partitions 2021 2022 It en Glas Italia 0 Cat150e611fNihal JafarNo ratings yet

- Why Don't We Deduct The Steel Volume While Calculating The Concrete Volume in RCC StructuresDocument5 pagesWhy Don't We Deduct The Steel Volume While Calculating The Concrete Volume in RCC StructuressitaracommercialcomplexNo ratings yet

- Manufacturing Defects of Brass Products and Suggested RemediesDocument18 pagesManufacturing Defects of Brass Products and Suggested RemediesMichael ThompsonNo ratings yet

- Eddy Current Testing ApplicationsDocument21 pagesEddy Current Testing ApplicationsvibinkumarsNo ratings yet

- Fin HMTDocument12 pagesFin HMTbalakalees100% (1)

- VagogyuruDocument856 pagesVagogyurupsnmyNo ratings yet

- Production SystemDocument100 pagesProduction Systembroshan100% (1)

- U-Boot: TechnologyDocument12 pagesU-Boot: TechnologyPrince AshNo ratings yet

- JR R P Asphalt Reinforcement Rehabilitaion of Concrete Pavements HaTelit-DresdenDocument2 pagesJR R P Asphalt Reinforcement Rehabilitaion of Concrete Pavements HaTelit-DresdenjasbojanotNo ratings yet

- Cored Wires - ESAB - OK TubrodDocument87 pagesCored Wires - ESAB - OK TubrodElias KapaNo ratings yet

- Iron Carbon Diagram of Steel PDFDocument6 pagesIron Carbon Diagram of Steel PDFshihabscb1971100% (1)

- Chemical Engineering Lab I Manual - SP15Document66 pagesChemical Engineering Lab I Manual - SP15MohammedAliMohammed100% (2)