Professional Documents

Culture Documents

FRWDES Compilation

FRWDES Compilation

Uploaded by

Joshua DayritCopyright:

Available Formats

You might also like

- Geotech FormulasDocument4 pagesGeotech FormulasGaddiel AguilarNo ratings yet

- 9.design Plans and SpecificationsDocument15 pages9.design Plans and SpecificationsJoshua DayritNo ratings yet

- AASHTO T 267-86 - 08 Determination of Organic Content in Soils by Loss On Ignition PDFDocument2 pagesAASHTO T 267-86 - 08 Determination of Organic Content in Soils by Loss On Ignition PDFgilmer86% (7)

- Module 3 - Weight-Volume RelationshipDocument31 pagesModule 3 - Weight-Volume RelationshipkaicaNo ratings yet

- Geotechnical Module 1Document52 pagesGeotechnical Module 1athira100% (2)

- Lecture Module 1 - Index Properties of SoilDocument7 pagesLecture Module 1 - Index Properties of SoilDianne DavidNo ratings yet

- Chapter 3 Weight Volume Relationships For StudentsDocument35 pagesChapter 3 Weight Volume Relationships For StudentsHahahahahahahahahaNo ratings yet

- Ce 122 Chapter 2 PDFDocument11 pagesCe 122 Chapter 2 PDFJeisther Timothy GalanoNo ratings yet

- Geotecheng Module 01 Chapter 02Document32 pagesGeotecheng Module 01 Chapter 02Ace De GuzmanNo ratings yet

- Week 3 Volume and Weight RelationshipDocument43 pagesWeek 3 Volume and Weight RelationshiperljohngranaNo ratings yet

- Module 2 - Properties of SoilDocument38 pagesModule 2 - Properties of SoilEmmanuel De VeraNo ratings yet

- Module 2. Physical Properties of SoilDocument24 pagesModule 2. Physical Properties of SoilMark Andykenn Liaga MaglinteNo ratings yet

- Pce414 Geotechnical Engineering 1 Topic 2 Weight and Volume RelationshipDocument16 pagesPce414 Geotechnical Engineering 1 Topic 2 Weight and Volume RelationshipMayvyyNo ratings yet

- Chap 3Document31 pagesChap 3Parwiz YosofiNo ratings yet

- CH 3Document15 pagesCH 3omar TahaNo ratings yet

- Reference 1Document10 pagesReference 1Carl Harvey Agullo BriobesNo ratings yet

- Permeability and Seepage: Course Code: Course Title: Credit HoursDocument15 pagesPermeability and Seepage: Course Code: Course Title: Credit HoursSHAHRIER NAZIM SHUVRONo ratings yet

- Soil Profiles, Types and Classification MethodsDocument65 pagesSoil Profiles, Types and Classification MethodsBazimya DixonNo ratings yet

- Department of Geology University of Liberia Semester II-2019-2020Document37 pagesDepartment of Geology University of Liberia Semester II-2019-2020Edwin BallahNo ratings yet

- 2chapter-2 PPT - (Final)Document61 pages2chapter-2 PPT - (Final)Muhe JsNo ratings yet

- Chapter Three Phase RelationshipsDocument11 pagesChapter Three Phase Relationshipshussein darwishNo ratings yet

- CE111 - Duroja - Assignment 2Document2 pagesCE111 - Duroja - Assignment 2Jessie Jade Sestina Duroja - MainNo ratings yet

- Geotechnical Engineering-Weight Volume RelationshipsDocument33 pagesGeotechnical Engineering-Weight Volume RelationshipsLovely-Lynn EvangelistaNo ratings yet

- Soil Mechanics Unit 2Document24 pagesSoil Mechanics Unit 2ajai chyNo ratings yet

- EECQ 3171-Soil Mechanics IA-Slides 1-18Document19 pagesEECQ 3171-Soil Mechanics IA-Slides 1-18EICQ/00154/2020 SAMUEL MWANGI RUKWARONo ratings yet

- Teaching Demo - Soil MechanicsDocument29 pagesTeaching Demo - Soil Mechanicsengr.belcena0921No ratings yet

- Handout Minggu 02b Mektan - Soil Index and Gravimetry-1Document19 pagesHandout Minggu 02b Mektan - Soil Index and Gravimetry-1IkeNo ratings yet

- Lesson 3 PDFDocument10 pagesLesson 3 PDFJessie Jade Sestina Duroja - MainNo ratings yet

- CH 5 Soil MechanicsDocument89 pagesCH 5 Soil MechanicsPRINCE VISHALNo ratings yet

- Chapter 3Document18 pagesChapter 3anon_749279665No ratings yet

- MODULE 1 Unit 4 (Week 7 and 8) For Soil MechanicsDocument6 pagesMODULE 1 Unit 4 (Week 7 and 8) For Soil MechanicsMark Ruby OpawonNo ratings yet

- Lecture 3 Index PropertiesDocument26 pagesLecture 3 Index PropertiesMd. Ariful IslamNo ratings yet

- Lesson 2 Topic 1 Physical Properties of Soil 1Document12 pagesLesson 2 Topic 1 Physical Properties of Soil 1Jhonalyn LumogdangNo ratings yet

- Soil Mech Labwork 2Document6 pagesSoil Mech Labwork 2Laxamana, MarcNo ratings yet

- Geotechnical Engineering 1 T2Document16 pagesGeotechnical Engineering 1 T2ERJEAN SILVERIONo ratings yet

- Geotechnical EngineeringDocument7 pagesGeotechnical EngineeringWherlyne Lyka IslaNo ratings yet

- CE260c-Phase RelationsDocument12 pagesCE260c-Phase RelationsReginald AshongNo ratings yet

- Soil Classification and Laboratory Testing: 5.0 General: Weight Volume RelationshipDocument19 pagesSoil Classification and Laboratory Testing: 5.0 General: Weight Volume RelationshipayeblessNo ratings yet

- Soil Mechanics I Tutorial For Exit ExamDocument177 pagesSoil Mechanics I Tutorial For Exit ExamascendancyyfirisaNo ratings yet

- Lec 4 - Soil Composition and Index Properties F22Document23 pagesLec 4 - Soil Composition and Index Properties F22tyler bradfordNo ratings yet

- Soil Mechanics 2022-09-21 W-V As PostedDocument8 pagesSoil Mechanics 2022-09-21 W-V As PostedAhmed ZarkhaizNo ratings yet

- Chapter 2 PHYSICAL PROPERTY OF SOIL LastDocument30 pagesChapter 2 PHYSICAL PROPERTY OF SOIL Lastobsadaniel63No ratings yet

- Geotechnical Engineering 1Document31 pagesGeotechnical Engineering 1Ranajit MajhiNo ratings yet

- Soil Mechanics 3.0 For PDFDocument18 pagesSoil Mechanics 3.0 For PDFomay12No ratings yet

- MKCP 3313 Week 2 SynchronousDocument21 pagesMKCP 3313 Week 2 SynchronousXen GamesNo ratings yet

- Weight-Volume Relationships (Formulas)Document2 pagesWeight-Volume Relationships (Formulas)SolaNo ratings yet

- Problem Set 2Document2 pagesProblem Set 2Jay Ryan G. GajetonNo ratings yet

- 02 Phase RelationshipDocument12 pages02 Phase RelationshipDE DECADENo ratings yet

- Physical Properties of Soil PDFDocument16 pagesPhysical Properties of Soil PDFAshish MittalNo ratings yet

- Soil Aggregate: Weight Volume RelationshipsDocument9 pagesSoil Aggregate: Weight Volume RelationshipszenislerNo ratings yet

- Physical PropertiesDocument12 pagesPhysical PropertiesAli -No ratings yet

- Phase Relations: (Das, Chapter 3) Sections: All Except 3.6Document12 pagesPhase Relations: (Das, Chapter 3) Sections: All Except 3.6javier100% (1)

- University of Cebu - CE Review: Geotechnical Eng'G Phases of Soil and ClassificationDocument7 pagesUniversity of Cebu - CE Review: Geotechnical Eng'G Phases of Soil and Classificationjovar jumao-asNo ratings yet

- Soil Physical Properties - Atterberg - Soil ClassificationDocument7 pagesSoil Physical Properties - Atterberg - Soil ClassificationRay JillNo ratings yet

- Chapter Two Physical Characteristics of SoilsDocument32 pagesChapter Two Physical Characteristics of SoilsHiwot DemisseNo ratings yet

- Geotechnical Engineering I: Phase RelationshipsDocument12 pagesGeotechnical Engineering I: Phase RelationshipsKavish DayaNo ratings yet

- Chapter 2Document16 pagesChapter 2Casao JonroeNo ratings yet

- المحاضره الاولىDocument6 pagesالمحاضره الاولىايفان ال دليمNo ratings yet

- Soil Mechanics-I Physical Properties of SoilsDocument8 pagesSoil Mechanics-I Physical Properties of Soilsmidju dugassaNo ratings yet

- CON4341 - E - Note - 02 Phase RelationshipDocument12 pagesCON4341 - E - Note - 02 Phase Relationship123No ratings yet

- Pressure, Heat and Temperature - Physics for Kids - 5th Grade | Children's Physics BooksFrom EverandPressure, Heat and Temperature - Physics for Kids - 5th Grade | Children's Physics BooksNo ratings yet

- Laplace Transform November 16-17, 2020Document10 pagesLaplace Transform November 16-17, 2020Joshua DayritNo ratings yet

- Computer Fundamentals Final RequirementDocument3 pagesComputer Fundamentals Final RequirementJoshua DayritNo ratings yet

- Lesson 5 - Depreciation PDFDocument10 pagesLesson 5 - Depreciation PDFJoshua DayritNo ratings yet

- 03 STABILITY Sample Problems PDFDocument3 pages03 STABILITY Sample Problems PDFJoshua DayritNo ratings yet

- Three-Column Table Concept MapDocument5 pagesThree-Column Table Concept MapJoshua DayritNo ratings yet

- Triangular Weir PDFDocument9 pagesTriangular Weir PDFJoshua DayritNo ratings yet

- Dayrit, Joshua Michael Angelo - Activity No.2Document6 pagesDayrit, Joshua Michael Angelo - Activity No.2Joshua DayritNo ratings yet

- Hydraulics2 PrelimsDocument3 pagesHydraulics2 PrelimsJoshua DayritNo ratings yet

- Geotecheng Module 01 Chapter 01Document15 pagesGeotecheng Module 01 Chapter 01Joshua DayritNo ratings yet

- Dayrit, Joshua Michael Angelo - Activity No.4Document15 pagesDayrit, Joshua Michael Angelo - Activity No.4Joshua DayritNo ratings yet

- RAW ReviewerDocument3 pagesRAW ReviewerJoshua DayritNo ratings yet

- Module 5 Design of Isolated Spread FootingDocument24 pagesModule 5 Design of Isolated Spread FootingJoshua DayritNo ratings yet

- DAYRIT, JOSHUA MICHAEL ANGELO - ACTIVITY No.1Document9 pagesDAYRIT, JOSHUA MICHAEL ANGELO - ACTIVITY No.1Joshua DayritNo ratings yet

- DAYRIT, JOSHUA MICHAEL ANGELO - QUIZ No.2Document1 pageDAYRIT, JOSHUA MICHAEL ANGELO - QUIZ No.2Joshua DayritNo ratings yet

- DAYRIT, JOSHUA MICHAEL ANGELO - ACTIVITY No.3Document9 pagesDAYRIT, JOSHUA MICHAEL ANGELO - ACTIVITY No.3Joshua DayritNo ratings yet

- Jaipur Fire and Its Environmental Effects: Dr. Mukta GirdharDocument8 pagesJaipur Fire and Its Environmental Effects: Dr. Mukta GirdharvishuNo ratings yet

- Block 4 - BryophytesDocument105 pagesBlock 4 - BryophytesILMA ASLAMNo ratings yet

- Detail Phase 1Document15 pagesDetail Phase 1shobhitha shobhitha mNo ratings yet

- Soil Training Manual Text PDFDocument30 pagesSoil Training Manual Text PDFHesanRajaraniNo ratings yet

- Microbial Transformation of Metals (Review)Document6 pagesMicrobial Transformation of Metals (Review)H15H4MNo ratings yet

- Tripp Scott Exhibits For SWSDocument102 pagesTripp Scott Exhibits For SWSMy-Acts Of-SeditionNo ratings yet

- Paramagnetic Article PDFDocument5 pagesParamagnetic Article PDFJonathan SinclairNo ratings yet

- Grade 3 Science Revision 2Document2 pagesGrade 3 Science Revision 2diana rebkaNo ratings yet

- Leaf Analysis For California Deciduous Fruits: James Beutel, Uriu, and LillelandDocument4 pagesLeaf Analysis For California Deciduous Fruits: James Beutel, Uriu, and LillelandIrfanulAlamNo ratings yet

- Elodea Design LabDocument5 pagesElodea Design Labaug97girlNo ratings yet

- IUSS Bulletin 122 (June 2013)Document60 pagesIUSS Bulletin 122 (June 2013)Scary CreaturesNo ratings yet

- Select and Use Farm ToolsDocument29 pagesSelect and Use Farm ToolsAyeza Cadicoy-CelzoNo ratings yet

- Introduction To Soil Conservation-47Document18 pagesIntroduction To Soil Conservation-47Neeraj Kumar100% (2)

- The Vegetation of SocotraDocument21 pagesThe Vegetation of Socotramarwan98No ratings yet

- Depth of WaterDocument3 pagesDepth of Waterditano.mm68No ratings yet

- Potassium CycleDocument24 pagesPotassium CycleJoseph Kennedy OcarizaNo ratings yet

- Learning Guide Unit 7: Unit 7: Soil, Pest and Water ManagementDocument9 pagesLearning Guide Unit 7: Unit 7: Soil, Pest and Water ManagementNhat TranNo ratings yet

- A Position Paper On Mining in The PhilippinesDocument3 pagesA Position Paper On Mining in The PhilippinesCharles Niño OrionNo ratings yet

- MANUAL MEDICIÓN RODADO Custom Track Service HandbookDocument776 pagesMANUAL MEDICIÓN RODADO Custom Track Service HandbookAlejandro CortesNo ratings yet

- Effect of Plant Spacing's and Fertilizer Levels On Growth and Productivity of Desi Cotton (Gossypium Arboreum L.)Document6 pagesEffect of Plant Spacing's and Fertilizer Levels On Growth and Productivity of Desi Cotton (Gossypium Arboreum L.)Sudhir YadavNo ratings yet

- Cofee Husk AshDocument12 pagesCofee Husk AshElaMazlanNo ratings yet

- Schedule of Rates of LGED Bangladesh July 2015Document295 pagesSchedule of Rates of LGED Bangladesh July 2015kabir91% (32)

- Geotechnical Engineering Lecture NotesDocument5 pagesGeotechnical Engineering Lecture NotesSumalinog G. GelsonNo ratings yet

- Manta Ray BrochureDocument8 pagesManta Ray BrochureMIGUEL ANGEL ACON ROBLEDANo ratings yet

- R - Us20070178239a1 PDFDocument8 pagesR - Us20070178239a1 PDFbutuh ganalNo ratings yet

- Environment: Definition Scope & ImportanceDocument17 pagesEnvironment: Definition Scope & ImportanceNavjoshNo ratings yet

- Environmental Destruction in Ethiopia:A Leading Factor in Oromo MigrationFinalDocument21 pagesEnvironmental Destruction in Ethiopia:A Leading Factor in Oromo MigrationFinaloromopressNo ratings yet

- CS 601 Mast Advanced Field Crop SyllabusDocument5 pagesCS 601 Mast Advanced Field Crop SyllabusEsther Suan-LancitaNo ratings yet

- Environmental Impact of Soil and Sand MiningDocument10 pagesEnvironmental Impact of Soil and Sand MiningLaxmana GeoNo ratings yet

FRWDES Compilation

FRWDES Compilation

Uploaded by

Joshua DayritOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FRWDES Compilation

FRWDES Compilation

Uploaded by

Joshua DayritCopyright:

Available Formats

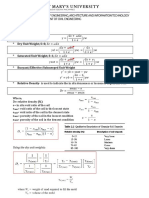

Module 1 – Index Properties of Soil

Three-phase systems. A large portion of the earth’s surface is covered by soils, and they are widely used as

construction and foundation materials. Soil mechanics is the branch of engineering that deals with the

engineering properties of soil and its behavior under stresses and strains.

Soil and Volume Relationships

Fig 1a shows a soil mass that has a total volume V and a total weight, W. to develop the weight-volume

relationship, the three phases of the soil mass, i.e., soil solids, air, and water, have been separated in Fig

1b

Fig 1

From the given figure we can conclude that;

Volume Relationship

𝑽𝑽 = 𝑽𝑽𝒂𝒂 + 𝑽𝑽𝒘𝒘 + 𝑽𝑽𝒔𝒔

or

𝑽𝑽 = 𝑽𝑽𝒗𝒗 + 𝑽𝑽𝒔𝒔

Weight Relationship

𝑾𝑾 = 𝑾𝑾𝒘𝒘 + 𝑾𝑾𝒔𝒔

where;

𝑉𝑉 = 𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡 𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣 𝑜𝑜𝑜𝑜 𝑡𝑡ℎ𝑒𝑒 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 𝑊𝑊 = 𝑊𝑊𝑊𝑊𝑊𝑊𝑊𝑊ℎ𝑡𝑡 𝑜𝑜𝑜𝑜 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠

𝑉𝑉𝑎𝑎 = 𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣 𝑜𝑜𝑜𝑜 𝑎𝑎𝑎𝑎𝑎𝑎 𝑊𝑊𝑤𝑤 = 𝑊𝑊𝑊𝑊𝑊𝑊𝑊𝑊ℎ𝑡𝑡 𝑜𝑜𝑜𝑜 𝑤𝑤𝑤𝑤𝑤𝑤𝑤𝑤𝑤𝑤

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 1 of 7

Module 1 – Index Properties of Soil

𝑉𝑉𝑤𝑤 = 𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣 𝑜𝑜𝑜𝑜 𝑤𝑤𝑤𝑤𝑤𝑤𝑤𝑤𝑤𝑤 𝑊𝑊𝑆𝑆 = 𝑊𝑊𝑊𝑊𝑊𝑊𝑊𝑊ℎ𝑡𝑡 𝑜𝑜𝑜𝑜 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠

𝑉𝑉𝑠𝑠 = 𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣 𝑜𝑜𝑜𝑜 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠

𝑉𝑉𝑣𝑣 = 𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣 𝑜𝑜𝑜𝑜 𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣

Void ratio (e) - The ratio of the volume of voids Vv to the volume of soils Vs in a given volume of material,

usually expressed as a decimal.

𝑽𝑽𝒗𝒗

𝒆𝒆 =

𝑽𝑽𝒔𝒔

For soils, e ranges from about 0.35 in the most dense state to seldom over 2 in the loosest state.

Porosity (n) - The ratio of the volume of voids to the total volume Vt expressed as either a decimal or a

percentage.

𝑽𝑽𝒗𝒗

𝒏𝒏 =

𝑽𝑽𝒕𝒕

For soils, n cannot exceed the value 1.0

Degree of saturation (S) - The ratio of the volume of water to the total volume of soil voids, expressed as

a percentage but used as a decimal.

𝑽𝑽𝒘𝒘

𝑺𝑺 =

𝑽𝑽𝒗𝒗

Water content (w) - The ratio of the weight of water Ww to the weight of soil solids Ws, usually expressed

as a percentage.

𝑾𝑾𝒘𝒘

𝒘𝒘 =

𝑾𝑾𝒔𝒔

Unit density (𝝆𝝆) - The ratio of mass per unit of volume. In the Fps system the values are the same as unit

weight following. The SI system gives units of 𝑘𝑘𝑘𝑘/𝑚𝑚3 but a preferred usage unit is 𝑔𝑔/𝑐𝑐𝑚𝑚3 .

𝒎𝒎

𝝆𝝆 =

𝑽𝑽

Unit weight (𝜸𝜸)- The weight of a unit volume of soil (or other material) in force units. The general

expression is;

𝑾𝑾

𝜸𝜸 =

𝑽𝑽

Dry Unit weight (𝜸𝜸𝒅𝒅 )- The unit weight of a dry soil is;

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 2 of 7

Module 1 – Index Properties of Soil

𝑾𝑾𝒔𝒔

𝜸𝜸𝒅𝒅 =

𝑽𝑽

Saturated Unit weight (𝜸𝜸𝒔𝒔𝒔𝒔𝒔𝒔 )- The unit weight of a saturated soil is; (note 𝑊𝑊𝑠𝑠𝑠𝑠𝑠𝑠 is obtained when the

degree of saturation is equivalent to 100%)

𝑾𝑾𝒔𝒔𝒔𝒔𝒔𝒔

𝜸𝜸𝒔𝒔𝒔𝒔𝒔𝒔 =

𝑽𝑽

Effective Unit weight (𝜸𝜸′)- Also called as, submerged unit weight and buoyant unit weight. It is the

saturated soil’s unit weight and deducting it by the unit weight of water

𝜸𝜸′ = 𝜸𝜸𝒔𝒔𝒔𝒔𝒔𝒔 − 𝜸𝜸𝒘𝒘

Unit weight of water (𝜸𝜸𝒘𝒘 )- The unit weight of water may be taken as 9.81 𝑘𝑘𝑘𝑘/𝑚𝑚3, 62.4 𝑝𝑝𝑝𝑝𝑝𝑝, or more

commonly as 1𝑔𝑔/𝑐𝑐𝑚𝑚3 so that the factor 𝛾𝛾𝑤𝑤 drops out of the calculation.

Specific gravity of soil solids (Gs) - The usual definition for soil is the same as found in most elementary

physics textbooks. The unit weight of distilled water is standard at 4°C, but the usual laboratory

temperatures in the range of 15 to 25°C do not introduce serious errors. G is usually subscripted to

identify the quantity; for soil grains, obtain Gs as;

𝑾𝑾𝒔𝒔 /𝑽𝑽𝒔𝒔 𝜸𝜸𝒔𝒔

𝑮𝑮𝒔𝒔 = =

𝜸𝜸𝒘𝒘 𝜸𝜸𝒘𝒘

These six basic definitions in equation form are sufficient to develop any needed relationships for

geotechnical engineering problems; these sets of equation may help you in solving more complicated

problems in solving for the properties of soil.

𝒆𝒆

𝒏𝒏 =

𝟏𝟏 + 𝒆𝒆

𝑮𝑮𝒔𝒔 𝒘𝒘 = 𝑺𝑺𝑺𝑺

𝜸𝜸 𝑮𝑮𝒔𝒔 + 𝑺𝑺𝑺𝑺

𝜸𝜸𝒅𝒅 = 𝜸𝜸 = 𝜸𝜸

𝟏𝟏 + 𝒘𝒘 𝟏𝟏 + 𝒆𝒆 𝒘𝒘

𝑮𝑮𝒔𝒔 𝑮𝑮𝒔𝒔 + 𝒆𝒆

𝜸𝜸𝒅𝒅 = 𝜸𝜸 𝜸𝜸𝒔𝒔𝒔𝒔𝒔𝒔 = 𝜸𝜸

𝟏𝟏 + 𝒆𝒆 𝒘𝒘 𝟏𝟏 + 𝒆𝒆 𝒘𝒘

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 3 of 7

Module 3 – Compressibility of Soils

When a load is acting on a soil, the soil is compressed, thereby causing its volume to decrease. This

decrease in volume results from reduction of void ratio of the soil by extruding of water and air from the

soil. If the saturated soil is subjected to the weight of a structure and water is subsequently squeezed out,

the resulting soil compression can cause undue building settlement.

Cohesionless soils usually compresses relatively quickly and settlement will undergo during the construction

phase whereas cohesive soil compress much more slowly because the expulsion of water from the small

soil pores is so slow. Hence, the settlement of a structure built on this soil may not occur until some time

after the structure is loaded. Total settlement involves two phase process, the immediate and consolidation

settlement. Immediate settlement occurs very rapidly within hours after the structure is loaded, where as

consolidation settlement occurs over an extended period of time (months or years). Consolidation

settlement is also divided into primary consolidation and secondary consolidation.

Settlement of Foundations

Settlement is the direct result of the decrease in the soil volume. Total settlement of a footing on clay maybe

considered to consists of three parts.

1.) Immediate Elastic Settlement (𝑆𝑆1 )

2.) Settlement due to primary consolidation of clay (𝑆𝑆𝑐𝑐 )

3.) Settlement due to secondary consolidation of clay (𝑆𝑆𝑠𝑠 )

Total Settlement (𝑆𝑆) can be computed as;

𝑺𝑺 = 𝑺𝑺𝟏𝟏 + 𝑺𝑺𝒔𝒔 + 𝑺𝑺𝒄𝒄

Immediate Elastic Settlement:

Immediately upon application of load on the footing, elastic compression of the underlying soil takes

place causing a settlement of the footing. However, this amount of settlement is usually very small and

can be neglected for all practical purposed. When a saturated compressible clay later is subjected to a

stress increase, elastic settlement occurs immediately.

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 1 of 16

Module 3 – Compressibility of Soils

In general, foundations are not perfectly flexible and are

embedded at a certain depth below the ground surface. It is

instructive, however, to evaluate the distribution of the contact

pressure under a foundation along with the settlement profile

under idealized conditions. A perfectly flexible foundation

resting on an elastic material such as saturated clay. If the

foundation is subjected to a uniformly distributed load, the

contact pressure will be uniform and the foundation will

experience a sagging profile. On the other hand, if we consider

a perfectly rigid foundation resting on the ground surface

subjected to a uniformly distributed load, the contact pressure

and foundation settlement profile will as shown. The foundation

will undergo a uniform settlement and the contact pressure will

be redistributed.

Theoretically, if the foundation is perfectly flexible, the settlement may be expressed as;

𝟏𝟏 − 𝝁𝝁𝒔𝒔

𝑺𝑺𝟏𝟏 = 𝒒𝒒(𝜶𝜶𝑩𝑩′ ) � � 𝑰𝑰𝒔𝒔 𝑰𝑰𝒇𝒇

𝑬𝑬𝒔𝒔

where;

𝑞𝑞 = net applied pressure on the foundation

𝐵𝐵′ = B/2 for center of the foundation

= B for the corner of the foundation

𝜇𝜇𝑠𝑠 = Poisson’s ratio of the soil

𝐸𝐸𝑠𝑠 = average modulus of elasticity of the soil under the foundation measured from z = 0 to about z = 5B

𝐼𝐼𝑠𝑠 = shape factor (Steinbrenner, 1934)

𝐼𝐼𝑓𝑓 = depth factor (Fox, 1948)

𝛼𝛼 = factor that depends on the location on the foundation where settlement is being calculated

= 4 for calculation of settlement at the CENTER of the foundation

= 1 for calculation of settlement at the CORNER of the foundation

𝟏𝟏 − 𝟐𝟐𝝁𝝁𝒔𝒔

𝑰𝑰𝒔𝒔 = 𝑭𝑭𝟏𝟏 + 𝑭𝑭

𝟏𝟏 − 𝝁𝝁𝒔𝒔 𝟐𝟐

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 2 of 16

Module 3 – Compressibility of Soils

For calculation of settlement at the center of the foundation:

𝐿𝐿 𝐻𝐻

𝑚𝑚′ = 𝑛𝑛′ =

𝐵𝐵 𝐵𝐵

�2�

For calculation of settlement at the corner of the foundation:

𝐿𝐿 𝐻𝐻

𝑚𝑚′ = 𝑛𝑛′ =

𝐵𝐵 𝐵𝐵

Due to the nonhomogeneous nature of soil deposits, the magnitude of Es may vary with

depth. For that reason, Bowles (1987) recommended using a weighted average value of

Es;

∑ 𝑬𝑬𝒔𝒔𝒔𝒔 ∆𝒛𝒛

𝑬𝑬𝒔𝒔 =

𝒛𝒛�

where;

𝑞𝑞 = soil modulus of elasticity within a depth ∆𝑧𝑧

𝑧𝑧̅ = H or 5B, whichever is smaller

The elastic settlement of a rigid foundation can be estimated as

𝑆𝑆1(𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟) = 0.93𝑆𝑆1(𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓)

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 3 of 16

Module 3 – Compressibility of Soils

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 4 of 16

Module 3 – Compressibility of Soils

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 5 of 16

Module 3 – Compressibility of Soils

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 6 of 16

Module 3 – Compressibility of Soils

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 7 of 16

Module 3 – Compressibility of Soils

Example 1:

A rigid shallow foundation 1m x 1m in plan is shown in the figure. Calculate the elastic settlement at the

center of the foundation.

• Given:

q = 200

α=4

𝑩𝑩 𝟏𝟏

𝐁𝐁′ = 𝟐𝟐 = 𝟐𝟐

𝝁𝝁𝒔𝒔 = 𝟎𝟎. 𝟑𝟑

• Solution:

• Elastic Settlement

𝟏𝟏 − 𝝁𝝁𝒔𝒔

𝑺𝑺𝟏𝟏 = 𝒒𝒒(𝜶𝜶𝑩𝑩′ ) � � 𝑰𝑰𝒔𝒔 𝑰𝑰𝒇𝒇

𝑬𝑬𝒔𝒔

∑ 𝑬𝑬𝒔𝒔𝒔𝒔 ∆𝒛𝒛

𝑬𝑬𝒔𝒔 = ? ; 𝑬𝑬𝒔𝒔 =

𝒛𝒛�

𝒛𝒛� = (5)(1) = 𝟓𝟓𝟓𝟓

8000(2) + 6000(1) + 10000(2)

𝑬𝑬𝒔𝒔 =

5

kN

𝑬𝑬𝒔𝒔 = 𝟖𝟖𝟖𝟖𝟖𝟖𝟖𝟖

m2

𝑳𝑳 1

𝒎𝒎′ = = = 𝟏𝟏

𝑩𝑩 1

𝑯𝑯 5 𝑭𝑭𝟏𝟏 = 𝟎𝟎. 𝟒𝟒𝟒𝟒𝟒𝟒; 𝑭𝑭𝟐𝟐 = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎

𝒏𝒏′ = = = 𝟏𝟏𝟏𝟏

𝑩𝑩 1�

� � 2

𝟐𝟐

𝟏𝟏 − 𝟐𝟐𝝁𝝁𝒔𝒔 1 − 2(0.3)

𝑰𝑰𝒔𝒔 = 𝑭𝑭𝟏𝟏 + 𝑭𝑭𝟐𝟐 = 0.498 + (0.016) → 𝑰𝑰𝒔𝒔 = 𝟎𝟎. 𝟓𝟓𝟓𝟓𝟓𝟓

𝟏𝟏 − 𝝁𝝁𝒔𝒔 1 − 0.3

𝑳𝑳 𝑫𝑫𝒇𝒇

= 1, = 1, 𝝁𝝁𝒔𝒔 = 0.3 →∴ 𝑰𝑰𝒇𝒇 = 𝟎𝟎. 𝟔𝟔𝟔𝟔

𝑩𝑩 𝑩𝑩

𝟏𝟏 − 𝝁𝝁𝒔𝒔 4 1 − 0.3

𝑺𝑺𝟏𝟏(𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇) = 𝒒𝒒(𝜶𝜶𝑩𝑩′ ) � � 𝑰𝑰𝒔𝒔 𝑰𝑰𝒇𝒇 = 200 � � � � (0.507)(0.65) → 𝑺𝑺𝟏𝟏(𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇) = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎 𝒎𝒎

𝑬𝑬𝒔𝒔 2 8400

𝑺𝑺𝟏𝟏(𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓) = 𝟎𝟎. 𝟗𝟗𝟗𝟗𝑺𝑺𝟏𝟏(𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇) = 0.93 (0.010985) → 𝑺𝑺𝟏𝟏(𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓) = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎 𝒎𝒎 = 𝟏𝟏𝟏𝟏. 𝟐𝟐𝟐𝟐𝟐𝟐𝟐𝟐

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 8 of 16

Module 3 – Compressibility of Soils

Primary Consolidation

NORMALLY CONSOLIDATED, OVERCONSOLIDATED, AND UNDERCONSOLIDATED SOILS

When performing consolidation analyses in the laboratory, we need to compare the preconsolidation

stress, 𝑃𝑃𝑐𝑐 , with the initial vertical effective stress, 𝑃𝑃𝑜𝑜 . The former is determined by laboratory test data

described earlier. Both values must be determined at the same depth, which normally is the depth of the

sample on which the consolidation test was performed. Once these values have been determined, we

need to asses which of the following three conditions exist in the field:

(a) Normally Consolidated (NC). If 𝑃𝑃𝑜𝑜 ≈ 𝑃𝑃𝐶𝐶 , then the vertical effective stress in the field has never been

higher than the current magnitude. In theory, these two must be exactly equal. However, in the reality,

both are subject to error due to sample disturbance and other factors, so the values obtained from

site characterization will rarely be exactly equal, even if the soil is truly normally consolidated.

Therefore, in order to avoid misclassifying the soil, we will consider it to be normally consolidated if 𝑃𝑃𝑜𝑜

and 𝑃𝑃𝑐𝑐 are equal within about ± 10%.

Preconsolidation Stress. The point where the slope of the consolidation curve changes is an important

event in the consolidation process. This stress is called the preconsolidation stress, 𝑃𝑃𝑐𝑐 . It is the greatest

vertical effective stress the soil has ever experienced. The value of 𝑃𝑃𝑐𝑐 is sometimes greater than 𝑃𝑃𝑜𝑜 at

the sample location, which means the soil was once subjected to a higher effective stress.

(b) Overconsolidated (OC). If 𝑃𝑃𝑜𝑜 < 𝑃𝑃𝑐𝑐 , then the vertical effective stress in the field was once higher than

its current magnitude. This condition is known as being preconsolidated. There are many processes

that can cause a soil to become overconsolidated, including:

a. Extensive corrosion or excavation such that the ground surface elevation is now much lower than it

was

b. Surcharge loading from a structure, such as a storage tank, which has since been removed

c. Increase in pore water pressure, such as from a rising groundwater table

d. Desiccation (drying) due to evaporation, plant roots, and other processes which produces negative

pore water pressure

e. Chemical changes in soil, such as accumulating of cementing agents

The term overconsolidated can be misleading because it implies there has been excessive

consolidation. Although there are few situations, such as cut slopes, where heavily consolidated soils

can be less desirable, overconsolidation is almost always a good thing.

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 9 of 16

Module 3 – Compressibility of Soils

(c) Underconsolidated. If 𝑃𝑃𝑜𝑜 > 𝑃𝑃𝑐𝑐 , which means the soil is still in the process of consolidating under a

previously applied load.

*Soil compressibility is based on the compression index, CC, for normally consolidated soils; or swell index,

CS , for overconsolidated soils.

OVERCONSOLIDATION RATIO

The 𝑃𝑃𝑜𝑜 values from the laboratory only represent the preconsolidation stress at the sample depth.

However, we sometimes need to compute 𝑃𝑃𝑐𝑐 in other depths. To do so, we compute the

overconsolidation ratio or OCR:

𝑷𝑷𝑪𝑪

𝑶𝑶𝑶𝑶𝑶𝑶 =

𝑷𝑷𝑶𝑶

OCR varies as a function of depth. For normally consolidated soils, OCR = 1 and does not vary with depth

CONSOLIDATION SETTLEMENT PREDICTIONS

(a) Normally Consolidated Clay Soil

𝑪𝑪𝒄𝒄 𝑯𝑯 𝑷𝑷𝒐𝒐 + ∆𝑷𝑷

𝑺𝑺𝑺𝑺 = 𝒍𝒍𝒍𝒍𝒍𝒍 � �

𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒐𝒐

When using the equation, compute the stresses at the midpoint of each soil layer.

(b) Overconsolidated Clay Soil – Case 1 when (𝑷𝑷𝒐𝒐 + ∆𝑷𝑷 < 𝑷𝑷𝒄𝒄 )

𝑪𝑪𝒔𝒔 𝑯𝑯 𝑷𝑷𝒐𝒐 + ∆𝑷𝑷

𝑺𝑺𝑺𝑺 = 𝒍𝒍𝒍𝒍𝒍𝒍 � �

𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒐𝒐

(c) Overconsolidated Clay Soil – Case 2 when (𝑷𝑷𝒐𝒐 + ∆𝑷𝑷 > 𝑷𝑷𝒄𝒄 )

𝑪𝑪𝒄𝒄 𝑯𝑯 𝑷𝑷𝒐𝒐 + ∆𝑷𝑷 𝑪𝑪𝒔𝒔 𝑯𝑯 𝑷𝑷𝒄𝒄

𝑺𝑺𝑺𝑺 = 𝒍𝒍𝒍𝒍𝒍𝒍 � �+ 𝒍𝒍𝒍𝒍𝒍𝒍 � �

𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒄𝒄 𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒐𝒐

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 10 of 16

Module 3 – Compressibility of Soils

COMPRESSION INDEX (𝑪𝑪𝒄𝒄 ) & SWELL INDEX (𝑪𝑪𝒔𝒔 )

Skempton (1944) suggested the following empirical expression for the compression index for

undisturbed clays

𝑪𝑪𝑪𝑪 = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎(𝑳𝑳𝑳𝑳 − 𝟏𝟏𝟏𝟏)

On the basis of observations on several natural clays, Rendon-Herrero (1983) gave the relationship for

the compression index in the form

𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝟐𝟐.𝟑𝟑𝟑𝟑

𝑪𝑪𝑪𝑪 = 𝟎𝟎. 𝟏𝟏𝟏𝟏𝟏𝟏𝑮𝑮𝟏𝟏.𝟐𝟐

𝒔𝒔 � �

𝑮𝑮𝒔𝒔

Nagaraj and Murty (1985) expressed the compression index as

𝑳𝑳𝑳𝑳(%)

𝑪𝑪𝑪𝑪 = 𝟎𝟎. 𝟐𝟐𝟐𝟐𝟐𝟐𝟐𝟐 � � 𝑮𝑮𝑺𝑺

𝟏𝟏𝟏𝟏𝟏𝟏

Park and Koumoto (2004) expressed the compression index by the following relationship

𝒏𝒏𝒐𝒐

𝑪𝑪𝑪𝑪 =

𝟑𝟑𝟑𝟑𝟑𝟑. 𝟕𝟕𝟕𝟕𝟕𝟕 − 𝟒𝟒. 𝟐𝟐𝟐𝟐𝟐𝟐𝒏𝒏𝒐𝒐

The swell index is appreciably smaller in magnitude than the compression index and generally can be

determined from laboratory tests. In most cases,

𝟏𝟏 𝟏𝟏

𝑪𝑪𝒔𝒔 = 𝑪𝑪𝒄𝒄 𝒕𝒕𝒕𝒕 𝑪𝑪

𝟓𝟓 𝟏𝟏𝟏𝟏 𝒄𝒄

CALCULATION OF SETTLEMENT UNDER A FOOTING ( 2 – 1 – Approximate Method)

The increase in the vertical stress in soil caused by a load applied over a limited area decreases with

depth 𝑧𝑧 measured from the ground surface downward. Hence to estimate the one-dimensional

settlement of a foundation, we can use the equations of consolidation settlement. However, the

increase of effective stress, 𝑃𝑃𝑜𝑜 , in these equations should be the average increase in the pressure

below the center of the foundation. Assuming that the pressure increase varies parabolically, using

Simpson’s rule, we can estimate the value of 𝑃𝑃𝑎𝑎𝑎𝑎𝑎𝑎 as;

∆𝑷𝑷𝒕𝒕𝒕𝒕𝒕𝒕 + 𝟒𝟒∆𝑷𝑷𝒎𝒎𝒊𝒊𝒅𝒅 + ∆𝑷𝑷𝒃𝒃𝒃𝒃𝒃𝒃

∆𝑷𝑷𝒂𝒂𝒂𝒂𝒂𝒂 =

𝟔𝟔

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 11 of 16

Module 3 – Compressibility of Soils

Where the stresses represent the increase in the effective pressure at the top, middle, and bottom of

the layer, respectively. This is known as the weighted average method.

Secondary Consolidation Settlement

Secondary Settlement is the additional settlement is the additional settlement that occurs at a constant

value of effective stress after excess pore water pressure has been dissipated. The process typically

continues slowly for a long period of time. Secondary settlement is usually small compared to primary

consolidation settlement.

𝑪𝑪𝜶𝜶 𝑯𝑯 𝑻𝑻𝟐𝟐

𝑺𝑺𝒔𝒔 = 𝐥𝐥𝐥𝐥𝐥𝐥 � �

𝟏𝟏 + 𝒆𝒆𝒑𝒑 𝑻𝑻𝟏𝟏

where;

𝑆𝑆𝑠𝑠 = Secondary Settlement

𝐶𝐶𝛼𝛼 = Secondary Compression Index

= 0.03𝐶𝐶𝑐𝑐 to 0.06𝐶𝐶𝑐𝑐

𝑒𝑒𝑝𝑝 = void ratio at the end of primary consolidation

= 𝑒𝑒𝑜𝑜 − ∆𝑒𝑒

𝑃𝑃𝑜𝑜 +∆𝑃𝑃

∆𝑒𝑒 = 𝐶𝐶𝑐𝑐 𝑙𝑙𝑙𝑙𝑙𝑙 � 𝑃𝑃𝑜𝑜

�

𝑇𝑇2 = time after completion of primary settlement

𝑇𝑇1 = time for completion of primary settlement

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 12 of 16

Module 3 – Compressibility of Soils

Example 2:

A 2.40m thick layer of compact sand overlies a 1.80 m thick clay layer. The unit weight of the compact

sand is 21.24 kN/m3, and the unit weight of clay is 15.74 kN/m3. The soil strata is subjected to a

surcharge pressure of 33.58 kPa located at the mid height of the clay layer. Laboratory testing indicates

that the clay is normally consolidated and the soil void ratio is 1.28. (a) Compute the compression index

if the clay has a liquid limit of 46.66. (b) Determine the effective stress at the mid height of the clay layer,

before the surcharge occurred. (c) What would be the settlement due to primary consolidation?

33.58 kPa • Given:

Normally Consolidated

eclay = 1.28

LLclay = 46.66

• Solution:

(A) Compression Index (CC)

𝑪𝑪𝑪𝑪 = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎(𝑳𝑳𝑳𝑳 − 𝟏𝟏𝟏𝟏) = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎(𝟒𝟒𝟒𝟒. 𝟔𝟔𝟔𝟔 − 𝟏𝟏𝟏𝟏)

𝑪𝑪𝑪𝑪 = 0.32994

(B) Effective Stress @ mid height of the clay layer

Pe = Pt – Pw ; P= γh

Pe = 21.24(2.40) +15.74(0.9)

Pe = 65.1420 kPa

(C) Settlement due to Primary Consolidation

𝑪𝑪𝒄𝒄 𝑯𝑯 𝑷𝑷𝒐𝒐 + ∆𝑷𝑷 Po = 65.1420 kPa

𝑺𝑺𝑺𝑺 = 𝒍𝒍𝒍𝒍𝒍𝒍 � � ΔP = 33.58 kPa

𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒐𝒐

0.32994(1800𝑚𝑚𝑚𝑚) 65.1420 + 33.58

𝑺𝑺𝑺𝑺 = 𝑙𝑙𝑙𝑙𝑙𝑙 � �

1 + 1.28 65.1420

𝑺𝑺𝑺𝑺 = 𝟒𝟒𝟒𝟒. 𝟎𝟎𝟎𝟎𝟎𝟎 𝒎𝒎𝒎𝒎

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 13 of 16

Module 3 – Compressibility of Soils

Example 3:

A 2.10 m layer of clay is buried beneath a 3 m stratum of very compact granular soil. Compact sand

underlies the clay. The layer of granular soil composed of material having a unit weight of 20.46 kN/m3.

The clay’s unit weight is 16.52 kN/m3. A laboratory compression test on a sample of the clay indicates a

compression index of 0.40 and a natural void ratio of 1.30. A planned building loading will cause a 26.38

kPa stress increase at the middle of the clay layer. (a) What amount of primary compression occurs in the

clay for the indicated conditions? (b) How much primary compression of the clay layer would result if the

groundwater table was at the ground surface? (Assuming that all the properties of the soil remains the

same). (c) How much clay layer compression would occur if the clay was an overconsolidated material,

the pre-consolidation pressure is known to be 95.94 kPa and the swell index was 0.10. (Assume that the

water table is very deep.

• Given:

Cc = 0.40

eclay = 1.30

ΔP = 26.38 kPa

• Solution: (C) Settlement; Overconsolidated State

(A) Settlement due to Primary Compression

Pc = 95.94 kPa; Cs = 0.10

Po = Pt – Pw ; P= γh

𝑷𝑷𝒐𝒐 + ∆𝑷𝑷 = 78.726 + 26.38 = 105.106 kPa

Po = 20.46(3.0) +16.52(1.05) = 78.726 kPa

𝑷𝑷𝒐𝒐 + ∆𝑷𝑷 > 𝑷𝑷𝒄𝒄 ∴ 𝐂𝐂𝐂𝐂𝐂𝐂𝐂𝐂 𝟐𝟐

𝑪𝑪𝒄𝒄 𝑯𝑯 𝑷𝑷𝒐𝒐 + ∆𝑷𝑷

𝑺𝑺𝑺𝑺 = 𝒍𝒍𝒍𝒍𝒍𝒍 � � 𝑪𝑪𝒄𝒄 𝑯𝑯 𝑷𝑷𝒐𝒐 + ∆𝑷𝑷 𝑪𝑪𝒔𝒔 𝑯𝑯 𝑷𝑷𝒄𝒄

𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒐𝒐 𝑺𝑺𝑺𝑺 = 𝒍𝒍𝒍𝒍𝒍𝒍 � �+ 𝒍𝒍𝒍𝒍𝒍𝒍 � �

0.40(2100𝑚𝑚𝑚𝑚) 78.7260 + 26.38 𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒄𝒄 𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒐𝒐

𝑺𝑺𝑺𝑺 = 𝑙𝑙𝑙𝑙𝑙𝑙 � �

1 + 1.30 78.7260

0.40(2100) 105.106 0.10(2100) 95.94

𝑺𝑺𝑺𝑺 = 𝟒𝟒𝟒𝟒. 𝟖𝟖𝟖𝟖𝟖𝟖𝟖𝟖 𝒎𝒎𝒎𝒎 𝑺𝑺𝑺𝑺 = 𝑙𝑙𝑙𝑙𝑙𝑙 � �+ 𝑙𝑙𝑙𝑙𝑙𝑙 � �

1 + 1.30 95.94 1 + 1.30 78.726

(B) Settlement; GWT at the ground surface 𝑺𝑺𝑺𝑺 = 𝟐𝟐𝟐𝟐. 𝟑𝟑𝟑𝟑𝟑𝟑𝟑𝟑 𝒎𝒎𝒎𝒎

Po = 78.726 – 9.81(3+1.05) = 38.9955 kPa

0.40(2100𝑚𝑚𝑚𝑚) 38.9955 + 26.38

𝑺𝑺𝑺𝑺 = 𝑙𝑙𝑙𝑙𝑙𝑙 � �

1 + 1.30 38.9955

𝑺𝑺𝑺𝑺 = 𝟖𝟖𝟖𝟖. 𝟗𝟗𝟗𝟗𝟗𝟗𝟗𝟗 𝒎𝒎𝒎𝒎

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 14 of 16

Module 3 – Compressibility of Soils

Example 4:

Assume a buried stratum of clay 1.83 m thick will subjected to a stress increase of 33.6 kPa at the center

of the clay. The magnitude of the pre-construction soil overburden pressure 𝑃𝑃𝑜𝑜 =48 kPa at the center of

the clay layer. A laboratory compression test indicates that the clay has pre-consolidation pressure of 72

kPa. Compression index is 0.30 and the value of swell index is 0.05. The void ratio of the clay is 1.50. (a)

Compute the settlement due to primary compression of clay. (b) If full consolidation settlement will require

approximately 8 years, compute the settlement due to secondary compression of clay over a period of

20 year time span. Assume secondary compression index is 0.008. (c) Estimate the total settlement to be

expected over a 20 year time span considering the effects of secondary compression.

• Given:

Clay • ΔP = 33.60 kPa

Cc = 0.30 • Po = 48 kPa

Cs = 0.05 • Pc = 72 kPa

eo = 1.50

1.83m

• Solution: 𝑪𝑪𝜶𝜶 = 0.008

(A) Settlement; Overconsolidated State 0.008(1830) 20

𝑺𝑺𝒔𝒔 = 𝑙𝑙𝑙𝑙𝑙𝑙 � �

1 + 1.4309 8

𝑷𝑷𝒐𝒐 + ∆𝑷𝑷 = 48 + 33.60 = 81.60 kPa

𝑺𝑺𝒔𝒔 = 𝟐𝟐. 𝟑𝟑𝟑𝟑𝟑𝟑 𝒎𝒎𝒎𝒎

𝑷𝑷𝒐𝒐 + ∆𝑷𝑷 > 𝑷𝑷𝒄𝒄 ∴ 𝐂𝐂𝐂𝐂𝐂𝐂𝐂𝐂 𝟐𝟐

𝑪𝑪𝒄𝒄 𝑯𝑯 𝑷𝑷𝒐𝒐 + ∆𝑷𝑷 𝑪𝑪𝒔𝒔 𝑯𝑯 𝑷𝑷𝒄𝒄

𝑺𝑺𝑺𝑺 = 𝒍𝒍𝒍𝒍𝒍𝒍 � �+ 𝒍𝒍𝒍𝒍𝒍𝒍 � �

𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒄𝒄 𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒐𝒐 (C) Total Settlement

0.30(1830) 81.60 0.05(1830) 72 𝑺𝑺𝒕𝒕 = 𝑺𝑺𝒄𝒄 + 𝑺𝑺𝒔𝒔

𝑺𝑺𝑺𝑺 = 𝑙𝑙𝑙𝑙𝑙𝑙 � �+ 𝑙𝑙𝑙𝑙𝑙𝑙 � �

1 + 1.50 72 1 + 1.50 48

𝑺𝑺𝒕𝒕 = 𝟏𝟏𝟏𝟏. 𝟑𝟑𝟑𝟑𝟑𝟑𝟑𝟑 + 𝟐𝟐. 𝟑𝟑𝟑𝟑𝟑𝟑

𝑺𝑺𝑺𝑺 = 𝟏𝟏𝟏𝟏. 𝟑𝟑𝟑𝟑𝟑𝟑𝟑𝟑 𝒎𝒎𝒎𝒎

𝑺𝑺𝒕𝒕 = 𝟐𝟐𝟐𝟐. 𝟕𝟕𝟕𝟕𝟕𝟕𝟕𝟕 𝒎𝒎𝒎𝒎

(B) Settlement due to Secondary Compression

T1 = 8 years; T2 = 20 years

𝑪𝑪𝜶𝜶 𝑯𝑯 𝑻𝑻𝟐𝟐 𝑷𝑷𝒐𝒐 + ∆𝑷𝑷

𝑺𝑺𝒔𝒔 = 𝒍𝒍𝒍𝒍𝒍𝒍 � � ; ∆𝒆𝒆 = 𝑪𝑪𝒄𝒄 𝒍𝒍𝒍𝒍𝒍𝒍 � �

𝟏𝟏 + 𝒆𝒆𝒑𝒑 𝑻𝑻𝟏𝟏 𝑷𝑷𝒄𝒄

81.60

∆𝒆𝒆 = 0.30 𝑙𝑙𝑙𝑙𝑙𝑙 � � = 0.0691

72

𝒆𝒆𝒑𝒑 = 𝒆𝒆𝒐𝒐 − ∆𝒆𝒆 = 1.50 − 0.0691 → 𝒆𝒆𝒑𝒑 = 𝟏𝟏. 𝟒𝟒𝟒𝟒𝟒𝟒𝟒𝟒

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 15 of 16

Module 3 – Compressibility of Soils

Example 5:

A rigid 3m x 4m rectangular footing is constructed over a loose sand layer as shown. (a) Compute the

average increase in pressure on the mid height of the clay layer. (b) Compute the primary consolidation

settlement if it is normally consolidated. (c) Compute the total consolidation settlement of the clay 5 years

after the completion of primary consolidation settlement. Time for completion of primary settlement is 2

years. Secondary compression index = 0.002.

• Solution:

(A) Average increase in pressure

𝑷𝑷𝑻𝑻𝑻𝑻𝑻𝑻 + 𝑷𝑷𝑴𝑴𝑴𝑴𝑴𝑴 + 𝑷𝑷𝑩𝑩𝑩𝑩𝑩𝑩

∆𝑷𝑷 =

𝟔𝟔

𝑭𝑭 710 𝑘𝑘𝑘𝑘

𝑷𝑷𝑻𝑻𝑻𝑻𝑻𝑻 = = = 𝟕𝟕. 𝟖𝟖𝟖𝟖 𝒌𝒌𝒌𝒌𝒌𝒌

𝑨𝑨 (3 + 6)(4 + 6)

𝑭𝑭 710 𝑘𝑘𝑘𝑘

𝑷𝑷𝑴𝑴𝑴𝑴𝑴𝑴 = = = 𝟓𝟓. 𝟑𝟑𝟑𝟑 𝒌𝒌𝒌𝒌𝒌𝒌

𝑨𝑨 (3 + 8)(4 + 8)

𝑭𝑭 710 𝑘𝑘𝑘𝑘

𝑷𝑷𝑩𝑩𝑩𝑩𝑩𝑩 = = = 𝟑𝟑. 𝟗𝟗𝟗𝟗 𝒌𝒌𝒌𝒌𝒌𝒌

𝑨𝑨 (3 + 10)(4 + 10)

PTOP

7.89 + 5.38 + 3.90

∆𝑷𝑷 =

6 PMID

∆𝑷𝑷 = 𝟓𝟓. 𝟓𝟓𝟓𝟓 𝒌𝒌𝒌𝒌𝒌𝒌

PBOT

(B) Primary Consolidation Settlement

𝑷𝑷𝒐𝒐 = 16(5.2) + 18(2.0) + 20(4.0) → 𝑷𝑷𝒐𝒐 = 𝟏𝟏𝟏𝟏𝟏𝟏. 𝟗𝟗𝟗𝟗 𝒌𝒌𝒌𝒌𝒌𝒌

𝑪𝑪𝒄𝒄 𝑯𝑯 𝑷𝑷𝒐𝒐 + ∆𝑷𝑷

𝑺𝑺𝑺𝑺 = 𝒍𝒍𝒍𝒍𝒍𝒍 � �

𝟏𝟏 + 𝒆𝒆𝒐𝒐 𝑷𝑷𝒐𝒐

0.315(4000𝑚𝑚𝑚𝑚) 119.96 + 5.55

𝑺𝑺𝑺𝑺 = 𝑙𝑙𝑙𝑙𝑙𝑙 � �

1 + 0.60 119.96

𝑺𝑺𝑺𝑺 = 𝟏𝟏𝟏𝟏 𝒎𝒎𝒎𝒎

(C) Total Consolidation Settlement

T1 = 2 years; T2 = 5 years

𝑪𝑪𝜶𝜶 𝑯𝑯 𝑻𝑻𝟐𝟐 𝑷𝑷𝒐𝒐 + ∆𝑷𝑷

𝑺𝑺𝒔𝒔 = 𝒍𝒍𝒍𝒍𝒍𝒍 � � ; ∆𝒆𝒆 = 𝑪𝑪𝒄𝒄 𝒍𝒍𝒍𝒍𝒍𝒍 � �

𝟏𝟏 + 𝒆𝒆𝒑𝒑 𝑻𝑻𝟏𝟏 𝑷𝑷𝒄𝒄

119.96 + 5.55

∆𝒆𝒆 = 0.315 𝑙𝑙𝑙𝑙𝑙𝑙 � � = 0.006187

119.96

𝒆𝒆𝒑𝒑 = 𝒆𝒆𝒐𝒐 − ∆𝒆𝒆 = 0.6 − 0.006187 → 𝒆𝒆𝒑𝒑 = 𝟎𝟎. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓

𝑪𝑪𝜶𝜶 𝑯𝑯 𝑻𝑻𝟐𝟐 0.002(4000) 5

𝑺𝑺𝒔𝒔 = 𝒍𝒍𝒍𝒍𝒍𝒍 � � = 𝑙𝑙𝑙𝑙𝑙𝑙 � � → 𝑺𝑺𝒔𝒔 = 𝟏𝟏. 𝟗𝟗𝟗𝟗𝟗𝟗𝟗𝟗𝟗𝟗𝟗𝟗

𝟏𝟏 + 𝒆𝒆𝒑𝒑 𝑻𝑻𝟏𝟏 1 + 0.5938 2

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 16 of 16

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

The lowest part of a structure generally is referred to as the foundation. Its function is to transfer the load

of the structure to the soil on which it is resting. A properly designed foundation transfers the load

throughout the soil without overstressing the soil.

Overstressing the soil can result in either excessive settlement or shear failure of the soil, both of which

cause damage to the structure. Thus, geotechnical and structural engineers who design foundations must

evaluate the bearing capacity of soils.

Shallow Foundation

Isolated Footings

Shallow foundations are those that transmit the structural loads to the near-surface soil or rock. There are

two types: spread footings and mats. Spread footings are by far the most common type of foundation.

The vast majority of one- and two-storey buildings use them, and if the ground conditions are good even

much larger structures can be supported on spread footings. Mats are commonly used on moderate-

sized structures.

• Spread footings spread the structural loads across a sufficiently large soil area that induced stresses

are reduced to acceptable levels.

• Foundation may be defined as a shallow foundation if the depth 𝐷𝐷𝐷𝐷 is less than or equal to its

width 𝐵𝐵 (Terzaghi)

• They can be built in a wide variety of shapes and sized to suit individual needs, and are nearly

always made of reinforced concrete.

• Most common shape is a square footing, which usually supports a single column.

• A combined footing is one that supports more than one column.

• A continuous footing (sometimes referred as strip footing) supports a bearing wall.

• Most continuous footings are linear, but a continuous footing may wrap around in a circle to

support the exterior wall of a tank, thus forming a ring footing.

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 1 of 11

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

Behaviour of Spread Footings with different types of loads

Isolated and Spread Footing

Combined Footing

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 2 of 11

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

Mat Footings

• If structural loads are too large or if the soil conditions are too poor, spread footings become unacceptably

large so the need to construct a mat foundation is a must

• Essentially one large spread footing that encompasses the entire structure.

• A mat distributes the weight of the structure across a larger area, thus reducing induced stresses in the

underlying soils.

• Mats also have the advantage of structural continuity and thus reduce the potential for differential

settlements.

Bearing Capacity

During the late nineteenth and early twentieth centuries, engineers realized that the design of spread

footings could be based on the contact pressure between the footing and the underlying ground. This

important parameter is called the bearing pressure (or gross bearing pressure), and is still used in

modern foundation design. In determining this value, the effects of the superimposed loads, self-weight,

and the weight of the overburden soil is divided by the total area of the shallow foundation.

A bearing capacity failure occurs when the soil fails in shear beneath the footing. This is a catastrophic

foundation failure that clearly must be avoided. To prevent a bearing capacity failure, the strength

requirement is needed to be evaluated similar to structural engineers’ requirements of strength of

structural members.

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 3 of 11

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

The bearing capacity failure just described is called a general shear failure and can be explained with

reference to the figure below. When the foundation settles under the application of a load, a triangular

wedge-shaped zone of soil (marked) is pushed down, and, in turn, it presses the zones marked II and III

sideways and then upward. At the ultimate pressure, 𝑞𝑞𝑞𝑞, the soil passes into a state of plastic equilibrium

and failure occurs by sliding.

If the footing test is conducted instead in a loose-to-medium dense sand, the load settlement relationship

is like Curve II. Beyond a certain value of 𝑞𝑞 = 𝑞𝑞𝑞𝑞’ the load-settlement relationship becomes a steep, inclined

straight line. In this case, 𝑞𝑞𝑞𝑞’ is defined as the ultimate bearing capacity of soil. This type of soil failure is

referred to as local shear failure and is shown in the figure below. The triangular wedge-shaped zone

(marked I) below the footing moves downward, but unlike general shear failure, the slip surfaces end

somewhere inside the soil. Some signs of soil bulging are seen, however.

General Shear Failure Local Shear Failure

Ultimate Bearing Capacity

The ultimate bearing capacity, 𝑞𝑞𝑞𝑞, is the bearing pressure required to produce a bearing capacity failure.

In 1943, Karl Terzaghi developed the first widely accepted formulas for computing the ultimate bearing

capacity.

The failure mechanism assumed by Terzaghi for determining the ultimate soil bearing capacity (general

shear failure) for a rough strip footing located at a depth 𝐷𝐷𝐷𝐷 measured from the ground surface is shown

in the figure below.

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 4 of 11

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

Using equilibrium analysis, Terzaghi expressed the ultimate bearing capacity in the form;

𝒒𝒒𝒖𝒖 = 𝒄𝒄𝑵𝑵𝒄𝒄 + 𝒒𝒒𝑵𝑵𝒒𝒒 + 𝟎𝟎. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝑵𝑵𝜸𝜸 for strip footing.

The equation contains three separate terms each capturing one part of the resistance to bearing capacity

failure. The first term, 𝑐𝑐𝑐𝑐 , is the cohesion term and accounts for the cohesive resistance along failure

surface. The second term, 𝑞𝑞𝑞𝑞𝑞𝑞, is the surcharge term and accounts for the resistance supplied the by

mass of soil above the base of the footing. The third term, 0.5𝐵𝐵𝐵𝐵𝐵𝐵𝐵𝐵, is the self-weight term and accounts

for the frictional resistance generated along the failure surface. The self-weight term is a function of the

footing width, 𝐵𝐵, because increasing the footing width increases the volume of the soil in Zones II and III,

thereby increasing the normal forces acting on the failure surface. This increase of normal forces on the

failure surface in turn increases the frictional resistance along the failure surface. Each of the bearing

capacity factors, 𝑁𝑁 , 𝑁𝑁𝑁𝑁, and 𝑁𝑁𝑁𝑁 increases with the friction angle of the soil. Note that each bearing

capacity factor increases at a different rate.

To estimate the ultimate bearing capacity of square and circular foundations, the equation is modified to;

𝒒𝒒𝒖𝒖 = 𝟏𝟏. 𝟑𝟑𝒄𝒄𝑵𝑵𝒄𝒄 + 𝒒𝒒𝑵𝑵𝒒𝒒 + 𝟎𝟎. 𝟒𝟒𝑩𝑩𝑩𝑩𝑵𝑵𝜸𝜸 Square Footing

𝟎𝟎.𝟑𝟑𝟑𝟑 𝟎𝟎.𝟐𝟐𝟐𝟐

𝒒𝒒𝒖𝒖 = �𝟏𝟏 + � 𝒄𝒄𝑵𝑵𝑪𝑪 + 𝒒𝒒𝑵𝑵𝒒𝒒 + 𝟎𝟎. 𝟓𝟓𝟓𝟓 �𝟏𝟏 − � 𝑩𝑩𝑩𝑩𝑵𝑵𝜸𝜸 Rectangular Footing

𝑳𝑳 𝑳𝑳

𝒒𝒒𝒖𝒖 = 𝟏𝟏. 𝟑𝟑𝒄𝒄𝑵𝑵𝒄𝒄 + 𝒒𝒒𝑵𝑵𝒒𝒒 + 𝟎𝟎. 𝟑𝟑𝑩𝑩𝑩𝑩𝑵𝑵𝜸𝜸 Circular Footing

After the development of Terzaghi’s bearing capacity equation, several investigators worked in this area

and refined the solution (that is, Meyerhof, 1951 and 1963; Lundgren and Mortensen, 1953; Balla, 1962;

Vesic, 1973; and Hansen, 1970). Different solutions show that the bearing capacity factors 𝑁𝑁𝑁𝑁 and 𝑁𝑁𝑁𝑁 do

not change much. However, for a given value of 𝜙𝜙, the values of 𝑁𝑁𝑁𝑁 obtained by different investigators

vary widely. This difference is because of the variation of the assumption of the wedge shape of soil

located directly below the footing

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 5 of 11

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

Reissner, 1924

∅

𝑵𝑵𝒒𝒒 = 𝐭𝐭𝐭𝐭𝐭𝐭𝟐𝟐 �𝟒𝟒𝟒𝟒 + 𝟐𝟐� 𝒆𝒆𝝅𝝅𝝅𝝅𝝅𝝅𝝅𝝅∅

𝑵𝑵𝒄𝒄 = �𝑵𝑵𝒒𝒒 − 𝟏𝟏�𝒄𝒄𝒄𝒄𝒄𝒄∅ Prandtl, 1921

𝑵𝑵𝜸𝜸 = �𝑵𝑵𝒒𝒒 − 𝟏𝟏�𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕. 𝟒𝟒∅ Meyerhoff, 1963

Equations above were derived on the assumption that the bearing capacity failure of soil takes place by

general shear failure. In the case of local shear failure, we may assume that the values of cohesion and

angle of internal friction are;

𝟐𝟐

𝒄𝒄� = 𝒄𝒄

𝟑𝟑

𝟐𝟐

� = 𝒕𝒕𝒕𝒕𝒕𝒕∅

𝒕𝒕𝒕𝒕𝒕𝒕∅

𝟑𝟑

The ultimate bearing capacity of soil for a strip footing may be given by

𝒒𝒒𝒖𝒖 = 𝒄𝒄�𝑵𝑵𝒄𝒄 + 𝒒𝒒𝑵𝑵𝒒𝒒 + 𝟎𝟎. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝑵𝑵𝜸𝜸 for strip footing

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 6 of 11

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

GROUNDWATER EFFECTS IN THE ULTIMATE SOIL BEARING CAPACITY

Terzaghi’s ultimate bearing capacity equations presented before are based on the assumption that the

water table is located well below the foundation. However, if the water table is close to the foundation,

some modifications of the bearing capacity equations will be necessary.

In the field, if there is enough water in the soil to develop a groundwater table, and this groundwater

table is within the potential shear zone, then pore water pressures will be present, the effective stress and

shear strength along the failure surface will be smaller, and the ultimate bearing capacity will be reduced

(Meyerhof, 1955). We must consider this effect when conducting bearing capacity computations.

When exploring the subsurface conditions, we determine the current location of the groundwater table

and worstcase (highest) location that might reasonably be expected during the life of the proposed

structure. We then determine which of the following three cases describes the worst-case field conditions.

In developing the bearing-capacity equations given in the preceding section, we assumed that the

groundwater table is located at a depth much greater than the width, B, of the footing.

Case I: If the groundwater table is located at a distance

D above the bottom of the foundation, the magnitude

of q in the second term of the bearing-capacity

equation should be calculated as;

𝒒𝒒 = 𝜸𝜸�𝑫𝑫𝒇𝒇 − 𝑫𝑫� + 𝜸𝜸′ 𝑫𝑫

𝜸𝜸 = 𝜸𝜸′

Case II: If the groundwater table coincides with the

bottom of the foundation

𝒒𝒒 = 𝜸𝜸𝑫𝑫𝒇𝒇

𝜸𝜸 = 𝜸𝜸′

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 7 of 11

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

Case III: When the groundwater table is at a depth D below the bottom of the foundation.

𝒒𝒒 = 𝜸𝜸𝑫𝑫𝒇𝒇

When D ≤ B

𝟏𝟏

𝜸𝜸 = [𝜸𝜸𝜸𝜸 + 𝜸𝜸′ (𝑩𝑩 − 𝑫𝑫)]

𝑩𝑩

When D > B

𝜸𝜸 = 𝜸𝜸

FACTOR OF SAFETY

Generally, a factor of safety, 𝐹𝐹𝐹𝐹, of about 3 or more is applied to the ultimate soil-bearing capacity to

arrive at the value of the allowable bearing capacity. An 𝐹𝐹𝐹𝐹 of 3 or more is not considered too

conservative. In nature, soils are neither homogeneous nor isotropic. Much uncertainty is involved in

evaluating the basic shear strength parameters of soil.

Using the definition of mechanics, allowable loads directly refer to working loads in a structural member.

The allowable bearing pressure is then;

𝑷𝑷𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕 𝑾𝑾𝑫𝑫+𝑳𝑳 + 𝑾𝑾𝒇𝒇𝒇𝒇𝒇𝒇 + 𝑾𝑾𝒔𝒔𝒔𝒔𝒔𝒔𝒔𝒔

𝒒𝒒𝒂𝒂 = =

𝑨𝑨𝒇𝒇𝒇𝒇𝒇𝒇 𝑨𝑨𝒇𝒇𝒇𝒇𝒇𝒇

The net allowable bearing capacity is the allowable load per unit area of the foundation in excess of the

existing vertical effective stress at the level of the foundation. The vertical effective stress at the foundation

level is equal to 𝑞𝑞 = 𝛾𝛾𝐷𝐷𝑓𝑓 .

𝒒𝒒𝒖𝒖 (𝒏𝒏𝒏𝒏𝒏𝒏) 𝒒𝒒𝒖𝒖 − 𝜸𝜸𝑫𝑫𝒇𝒇

𝒒𝒒𝒂𝒂(𝒏𝒏𝒏𝒏𝒏𝒏) = =

𝑭𝑭𝑭𝑭 𝑭𝑭𝑭𝑭

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 8 of 11

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

Example 1:

A square footing has a dimension of 1.20 m x 1.20 m. The bottom of the footing is 1.0m below the ground

surface. (a) If the groundwater table is located at a depth of 1.20 m below the ground surface, compute

the allowable load that the footing could carry if it has a factor of safety of 3.0. (b) Find the ultimate

bearing capacity if the soil if the groundwater table is at the bottom of the footing. (c) Find the ultimate

bearing capacity of the soil if the groundwater table is 0.50 m above the bottom of the footing.

• Solution:

(C) Allowable load, GWT @ 1.20m depth

q =𝛄𝛄𝑫𝑫𝒇𝒇 ∶ 𝑪𝑪𝑪𝑪𝑪𝑪𝑪𝑪 𝑵𝑵𝑵𝑵. 𝟑𝟑

1846 𝐤𝐤𝐤𝐤

q= (9.81)(1.0) = 𝟏𝟏𝟏𝟏. 𝟏𝟏𝟏𝟏 𝟐𝟐

1000 𝐦𝐦

1965 − 1000 𝐤𝐤𝐤𝐤

𝛄𝛄′ = (9.81) = 𝟗𝟗. 𝟒𝟒𝟒𝟒 𝟑𝟑

1000 𝐦𝐦

1 𝐤𝐤𝐤𝐤

𝛄𝛄 = [18.11(0.2) + 9.47(1.2 − 0.2)] = 𝟏𝟏𝟏𝟏. 𝟗𝟗𝟗𝟗 𝟑𝟑

1.2 𝐦𝐦

𝒒𝒒𝒖𝒖 = 𝟏𝟏. 𝟑𝟑𝟑𝟑𝑵𝑵𝒄𝒄 + 𝒒𝒒𝑵𝑵𝒒𝒒 + 𝟎𝟎. 𝟒𝟒𝟒𝟒𝟒𝟒𝑵𝑵𝜸𝜸

𝒒𝒒𝒖𝒖 = 1.3(15.75)(35) + 18.11(22) + 0.4(1.2)(10.91)(19)

𝒒𝒒𝒖𝒖 1214.51 (C) Ultimate bearing capacity, GWT @ 0.5m above ftg.

𝒒𝒒𝒖𝒖 = 𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏. 𝟓𝟓𝟓𝟓 𝒌𝒌𝒌𝒌𝒌𝒌; 𝒒𝒒𝒂𝒂 = = = 𝟒𝟒𝟒𝟒𝟒𝟒 𝒌𝒌𝒌𝒌𝒌𝒌

𝑭𝑭𝑭𝑭 3

𝒒𝒒 = 𝜸𝜸�𝑫𝑫𝒇𝒇 − 𝑫𝑫� + 𝜸𝜸′ 𝑫𝑫 ∶ 𝑪𝑪𝑪𝑪𝑪𝑪𝑪𝑪 𝑵𝑵𝑵𝑵. 𝟏𝟏

𝑷𝑷𝒂𝒂 𝑷𝑷𝒂𝒂 1846 𝐤𝐤𝐤𝐤

𝒒𝒒𝒂𝒂 = ; 405 𝑘𝑘𝑘𝑘𝑘𝑘 = → 𝑷𝑷𝒂𝒂 = 𝟓𝟓𝟓𝟓𝟓𝟓. 𝟐𝟐𝟐𝟐𝟐𝟐 𝛄𝛄 = 𝛄𝛄′ ; 𝛄𝛄 = (9.81) − 9.81 = 𝟗𝟗. 𝟒𝟒𝟒𝟒𝟒𝟒 𝟑𝟑

𝑨𝑨 1.2 × 1.2 1000 𝐦𝐦

(D) Ultimate bearing capacity, GWT @ bottom ftg. 1846

q= (9.81)(1.0 − 0.5) + 9.467(0.5) = 𝟏𝟏𝟏𝟏. 𝟕𝟕𝟕𝟕𝟕𝟕 𝐤𝐤𝐤𝐤𝐤𝐤

1000

q =𝛄𝛄𝑫𝑫𝒇𝒇

𝒒𝒒𝒖𝒖 = 𝟏𝟏. 𝟑𝟑𝟑𝟑𝑵𝑵𝒄𝒄 + 𝒒𝒒𝑵𝑵𝒒𝒒 + 𝟎𝟎. 𝟒𝟒𝟒𝟒𝟒𝟒𝑵𝑵𝜸𝜸

1846 𝐤𝐤𝐤𝐤

q= (9.81)(1.0) = 𝟏𝟏𝟏𝟏. 𝟏𝟏𝟏𝟏 𝟑𝟑

1000 𝐦𝐦 𝒒𝒒𝒖𝒖 = 1.3(15.75)(35) + 13.788(22) + 0.4(1.2)(9.467)(19)

𝐤𝐤𝐤𝐤 𝒒𝒒𝒖𝒖 = 𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏. 𝟎𝟎𝟎𝟎𝟎𝟎 𝒌𝒌𝒌𝒌𝒌𝒌

𝛄𝛄 = 𝛄𝛄′ ; 𝛄𝛄 = 1965(9.81) − 9810 = 𝟗𝟗. 𝟒𝟒𝟒𝟒𝟒𝟒

𝐦𝐦𝟑𝟑

𝒒𝒒𝒖𝒖 = 𝟏𝟏. 𝟑𝟑𝟑𝟑𝑵𝑵𝒄𝒄 + 𝒒𝒒𝑵𝑵𝒒𝒒 + 𝟎𝟎. 𝟒𝟒𝟒𝟒𝟒𝟒𝑵𝑵𝜸𝜸

𝒒𝒒𝒖𝒖 = 1.3(15.75)(35) + 18.11(22) + 0.4(1.2)(9.468)(19)

𝒒𝒒𝒖𝒖 = 𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏. 𝟏𝟏𝟏𝟏 𝒌𝒌𝒌𝒌𝒌𝒌

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 9 of 11

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

Example 2:

A square footing has a dimension of 1.0m. The bottom of the footing is located at 2.50 m below the

ground surface. The angle of friction of the soil foundation is 30o. The unit weight and the saturated unit

weight of of the soil is 18.10 kN/m3 and 19.30 kN/m3, respectively, with a cohesion of 15.70 kN/m3. Assume

a factor of safety 3.0. (a) Compute the value of the bearing capacity factor 𝑁𝑁𝑞𝑞 . (b) Compute the net

allowable load that the footing could carry if the GWT is located 0.20 m below the foundation of the

footing. (c) Compute the net allowable load that the footing could carry if the GWT is located 1.20 m

below the ground surface.

• Given: (C) Net Allowable Load; GWT @ 1.2m depth

B = 1.0m γ = 18.10mkN3

𝑫𝑫𝒇𝒇 = 2.5m γsat = 19.30mkN3 Case No.1: D=1.20m

∅ = 30 °

C = 15.70mkN3

𝒒𝒒 = 𝜸𝜸�𝑫𝑫𝒇𝒇 − 𝑫𝑫� + 𝜸𝜸′ 𝑫𝑫 = 18.10(2.5 − 1.2) + (19.3 − 9.81)(1.2)

• Solution: 𝐤𝐤𝐤𝐤

(A) Bearing Capacity Factor (Nq) 𝒒𝒒 = 𝟑𝟑𝟑𝟑. 𝟗𝟗𝟗𝟗𝟗𝟗

𝐦𝐦𝟐𝟐

∅ 𝐤𝐤𝐤𝐤

𝑵𝑵𝒒𝒒 = 𝒕𝒕𝒕𝒕𝒕𝒕𝟐𝟐 �𝟒𝟒𝟒𝟒 + � 𝒆𝒆𝝅𝝅𝝅𝝅𝝅𝝅𝝅𝝅∅ 𝛄𝛄 = 19.3 − 9.81 → 𝛄𝛄 = 𝟗𝟗. 𝟒𝟒𝟒𝟒

𝟐𝟐 𝐦𝐦𝟑𝟑

30 𝜋𝜋𝜋𝜋𝜋𝜋𝜋𝜋30 °

𝑵𝑵𝒒𝒒 = 𝑡𝑡𝑡𝑡𝑡𝑡2 �45 + � 𝑒𝑒 → 𝑵𝑵𝒒𝒒 = 𝟏𝟏𝟏𝟏. 𝟒𝟒𝟒𝟒 𝒒𝒒𝒖𝒖 = 𝟏𝟏. 𝟑𝟑𝟑𝟑𝑵𝑵𝒄𝒄 + 𝒒𝒒𝑵𝑵𝒒𝒒 + 𝟎𝟎. 𝟒𝟒𝟒𝟒𝟒𝟒𝑵𝑵𝜸𝜸

2

𝒒𝒒𝒖𝒖 = 1.3(15.7)(30.14) + 34.918(18.4) + 0.4(1)(9.49)(15.668)

(B) Net Allowable Load; GWT @ 0.2m depth

𝒒𝒒𝒖𝒖 = 𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏. 𝟔𝟔𝟔𝟔 𝒌𝒌𝒌𝒌𝒌𝒌

b = 0.2m; 𝑫𝑫𝒇𝒇 = 2.5m; B = 1.0m

1430.62 − 18.10(2.5)

𝐤𝐤𝐤𝐤 𝒒𝒒𝒂𝒂(𝒏𝒏𝒏𝒏𝒏𝒏) = → 𝒒𝒒𝒂𝒂(𝒏𝒏𝒏𝒏𝒏𝒏) = 𝟒𝟒𝟒𝟒𝟒𝟒. 𝟕𝟕𝟕𝟕 𝒌𝒌𝒌𝒌𝒌𝒌

q =𝛄𝛄𝑫𝑫𝒇𝒇 ; q= 18.10(2.5) = 𝟒𝟒𝟒𝟒. 𝟐𝟐𝟐𝟐 3

𝐦𝐦𝟐𝟐

𝑷𝑷𝒂𝒂(𝒏𝒏𝒏𝒏𝒏𝒏) = 461.71 × (1.0)2

1

D<B ∴ 𝛄𝛄 = [18.1(0.2) + 9.49(1 − 0.2)]

1 𝑷𝑷𝒂𝒂(𝒏𝒏𝒏𝒏𝒏𝒏) = 𝟒𝟒𝟒𝟒𝟒𝟒. 𝟕𝟕𝟕𝟕 𝒌𝒌𝒌𝒌

𝐤𝐤𝐤𝐤

𝛄𝛄 = 𝟏𝟏𝟏𝟏. 𝟐𝟐𝟐𝟐 𝟑𝟑

𝐦𝐦

𝒒𝒒𝒖𝒖 = 𝟏𝟏. 𝟑𝟑𝟑𝟑𝑵𝑵𝒄𝒄 + 𝒒𝒒𝑵𝑵𝒒𝒒 + 𝟎𝟎. 𝟒𝟒𝟒𝟒𝟒𝟒𝑵𝑵𝜸𝜸

𝒒𝒒𝒖𝒖 = 1.3(15.7)(30.14) + 45.25(18.4) + 0.4(1)(11.21)(15.668)

𝒒𝒒𝒖𝒖 = 𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏. 𝟎𝟎𝟎𝟎 𝒌𝒌𝒌𝒌𝒌𝒌

1518.01 − 18.10(2.5)

𝒒𝒒𝒂𝒂(𝒏𝒏𝒏𝒏𝒏𝒏) = → 𝒒𝒒𝒂𝒂(𝒏𝒏𝒏𝒏𝒏𝒏) = 𝟒𝟒𝟒𝟒𝟒𝟒. 𝟗𝟗𝟗𝟗 𝒌𝒌𝒌𝒌𝒌𝒌

3

𝑷𝑷𝒂𝒂(𝒏𝒏𝒏𝒏𝒏𝒏) = 490.92 × (1.0)2

𝑷𝑷𝒂𝒂(𝒏𝒏𝒏𝒏𝒏𝒏) = 𝟒𝟒𝟒𝟒𝟒𝟒. 𝟗𝟗𝟗𝟗 𝒌𝒌𝒌𝒌

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 10 of 11

Module 4 – Terzaghi’s Bearing Capacity of a Shallow Footing

Example 3:

A continuous footing is to be constructed in a uniform deposit of stiff clay and must support a wall of a

tilt-up structure. If the wall has a super imposed load of 142 kN/m, and a self-load of 10 kN/m of wall

length. The footing will be founded at a depth of 1.20 m on a medium dense sand with an undrained

shear strength of 146 kPa, a dry unit weight of 13.86 kN/m3, a void ratio of 0.89, and a moisture content

of 14%. (a) If the groundwater table elevation is below the footing, calculate the ultimate bearing capacity

of the soil. (b) Determine the allowable bearing capacity if the factor of safety against bearing capacity

failure is 3.00. (c) Determine the width of the wall footing.

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

…. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. …. ….

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 11 of 11

Module 5 – Design of Isolated Footings

Foundation is a part of an engineered system that transmits to, and into, the underlying soil or rock the

loads supported by the foundation and its self-weight. It may carry only machinery, support industrial

equipment (pipes, tower, tanks), act as sign bases, and the like. It is noted as the most important part of the

engineering system.

Foundation Engineer

• Given that person who by reason of training and experience is sufficiently versed in scientific principles and

engineering judgment to design a foundation.

• Necessary scientific principles are acquired through formal education courses in geotechnical (soil

mechanics, geology, foundation engineering) and structural (analysis, design in reinforced concrete and

steel, etc.) engineering and continued self-study via short courses, professional conferences, journal

reading, and the like

• The foundation engineer and geotechnical consultant must work closely together, or at least have frequent

conferences as the design progresses.

Superstructure and Substructure

Superstructure - Commonly used to describe the engineered part of the system bringing load to the

foundation. Part of the structure from ground surface up to the peak.

Substructure – part of the structure from ground surface down to the lowest point of the foundation.

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 1 of 24

Module 5 – Design of Isolated Footings

Classification of Foundations

Shallow/Spread Foundations

Shallow foundations are those that transmit the structural loads to the near-surface soil or rock. There are

two types: spread footings and mats. Spread footings are by far the most common type of foundation.

The vast majority of one- and two-storey buildings use them, and if the ground conditions are good even

much larger structures can be supported on spread footings. Mats are commonly used on moderate-

sized structures.

• Isolated footing - supports a single column load. May be classified as square, rectangular, rectangular

circular or any regular shaped polygon.

• Combined footing and strap footing - supports two to four columns in one row. Combined footing may be

classified as rectangular and trapezoidal.

• Mat footing - a special footing used to support several randomly spaced columns or to support several

rows of parallel columns and may underlie a portion of or the entire building. Bases are foundations

supporting machinery and other equipment.

• Wall footing - supports a concrete or masonry (load or non-load bearing) wall.

Deep Foundation

Deep foundation is required to carry loads from a structure through weak compressible soils or fills on

to stronger and less compressible soils or rocks at depth, or for functional reasons. Deep foundations

are founded too deeply below the finished ground surface for their base bearing capacity to be affected

by surface conditions, this is usually at depths >3 m below finished ground level.

• If structural loads are too large or if the soil conditions are too poor, spread footings become unacceptably

large so the need to construct a mat foundation is a must

• Essentially one large spread footing that encompasses the entire structure.

• A mat distributes the weight of the structure across a larger area, thus reducing induced stresses in the

underlying soils.

• Mats also have the advantage of structural continuity and thus reduce the potential for differential

settlements.

What do you need to consider in choosing a footing type?

• The bearing capacity of the underlying soil.

• The magnitude of the column loads.

• The position of the water table.

• The depth of foundations of adjacent buildings.

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 2 of 24

Module 5 – Design of Isolated Footings

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 3 of 24

Module 5 – Design of Isolated Footings

Spread Footing

• A footing carrying a single column.

• Its function is to “spread” the column load laterally to the soil so that the stress intensity is

reduced to a value that the soil can safely carry sometimes called ‘single or isolated footings’.

• Wall footings are also types of spread footings, however, wall footing widths are controlled by

factors other than the allowable soil pressure since wall loads including wall weight are usually

rather low.

• May be called two-way or one-way depending on whether the steel used for bending runs both

ways or in one direction.

• May be stepped or sloped footings.

NSCP 2010 STANDARD IN DESIGNING A FOOTING

Section 407.8: Concrete Protection for Reinforcement

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 4 of 24

Module 5 – Design of Isolated Footings

Section 409.3: Required Strength

Section 409.4.2: Strength-Reduction Factor

Section 415.3: Loads and Reaction Section 415.8: Minimum Footing Depth

Section 415.4: Footings Supporting Circular or Regular Polygon-Shaped Columns or Pedestals

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 5 of 24

Module 5 – Design of Isolated Footings

Section 415.5: Moment in Footings

Shear Design of Footing

411.2.1 Except for members designed in accordance with Section 423 (Strut-and-Tie Models), design of cross

sections subject to shear shall be based in

𝑽𝑽𝒖𝒖 = ∅𝑽𝑽𝒏𝒏

Where Vu is the factored shear force considered and Vn is nominal shear strength computed by:

𝑽𝑽𝒏𝒏 = 𝑽𝑽𝒄𝒄 + 𝑽𝑽𝒔𝒔

Where 𝑉𝑉𝑐𝑐 is nominal shear strength provided by concrete in accordance with Section 411.3 or Section 411.4,

and 𝑉𝑉𝑠𝑠 is nominal shear strength provided by shear reinforcement in accordance with Section 411.5.6 (𝑉𝑉𝑠𝑠 for

footings is usually equal to zero since they do not usually require stirrups).

One-Way shear (Beam Shear) and Two-Way Shear (Punching Shear)

DETERMINING ONE-WAY SHEAR (BEAM SHEAR)

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 6 of 24

Module 5 – Design of Isolated Footings

411.2.3.1 For nonprestressed members, sections located less than a distance d from face of support shall be

permitted to be designed for the same shear 𝑉𝑉𝑢𝑢 computed at a distance d.

411.3.1.1 For members subject to shear and flexure only: The maximum permissible value of the concrete shear

stress due to one-way shear can be computed as;

𝑽𝑽𝒄𝒄 = 𝟎𝟎. 𝟏𝟏𝟏𝟏𝟏𝟏�𝒇𝒇′𝒄𝒄 𝒃𝒃𝒘𝒘 𝒅𝒅

408.7.1 states that for

sand-lightweight concrete, λ=0.85;

for all-lightweight concrete, λ=0.75;

for normal-weight concrete, λ=1.00.

DETERMINING TWO-WAY SHEAR PUNCHING SHEAR

411.12.1.2 For two-way action where each of the critical sections to be investigated shall be located so that its

perimeter, 𝑏𝑏𝑂𝑂 , is a minimum, but need not approach closer than d/2 to:

411.12.2.1, 411.12.2.2, or 411.12.3.1. For members subject to shear and flexure only: The maximum permissible

value of the concrete shear stress due to two-way shear can be computed as;

1 2

𝑉𝑉𝐶𝐶 = �1 + � 𝜆𝜆�𝑓𝑓′𝑐𝑐 𝑏𝑏𝑜𝑜 𝑑𝑑

6 𝛽𝛽

where β is the ratio of long side to short side of the column, concentrated load, or reaction area

1 𝛼𝛼𝑠𝑠 𝑑𝑑

𝑉𝑉𝐶𝐶 = � + 2� 𝜆𝜆�𝑓𝑓′𝑐𝑐 𝑏𝑏𝑜𝑜 𝑑𝑑

12 𝑏𝑏𝑜𝑜

where αs is 40 for interior columns, 30 for edge columns, and 20 for corner columns

1

𝑉𝑉𝐶𝐶 = 𝜆𝜆�𝑓𝑓′𝑐𝑐 𝑏𝑏𝑤𝑤 𝑑𝑑

3

this is the default and frequently used formula used for two-way shear

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 7 of 24

Module 5 – Design of Isolated Footings

Design of flexural reinforcements

𝝆𝝆𝒇𝒇𝒚𝒚

𝑴𝑴𝒖𝒖 = 𝝓𝝓𝝓𝝓𝒇𝒇𝒚𝒚 𝒃𝒃𝒅𝒅𝟐𝟐 �𝟏𝟏 − �

𝟏𝟏. 𝟕𝟕𝒇𝒇′𝒄𝒄

410.6.1 Minimum Steel Percentage ratio

�𝒇𝒇′𝒄𝒄 𝟏𝟏.𝟒𝟒

𝝆𝝆𝒎𝒎𝒎𝒎𝒎𝒎 = 𝝆𝝆𝒎𝒎𝒎𝒎𝒎𝒎 =

𝟒𝟒𝒇𝒇𝒚𝒚 𝒇𝒇𝒚𝒚

*choose lower value

410.4.3 Maximum Steel Percentage ratio

𝟔𝟔𝟔𝟔𝟔𝟔 𝟎𝟎. 𝟖𝟖𝟖𝟖𝒇𝒇′𝒄𝒄 𝜷𝜷𝟏𝟏

𝝆𝝆𝒃𝒃 = � �

𝟔𝟔𝟔𝟔𝟔𝟔 + 𝒇𝒇𝒚𝒚 𝒇𝒇𝒚𝒚

𝝆𝝆𝒎𝒎𝒎𝒎𝒎𝒎 = 𝟎𝟎. 𝟕𝟕𝟕𝟕𝝆𝝆𝒃𝒃𝒃𝒃𝒃𝒃

407.13 Temperature and Shrinking Reinforcements (for WALL FOOTING)

Area of shrinkage and temperature reinforcement shall provide at least the following ratios of reinforcement area to

gross concrete area, but not less than 0.0014:

a.) When Grade 275 or 530 deformed bars are used..................0.0020

b.) When Grade 415 deformed bars or welded wire

fabric (smooth or deformed) are used………………………………...0.0018

c.) When reinforcement with fy = 415 MPa measured

at a yield strain of 0.35% is used………………..........…………………0.0018(45/𝑓𝑓𝑓𝑓)

Bearing Strength of Column

All forces acting at the base of a column must be transferred into the footing. Compressive forces may be

transferred directly by bearing, while uplift or tensile forces must be transferred by developed reinforcing

such as dowels and mechanical connectors.

𝜙𝜙𝑃𝑃𝑛𝑛 = 𝜙𝜙0.85𝑓𝑓𝑐𝑐′ 𝐴𝐴1

𝟒𝟒𝟒𝟒𝟎𝟎 𝐴𝐴2

𝜙𝜙𝑃𝑃𝑛𝑛 = 𝜙𝜙0.85𝑓𝑓𝑐𝑐′ 𝐴𝐴1 �

𝐴𝐴1 A1= gross area of the column

A2= projected bearing area of the footing that

𝐴𝐴2 will resist the axial load

� ≤ 2.0

𝐴𝐴1

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 8 of 24

Module 5 – Design of Isolated Footings

FLOW IN DESIGNING AN ISOLATED COLUMN FOOTING

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 9 of 24

Module 5 – Design of Isolated Footings

Example 1: Wall Footing

Design a reinforced concrete wall footing to support a 300 mm wide reinforced concrete wall with a dead

load 300 kN/m and a live load 200 kN/m. The bottom of the footing is 1.0 m below the final grade, the

soil weight is 16 kN/m3, the concrete weight is 24kN/m3, the allowable soil pressure qa is 190 kPa, fy is

grade 60, f’c=28 MPa. Assume 450 mm deep footing for computation of footing weight.

• Given:

DL = 300 kN⁄m 𝒒𝒒𝒂𝒂 = 190 kPa

LL = 200 �m kN 𝒇𝒇𝒚𝒚 = G60; 414 MPa

kN

γsoil = 16 �m3 𝒇𝒇′𝒄𝒄 = 28 MPa

kN tftg = 450mm = 0.45m

γconc = 24 �m3

db = 16mm

• Solution:

1) Effective Bearing Capacity (qe)

𝒒𝒒𝒆𝒆 = 𝒒𝒒𝒂𝒂 − 𝜸𝜸𝒔𝒔 𝑫𝑫𝒇𝒇 − 𝜸𝜸𝒄𝒄 𝒕𝒕𝒇𝒇𝒇𝒇𝒇𝒇 = 190 − 16(1 − 0.45) − 24(0.45)

𝒒𝒒𝒆𝒆 = 𝟏𝟏𝟏𝟏𝟏𝟏. 𝟒𝟒𝟒𝟒 𝒌𝒌𝒌𝒌𝒌𝒌

2) Required Area and Base of the ftg

𝑷𝑷𝒏𝒏

𝒒𝒒𝒆𝒆 = ; 𝑷𝑷𝒏𝒏 = 𝑫𝑫𝑫𝑫 + 𝑳𝑳𝑳𝑳, 1 𝑚𝑚 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓

𝑨𝑨𝒇𝒇𝒇𝒇𝒇𝒇 0.3m

kN kN 5) Flexural Moment (Mu)

𝑷𝑷𝒏𝒏 = 300 (1.0𝑚𝑚) + 200 (1.0𝑚𝑚) → 𝑃𝑃𝑛𝑛 = 500 𝑘𝑘𝑘𝑘

m m 𝑾𝑾𝒖𝒖 𝑳𝑳𝟐𝟐 3 − 0.30

500 𝑘𝑘𝑘𝑘 𝑴𝑴𝒖𝒖 = ; 𝑳𝑳 = = 1.35𝑚𝑚 L

170.04 𝑘𝑘𝑘𝑘𝑘𝑘 = → 𝐴𝐴𝑓𝑓𝑓𝑓𝑓𝑓 = 2.9343m2 𝟐𝟐 2

𝐴𝐴𝑓𝑓𝑓𝑓𝑓𝑓 𝑾𝑾𝒖𝒖 = 𝒒𝒒𝒖𝒖 × 𝑼𝑼𝑼𝑼𝑼𝑼𝑼𝑼 𝑾𝑾𝑾𝑾𝑾𝑾𝑾𝑾𝑾𝑾 3m

𝐴𝐴𝑓𝑓𝑓𝑓𝑓𝑓

𝑩𝑩 = → 𝑩𝑩 = 𝟐𝟐. 𝟗𝟗𝟗𝟗𝟗𝟗𝟗𝟗𝟗𝟗 (𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓 𝒖𝒖𝒖𝒖 𝒕𝒕𝒕𝒕 𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏) 𝑾𝑾𝒖𝒖 = 266.6667 𝑘𝑘𝑘𝑘𝑘𝑘 (1𝑚𝑚) = 266.6667 𝑘𝑘𝑘𝑘/𝑚𝑚

1 𝑚𝑚

𝑩𝑩 = 𝟑𝟑. 𝟎𝟎 𝒎𝒎

(266.6667)(1.35)2

𝑴𝑴𝒖𝒖 = → 𝑴𝑴𝒖𝒖 =206.55 kN-m

3) Ultimate Bearing Pressure (qu) 2

𝑷𝑷𝒖𝒖 6) Actual Steel Ratio (ρactual)

𝒒𝒒𝒖𝒖 = ; 𝑷𝑷𝒖𝒖 = 𝟏𝟏. 𝟐𝟐𝟐𝟐𝟐𝟐 + 𝟏𝟏. 𝟔𝟔𝟔𝟔𝟔𝟔 𝒐𝒐𝒐𝒐 𝟏𝟏. 𝟒𝟒𝟒𝟒𝟒𝟒

𝑨𝑨𝒇𝒇𝒇𝒇𝒇𝒇(𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑) 𝝆𝝆𝒇𝒇𝒚𝒚

𝑷𝑷𝒖𝒖 = 300(1.2) + (200)(1.6) → 𝑃𝑃𝑛𝑛 = 680 𝑘𝑘𝑘𝑘 𝑴𝑴𝒖𝒖 = 𝝓𝝓𝝓𝝓𝒇𝒇𝒚𝒚 𝒃𝒃𝒅𝒅𝟐𝟐 �𝟏𝟏 − � ; 𝝓𝝓 = 𝟎𝟎. 𝟗𝟗𝟗𝟗

𝟏𝟏. 𝟕𝟕𝒇𝒇′𝒄𝒄

680 𝑘𝑘𝑘𝑘 206.55(1000)2 𝑁𝑁 − 𝑚𝑚𝑚𝑚

𝒒𝒒𝒖𝒖 = → 𝒒𝒒𝒖𝒖 = 𝟐𝟐𝟐𝟐𝟐𝟐. 𝟔𝟔𝟔𝟔𝟔𝟔𝟔𝟔 𝒌𝒌𝒌𝒌𝒌𝒌

3𝑚𝑚 × 1𝑚𝑚 (𝜌𝜌)(414)

= 0.90(𝜌𝜌)(414)(1000)(367)2 �1 − �

1.7(28)

4) “d” and “tprov”

One-Way Shear: 𝑽𝑽𝒖𝒖𝒖𝒖 < ∅𝑽𝑽𝒄𝒄𝒄𝒄 ; ∅ = 𝟎𝟎. 𝟕𝟕𝟕𝟕 𝝆𝝆𝒂𝒂𝒂𝒂𝒂𝒂𝒂𝒂𝒂𝒂𝒂𝒂 = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎

𝐵𝐵 𝑊𝑊

𝑽𝑽𝒖𝒖 = 𝑞𝑞𝑢𝑢 (1000𝑚𝑚𝑚𝑚)(𝑧𝑧) = 𝑞𝑞𝑢𝑢 (1000𝑚𝑚𝑚𝑚) � − − 𝑑𝑑� 7) Compare ρactual with ρmin

2 2

1 1 𝟏𝟏. 𝟒𝟒 1.4

∅𝑽𝑽𝒄𝒄𝒄𝒄 = ∅ � � 𝜆𝜆�𝑓𝑓 ′ 𝑐𝑐(𝑏𝑏𝑏𝑏) = 0.75 � � (1)�𝑓𝑓 ′ 𝑐𝑐(𝑏𝑏𝑏𝑏) 𝝆𝝆𝒎𝒎𝒎𝒎𝒎𝒎 = = = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎

6 6 𝒇𝒇𝒚𝒚 414

𝑩𝑩 𝑾𝑾 𝟏𝟏

∴ 𝒒𝒒𝒖𝒖 (𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏) � − − 𝒅𝒅� = 𝟎𝟎. 𝟕𝟕𝟕𝟕 � � (𝟏𝟏)�𝒇𝒇′ 𝒄𝒄(𝒃𝒃𝒃𝒃)

𝟐𝟐 𝟐𝟐 𝟔𝟔 �𝒇𝒇′ 𝒄𝒄 √28

226.6667 3000 − 300 0.75 𝝆𝝆𝒎𝒎𝒎𝒎𝒎𝒎 = = = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎

(1000) � − 𝑑𝑑1 � = � � (1)√28(1000)(𝑑𝑑1 ) 𝟒𝟒𝒇𝒇𝒚𝒚 4(414)

1000 2 6

𝒅𝒅𝟏𝟏 = 𝟑𝟑𝟑𝟑𝟑𝟑. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓 𝒎𝒎𝒎𝒎 𝝆𝝆𝒎𝒎𝒎𝒎𝒎𝒎 < 𝝆𝝆𝒂𝒂𝒂𝒂𝒂𝒂𝒂𝒂𝒂𝒂𝒂𝒂

𝒕𝒕𝒓𝒓𝒓𝒓𝒓𝒓 = 𝒅𝒅𝒓𝒓𝒓𝒓𝒓𝒓 + 𝑪𝑪𝒄𝒄 + 𝟎𝟎. 𝟓𝟓𝟓𝟓𝒃𝒃 = 344.5541 + 75 + 0.5(16) ∴ 𝝆𝝆 = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎

𝒕𝒕𝒓𝒓𝒓𝒓𝒓𝒓 = 427.56 𝑚𝑚𝑚𝑚 (𝑛𝑛𝑛𝑛𝑛𝑛𝑛𝑛𝑛𝑛𝑛𝑛𝑛𝑛 50𝑚𝑚𝑚𝑚) → 𝒕𝒕𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 = 𝟒𝟒𝟒𝟒𝟒𝟒 𝒎𝒎𝒎𝒎

𝒅𝒅𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 = 𝒕𝒕𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 − 𝑪𝑪𝒄𝒄 − 𝟎𝟎. 𝟓𝟓𝟓𝟓𝒃𝒃 = 450 − 75 − 8

𝒅𝒅𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 = 𝟑𝟑𝟑𝟑𝟑𝟑 𝒎𝒎𝒎𝒎

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 10 of 24

Module 5 – Design of Isolated Footings

8) Number of bars and required spacing

𝑨𝑨𝒔𝒔

𝝆𝝆 = ; 𝝆𝝆 = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎

𝒃𝒃𝒃𝒃

𝐴𝐴𝑠𝑠

0.004275 = → 𝐴𝐴𝑠𝑠 = 1568.81 𝑚𝑚𝑚𝑚2

(1000)(367)

𝝅𝝅

𝑨𝑨𝒔𝒔 = 𝒏𝒏 � 𝒅𝒅𝒃𝒃 𝟐𝟐 � ; 𝑨𝑨𝒔𝒔 = 𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏. 𝟖𝟖𝟖𝟖 𝒎𝒎𝒎𝒎𝟐𝟐

𝟒𝟒

𝜋𝜋

1568.81 𝑚𝑚𝑚𝑚2 = 𝑛𝑛 � (16𝑚𝑚𝑚𝑚)2 � → 𝒏𝒏 = 𝟕𝟕. 𝟖𝟖 (𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓 𝒖𝒖𝒖𝒖)

4

𝒏𝒏 = 𝟖𝟖 𝒃𝒃𝒃𝒃𝒃𝒃𝒃𝒃

𝑳𝑳𝑳𝑳𝑳𝑳𝑳𝑳𝑳𝑳𝑳𝑳

𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺 = ; 𝒏𝒏 = 𝟖𝟖, 𝟏𝟏 𝒎𝒎 𝒔𝒔𝒔𝒔𝒔𝒔𝒔𝒔𝒔𝒔 𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇𝒇

𝒏𝒏 − 𝟏𝟏

1000𝑚𝑚𝑚𝑚

𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺 = → 𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺 = 𝟏𝟏𝟏𝟏𝟏𝟏. 𝟖𝟖𝟖𝟖 𝒎𝒎𝒎𝒎

8−1

9) Temperature and Shrinking Reinforcements (Wall Footing)

𝑮𝑮𝑮𝑮𝑮𝑮𝑮𝑮𝑮𝑮 𝟒𝟒𝟒𝟒𝟒𝟒; 𝝆𝝆 = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎

𝑨𝑨𝒔𝒔(𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕) 𝐴𝐴𝑠𝑠(𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡)

𝝆𝝆 = → 0.0018 =

𝒃𝒃𝒃𝒃 (3000)(450)

𝐴𝐴𝑠𝑠(𝑡𝑡𝑡𝑡𝑡𝑡𝑡𝑡) = 2430 𝑚𝑚𝑚𝑚2

𝝅𝝅

𝑨𝑨𝒔𝒔(𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕) = 𝒏𝒏 � 𝒅𝒅𝒃𝒃 𝟐𝟐 � ; 𝑨𝑨𝒔𝒔(𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕) = 𝟐𝟐𝟐𝟐𝟐𝟐𝟐𝟐 𝒎𝒎𝒎𝒎𝟐𝟐

𝟒𝟒

𝜋𝜋

2430 𝑚𝑚𝑚𝑚2 = 𝑛𝑛 � (16𝑚𝑚𝑚𝑚)2 � → 𝒏𝒏 = 𝟏𝟏𝟏𝟏. 𝟎𝟎𝟎𝟎 (𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓 𝒖𝒖𝒖𝒖)

4

𝒏𝒏 = 𝟏𝟏𝟏𝟏 𝒃𝒃𝒃𝒃𝒃𝒃𝒃𝒃

16

𝒙𝒙 = 3000𝑚𝑚𝑚𝑚 − 2(75) − 2 � � = 2834 𝑚𝑚𝑚𝑚

2 CC=75 mm

𝒙𝒙

𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺 = ; 𝒏𝒏 = 𝟏𝟏𝟏𝟏, 𝒙𝒙 = 𝟐𝟐𝟐𝟐𝟐𝟐𝟐𝟐 𝒎𝒎𝒎𝒎

𝒏𝒏 − 𝟏𝟏 x

2834 𝑚𝑚𝑚𝑚

𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺 = → 𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺𝑺 = 𝟐𝟐𝟐𝟐𝟐𝟐. 𝟏𝟏𝟏𝟏 𝒎𝒎𝒎𝒎

13 − 1 3000 mm

Engr. Bryan Dale P. Yu FOUNDATION ENGINEERING Page 11 of 24

Module 5 – Design of Isolated Footings

Example 2: Isolated Square Footing

Design a square concrete column footing to support a 300-mm x 300-mm reinforced concrete column

that in turn is supporting a 130-kN dead load and a 200-kN live load. f’c = 28MPa, fy= 414, and qa = 210

kPa. The base of the footing is to be 1.50 m below the final grade. Concrete weight = 24kN/m3 and soil

weight = 16kN/m3. Assume 500mm thick for footing. Also check the bearing strength and the required

development length. The bar diameter of the footing is 16 mm,

• Given:

DL = 130 kN 𝒒𝒒𝒂𝒂 = 190 kPa db= 16 mm

LL = 200kN 𝒇𝒇𝒚𝒚 = 414 MPa 𝑫𝑫𝒇𝒇 = 1.50 m

γsoil = 16 kN�m3 𝒇𝒇′𝒄𝒄 = 28 MPa

γconc = 24 �m3kN tftg = 500mm = 0.5m

• Solution:

1) Effective Bearing Capacity (qe);

𝒒𝒒𝒆𝒆 = 190 − 16(0.5) − 24(1.5 − 0.5)

𝒒𝒒𝒆𝒆 = 𝟏𝟏𝟏𝟏𝟏𝟏 𝒌𝒌𝒌𝒌𝒌𝒌

2) Required Area and Base of the ftg

𝑷𝑷𝒏𝒏

𝒒𝒒𝒆𝒆 = ; 𝑷𝑷𝒏𝒏 = 𝑫𝑫𝑫𝑫 + 𝑳𝑳𝑳𝑳

𝑨𝑨𝒇𝒇𝒇𝒇𝒇𝒇 𝒕𝒕𝒓𝒓𝒓𝒓𝒓𝒓 = 𝒅𝒅𝒓𝒓𝒓𝒓𝒓𝒓 + 𝑪𝑪𝒄𝒄 + 𝒅𝒅𝒃𝒃 + 𝟎𝟎. 𝟓𝟓𝟓𝟓𝒃𝒃

𝑷𝑷𝒏𝒏 = 130 + 200 → 𝑃𝑃𝑛𝑛 = 330 𝑘𝑘𝑘𝑘 𝒕𝒕𝒓𝒓𝒓𝒓𝒓𝒓 = 169.8787 + 75 + 16 + 0.5(16)

330 𝑘𝑘𝑘𝑘 𝒕𝒕𝒓𝒓𝒓𝒓𝒓𝒓 = 268.8784 𝑚𝑚𝑚𝑚 (𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 𝑢𝑢𝑢𝑢) → 𝒕𝒕𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 = 𝟑𝟑𝟑𝟑𝟑𝟑 𝒎𝒎𝒎𝒎

182 𝑘𝑘𝑘𝑘𝑘𝑘 = → 𝐴𝐴𝑓𝑓𝑓𝑓𝑓𝑓 = 1.8132 m2

𝐴𝐴𝑓𝑓𝑓𝑓𝑓𝑓 𝒅𝒅𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 = 𝒕𝒕𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 − 𝑪𝑪𝒄𝒄 − 𝒅𝒅𝒃𝒃 − 𝟎𝟎. 𝟓𝟓𝟓𝟓𝒃𝒃 = 300 − 75 − 16 − 8

𝑩𝑩𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 = √1.8132 m2 → 𝑩𝑩 = 𝟏𝟏. 𝟑𝟑𝟑𝟑𝟑𝟑𝟑𝟑 (𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓𝒓 𝒖𝒖𝒖𝒖 𝒕𝒕𝒕𝒕 𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏𝟏) 𝒅𝒅𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 = 𝟐𝟐𝟐𝟐𝟐𝟐 𝒎𝒎𝒎𝒎

𝑩𝑩𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 = 𝟏𝟏. 𝟒𝟒 𝒎𝒎

5) Flexural Moment (Mu) 0.3m

3) Ultimate Bearing Pressure (qu) 𝑾𝑾𝒖𝒖 𝑳𝑳𝟐𝟐 1.4 − 0.30

𝑷𝑷𝒖𝒖 𝑴𝑴𝒖𝒖 = ; 𝑳𝑳 = = 0.55 𝑚𝑚

𝒒𝒒𝒖𝒖 = ; 𝑷𝑷𝒖𝒖 = 𝟏𝟏. 𝟐𝟐𝟐𝟐𝟐𝟐 + 𝟏𝟏. 𝟔𝟔𝟔𝟔𝟔𝟔 𝒐𝒐𝒐𝒐 𝟏𝟏. 𝟒𝟒𝟒𝟒𝟒𝟒 𝟐𝟐 2

L

𝑨𝑨𝒇𝒇𝒇𝒇𝒇𝒇(𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑) 𝑾𝑾𝒖𝒖 = 𝒒𝒒𝒖𝒖 × 𝑼𝑼𝑼𝑼𝑼𝑼𝑼𝑼 𝑾𝑾𝑾𝑾𝑾𝑾𝑾𝑾𝑾𝑾

𝑷𝑷𝒖𝒖 = 130(1.2) + (200)(1.6) → 𝑃𝑃𝑢𝑢 = 476 𝑘𝑘𝑘𝑘 1.4m

476 𝑘𝑘𝑘𝑘 𝑾𝑾𝒖𝒖 = 242.8571 𝑘𝑘𝑘𝑘𝑘𝑘 (1.4𝑚𝑚)

𝒒𝒒𝒖𝒖 = → 𝒒𝒒𝒖𝒖 = 𝟐𝟐𝟐𝟐𝟐𝟐. 𝟖𝟖𝟖𝟖𝟖𝟖𝟖𝟖 𝒌𝒌𝒌𝒌𝒌𝒌 (0.55)2

1.4𝑚𝑚 × 1.4𝑚𝑚 𝑴𝑴𝒖𝒖 =242.8571 𝑘𝑘𝑘𝑘𝑘𝑘 (1.4𝑚𝑚)

2

𝑴𝑴𝒖𝒖 =51.4250 kN-m

4) “d” and “tprov”

d1 One-Way Shear: 𝑉𝑉𝑢𝑢1 < ∅𝑉𝑉𝑐𝑐1 ; ∅ = 0.75 6) Actual Steel Ratio (ρactual)

𝑩𝑩 − 𝑾𝑾 𝟏𝟏 𝝆𝝆𝒇𝒇𝒚𝒚

𝒒𝒒𝒖𝒖 (𝒃𝒃) � − 𝒅𝒅� = 𝟎𝟎. 𝟕𝟕𝟕𝟕 � � (𝟏𝟏)�𝒇𝒇′ 𝒄𝒄(𝒃𝒃𝒃𝒃) 𝑴𝑴𝒖𝒖 = 𝝓𝝓𝝓𝝓𝒇𝒇𝒚𝒚 𝒃𝒃𝒅𝒅𝟐𝟐 �𝟏𝟏 − � ; 𝝓𝝓 = 𝟎𝟎. 𝟗𝟗𝟗𝟗

𝟐𝟐 𝟔𝟔 𝟏𝟏. 𝟕𝟕𝒇𝒇′𝒄𝒄

242.8571 1400 − 300 0.75

(1400) � − 𝑑𝑑1 � = � � (1)√28(1400)(𝑑𝑑1 ) 51.4250(1000)2 𝑁𝑁 − 𝑚𝑚𝑚𝑚

1000 2 6 (𝜌𝜌)(414)

𝒅𝒅𝟏𝟏 = 𝟏𝟏𝟏𝟏𝟏𝟏. 𝟕𝟕𝟕𝟕𝟕𝟕𝟕𝟕 𝒎𝒎𝒎𝒎 = 0.90(𝜌𝜌)(414)(1400)(201)2 �1 − �

1.7(28)