Professional Documents

Culture Documents

Catálogo IPB 10-12 - Ing

Catálogo IPB 10-12 - Ing

Uploaded by

marcosCopyright:

Available Formats

You might also like

- Isoladores Polimericos para Ancoragem Ou Suspensao IngDocument2 pagesIsoladores Polimericos para Ancoragem Ou Suspensao IngRenzo Romero ArenasNo ratings yet

- Piezo Copolymer Coaxial Cable: SpecificationsDocument4 pagesPiezo Copolymer Coaxial Cable: SpecificationsArnas MAJUMDERNo ratings yet

- LBX 6516DS T0MDocument3 pagesLBX 6516DS T0Mmhmahmoudhassan1649No ratings yet

- VIVANCO Unitube Light - Armoured Optical Fibre Cable, Single ModeDocument2 pagesVIVANCO Unitube Light - Armoured Optical Fibre Cable, Single ModeMd. Ishaque Hossain TipuNo ratings yet

- Jointfill - Cable Jointing Kit - Cast ResinDocument2 pagesJointfill - Cable Jointing Kit - Cast ResinVenkata ReddyNo ratings yet

- Produktinformation EN.132927328Document2 pagesProduktinformation EN.132927328Songkunhua SongNo ratings yet

- Data Sheet YCP EN 0420Document1 pageData Sheet YCP EN 0420Fareed KhanNo ratings yet

- 199 Imi EkoguardDocument2 pages199 Imi EkoguardEngr KamalNo ratings yet

- 12 Fiber Multi Tube 2120112Document1 page12 Fiber Multi Tube 2120112ganeshinamdarNo ratings yet

- Product Specifications: HBXX-6516DS-VTMDocument3 pagesProduct Specifications: HBXX-6516DS-VTMDM Farm -No ratings yet

- Product Information: Data Cable, U/UTP, Category 6, AWG23Document4 pagesProduct Information: Data Cable, U/UTP, Category 6, AWG23Numan AminNo ratings yet

- Rolliflex Cables: Field-Bus CablesDocument2 pagesRolliflex Cables: Field-Bus CablesnikhilbhorNo ratings yet

- FOUNDATION Fieldbus Cable: Data SheetDocument4 pagesFOUNDATION Fieldbus Cable: Data SheetMiller Alexander Mora VargasNo ratings yet

- HBX 6516DS T2MDocument3 pagesHBX 6516DS T2MAnjit RajkarnikarNo ratings yet

- Product Specifications Product Specifications: LBX LBX - 6516DS 6516DS - T0M T0MDocument2 pagesProduct Specifications Product Specifications: LBX LBX - 6516DS 6516DS - T0M T0MИван КадигробNo ratings yet

- Andrew LBX 3319ds t0mDocument2 pagesAndrew LBX 3319ds t0mРусланNo ratings yet

- Line Item 18 To 24 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F D MTA SS PE BKDocument3 pagesLine Item 18 To 24 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F D MTA SS PE BKSadiqNo ratings yet

- JCV4-65B-R6: General SpecificationsDocument5 pagesJCV4-65B-R6: General Specificationsalbertho12No ratings yet

- Optical Patch Cables Data Sheet by JTOPTICSDocument8 pagesOptical Patch Cables Data Sheet by JTOPTICSJayani Technologies LtdNo ratings yet

- A2F-FF: CMP Products Cable Gland CatalogueDocument1 pageA2F-FF: CMP Products Cable Gland CataloguePaulo CostaNo ratings yet

- 6 Fiber Multi Tube Fiber Optic Cable 2120006Document1 page6 Fiber Multi Tube Fiber Optic Cable 2120006Diego ValenteNo ratings yet

- CAT6 PVC-U-UTP CableDocument2 pagesCAT6 PVC-U-UTP CableMahmoud MetwallyNo ratings yet

- FLR4G11Y-FL4G11Y CablesDocument1 pageFLR4G11Y-FL4G11Y CablesVijay KarthikeyanNo ratings yet

- L2B2AT-Canare Corp. - Two-Conductor Shielded Cables - Two-Conductor Shielded Cables (Single) Aluminum Foil Shield (L-2B2AT)Document3 pagesL2B2AT-Canare Corp. - Two-Conductor Shielded Cables - Two-Conductor Shielded Cables (Single) Aluminum Foil Shield (L-2B2AT)Antonius Patra100% (1)

- Pararrayos Tipo BalestroDocument3 pagesPararrayos Tipo BalestroBladimir Michel100% (1)

- E14F05P03 Product SpecificationsDocument4 pagesE14F05P03 Product SpecificationsVasile IonNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- Patchcord Fo SM G652D KhomaxDocument2 pagesPatchcord Fo SM G652D KhomaxGuillermo MurrielNo ratings yet

- Cable GlandDocument1 pageCable GlandAntonio EnaguasNo ratings yet

- Andrew Csh-6516a-VtDocument3 pagesAndrew Csh-6516a-VtLeo DuranNo ratings yet

- Instrumentation Cable Gen. To EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable Gen. To EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- NKL F Xxxyytg 02b BK - en - Pe - v20200413Document2 pagesNKL F Xxxyytg 02b BK - en - Pe - v20200413Mervin YeoNo ratings yet

- PG 00332 HK1819 UNITRONIC BUS PBDocument1 pagePG 00332 HK1819 UNITRONIC BUS PBClifford BaangNo ratings yet

- DBXCP 4545a VTM PDFDocument4 pagesDBXCP 4545a VTM PDFRolando TupizaNo ratings yet

- Seacon Catalog - Hummer ConnectorDocument8 pagesSeacon Catalog - Hummer ConnectorBruno SallesNo ratings yet

- Line Item 11 To 17 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F Duct MTUA SS PE BKDocument3 pagesLine Item 11 To 17 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F Duct MTUA SS PE BKSadiqNo ratings yet

- Product Specifications Product Specifications: DB408 DB408 - BBDocument2 pagesProduct Specifications Product Specifications: DB408 DB408 - BBCesar LopezNo ratings yet

- Andrew 932DG65Т6EKLDocument3 pagesAndrew 932DG65Т6EKLКазьмин ОлегNo ratings yet

- HBX 3319DS VTM PDFDocument3 pagesHBX 3319DS VTM PDFcesarbayonaNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- 15KW On Grid Roof Top HP STATIONDocument7 pages15KW On Grid Roof Top HP STATIONAjayNo ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- EUPEN A-2Y2YB2Y DB AG 4160113 Ed 06 2017-05-17Document1 pageEUPEN A-2Y2YB2Y DB AG 4160113 Ed 06 2017-05-17Songkunhua SongNo ratings yet

- The Alto Photofission Facility at IPN Orsay: Serge FranchooDocument29 pagesThe Alto Photofission Facility at IPN Orsay: Serge FranchooAnnie SegoviaNo ratings yet

- Product Specifications Product Specifications: MBLHH MBLHH - 65C 65C - VTM VTMDocument2 pagesProduct Specifications Product Specifications: MBLHH MBLHH - 65C 65C - VTM VTMSpam SpamNo ratings yet

- EUPEN AJ-2Y2YDB2Y DB AG 4160113 Ed 07 2022-06-27Document1 pageEUPEN AJ-2Y2YDB2Y DB AG 4160113 Ed 07 2022-06-27Songkunhua SongNo ratings yet

- Catalog Leoni CableDocument2 pagesCatalog Leoni CablesubodhNo ratings yet

- Freedm One Tight-Buffered, Interlocking Armored Cable, RiserDocument3 pagesFreedm One Tight-Buffered, Interlocking Armored Cable, RiserFranklin CabreraNo ratings yet

- RG 58LL Co-Axial CableDocument1 pageRG 58LL Co-Axial CableKristaNo ratings yet

- Belden P/N 50106F: Industrial CAT 6 F/UTPDocument2 pagesBelden P/N 50106F: Industrial CAT 6 F/UTPAsep heriyanaNo ratings yet

- Multicore Armoured Shaped Conductor - XLPE InsulatedDocument1 pageMulticore Armoured Shaped Conductor - XLPE InsulatedMohamed InshafNo ratings yet

- V4-65D-R4-V2: General SpecificationsDocument5 pagesV4-65D-R4-V2: General SpecificationsFernando Cuestas RamirezNo ratings yet

- Db854dg65esy PDFDocument3 pagesDb854dg65esy PDFfaapctbaNo ratings yet

- Andrew COMMSCOPE CSH-6516A-VTDocument2 pagesAndrew COMMSCOPE CSH-6516A-VThasib_muhammedNo ratings yet

- Antenna Commscope CSH 6516A VTDocument2 pagesAntenna Commscope CSH 6516A VTvohoangphuNo ratings yet

- GTP 185Document3 pagesGTP 185er.manishnhpcNo ratings yet

- Cable Siemon-SFTP CAT7A PDFDocument2 pagesCable Siemon-SFTP CAT7A PDFRenzo GuizadoNo ratings yet

- 932qlg65vteb PDFDocument4 pages932qlg65vteb PDFMariaNo ratings yet

- Flexible Budgets and Performance AnalysisDocument37 pagesFlexible Budgets and Performance AnalysisSana IjazNo ratings yet

- Second Analysis of DaffodilsDocument2 pagesSecond Analysis of DaffodilsSimone CagnazzoNo ratings yet

- BonofideDocument1 pageBonofideQusai KHNo ratings yet

- Performance and Design Analysis of Domestic LPG StoveDocument73 pagesPerformance and Design Analysis of Domestic LPG StoveRupali Patil100% (1)

- Lecture 2.2 Merge Sort AlgorithmsDocument59 pagesLecture 2.2 Merge Sort AlgorithmsPablo ChanNo ratings yet

- Handheld Air Particle Counter MET ONE HHPC+ Series BrochureDocument4 pagesHandheld Air Particle Counter MET ONE HHPC+ Series BrochureFirdaus ZaidNo ratings yet

- Subject Grade Boundaries - June 2019 Exams Oxfordaqa International GcseDocument3 pagesSubject Grade Boundaries - June 2019 Exams Oxfordaqa International GcseHala ShetaNo ratings yet

- League of Legends - Summoners Call - FullScoreDocument28 pagesLeague of Legends - Summoners Call - FullScoreNghi RòmNo ratings yet

- Business Studies RevisionDocument2 pagesBusiness Studies RevisionSwapnil NaskarNo ratings yet

- Paper1 1Document119 pagesPaper1 1Damián VillegasNo ratings yet

- Validation and Dissoiution Enhacement of Loratadine and Desloratadine Tablets by Various Spctrophotometric MethodsDocument40 pagesValidation and Dissoiution Enhacement of Loratadine and Desloratadine Tablets by Various Spctrophotometric MethodsDr. Vishal BabarNo ratings yet

- Megaman PatternDocument9 pagesMegaman PatternBelen Solis Maravillas100% (2)

- 3M CatalogueDocument32 pages3M Cataloguefandi.azs37No ratings yet

- Exercise Questions On Regular Language and Regular ExpressionDocument56 pagesExercise Questions On Regular Language and Regular ExpressionAnonymous t1W5G4UZw100% (1)

- Toyota Vios Manual Book DownloadDocument24 pagesToyota Vios Manual Book DownloadVidi EfendiNo ratings yet

- Volume 69 PDFDocument84 pagesVolume 69 PDFShobit Sharma100% (3)

- Report RUSADocument16 pagesReport RUSApawan kumar100% (1)

- UPDATE YANG BELUM Mengerjakan Sertifikasi TCO Maret Update 0804 Jam 08.00 WIBDocument2 pagesUPDATE YANG BELUM Mengerjakan Sertifikasi TCO Maret Update 0804 Jam 08.00 WIBWendi ArtheaNo ratings yet

- Chap 4 Research Method and Technical WritingDocument33 pagesChap 4 Research Method and Technical WritingEndalkchew FentahunNo ratings yet

- DSP 6 - FIR Filter DesignDocument23 pagesDSP 6 - FIR Filter DesignJehan Zeb BhattiNo ratings yet

- Microcatchment: NegarimDocument11 pagesMicrocatchment: Negarimhaithamelramlawi7503100% (1)

- MA REV 1 Finals Dec 2017Document33 pagesMA REV 1 Finals Dec 2017Dale PonceNo ratings yet

- Linux PracticalDocument18 pagesLinux PracticalAnonymous x6UDQVBHawNo ratings yet

- Cloud Computing in Distributed System IJERTV1IS10199Document8 pagesCloud Computing in Distributed System IJERTV1IS10199Nebula OriomNo ratings yet

- Metaphor AgerosegelelectroforeseDocument2 pagesMetaphor AgerosegelelectroforeseSuus.veluwenkampNo ratings yet

- ML Lab Manual-2019Document85 pagesML Lab Manual-2019ManjulaNo ratings yet

- Case Study: Pizza Delivered Quickly (PDQ)Document3 pagesCase Study: Pizza Delivered Quickly (PDQ)Jose Abanto GozalvezNo ratings yet

- 1 FffffanyDocument1 page1 FffffanyLuis SolisNo ratings yet

- Abs v. NTCDocument2 pagesAbs v. NTCLadyfirst SMNo ratings yet

- Roof Mounted Fans HCTB - HCTT Series, Axial Flow Fans: Applications Description Air ExtractionDocument9 pagesRoof Mounted Fans HCTB - HCTT Series, Axial Flow Fans: Applications Description Air ExtractionmarckalhiNo ratings yet

Catálogo IPB 10-12 - Ing

Catálogo IPB 10-12 - Ing

Uploaded by

marcosOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catálogo IPB 10-12 - Ing

Catálogo IPB 10-12 - Ing

Uploaded by

marcosCopyright:

Available Formats

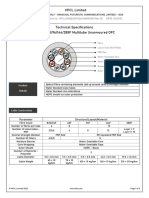

Insulators

Polymeric for Dead-End ans Suspension

type IPB

Balestro polymeric insulators IPB series are produced for use in electrical power distribution suspension or dead end instalation, replacing the

conventional porcelain or glass chains. Polymeric insulators are produced initially from a fiberglass rod (core) which is fixed to the connection tools

(clevis and tongue type in special hot-galvanized iron alloy) and later the insulating envelope (in silicone rubber) is applied on this set, resulting in

a compact, light insulator of great mechanical resistence and highly resistant to weather conditions. The main advantage with the use of polymeric

Balestro insulators of the IPB series are:

Advantages

• Compact dimensions, resulting in insulator which are lighter than the conventional ones, reducing the cost of structures, transport and warehosing,

as well as labour for installation and so on;

• Immunity to vandalism;

• Highly resistant to traction;

• Excellent performance in bad weather, especially in highly polluted environments, thanks to the peculiar characteristic of the silicone envelope system,

such as hydrophobicity, which ensures high superficial resistance to the insulator ever under rainy conditions, avoiding the forming of continuos water

films, dry channels and arcs on the surface of the insulator, which reduces the risk of flashover. This characteristic of the silicone is transferred to

possible deposits of solid pollutants on the surface of the insulator, maintaining hydrophobicity even under polluting conditions;

• High resistence to electrical tracking and erosion, and also to the proliferation of fungus;

• Moulded in a single piece, ensuring excellent hermethicity and preventing water or moisture ingress inside the insulators.

Brazilian Industry

Changing Technology into Protection.

type

IPB

Insulators

Polymeric for Dead-End and Suspension

Dimensions Ordering Code for the Balestro Polymeric Insulators

Balestro Polymeric Insulator Insulator Voltage Rating Pollutions Level as per IEC 60815

Dry Arc Distance NP - Normal Pollution

L

Leakage Distance

IPB 15/GO/50/NP/4 AP - High Pollution

EAP - Extra High Pollution

Type of End Fittings Specified Mechanical Load (SML) in kN Number of Sheeds

G: Clévis O: Tongue 50 kN (5.000 daN), 70 kN (7.000 daN)

B: Ball C: Socket ou 80kN (8.000 daN)

18 mm In case of GO (clevis/tongue) end fitting, Balestro offers the option of it in aluminium. Please,

consult us to further information. Tongue can have optionally a 22 mm bore diameter.

Mechanical Characteristcs

Length “L”

IPB / NP

Rated Voltage Leakage Distance Dry Arc Distance Package Weight

Model No of Sheeds SML (kN) Net weight (kg)

(kV) (c-c) (mm) (mm) (mm) 6 units (kg)

IPB 15/XX/CMN/NP/4 15 4 335 430 200 1,3 7,8 �88

IPB 25/XX/CMN/NP/6 24,2 6 428 650 300 50, 70 ou 80 1,4 8,4 37

37

IPB 34/XX/CMN/NP/8 36,2 8 480 810 355 1,5 9,0

Electrical Characteristcs

Power frequency withstand voltage Critical impulse flashover

Lightning impulse withstand voltage Power frequency flashover

Model (kV RMS) (kV RMS) RIV (μV)

(both polarities) (kV peak) voltage wet (kV RMS)

DRY WET POSITIVO NEGATIVO

IPB 15/XX/CMN/NP/4 140 80 70 150 210 90 < 10

IPB 25/XX/CMN/NP/6 180 100 90 200 260 115 < 10

IPB 34/XX/CMN/NP/8 190 115 110 235 295 130 < 10

Mechanical Characteristcs

Length “L”

IPB / AP

Rated Voltage Leakage Distance Dry Arc Distance Package Weight

Model No of Sheeds SML (kN) Net weight (kg)

(kV) (c-c) (mm) (mm) (mm) 6 units (kg)

IPB 15/XX/CMN/AP/5 15 5 410 545 250 1,5 9,0 �100

IPB 25/XX/CMN/AP/7 24,2 7 480 735 317 50, 70 ou 80 1,7 10,2 35 �88

IPB 34/XX/CMN/AP/9 36,2 9 550 920 390 1,9 11,4 35

Electrical Characteristcs

Power frequency withstand voltage Critical impulse flashover

Lightning impulse withstand voltage Power frequency flashover

Model (kV RMS) (kV RMS) RIV (μV)

(both polarities) (kV peak) voltage wet (kV RMS)

DRY WET POSITIVO NEGATIVO

IPB 15/XX/CMN/AP/5 155 95 75 165 235 85 < 10

IPB 25/XX/CMN/AP/7 185 110 100 195 270 105 < 10

IPB 34/XX/CMN/AP/9 220 125 115 230 340 125 < 10

Mechanical Characteristcs

Length “L”

IPB / EAP

Rated Voltage Leakage Distance Dry Arc Distance Package Weight

Model No of Sheeds SML (kN) Net weight (kg)

(kV) (c-c) (mm) (mm) (mm) 6 units (kg)

IPB 15/XX/CMN/EAP/5 15 5 360 680 260 1,6 9,6 �138

IPB 25/XX/CMN/EAP/7 24,2 7 420 920 320 50, 70 ou 80 1,8 10,8 27,5

�110

27,5

IPB 34/XX/CMN/EAP/9 36,2 9 480 1.160 370 2,0 12,0

Electrical Characteristcs

Power frequency withstand voltage Critical impulse flashover

Lightning impulse withstand voltage Power frequency flashover

Model (kV RMS) (kV RMS) RIV (μV)

(both polarities) (kV peak) voltage wet (kV RMS)

DRY WET POSITIVO NEGATIVO

IPB 15/XX/CMN/EAP/5 180 110 95 185 250 105 < 10

IPB 25/XX/CMN/EAP/7 220 125 110 225 300 115 < 10

IPB 34/XX/CMN/EAP/9 245 145 130 250 335 140 < 10

Due to constante development, this information may be changed without notice. Other models on request.

Indústria Eletromecânica Balestro Ltda.

Rua Santa Cruz, 1550 CEP 13 800 911 - Unid. 1

Av. Geraldo Potyguara Silveira Franco, 298 Distrito Industrial I CEP 13803-280 - Unid. 2

Mogi Mirim SP - Cx. Postal 80 Brazil - PABX 55 (19) 3814 9000

10/12

sales@balestro.com www.balestro.com SAC 0800 704 3446

You might also like

- Isoladores Polimericos para Ancoragem Ou Suspensao IngDocument2 pagesIsoladores Polimericos para Ancoragem Ou Suspensao IngRenzo Romero ArenasNo ratings yet

- Piezo Copolymer Coaxial Cable: SpecificationsDocument4 pagesPiezo Copolymer Coaxial Cable: SpecificationsArnas MAJUMDERNo ratings yet

- LBX 6516DS T0MDocument3 pagesLBX 6516DS T0Mmhmahmoudhassan1649No ratings yet

- VIVANCO Unitube Light - Armoured Optical Fibre Cable, Single ModeDocument2 pagesVIVANCO Unitube Light - Armoured Optical Fibre Cable, Single ModeMd. Ishaque Hossain TipuNo ratings yet

- Jointfill - Cable Jointing Kit - Cast ResinDocument2 pagesJointfill - Cable Jointing Kit - Cast ResinVenkata ReddyNo ratings yet

- Produktinformation EN.132927328Document2 pagesProduktinformation EN.132927328Songkunhua SongNo ratings yet

- Data Sheet YCP EN 0420Document1 pageData Sheet YCP EN 0420Fareed KhanNo ratings yet

- 199 Imi EkoguardDocument2 pages199 Imi EkoguardEngr KamalNo ratings yet

- 12 Fiber Multi Tube 2120112Document1 page12 Fiber Multi Tube 2120112ganeshinamdarNo ratings yet

- Product Specifications: HBXX-6516DS-VTMDocument3 pagesProduct Specifications: HBXX-6516DS-VTMDM Farm -No ratings yet

- Product Information: Data Cable, U/UTP, Category 6, AWG23Document4 pagesProduct Information: Data Cable, U/UTP, Category 6, AWG23Numan AminNo ratings yet

- Rolliflex Cables: Field-Bus CablesDocument2 pagesRolliflex Cables: Field-Bus CablesnikhilbhorNo ratings yet

- FOUNDATION Fieldbus Cable: Data SheetDocument4 pagesFOUNDATION Fieldbus Cable: Data SheetMiller Alexander Mora VargasNo ratings yet

- HBX 6516DS T2MDocument3 pagesHBX 6516DS T2MAnjit RajkarnikarNo ratings yet

- Product Specifications Product Specifications: LBX LBX - 6516DS 6516DS - T0M T0MDocument2 pagesProduct Specifications Product Specifications: LBX LBX - 6516DS 6516DS - T0M T0MИван КадигробNo ratings yet

- Andrew LBX 3319ds t0mDocument2 pagesAndrew LBX 3319ds t0mРусланNo ratings yet

- Line Item 18 To 24 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F D MTA SS PE BKDocument3 pagesLine Item 18 To 24 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F D MTA SS PE BKSadiqNo ratings yet

- JCV4-65B-R6: General SpecificationsDocument5 pagesJCV4-65B-R6: General Specificationsalbertho12No ratings yet

- Optical Patch Cables Data Sheet by JTOPTICSDocument8 pagesOptical Patch Cables Data Sheet by JTOPTICSJayani Technologies LtdNo ratings yet

- A2F-FF: CMP Products Cable Gland CatalogueDocument1 pageA2F-FF: CMP Products Cable Gland CataloguePaulo CostaNo ratings yet

- 6 Fiber Multi Tube Fiber Optic Cable 2120006Document1 page6 Fiber Multi Tube Fiber Optic Cable 2120006Diego ValenteNo ratings yet

- CAT6 PVC-U-UTP CableDocument2 pagesCAT6 PVC-U-UTP CableMahmoud MetwallyNo ratings yet

- FLR4G11Y-FL4G11Y CablesDocument1 pageFLR4G11Y-FL4G11Y CablesVijay KarthikeyanNo ratings yet

- L2B2AT-Canare Corp. - Two-Conductor Shielded Cables - Two-Conductor Shielded Cables (Single) Aluminum Foil Shield (L-2B2AT)Document3 pagesL2B2AT-Canare Corp. - Two-Conductor Shielded Cables - Two-Conductor Shielded Cables (Single) Aluminum Foil Shield (L-2B2AT)Antonius Patra100% (1)

- Pararrayos Tipo BalestroDocument3 pagesPararrayos Tipo BalestroBladimir Michel100% (1)

- E14F05P03 Product SpecificationsDocument4 pagesE14F05P03 Product SpecificationsVasile IonNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- Patchcord Fo SM G652D KhomaxDocument2 pagesPatchcord Fo SM G652D KhomaxGuillermo MurrielNo ratings yet

- Cable GlandDocument1 pageCable GlandAntonio EnaguasNo ratings yet

- Andrew Csh-6516a-VtDocument3 pagesAndrew Csh-6516a-VtLeo DuranNo ratings yet

- Instrumentation Cable Gen. To EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable Gen. To EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- NKL F Xxxyytg 02b BK - en - Pe - v20200413Document2 pagesNKL F Xxxyytg 02b BK - en - Pe - v20200413Mervin YeoNo ratings yet

- PG 00332 HK1819 UNITRONIC BUS PBDocument1 pagePG 00332 HK1819 UNITRONIC BUS PBClifford BaangNo ratings yet

- DBXCP 4545a VTM PDFDocument4 pagesDBXCP 4545a VTM PDFRolando TupizaNo ratings yet

- Seacon Catalog - Hummer ConnectorDocument8 pagesSeacon Catalog - Hummer ConnectorBruno SallesNo ratings yet

- Line Item 11 To 17 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F Duct MTUA SS PE BKDocument3 pagesLine Item 11 To 17 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F Duct MTUA SS PE BKSadiqNo ratings yet

- Product Specifications Product Specifications: DB408 DB408 - BBDocument2 pagesProduct Specifications Product Specifications: DB408 DB408 - BBCesar LopezNo ratings yet

- Andrew 932DG65Т6EKLDocument3 pagesAndrew 932DG65Т6EKLКазьмин ОлегNo ratings yet

- HBX 3319DS VTM PDFDocument3 pagesHBX 3319DS VTM PDFcesarbayonaNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- 15KW On Grid Roof Top HP STATIONDocument7 pages15KW On Grid Roof Top HP STATIONAjayNo ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- EUPEN A-2Y2YB2Y DB AG 4160113 Ed 06 2017-05-17Document1 pageEUPEN A-2Y2YB2Y DB AG 4160113 Ed 06 2017-05-17Songkunhua SongNo ratings yet

- The Alto Photofission Facility at IPN Orsay: Serge FranchooDocument29 pagesThe Alto Photofission Facility at IPN Orsay: Serge FranchooAnnie SegoviaNo ratings yet

- Product Specifications Product Specifications: MBLHH MBLHH - 65C 65C - VTM VTMDocument2 pagesProduct Specifications Product Specifications: MBLHH MBLHH - 65C 65C - VTM VTMSpam SpamNo ratings yet

- EUPEN AJ-2Y2YDB2Y DB AG 4160113 Ed 07 2022-06-27Document1 pageEUPEN AJ-2Y2YDB2Y DB AG 4160113 Ed 07 2022-06-27Songkunhua SongNo ratings yet

- Catalog Leoni CableDocument2 pagesCatalog Leoni CablesubodhNo ratings yet

- Freedm One Tight-Buffered, Interlocking Armored Cable, RiserDocument3 pagesFreedm One Tight-Buffered, Interlocking Armored Cable, RiserFranklin CabreraNo ratings yet

- RG 58LL Co-Axial CableDocument1 pageRG 58LL Co-Axial CableKristaNo ratings yet

- Belden P/N 50106F: Industrial CAT 6 F/UTPDocument2 pagesBelden P/N 50106F: Industrial CAT 6 F/UTPAsep heriyanaNo ratings yet

- Multicore Armoured Shaped Conductor - XLPE InsulatedDocument1 pageMulticore Armoured Shaped Conductor - XLPE InsulatedMohamed InshafNo ratings yet

- V4-65D-R4-V2: General SpecificationsDocument5 pagesV4-65D-R4-V2: General SpecificationsFernando Cuestas RamirezNo ratings yet

- Db854dg65esy PDFDocument3 pagesDb854dg65esy PDFfaapctbaNo ratings yet

- Andrew COMMSCOPE CSH-6516A-VTDocument2 pagesAndrew COMMSCOPE CSH-6516A-VThasib_muhammedNo ratings yet

- Antenna Commscope CSH 6516A VTDocument2 pagesAntenna Commscope CSH 6516A VTvohoangphuNo ratings yet

- GTP 185Document3 pagesGTP 185er.manishnhpcNo ratings yet

- Cable Siemon-SFTP CAT7A PDFDocument2 pagesCable Siemon-SFTP CAT7A PDFRenzo GuizadoNo ratings yet

- 932qlg65vteb PDFDocument4 pages932qlg65vteb PDFMariaNo ratings yet

- Flexible Budgets and Performance AnalysisDocument37 pagesFlexible Budgets and Performance AnalysisSana IjazNo ratings yet

- Second Analysis of DaffodilsDocument2 pagesSecond Analysis of DaffodilsSimone CagnazzoNo ratings yet

- BonofideDocument1 pageBonofideQusai KHNo ratings yet

- Performance and Design Analysis of Domestic LPG StoveDocument73 pagesPerformance and Design Analysis of Domestic LPG StoveRupali Patil100% (1)

- Lecture 2.2 Merge Sort AlgorithmsDocument59 pagesLecture 2.2 Merge Sort AlgorithmsPablo ChanNo ratings yet

- Handheld Air Particle Counter MET ONE HHPC+ Series BrochureDocument4 pagesHandheld Air Particle Counter MET ONE HHPC+ Series BrochureFirdaus ZaidNo ratings yet

- Subject Grade Boundaries - June 2019 Exams Oxfordaqa International GcseDocument3 pagesSubject Grade Boundaries - June 2019 Exams Oxfordaqa International GcseHala ShetaNo ratings yet

- League of Legends - Summoners Call - FullScoreDocument28 pagesLeague of Legends - Summoners Call - FullScoreNghi RòmNo ratings yet

- Business Studies RevisionDocument2 pagesBusiness Studies RevisionSwapnil NaskarNo ratings yet

- Paper1 1Document119 pagesPaper1 1Damián VillegasNo ratings yet

- Validation and Dissoiution Enhacement of Loratadine and Desloratadine Tablets by Various Spctrophotometric MethodsDocument40 pagesValidation and Dissoiution Enhacement of Loratadine and Desloratadine Tablets by Various Spctrophotometric MethodsDr. Vishal BabarNo ratings yet

- Megaman PatternDocument9 pagesMegaman PatternBelen Solis Maravillas100% (2)

- 3M CatalogueDocument32 pages3M Cataloguefandi.azs37No ratings yet

- Exercise Questions On Regular Language and Regular ExpressionDocument56 pagesExercise Questions On Regular Language and Regular ExpressionAnonymous t1W5G4UZw100% (1)

- Toyota Vios Manual Book DownloadDocument24 pagesToyota Vios Manual Book DownloadVidi EfendiNo ratings yet

- Volume 69 PDFDocument84 pagesVolume 69 PDFShobit Sharma100% (3)

- Report RUSADocument16 pagesReport RUSApawan kumar100% (1)

- UPDATE YANG BELUM Mengerjakan Sertifikasi TCO Maret Update 0804 Jam 08.00 WIBDocument2 pagesUPDATE YANG BELUM Mengerjakan Sertifikasi TCO Maret Update 0804 Jam 08.00 WIBWendi ArtheaNo ratings yet

- Chap 4 Research Method and Technical WritingDocument33 pagesChap 4 Research Method and Technical WritingEndalkchew FentahunNo ratings yet

- DSP 6 - FIR Filter DesignDocument23 pagesDSP 6 - FIR Filter DesignJehan Zeb BhattiNo ratings yet

- Microcatchment: NegarimDocument11 pagesMicrocatchment: Negarimhaithamelramlawi7503100% (1)

- MA REV 1 Finals Dec 2017Document33 pagesMA REV 1 Finals Dec 2017Dale PonceNo ratings yet

- Linux PracticalDocument18 pagesLinux PracticalAnonymous x6UDQVBHawNo ratings yet

- Cloud Computing in Distributed System IJERTV1IS10199Document8 pagesCloud Computing in Distributed System IJERTV1IS10199Nebula OriomNo ratings yet

- Metaphor AgerosegelelectroforeseDocument2 pagesMetaphor AgerosegelelectroforeseSuus.veluwenkampNo ratings yet

- ML Lab Manual-2019Document85 pagesML Lab Manual-2019ManjulaNo ratings yet

- Case Study: Pizza Delivered Quickly (PDQ)Document3 pagesCase Study: Pizza Delivered Quickly (PDQ)Jose Abanto GozalvezNo ratings yet

- 1 FffffanyDocument1 page1 FffffanyLuis SolisNo ratings yet

- Abs v. NTCDocument2 pagesAbs v. NTCLadyfirst SMNo ratings yet

- Roof Mounted Fans HCTB - HCTT Series, Axial Flow Fans: Applications Description Air ExtractionDocument9 pagesRoof Mounted Fans HCTB - HCTT Series, Axial Flow Fans: Applications Description Air ExtractionmarckalhiNo ratings yet