Professional Documents

Culture Documents

Lapox AC14 PDF

Lapox AC14 PDF

Uploaded by

Osama GabrCopyright:

Available Formats

You might also like

- Adcote76P1 38TDS PDFDocument3 pagesAdcote76P1 38TDS PDFLaury Suarez BayonaNo ratings yet

- Lapox AC-14: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox AC-14: Technical Data Sheet - Polymers Businesssriatul2006No ratings yet

- Lapox ARF 11Document2 pagesLapox ARF 11Osama GabrNo ratings yet

- Lapox AR-101: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox AR-101: Technical Data Sheet - Polymers Businesssriatul2006No ratings yet

- Lapox K-540: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox K-540: Technical Data Sheet - Polymers BusinessAMIT HALDERNo ratings yet

- Lapox B-11: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox B-11: Technical Data Sheet - Polymers Businessankitmohanty01No ratings yet

- Palox 42KDocument2 pagesPalox 42KSam WitwickyNo ratings yet

- Lapox ARPN 36 X80 PDFDocument2 pagesLapox ARPN 36 X80 PDFOsama GabrNo ratings yet

- Lapox ARPN-25: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox ARPN-25: Technical Data Sheet - Polymers Businesssriatul2006No ratings yet

- PO - Lapox P 62Document2 pagesPO - Lapox P 62alpesh.samruddhigroupNo ratings yet

- Lapox AR-101 PDFDocument2 pagesLapox AR-101 PDFOsama GabrNo ratings yet

- Spec Data Sheet: Metalex Red Oxide Metal PrimerDocument2 pagesSpec Data Sheet: Metalex Red Oxide Metal Primerjustin trochezNo ratings yet

- Lapox ARD-13 PDFDocument2 pagesLapox ARD-13 PDFOsama GabrNo ratings yet

- PO - Polygrip SP 809Document2 pagesPO - Polygrip SP 809gulam safiNo ratings yet

- Adhesive PDS & MSDS PDFDocument25 pagesAdhesive PDS & MSDS PDFsmartayaz1987No ratings yet

- Adalin 4797-UndetailedDocument3 pagesAdalin 4797-UndetailedMuhammad Aasim HassanNo ratings yet

- Synocure 7715 S 60Document2 pagesSynocure 7715 S 60Şebnem İlarslanNo ratings yet

- RF-9801 Lamination Adhesive For Soft PackageDocument4 pagesRF-9801 Lamination Adhesive For Soft PackageWasif AzimNo ratings yet

- Altamix-P200 KG PDFDocument1 pageAltamix-P200 KG PDFZeeshan AhmadNo ratings yet

- Technical Information: TMS - VHPDocument1 pageTechnical Information: TMS - VHPVictor CastrejonNo ratings yet

- TDS Dsa-380Document3 pagesTDS Dsa-380A MahmoodNo ratings yet

- Acrodur DS 3530 February 2018 R3 EDFDocument3 pagesAcrodur DS 3530 February 2018 R3 EDFAllen de RichardNo ratings yet

- Sylobead® Ms 512: Product DescriptionDocument5 pagesSylobead® Ms 512: Product Descriptionyohan pramonoNo ratings yet

- Silica Fume 92% Technical Data Sheet: Description Physical PropertiesDocument1 pageSilica Fume 92% Technical Data Sheet: Description Physical PropertiesDileepa DissanayakeNo ratings yet

- Lotader: Ethylene - Acrylic Ester - Maleic Anhydride TerpolymerDocument2 pagesLotader: Ethylene - Acrylic Ester - Maleic Anhydride TerpolymerLe MinhNo ratings yet

- Da 128Document1 pageDa 128chayanunNo ratings yet

- ALBATEX AD - Protective ColloidDocument5 pagesALBATEX AD - Protective Colloid郭哲宏0% (1)

- DermaDamp HDDocument2 pagesDermaDamp HDJacob Norman CruzNo ratings yet

- HD Ar-Afff Foam Concentrate: Alcohol Resistant Aqueous Film Forming Foam Concentrate (Arafff) CompatibilityDocument3 pagesHD Ar-Afff Foam Concentrate: Alcohol Resistant Aqueous Film Forming Foam Concentrate (Arafff) CompatibilityDHAVAL PANCHALNo ratings yet

- SikagardPatioGloss en (11 2018) 1Document2 pagesSikagardPatioGloss en (11 2018) 1Andrei GheoNo ratings yet

- Tds - Emaco r307Document2 pagesTds - Emaco r307Venkata RaoNo ratings yet

- Technical Information: Sodium Antimonate-EDocument1 pageTechnical Information: Sodium Antimonate-EVictor CastrejonNo ratings yet

- Elastosil Aux G 3243Document4 pagesElastosil Aux G 3243KeremNo ratings yet

- SDS Sarafil Polyester Film 2023Document4 pagesSDS Sarafil Polyester Film 2023Chiaranan KerdsamutNo ratings yet

- Anti Carbonation PaintDocument4 pagesAnti Carbonation Paintptk94287No ratings yet

- Msds - Unitrade Capital Solution Sdn. Bhd.Document5 pagesMsds - Unitrade Capital Solution Sdn. Bhd.lou janeNo ratings yet

- MesamollDocument3 pagesMesamollKiên PhùngNo ratings yet

- PolybitpolyprimeDocument2 pagesPolybitpolyprimerazeeth1212No ratings yet

- TDS - TERRAWET Primer G 9 - 733 Inline - 060 - enDocument2 pagesTDS - TERRAWET Primer G 9 - 733 Inline - 060 - enJavier Martinez CañalNo ratings yet

- Jointing Compound Datasheet - Third Edition3.1 - 13apr20 1Document4 pagesJointing Compound Datasheet - Third Edition3.1 - 13apr20 1Allan ManumbasNo ratings yet

- All Alçi Derz Dolgu AlçisiDocument3 pagesAll Alçi Derz Dolgu AlçisiAgit SipkaNo ratings yet

- All Alçi Saten Perdah AlçisiDocument3 pagesAll Alçi Saten Perdah AlçisiAgit SipkaNo ratings yet

- Tds Dep 330nDocument3 pagesTds Dep 330nA MahmoodNo ratings yet

- MSDS Kan HB Epoxy LinerDocument6 pagesMSDS Kan HB Epoxy LinerHafiza UlfatNo ratings yet

- Ap 13Document2 pagesAp 13Muhammad AHSAN ISHAQNo ratings yet

- TDS - Encor 2750 - 01-12Document2 pagesTDS - Encor 2750 - 01-12APEX SONNo ratings yet

- MSDS Gandar 800XDocument4 pagesMSDS Gandar 800XSukmaNo ratings yet

- TDS iPolySpl FR White 1136Document2 pagesTDS iPolySpl FR White 1136Popular videos Pinkal Sparsh ShailajaNo ratings yet

- Acrilem ST190: Product DescriptionDocument2 pagesAcrilem ST190: Product DescriptionMachidon OanaNo ratings yet

- BI - Resoform P18Document2 pagesBI - Resoform P18MehulNo ratings yet

- ADCOTE™ 76P1-38: Laminating AdhesiveDocument3 pagesADCOTE™ 76P1-38: Laminating AdhesiveLaury Suarez BayonaNo ratings yet

- Adcote76P1 38TDS PDFDocument3 pagesAdcote76P1 38TDS PDFLaury Suarez BayonaNo ratings yet

- Hyperdesmo®-Ady 610 - enDocument3 pagesHyperdesmo®-Ady 610 - enMajd M. KhalilNo ratings yet

- TDS Hostapur OS LiqDocument2 pagesTDS Hostapur OS LiqRabah ABBASNo ratings yet

- Lapox AH 713 PDFDocument2 pagesLapox AH 713 PDFOsama GabrNo ratings yet

- 380 TDSDocument1 page380 TDSrishibindra55555No ratings yet

- Lite 3060 - TdsDocument2 pagesLite 3060 - TdsJuan Sebastián Fernández RamírezNo ratings yet

- Adalin KDocument3 pagesAdalin KAziz100% (1)

Lapox AC14 PDF

Lapox AC14 PDF

Uploaded by

Osama GabrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lapox AC14 PDF

Lapox AC14 PDF

Uploaded by

Osama GabrCopyright:

Available Formats

LAPOX® AC-14

Technical Data Sheet | Polymers Business

Description Lapox AC-14 is a chemically 2,4,6-tris(dimethyl aminomethyl) phenol. It is tertiary amine

accelerator recommended to use along with other curing agents like polyamidoamides,

amine adducts, mercaptans and anhydrides to increase cure speed. It improves cure of

thin film and facilitate complete cure. The amount of Lapox AC-14 to be added into

hardener depends on the speed of cure required.

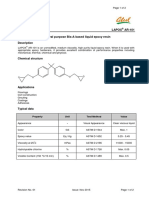

Chemical structure

Advantages Faster drying of films

Increases cure speed

Light colour

Applications Adhesives and sealants

Paints

Protective coatings

Typical specifications Properties Unit Test method Values

Appearance - Visual Clear, yellow liquid

Colour GS ASTM D1544 Max 6

Amine value mg KOH/g ASTM D2073 580 - 635

Viscosity at 25°C m Pas ASTM D2196 150 - 300

Recommended dosage w/w - 0.5 - 10

Packaging Lapox AC-14 is available in 200 kg MS | HDPE drums and 1,000 kg IBC. Other packing

may be considered on request.

Storage and handling Lapox AC-14 should be stored in a cool and dry place, preferably in a sealed container and

should not be exposed to direct sunlight. This product has a shelf-life of 1 year, if stored in

its original container between 18°C and 25°C away from humidity and excessive heat.

Please refer to the Safety Data Sheet (SDS) for detailed instructions on storage and

handling.

Safety Wear personal protective equipment (PPE). Avoid contact with the eyes and skin. In case

of direct contact and irritation, the resin should be washed off immediately with soap and

warm water. Avoid breathing vapours, mist or gas. Please refer to the SDS for detailed

safety instructions.

February 2018 Page 1 of 2

LAPOX® AC-14

Technical Data Sheet | Polymers Business

Spills and disposal In case of spills, sweep up and shovel the spilled material. Keep spilled material in suitable,

closed containers for disposal. Soak up with an absorbent such as clay, sand or other

suitable material. Flush area with water to remove trace residue. Do not allow the product

to reach the sewage system. Waste must be disposed of in accordance with federal, state

or local regulations, as applicable.

Contact E-mail: polymers@atul.co.in

Website: www.atul.co.in

Note Lapox® is a registered trademark of Atul Ltd.

Manufacturing site

Atul 396 020, Gujarat, India

Telephone: (+91 2632) 230000 | 233261

E-mail: contact@atul.co.in

Disclaimer: The information contained herein is for information purposes only. While enough care is taken in disclosing the information, users of this

information are advised to cross-check the same depending upon use | application. Atul Ltd does not give any assurance or warranty or guarantee in

regard to the accuracy or completeness of the information and no claim or liability will be accepted or entertained in regard thereto. Atul Ltd makes no

warranty of any kind, expressed or implied, including, but not limited to, any implied warranty of merchantability or fitness for a particular purpose or

performance or usage of trade.

February 2018 Page 2 of 2

You might also like

- Adcote76P1 38TDS PDFDocument3 pagesAdcote76P1 38TDS PDFLaury Suarez BayonaNo ratings yet

- Lapox AC-14: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox AC-14: Technical Data Sheet - Polymers Businesssriatul2006No ratings yet

- Lapox ARF 11Document2 pagesLapox ARF 11Osama GabrNo ratings yet

- Lapox AR-101: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox AR-101: Technical Data Sheet - Polymers Businesssriatul2006No ratings yet

- Lapox K-540: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox K-540: Technical Data Sheet - Polymers BusinessAMIT HALDERNo ratings yet

- Lapox B-11: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox B-11: Technical Data Sheet - Polymers Businessankitmohanty01No ratings yet

- Palox 42KDocument2 pagesPalox 42KSam WitwickyNo ratings yet

- Lapox ARPN 36 X80 PDFDocument2 pagesLapox ARPN 36 X80 PDFOsama GabrNo ratings yet

- Lapox ARPN-25: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox ARPN-25: Technical Data Sheet - Polymers Businesssriatul2006No ratings yet

- PO - Lapox P 62Document2 pagesPO - Lapox P 62alpesh.samruddhigroupNo ratings yet

- Lapox AR-101 PDFDocument2 pagesLapox AR-101 PDFOsama GabrNo ratings yet

- Spec Data Sheet: Metalex Red Oxide Metal PrimerDocument2 pagesSpec Data Sheet: Metalex Red Oxide Metal Primerjustin trochezNo ratings yet

- Lapox ARD-13 PDFDocument2 pagesLapox ARD-13 PDFOsama GabrNo ratings yet

- PO - Polygrip SP 809Document2 pagesPO - Polygrip SP 809gulam safiNo ratings yet

- Adhesive PDS & MSDS PDFDocument25 pagesAdhesive PDS & MSDS PDFsmartayaz1987No ratings yet

- Adalin 4797-UndetailedDocument3 pagesAdalin 4797-UndetailedMuhammad Aasim HassanNo ratings yet

- Synocure 7715 S 60Document2 pagesSynocure 7715 S 60Şebnem İlarslanNo ratings yet

- RF-9801 Lamination Adhesive For Soft PackageDocument4 pagesRF-9801 Lamination Adhesive For Soft PackageWasif AzimNo ratings yet

- Altamix-P200 KG PDFDocument1 pageAltamix-P200 KG PDFZeeshan AhmadNo ratings yet

- Technical Information: TMS - VHPDocument1 pageTechnical Information: TMS - VHPVictor CastrejonNo ratings yet

- TDS Dsa-380Document3 pagesTDS Dsa-380A MahmoodNo ratings yet

- Acrodur DS 3530 February 2018 R3 EDFDocument3 pagesAcrodur DS 3530 February 2018 R3 EDFAllen de RichardNo ratings yet

- Sylobead® Ms 512: Product DescriptionDocument5 pagesSylobead® Ms 512: Product Descriptionyohan pramonoNo ratings yet

- Silica Fume 92% Technical Data Sheet: Description Physical PropertiesDocument1 pageSilica Fume 92% Technical Data Sheet: Description Physical PropertiesDileepa DissanayakeNo ratings yet

- Lotader: Ethylene - Acrylic Ester - Maleic Anhydride TerpolymerDocument2 pagesLotader: Ethylene - Acrylic Ester - Maleic Anhydride TerpolymerLe MinhNo ratings yet

- Da 128Document1 pageDa 128chayanunNo ratings yet

- ALBATEX AD - Protective ColloidDocument5 pagesALBATEX AD - Protective Colloid郭哲宏0% (1)

- DermaDamp HDDocument2 pagesDermaDamp HDJacob Norman CruzNo ratings yet

- HD Ar-Afff Foam Concentrate: Alcohol Resistant Aqueous Film Forming Foam Concentrate (Arafff) CompatibilityDocument3 pagesHD Ar-Afff Foam Concentrate: Alcohol Resistant Aqueous Film Forming Foam Concentrate (Arafff) CompatibilityDHAVAL PANCHALNo ratings yet

- SikagardPatioGloss en (11 2018) 1Document2 pagesSikagardPatioGloss en (11 2018) 1Andrei GheoNo ratings yet

- Tds - Emaco r307Document2 pagesTds - Emaco r307Venkata RaoNo ratings yet

- Technical Information: Sodium Antimonate-EDocument1 pageTechnical Information: Sodium Antimonate-EVictor CastrejonNo ratings yet

- Elastosil Aux G 3243Document4 pagesElastosil Aux G 3243KeremNo ratings yet

- SDS Sarafil Polyester Film 2023Document4 pagesSDS Sarafil Polyester Film 2023Chiaranan KerdsamutNo ratings yet

- Anti Carbonation PaintDocument4 pagesAnti Carbonation Paintptk94287No ratings yet

- Msds - Unitrade Capital Solution Sdn. Bhd.Document5 pagesMsds - Unitrade Capital Solution Sdn. Bhd.lou janeNo ratings yet

- MesamollDocument3 pagesMesamollKiên PhùngNo ratings yet

- PolybitpolyprimeDocument2 pagesPolybitpolyprimerazeeth1212No ratings yet

- TDS - TERRAWET Primer G 9 - 733 Inline - 060 - enDocument2 pagesTDS - TERRAWET Primer G 9 - 733 Inline - 060 - enJavier Martinez CañalNo ratings yet

- Jointing Compound Datasheet - Third Edition3.1 - 13apr20 1Document4 pagesJointing Compound Datasheet - Third Edition3.1 - 13apr20 1Allan ManumbasNo ratings yet

- All Alçi Derz Dolgu AlçisiDocument3 pagesAll Alçi Derz Dolgu AlçisiAgit SipkaNo ratings yet

- All Alçi Saten Perdah AlçisiDocument3 pagesAll Alçi Saten Perdah AlçisiAgit SipkaNo ratings yet

- Tds Dep 330nDocument3 pagesTds Dep 330nA MahmoodNo ratings yet

- MSDS Kan HB Epoxy LinerDocument6 pagesMSDS Kan HB Epoxy LinerHafiza UlfatNo ratings yet

- Ap 13Document2 pagesAp 13Muhammad AHSAN ISHAQNo ratings yet

- TDS - Encor 2750 - 01-12Document2 pagesTDS - Encor 2750 - 01-12APEX SONNo ratings yet

- MSDS Gandar 800XDocument4 pagesMSDS Gandar 800XSukmaNo ratings yet

- TDS iPolySpl FR White 1136Document2 pagesTDS iPolySpl FR White 1136Popular videos Pinkal Sparsh ShailajaNo ratings yet

- Acrilem ST190: Product DescriptionDocument2 pagesAcrilem ST190: Product DescriptionMachidon OanaNo ratings yet

- BI - Resoform P18Document2 pagesBI - Resoform P18MehulNo ratings yet

- ADCOTE™ 76P1-38: Laminating AdhesiveDocument3 pagesADCOTE™ 76P1-38: Laminating AdhesiveLaury Suarez BayonaNo ratings yet

- Adcote76P1 38TDS PDFDocument3 pagesAdcote76P1 38TDS PDFLaury Suarez BayonaNo ratings yet

- Hyperdesmo®-Ady 610 - enDocument3 pagesHyperdesmo®-Ady 610 - enMajd M. KhalilNo ratings yet

- TDS Hostapur OS LiqDocument2 pagesTDS Hostapur OS LiqRabah ABBASNo ratings yet

- Lapox AH 713 PDFDocument2 pagesLapox AH 713 PDFOsama GabrNo ratings yet

- 380 TDSDocument1 page380 TDSrishibindra55555No ratings yet

- Lite 3060 - TdsDocument2 pagesLite 3060 - TdsJuan Sebastián Fernández RamírezNo ratings yet

- Adalin KDocument3 pagesAdalin KAziz100% (1)