Professional Documents

Culture Documents

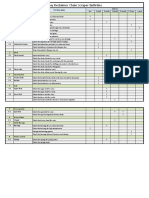

Yacht Annual Maintenance List

Yacht Annual Maintenance List

Uploaded by

Capt. Cole SislerOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yacht Annual Maintenance List

Yacht Annual Maintenance List

Uploaded by

Capt. Cole SislerCopyright:

Available Formats

Area Description of Work By Hours Daily Weekly Bi-weekly Monthly 3 Month 6 Months Annually Bi-Annually

Appliances Clean external coils on all refrigeration units by vacuuming or using x

Appliances Acid flush clear

compressed air ice machines with MFR suggested cleaning solution x

Appliances BBQ grill on Fly bridge/sundeck. Thoroughly clean, replace grease x

Appliances Clean and

filters individual

greasedryer

catchducts

cup. Inspect safety switch for moisture x

Bottom Haul and launch

intrusion. Test & prove closed lid safety cut-off switch x

Bottom Pressure wash bottom x

Bottom Hand scrape bottom as needed x

Bottom Soft pad sand bottom prior to application of new bottom paint x

Bottom Paint bottom (2) coats compatible bottom paint. x

Bottom Remove props and have checked, tracked and balanced x

Bottom Apply Prop Speed to propellers and shafts x

Bottom Dial indicate end tapers of main shafts. Remove shafts and straighten x

Bottom Inspect

if needed.cutlass bearings for excessive wear. Replace if needed x

Bottom Drop all intake strainer external grates, sand blast, prime and paint x

Bottom Check transom, anti-fouling

with compatible strut and shaft zincs. Replace when they are less

paint x

Bottom Clean

than 25%bow thruster props and apply Prop Speed x

Bottom Replace bow thruster shaft/prop nut zincs if applicable x

Bottom Drop stabilizer fins and replace seals every 2 years x

Electrical Check all bonding wires and connections. x

Electrical Check all electrical sub panel wiring connections to be tight and in x

Electrical Check all electrical connections in Main distribution panel, contactors,

good order x

Electrical Dis-assemble

breakers etc.. all shore power and adapter ends. Clean connections or x

Electrical Test all possible

cut back cable toconfigurations of shore

clean wire. Apply powercoating

protective throughon A-Sea

connections. x

Electrical Inspect and prove main engine shaft grounding brush is making good

converters. x

Fluids Replace bowthe

contact with thruster/windlass

shaft hydraulic fluid filter on reservoir. Drain x

Fluids Replace

and refill fluid filter with

reservoir on Naiad reservoir fluid

new hydraulic every 2 years or when lower x

Fluids Replace

shaft sealsfluid

arefilter on steering tank reservoir. Drain reservoir and refill

replaced x

Fluids Replace

with cleanfluid filter onfluid

Hydraulic Nautical Structures HPU every 70-100 Hours of x

Freshwater Drain hot water heater and replace zinc anode.

operation x

Grey Water

System Clean grey water sump boxes. Prove AC & DC pump operation x

Grey Water

System Drain and flush grey water tanks x

Gyros

System Service per Manufacturer Specifications x

Head System Replace vented loop anti-siphon valve flaps for all Headhunter Heads x

Head System Remove Black water tank sensor plate. Clean waste and x

Hull Touch up bootprocessed

accumulated stripe as needed.

debris from the float switches x

Hull Touch up paint on hullsides as needed. x

Hull Polish stainless steel anchor chafe plates x

Hull Wax hullsides. De-scale and wax boot stripe x

HVAC Check HVAC closed loop pressure and maintain at 13-15 Psi x

HVAC Remove and clean return air handler filters/screens. Inspect plumbing x

HVAC Acidleaks

for flush Air conditioning chillers as needed x

HVAC Clear individual air handler condensation drains. Prove to be free x

HVAC Clean fresh air intake box/plenum .

flowing x

Machinery Lubricate all points on the steering gear. Includes ball joints, tie bar x

Machinery Main

ends Engines PM adjustments

and quadrant and checks per MTU at specific hour

plate bearings x

Machinery Check engine oil and transmission fluid

intervals x

Machinery Generator PM adjustments and checks per Northern Lights at specific x

Machinery Check

hour generator engine oil and inspect unit for leaks

intervals x

Machinery Remove and clean all zinc anodes, oil coolers, stabilizer cooler, gears, x

Machinery Back Flush etc..

generators the MSD chambers

Replace if needed x

Machinery Disassemble and clean valves and coils on the MSD x

Machinery Complete service of MSD system by Headhunter x

Machinery Disconnect main shaft couplings and check engine alignment. Adjust x

Machinery Disassemble

as needed to windlass andalignment

get coupling aft winch drums

back tofrom shafts.

<.003 in (4)Clean

pointsand

12:00, x

Machinery Drain oil from

lubricate

3:00, 6:00 brake Aft winchApply

plates.

& 9:00. gear boxes

lithium and refill.onClean

grease shaftsand apply

when re- x

Machinery Replace

installing or

corrosion rebuild

block

drum pump heads

on exposed

heads. on air conditioner raw water pumps.

metals. x

Machinery Deploy all anchor chain. Clean chain locker below grates. Clean and x

Machinery Inspect davittocable,

prove drain hook

be clear. andanchor

Run sheaves. Replace pump

wash-down if frayed,

anddamaged

prove or x

Machinery Full

worn.Service

workingInspectonforwatermakers

fluid leaks at valves and rams. Grease all hinge/pivot x x

Machinery Prove operation of AC black water overboard discharge pump. Clean

points x

exterior or pump/body and apply corrosion block

Machinery Prove operation of DC black water overboard discharge pump. Clean x

Machinery Load test

exterior orbatteries,

pump/body engine, house

and apply and generator.

corrosion block. Replace as needed x

Machinery Prove operation of DC freshwater pump. x

Machinery Test main engine back up controls. x

Machinery Drain and refill bow thruster leg with clean oil. x

Machinery Check manual operation of passarelle hand pump HPU. x

Machinery Check and prove manual operation of Davit valves inside the davit. x

Machinery Service Alpha Lavel x

Machinery Change oil in the transmissions x x

Preventive Inspect hose clamps on the main shaft seals to be intact and in good x

Preventive

Maintenance Inspect

conditionhose clamps on rudder seals to be intact and in good x

Preventive

Maintenance Test and prove

condition. General AC inspect

emergency bilge pumps,

of lazarette space flush with

to find anyfreshwater

saltwater if x

Preventive

Maintenance Clean

leaks andwas

saltwater apply

usedcorrosion block on all exposed bronze/brass fittings x

Preventive

Maintenance Clean and apply

in the engine room corrosion block

and bilge to wiring terminal strips in lazarette

spaces. x

Preventive

Maintenance Exercise

bilge and all underwater

forward intake thru-hulls to open and close freely

bilge spaces. x

Preventive

Maintenance Exercise all above water discharge thru-hulls to open and close freely x

Preventive

Maintenance Inspect freshwater pump plumbing and filters for leaks x

Preventive

Maintenance Replace carbon and pleated freshwater filter elements x

Preventive

Maintenance Inspect and replace Silver Ion probe as needed x

Preventive

Maintenance Back flush and recharge the water softener system x

Preventive

Maintenance Replace freshwater system UV light bulb with new x x

Preventive

Maintenance Replace sediment filters for Jacuzzi x

Preventive

Maintenance Operate and lubricate Delta T intake and exhaust dampeners x

Preventive

Maintenance Operate all fuel tank shut off valves and cross over valves to open and x

Preventive

Maintenance Operate and prove all emergency exits/hatches

close freely x

Preventive

Maintenance Clean and lube all exterior bar stool spiders and bases. x

Preventive

Maintenance Free up all used and unused deck tie down receivers and eyes. x

Preventive

Maintenance Dis-assemble and clean all sink P-traps X

Preventive

Maintenance Lubricate all sliding door rollers with silicone spray x

Preventive

Maintenance Dis-assemble, clean and lubricate all lock tumblers for interior and x

Preventive

Maintenance Remove all A/V

exterior doors equipment

where from their installed spaces and clean to rid

applicable. x

Preventive

Maintenance Remove Delta

of dust/dirt. T diffuser

Prove pancake . Clean interior

extraction fansorare

cabinet and main tube

operational. x

Preventive

Maintenance Open/close

going down all hydraulic

to the enginetank

room.shut off valves

Re-bed to prove

diffuser to boxoperational

when re- x

Preventive

Maintenance Empty gas tank in swim step, check for water and refill.

installing. x

Preventive

Maintenance Change oil air compressor. Clean or replace foam air inlet filter. Drain x x

Preventive

Maintenance Dis-assemble Kahlenberg

water from compressor tank. horns, clean and service reeds on end x

Preventive

Maintenance Prove Apply

caps. all fuela tank sight

quality tubewax

metal valves open and close fully.

on trumpets x

Preventive

Maintenance Clean intake fans on A-Sea converter cabinets x

Preventive

Maintenance Replace pancake fans on A-Sea converter cabinets x

Preventive

Maintenance Check mounting hardware on Sat Domes to be tight and secure x

Preventive

Maintenance Test and prove AC Fire pump, Diesel pump and associated valves. x

Preventive

Maintenance anda flow

Test as fire sprinkler

fire pump and as pumps

a bilge at the manifold..

pump x

Preventive

Maintenance Test and prove Air operated valve for the fire sprinkler system to be x

Preventive

Maintenance Inspect all piping and plumbing in the engine room for oil and water

operational x

Preventive

Maintenance Inspect

leaks all hoses and piping at the stabilizer actuators for oil leaks and x

Preventive

Maintenance Check oil level in the Davit back up HPU or the davit main HPU

chafing x

Preventive

Maintenance Inspect wiring at the exterior wings stations for moisture or corrosion x

Preventive

Maintenance Replace

build up pilothouse windshield wiper blades with new as needed or at x

Preventive

Maintenance Clean and polish electric table lift bases and prove they are operating

wear intervals x

Maintenance smoothly without binding

Preventive Adjust and tighten all interior and exterior hinges, door handles, lock x

Preventive

Maintenance Check alldrawer

sets and mounting hardware for antennas, domes and accessories on

slides X

Safety

Maintenance Recertify

the mast andFixed and portable fire system

hardtop x

Safety Recertify life rafts x

Safety Test Pnuematic Fuel Shut off Valves in the engineroom x

Safety Test all fire/heat sensors onboard through Alarm system x x

Safety Test all door alarm functions through Alarm System x x

Safety Test all high bilge alarms through Alarm System. x x

Safety Test emergency light system throughout vessel x x

Safety Recertify EPIRB as needed. x

Safety Swing compass and Gyro. Provide current deviation card. x

You might also like

- XVS1100 V-Star 1100 (99-00) Service ManualDocument420 pagesXVS1100 V-Star 1100 (99-00) Service Manualbullwinkle105477675% (8)

- Lighting PPMDocument9 pagesLighting PPMMohammed SayeeduddinNo ratings yet

- York Chiller Log SheetDocument4 pagesYork Chiller Log SheetEngr Fazal AkbarNo ratings yet

- Home Maintenance ChecklistDocument1 pageHome Maintenance ChecklistKit ChampNo ratings yet

- Variable Frequency DrivesDocument6 pagesVariable Frequency DrivesMohammed Sayeeduddin100% (1)

- Maintenance Lists: (3A) Preventive Maintenance ScheduleDocument4 pagesMaintenance Lists: (3A) Preventive Maintenance Scheduleyoucef tecNo ratings yet

- UPSDocument8 pagesUPSMohammed Sayeeduddin100% (1)

- Preventative Maintenance Activity A B C D E: Type of Visit For Each Specific Year, Running Hours Per Year 8000 HRSDocument1 pagePreventative Maintenance Activity A B C D E: Type of Visit For Each Specific Year, Running Hours Per Year 8000 HRSSeif AlbaghdadyNo ratings yet

- MaintenanceOfIndUnits2019V001 Industrial UnitsDocument2 pagesMaintenanceOfIndUnits2019V001 Industrial UnitsMiguel Angel Flores MojicaNo ratings yet

- Basic Barrier Maintenance Guide: Tasks Hydraulic ElectricDocument2 pagesBasic Barrier Maintenance Guide: Tasks Hydraulic Electricbaguspermana7No ratings yet

- Standard Service Oil Injected Compressor Atlas CopcoDocument1 pageStandard Service Oil Injected Compressor Atlas CopcoAhmad FauzieNo ratings yet

- ... An Energy-Saving Approach To Your Service Needs..Document4 pages... An Energy-Saving Approach To Your Service Needs..Robert sherrodNo ratings yet

- SKF Static Motor Analyzer Baker DX SeriesDocument4 pagesSKF Static Motor Analyzer Baker DX SeriesAlex Aros CNo ratings yet

- SampleReport PDFDocument6 pagesSampleReport PDFjidebiz6797No ratings yet

- 160.81-MR1 (Log Sheet)Document4 pages160.81-MR1 (Log Sheet)dhcastanoNo ratings yet

- DG Maintenance PlanDocument2 pagesDG Maintenance PlanYasir Mehmood100% (1)

- Equipment GA132 75 Bar (W) PackDocument1 pageEquipment GA132 75 Bar (W) Packsurendra SinghNo ratings yet

- 160 54-MR1Document3 pages160 54-MR1Areeb FizaNo ratings yet

- HL Owners Manual 2021Document2 pagesHL Owners Manual 2021Dutchie169No ratings yet

- HVAC Maintenance ActivitiesDocument23 pagesHVAC Maintenance ActivitiesLungisaniNo ratings yet

- Pages From 228078564-LssT9Document1 pagePages From 228078564-LssT9RezhaNo ratings yet

- Ware W Wash CH Hemical Dispens Sing: DEM MA NitrDocument8 pagesWare W Wash CH Hemical Dispens Sing: DEM MA Nitrtyan172No ratings yet

- Renold Rev2015Document12 pagesRenold Rev2015anandparasu5459No ratings yet

- D Dema N Nitro Ex Xpress: Ware Wash C Chemical L Dispen NserDocument8 pagesD Dema N Nitro Ex Xpress: Ware Wash C Chemical L Dispen Nsertyan172No ratings yet

- Maintenance Checklist Land Mud CoolerDocument1 pageMaintenance Checklist Land Mud CoolerApneryanus LepingNo ratings yet

- Scheduled Maintenance Allegro-BreezeDocument3 pagesScheduled Maintenance Allegro-BreezeamarcotteNo ratings yet

- Maintenance Schedule Bauer CompressorsDocument1 pageMaintenance Schedule Bauer CompressorsCristel_DC100% (3)

- Energy Saving Techniques Applicablity Matrix - (2022-23)Document6 pagesEnergy Saving Techniques Applicablity Matrix - (2022-23)Mohamedsameer ANo ratings yet

- 160 54-MR1 PDFDocument1 page160 54-MR1 PDFghilesNo ratings yet

- Baker dx12 Static Motor AnalyzerDocument4 pagesBaker dx12 Static Motor AnalyzerRicardo AnastácioNo ratings yet

- A/c Duct Network (VCD, VAV, FD, SD, Grillers & Diffusers Etc)Document2 pagesA/c Duct Network (VCD, VAV, FD, SD, Grillers & Diffusers Etc)Mohammed SayeeduddinNo ratings yet

- Centrifugal Pump ChecklistDocument1 pageCentrifugal Pump ChecklistApneryanus LepingNo ratings yet

- Manual 5Document3 pagesManual 5CCR GPPNo ratings yet

- Amp200 300Document9 pagesAmp200 300Daniel PinheiroNo ratings yet

- SI RT: Only To B Us DB PR F Sion LsDocument2 pagesSI RT: Only To B Us DB PR F Sion LsbarbarabluNo ratings yet

- Table 3. Recommended Field Tests (B) .: Creating An Effective Maintenance Program GEK 103566hDocument1 pageTable 3. Recommended Field Tests (B) .: Creating An Effective Maintenance Program GEK 103566hRajesh BNo ratings yet

- Heavy-Duty Vibrating FeedersDocument4 pagesHeavy-Duty Vibrating FeedersErsin SucuNo ratings yet

- 06-Sea Water Auto Wash StrainerDocument2 pages06-Sea Water Auto Wash StrainerIvan ShiuNo ratings yet

- 1341832085307-Air ConditioningDocument28 pages1341832085307-Air ConditioningMECHANICAL ENGINEERINGNo ratings yet

- Randcastle'S Taskmaster: Features: Control PanelDocument7 pagesRandcastle'S Taskmaster: Features: Control PanelTarekNo ratings yet

- Table 1. Recommended Stator Tests (A) .: Creating An Effective Maintenance Program GEK 103566hDocument1 pageTable 1. Recommended Stator Tests (A) .: Creating An Effective Maintenance Program GEK 103566hRajesh BNo ratings yet

- Clay Reclaimer Chain Scraper BulletinsDocument2 pagesClay Reclaimer Chain Scraper Bulletinshaitham tamerNo ratings yet

- Art 3A10.1007 2Fs12239 008 0008 7Document10 pagesArt 3A10.1007 2Fs12239 008 0008 7VishalSharmaNo ratings yet

- Resistoflex Rubber PadsDocument2 pagesResistoflex Rubber PadsAnderson SNo ratings yet

- 216 Rotary Actuators: Heavy Duty, Torque Generating Devices Designed For Precise Servo-Control ApplicationsDocument20 pages216 Rotary Actuators: Heavy Duty, Torque Generating Devices Designed For Precise Servo-Control ApplicationsSachin PatelNo ratings yet

- Rig:50 Diesel / Hydraulic Crane Weekly and Monthly ChecksDocument1 pageRig:50 Diesel / Hydraulic Crane Weekly and Monthly Checksvikrant911No ratings yet

- Diagnostic Test Chart Transformers Reactors Regulators-IEEE STD 62-1995Document2 pagesDiagnostic Test Chart Transformers Reactors Regulators-IEEE STD 62-1995GualadrakeNo ratings yet

- Centrifugation Poster Maintenance-Centrifuges Maintenance-CentrifugesDocument2 pagesCentrifugation Poster Maintenance-Centrifuges Maintenance-CentrifugesBook BookNo ratings yet

- Uploads Media Document BAC Rigging-VXI RVXIv15ENDocument28 pagesUploads Media Document BAC Rigging-VXI RVXIv15ENsidsaleemNo ratings yet

- Main Switch Panel IntakeDocument4 pagesMain Switch Panel IntakeMohammed Sayeeduddin100% (1)

- Cautery Machines and Electrosurgical Units PREVENTIVE MAINTENANCEDocument2 pagesCautery Machines and Electrosurgical Units PREVENTIVE MAINTENANCERaymond Ogi100% (2)

- 160 78-MR1Document3 pages160 78-MR1vitor andrewsNo ratings yet

- Rig:50 Diesel / Hydraulic Crane Weekly and Monthly ChecksDocument1 pageRig:50 Diesel / Hydraulic Crane Weekly and Monthly Checksvikrant911No ratings yet

- BAC Maintenance-VXI MVXIv17EN-SADocument34 pagesBAC Maintenance-VXI MVXIv17EN-SAEurotech Tra TranNo ratings yet