Professional Documents

Culture Documents

Eccoh Xls Cat Tds01 2017-05

Eccoh Xls Cat Tds01 2017-05

Uploaded by

Moni ParadaCopyright:

Available Formats

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Datasheet PA66 TT6600-5001 EC GreyDocument2 pagesDatasheet PA66 TT6600-5001 EC GreySeahawk76No ratings yet

- Spirapak 4033 HFM 183 VPP Uf DatasheetDocument2 pagesSpirapak 4033 HFM 183 VPP Uf DatasheetJohnNo ratings yet

- Cardolite Ultra LITE 2009: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite Ultra LITE 2009: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Ficha Tecnica - TUBO PEAD v1.2 ANEXODocument2 pagesFicha Tecnica - TUBO PEAD v1.2 ANEXOhenrivsNo ratings yet

- PETRONAS Syntium 7000 0W-20 SN PLUSDocument2 pagesPETRONAS Syntium 7000 0W-20 SN PLUSMujeeb SiddiqueNo ratings yet

- VpCI 368Document2 pagesVpCI 368Jenelyn CastilloNo ratings yet

- Flow Check™ MicroparticlesDocument1 pageFlow Check™ Microparticlesliang102009No ratings yet

- Taylor QAC and Polyquat Test KitsDocument2 pagesTaylor QAC and Polyquat Test KitsSidik PamungkasNo ratings yet

- Stork - Composite Repair Solutions - Ebinder April 2014Document158 pagesStork - Composite Repair Solutions - Ebinder April 2014Paul StuttNo ratings yet

- IDEAL Networks Network Tester Selection GuideDocument2 pagesIDEAL Networks Network Tester Selection GuideSergio ChicNo ratings yet

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzeNo ratings yet

- Eci 1010 Ec-EnDocument2 pagesEci 1010 Ec-EnPRATIKPATELNo ratings yet

- Kjeltec 8000 Solution Brochure GB PDFDocument10 pagesKjeltec 8000 Solution Brochure GB PDFFeridaNo ratings yet

- GI EMEAI Sell Sheet ECOATDocument4 pagesGI EMEAI Sell Sheet ECOATSy Nguyen VietNo ratings yet

- H5211PCDocument2 pagesH5211PCFranco Antonio Callejas CalleNo ratings yet

- Alpha Telecore Plus WRC TB SM416-13 English 20180126Document4 pagesAlpha Telecore Plus WRC TB SM416-13 English 20180126raghulramasamyNo ratings yet

- High Performance Valve Materials (HPVM) (Agreement 16304) : Title SlideDocument13 pagesHigh Performance Valve Materials (HPVM) (Agreement 16304) : Title SlidesvijayNo ratings yet

- Parylene Coatings For Enhanced Reliability of Electronics - Semicon Taiwan 2011Document49 pagesParylene Coatings For Enhanced Reliability of Electronics - Semicon Taiwan 2011denghuei100% (1)

- Catalog Expansion Joints For The Food and Beverage IndustryDocument16 pagesCatalog Expansion Joints For The Food and Beverage IndustrySiampol FeepakphorNo ratings yet

- Affirma In-Service Lubricant FTIR Analysis - Sales TrainingDocument33 pagesAffirma In-Service Lubricant FTIR Analysis - Sales TrainingMiguel Aurelio HernándezNo ratings yet

- Delo® Gold MultigradeDocument2 pagesDelo® Gold MultigradeAymanSayedElantableeNo ratings yet

- A541-Ccag Aoc Eco TekDocument2 pagesA541-Ccag Aoc Eco TekHemmingsNo ratings yet

- Vulcan XC68 Conductive Carbon BlackDocument2 pagesVulcan XC68 Conductive Carbon BlackBandana DholeNo ratings yet

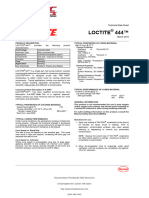

- HMC Loctite 444Document2 pagesHMC Loctite 444sengottNo ratings yet

- 186 Soldering Flux Data SheetDocument2 pages186 Soldering Flux Data SheetBéla BődiNo ratings yet

- Taylor QAC and Polyquat Test Kits BrochureDocument2 pagesTaylor QAC and Polyquat Test Kits BrochurePablo MéndezNo ratings yet

- Exceed 0015XCDocument2 pagesExceed 0015XCzhen liuNo ratings yet

- Lite 3060 - TdsDocument2 pagesLite 3060 - TdsJuan Sebastián Fernández RamírezNo ratings yet

- Cardolite NX-2007: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite NX-2007: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Kjeltec™ 8000 Kjeldahl Distillation Solutions For Food and FeedDocument9 pagesKjeltec™ 8000 Kjeldahl Distillation Solutions For Food and FeedvetbcasNo ratings yet

- Single End Roving For Knitting, Weaving, and Filament WindingDocument2 pagesSingle End Roving For Knitting, Weaving, and Filament WindingSofya AndarinaNo ratings yet

- Csge1508 04Document28 pagesCsge1508 04rahmat hidayatNo ratings yet

- PDS En-G0 20220126Document2 pagesPDS En-G0 20220126HectorNo ratings yet

- Binder Systems For: Vehicle Refinishing CoatingsDocument4 pagesBinder Systems For: Vehicle Refinishing CoatingsMaxiliano MACKEVICIUSNo ratings yet

- Wipro Tarang Brochure 03.2018Document12 pagesWipro Tarang Brochure 03.2018Abishek AbhNo ratings yet

- Electrical & Electronics Applications: Epotec Epoxy SystemsDocument2 pagesElectrical & Electronics Applications: Epotec Epoxy SystemsAditya ShrivastavaNo ratings yet

- Tyfo UC StripsDocument2 pagesTyfo UC Stripsyusak santosoNo ratings yet

- PDF 1Document23 pagesPDF 1Hyujeii MceNo ratings yet

- Cables and Wires CatalogueDocument16 pagesCables and Wires CatalogueVENITHA KNo ratings yet

- Everslik - 1201 TDSDocument2 pagesEverslik - 1201 TDShvdb72100% (1)

- H70EDocument2 pagesH70ENaveenNo ratings yet

- Sikaflex®-221: Product Data SheetDocument2 pagesSikaflex®-221: Product Data SheetNurdin YusupNo ratings yet

- JTBaker Solid Phase ExtractionDocument16 pagesJTBaker Solid Phase Extractionerminb1525No ratings yet

- ESR-3899 TaktlDocument6 pagesESR-3899 TaktlVirendra ChavdaNo ratings yet

- Parker icountBSplus - WG Data SheetDocument2 pagesParker icountBSplus - WG Data SheetfarahNo ratings yet

- Treat: Koch 275 AntiscalantDocument2 pagesTreat: Koch 275 Antiscalantdalton2004No ratings yet

- Semi-Circular Bend (SCB) Jigs: AccessoriesDocument2 pagesSemi-Circular Bend (SCB) Jigs: AccessoriesFaber VillaNo ratings yet

- Brochure FerroviaireDocument48 pagesBrochure FerroviairetahaNo ratings yet

- Bpxe 9Q932NDocument2 pagesBpxe 9Q932NArthur Sanda LayukNo ratings yet

- Texamatic 1888: Automatic Transmission & Power Steering FluidDocument2 pagesTexamatic 1888: Automatic Transmission & Power Steering Fluidhoussem houssemNo ratings yet

- Inclined Drop TesterDocument23 pagesInclined Drop TesterDeepak BhanjiNo ratings yet

- ISeries BrochureDocument24 pagesISeries Brochuredavegrohl127No ratings yet

- Optiflash PM A4 LRDocument4 pagesOptiflash PM A4 LRalinealmuzainiNo ratings yet

- Vistalon 6602Document1 pageVistalon 6602ANo ratings yet

- ENG DS 2363319-1 Seacon 75ohm 0220Document2 pagesENG DS 2363319-1 Seacon 75ohm 0220ZorbanfrNo ratings yet

- Spec Sheet Pegasus BT 4DDocument2 pagesSpec Sheet Pegasus BT 4DWempic Aulia FauziNo ratings yet

- SMART Q Flyer Plastics Industry B147Document2 pagesSMART Q Flyer Plastics Industry B147SurgimedikNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Automated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionFrom EverandAutomated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionNo ratings yet

Eccoh Xls Cat Tds01 2017-05

Eccoh Xls Cat Tds01 2017-05

Uploaded by

Moni ParadaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eccoh Xls Cat Tds01 2017-05

Eccoh Xls Cat Tds01 2017-05

Uploaded by

Moni ParadaCopyright:

Available Formats

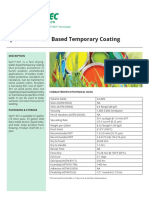

Technical Data sheet edition 01, 2017-05

ECCOH™ XLS CAT

Product Description

ECCOHTM XLS CAT refers to a catalyst compound specially designed to be added to

ECCOHTM XLS grafted solutions.

Several grades of the curing catalyst are available. The selection of the catalyst grade will depend

upon the available extrusion equipment and the required curing performance. Please contact

PolyOne Technical Support for the appropriate recommendation.

General

Material Status Commercial Active

Regional Availability • Africa & Middle East • North America

• Asia Pacific • South America

• Europe

Features • Accelerates crosslinking rate of ECCOH™ XLS

• CAT 001: standard reactivity

• CAT 005: stronger reactivity

Uses Wire&Cable

Forms Pellets

Technical Properties

Density, 23°C Typical Value(Imperial) Typical Value (SI) Test Method

3 3

CAT 001 0.917 g/cm 0.917 g/cm ISO 1183-1 (ASTM D792)

CAT 005 0.916 g/cm3 0.916 g/cm3

MFR, 190°C 2.16kg Typical Value(Imperial) Typical Value (SI) Test Method

CAT 001 6-9 g/10min 6-9 g/10min ISO 1133 (b)

CAT 005 7-10 g/10min 7-10 g/10min

These properties were measured once within PolyOne laboratory. However, it is mandatory that customers should conduct their own

evaluations to ensure any compliance on cable. Data are typical values and must not to be construed as specification limits.

Pre-Drying

ECCOHTM XLS CAT must not be predried. The aluminium foil lined bags should be kept field until usage.

Shelf life

ECCOH™XLS solutions are supplied in aluminium foil lined bags or octa-boxes and, based upon experience, this

ensures a shelf life of 6 months - providing the bag has not been opened and the material has been kept in a cool

(0°C < Temp. < 25°C) dry environment.

PolyOne advises customers to conduct a full homologation program on their final cable construction to

confirm acceptability.

CONTACT INFORMATION

Americas ASIA Europe

U.S. – Avon Lake, Ohio China – Shanghai Belgium – Assesse

+1 440 930 1000 +86 (0) 21 5080 1188 +32 (0) 830 660 211

Brasil – Campinas India – Mumbai

+55 19 3206 0561 +91 22 2564 0750

+91 9820 194 220

Copyright © 2014, PolyOne Corporation. PolyOne makes no representations, guarantees, or warranties of any kind with respect to the Information contained in this

document about its accuracy, suitability for particular applications, or the results obtained or obtainable using the information. Some of the Information arises from 1/1

laboratory work with small-scale equipment which may not provide a reliable indication of performance or properties obtained or obtainable on larger-scale equipment.

Values reported as “typical” or stated without a range do not state minimum or maximum properties; consult your sales representative for property ranges and

min/max specifications. Processing conditions can cause material properties to shift from the values stated in the Information. PolyOne makes no warranties or

guarantees respecting suitability of either PolyOne’s products or the Information for your process or end-use application. You have the responsibility to conduct full-

scale end-product performance testing to determine suitability in your application, and you assume all risk and liability arising from your use of the Information and/or

use or handling of any product. POLYONE MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, either with respect to the Information or products reflected by the Information. This data sheet

shall NOT operate as permission, recommendation, or inducement to practice any patented invention without permission of the patent owner.

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Datasheet PA66 TT6600-5001 EC GreyDocument2 pagesDatasheet PA66 TT6600-5001 EC GreySeahawk76No ratings yet

- Spirapak 4033 HFM 183 VPP Uf DatasheetDocument2 pagesSpirapak 4033 HFM 183 VPP Uf DatasheetJohnNo ratings yet

- Cardolite Ultra LITE 2009: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite Ultra LITE 2009: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Ficha Tecnica - TUBO PEAD v1.2 ANEXODocument2 pagesFicha Tecnica - TUBO PEAD v1.2 ANEXOhenrivsNo ratings yet

- PETRONAS Syntium 7000 0W-20 SN PLUSDocument2 pagesPETRONAS Syntium 7000 0W-20 SN PLUSMujeeb SiddiqueNo ratings yet

- VpCI 368Document2 pagesVpCI 368Jenelyn CastilloNo ratings yet

- Flow Check™ MicroparticlesDocument1 pageFlow Check™ Microparticlesliang102009No ratings yet

- Taylor QAC and Polyquat Test KitsDocument2 pagesTaylor QAC and Polyquat Test KitsSidik PamungkasNo ratings yet

- Stork - Composite Repair Solutions - Ebinder April 2014Document158 pagesStork - Composite Repair Solutions - Ebinder April 2014Paul StuttNo ratings yet

- IDEAL Networks Network Tester Selection GuideDocument2 pagesIDEAL Networks Network Tester Selection GuideSergio ChicNo ratings yet

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzeNo ratings yet

- Eci 1010 Ec-EnDocument2 pagesEci 1010 Ec-EnPRATIKPATELNo ratings yet

- Kjeltec 8000 Solution Brochure GB PDFDocument10 pagesKjeltec 8000 Solution Brochure GB PDFFeridaNo ratings yet

- GI EMEAI Sell Sheet ECOATDocument4 pagesGI EMEAI Sell Sheet ECOATSy Nguyen VietNo ratings yet

- H5211PCDocument2 pagesH5211PCFranco Antonio Callejas CalleNo ratings yet

- Alpha Telecore Plus WRC TB SM416-13 English 20180126Document4 pagesAlpha Telecore Plus WRC TB SM416-13 English 20180126raghulramasamyNo ratings yet

- High Performance Valve Materials (HPVM) (Agreement 16304) : Title SlideDocument13 pagesHigh Performance Valve Materials (HPVM) (Agreement 16304) : Title SlidesvijayNo ratings yet

- Parylene Coatings For Enhanced Reliability of Electronics - Semicon Taiwan 2011Document49 pagesParylene Coatings For Enhanced Reliability of Electronics - Semicon Taiwan 2011denghuei100% (1)

- Catalog Expansion Joints For The Food and Beverage IndustryDocument16 pagesCatalog Expansion Joints For The Food and Beverage IndustrySiampol FeepakphorNo ratings yet

- Affirma In-Service Lubricant FTIR Analysis - Sales TrainingDocument33 pagesAffirma In-Service Lubricant FTIR Analysis - Sales TrainingMiguel Aurelio HernándezNo ratings yet

- Delo® Gold MultigradeDocument2 pagesDelo® Gold MultigradeAymanSayedElantableeNo ratings yet

- A541-Ccag Aoc Eco TekDocument2 pagesA541-Ccag Aoc Eco TekHemmingsNo ratings yet

- Vulcan XC68 Conductive Carbon BlackDocument2 pagesVulcan XC68 Conductive Carbon BlackBandana DholeNo ratings yet

- HMC Loctite 444Document2 pagesHMC Loctite 444sengottNo ratings yet

- 186 Soldering Flux Data SheetDocument2 pages186 Soldering Flux Data SheetBéla BődiNo ratings yet

- Taylor QAC and Polyquat Test Kits BrochureDocument2 pagesTaylor QAC and Polyquat Test Kits BrochurePablo MéndezNo ratings yet

- Exceed 0015XCDocument2 pagesExceed 0015XCzhen liuNo ratings yet

- Lite 3060 - TdsDocument2 pagesLite 3060 - TdsJuan Sebastián Fernández RamírezNo ratings yet

- Cardolite NX-2007: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite NX-2007: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Kjeltec™ 8000 Kjeldahl Distillation Solutions For Food and FeedDocument9 pagesKjeltec™ 8000 Kjeldahl Distillation Solutions For Food and FeedvetbcasNo ratings yet

- Single End Roving For Knitting, Weaving, and Filament WindingDocument2 pagesSingle End Roving For Knitting, Weaving, and Filament WindingSofya AndarinaNo ratings yet

- Csge1508 04Document28 pagesCsge1508 04rahmat hidayatNo ratings yet

- PDS En-G0 20220126Document2 pagesPDS En-G0 20220126HectorNo ratings yet

- Binder Systems For: Vehicle Refinishing CoatingsDocument4 pagesBinder Systems For: Vehicle Refinishing CoatingsMaxiliano MACKEVICIUSNo ratings yet

- Wipro Tarang Brochure 03.2018Document12 pagesWipro Tarang Brochure 03.2018Abishek AbhNo ratings yet

- Electrical & Electronics Applications: Epotec Epoxy SystemsDocument2 pagesElectrical & Electronics Applications: Epotec Epoxy SystemsAditya ShrivastavaNo ratings yet

- Tyfo UC StripsDocument2 pagesTyfo UC Stripsyusak santosoNo ratings yet

- PDF 1Document23 pagesPDF 1Hyujeii MceNo ratings yet

- Cables and Wires CatalogueDocument16 pagesCables and Wires CatalogueVENITHA KNo ratings yet

- Everslik - 1201 TDSDocument2 pagesEverslik - 1201 TDShvdb72100% (1)

- H70EDocument2 pagesH70ENaveenNo ratings yet

- Sikaflex®-221: Product Data SheetDocument2 pagesSikaflex®-221: Product Data SheetNurdin YusupNo ratings yet

- JTBaker Solid Phase ExtractionDocument16 pagesJTBaker Solid Phase Extractionerminb1525No ratings yet

- ESR-3899 TaktlDocument6 pagesESR-3899 TaktlVirendra ChavdaNo ratings yet

- Parker icountBSplus - WG Data SheetDocument2 pagesParker icountBSplus - WG Data SheetfarahNo ratings yet

- Treat: Koch 275 AntiscalantDocument2 pagesTreat: Koch 275 Antiscalantdalton2004No ratings yet

- Semi-Circular Bend (SCB) Jigs: AccessoriesDocument2 pagesSemi-Circular Bend (SCB) Jigs: AccessoriesFaber VillaNo ratings yet

- Brochure FerroviaireDocument48 pagesBrochure FerroviairetahaNo ratings yet

- Bpxe 9Q932NDocument2 pagesBpxe 9Q932NArthur Sanda LayukNo ratings yet

- Texamatic 1888: Automatic Transmission & Power Steering FluidDocument2 pagesTexamatic 1888: Automatic Transmission & Power Steering Fluidhoussem houssemNo ratings yet

- Inclined Drop TesterDocument23 pagesInclined Drop TesterDeepak BhanjiNo ratings yet

- ISeries BrochureDocument24 pagesISeries Brochuredavegrohl127No ratings yet

- Optiflash PM A4 LRDocument4 pagesOptiflash PM A4 LRalinealmuzainiNo ratings yet

- Vistalon 6602Document1 pageVistalon 6602ANo ratings yet

- ENG DS 2363319-1 Seacon 75ohm 0220Document2 pagesENG DS 2363319-1 Seacon 75ohm 0220ZorbanfrNo ratings yet

- Spec Sheet Pegasus BT 4DDocument2 pagesSpec Sheet Pegasus BT 4DWempic Aulia FauziNo ratings yet

- SMART Q Flyer Plastics Industry B147Document2 pagesSMART Q Flyer Plastics Industry B147SurgimedikNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Automated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionFrom EverandAutomated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionNo ratings yet