Professional Documents

Culture Documents

Design of Beam Singapore Standard

Design of Beam Singapore Standard

Uploaded by

Glenn Enrico Muldez AmoloOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Beam Singapore Standard

Design of Beam Singapore Standard

Uploaded by

Glenn Enrico Muldez AmoloCopyright:

Available Formats

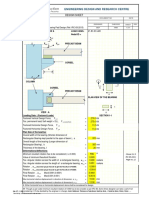

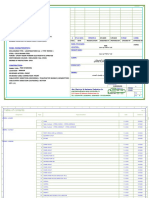

PROJECT TITLE LOCATION

MARK:

MEMBER DESIGN FOR BENDING

RC SHEAR & TORSION

TG FOUNDATION Singapore

MEMBER GX1A

KEPPEL LNTP PROJECT DATE -

In Accordance with SS EN 1992-1-1:2008

RC Beam Design_Ver.03

INPUT PARAMETERS MAJOR AXIS

Beam Properties

MEMBER DIAGRAM SUMMARY OF REBAR

Width of Beam b = 3490 mm

Depth of Beam h = 2430 mm TOP 20 - D32

MAIN BAR

Minimum Concrete cover cc = 119 mm b BOT 20 - D32

Effective Depth of Beam at Top dT = 2330 mm LEFT 10 - D32

d' SIDE BAR

Effective Depth of Beam at Bottom dB = 2295 mm RIGHT 10 - D32

Y

Outer 2 - D16

SHEAR BAR

Material Strengths Inner 5 - D16

dB

f ck N/mm2 SPACING sv =

h

Comp. Strength of Concrete (C28/35) = 28 Z dT 200 mm

Yield Strength of Main Rebar (G500) fyk = 500 N/mm2 EDGE DISTANCE TO CENTER OF REBAR

Yield Strength of Shear bars (G500) fykv = 500 N/mm2 TOP BAR d' = 100 mm

d" BOTTOM d" = 135 mm

Loading Data (See ANNEXURE B) c' c" LEFT SIDE c' = 130 mm

Ultimate Bending Moment (Top) MuT = 12947 kNm RIGHT SIDE c" = 130 mm

Ultimate Bending Moment (Bottom) MuB = 2800 kNm

Ultimate Torsion TEd = 1933 kNm Provided Main Bar

Ultimate Shear Force VEf = 3731 kN Top Bar 20 - D32 Astpvd = 16080 mm2

Bottom Bar 20 - D32 Asbpvd = 16080 mm2

Limit of Reinforcements Side Bar (Left) 10 - D32 AssLpvd = 8040 mm2

Side Bar (Right) 10 - D32 AssRpvd = 8040 mm2

As max

※ Maximum Steel Ratio ρ max 0.04 = 0.04 Aspvd = 48240 mm2

b.d

Provided Shear bar

Max. Steel Area (TOP) As max ρ max .b.d T = 325268 mm2 Outer Bar 2 - D16 Avo = 402 mm2

Inner Bar 5 - D16 Avi = 1005 mm2

Max. Steel Area (BOT) As max ρ max .b.d B = 320382 mm2 Total 7 - D16 Avprd = 1407 mm2

Spacing of Shear Bar sv = 200 mm

0.26f ctm

※ Minimum Steel Ratio ρ min = 0.0015

f yk

Material Partial Factors Mean Conc. Tensile Strength

Min. Steel Area (TOP) As _ ρ . b. d = 12198 mm2

Concrete c = 1.50

Min. Steel Area (BOT) As _ ρ . b. d = 12015 mm2 Steel s = 1.15 fctm = 2.8 N/mm2

CHECK THE CAPACITY OF TOP BAR CHECK THE CAPACITY OF BOTTOM BAR

Mu T Mu B

Resistance K 0.167 = 0.024 < 0.167 OK Resistance K 0.167 = 0.005 < 0.167 OK

b.d T2 .f ck b.d 2B .f ck

K K

Moment Arm z dT.0.5 0.25 = 2280 mm Moment Arm z dB.0.5 0.25 = 2285 mm

1.134 1.134

Mu t Mu B

Required Steel Area Ast = 13061 mm2 Required Steel Area Asb = 2819 mm2

(f yk / s ).z (f yk / s ).z

Provided Steel Area Astpvd (20-D32) = 16080 mm2 OK Provided Steel Area Asbpvd (20-D32) = 16080 mm2 OK

12198 < 16080 < 325268 OK 12015 < 16080 < 320382 OK

Ast pvd Asb pvd

Actual Reinf. Ratio ρ act 0.0020 < max OK Actual Reinf. Ratio ρ act 0.002 < max OK

b.d T b.d B

Ast f ⁄γ Ast f ⁄γ

Depth of Comp. Block s = 126 mm Depth of Comp. Block s = 126 mm

0.85 f ⁄γ · b 0.85 f ⁄γ · b

To ensure yielding of Tension Steel, x 0.617dT = 1438 mm To ensure yielding of Tension Steel, x 0.617d T = 1416 mm

s s

Depth of Neutral Axis x = 158 mm Depth of Neutral Axis x = 158 mm

0.8 0.8

158 mm < 1438 mm OK 158 mm < 1416 mm OK

s s

Moment Capacity Mn Ast f ⁄γ d = 15849 kNm Moment Capacity Mn Asb f ⁄γ d = 15605 kNm

2 2

Mn = 15849 > MuT = 12947 OK Mn = 15605 > MuB = 2800 OK

Reference Code: SS EN 1992-1-1:2008 Design of Concrete Structures Page 1 of 3

PROJECT TITLE LOCATION

MARK:

MEMBER DESIGN FOR BENDING

RC SHEAR & TORSION

TG FOUNDATION Singapore

MEMBER GX1A

KEPPEL LNTP PROJECT DATE -

In Accordance with SS EN 1992-1-1:2008

RC Beam Design_Ver.03

CHECK FOR COMBINED SHEAR & TORSION Design Notes

Design Parameters Section Properties for Torsion:

b.h

Width of Beam b = 3490 mm Equivalent thickness of Concrete t t = 716 mm

2.b h

Minimum Effective Depth of Beam d = 2295 mm Cross-section

Maximum Ultimate Shear VEf = 3731 kN

Maximum Ultimate Torsion TEd = 1933 kN-m Area of Equivalent Hollow box A k b t

. h t Ak = 5E+06 mm2

2

Yield Strength of transv Rebar fyv = 500 N/mm within centerline

2

Yield Strength of Longt'l Torsion Rebar fyL = 500 N/mm

Spacing of Transverse Rebar sv = 200 mm Perimeter of Equivalent Hollow u k 2b h 2t uk = 8976 mm2

Box cross-section

VEf

Actual Angle of Inclination θ a 0.5sin 1. 45

o

0.18b.d.1 f ck /250 .f ck Torsional Factor, 1: ν1 0.61 f ck /250 1 = 0.533

a = 3 deg

Angle of Crack Inclination = 22 deg < 45 deg OK

Usual Angle of Crack Inclination u = 22 deg

Max. Angle of Crack Inclination max = 45 deg Since the Angle of Crack Inclination < 45 deg, therefore, OK!

Maximum Design Shear Force Additional Horizontal Tensile Force due to Shear

0.36b.d.1 f ck /250 .f ck

VRd,max VRd,max = 24901 kN Ftd 0.5VEd .cotθ Ftd = 4,617 KN

cotθ tanθ

Design Shear Force The additional longitudinal tensile force is provided by extending the

curtailment point of the longitudinal reinforcement

VEd VEf VEd = 3731 kN

Minimum Reinforcement for Shear & Torsion:

Required Shear Rebar

0.08 f ck

VEd . tan θ A sw,min b.s v Asw,min = 591 mm2

Av sw .s v Avsw = 337 mm

2 f yv

0.78.f yv .d

Max. Spacing of Transv. Reinf. based on Shear:

Maximum Design Torsion 3d

s1_max or 600 mm s1_max = 600 mm

1.33ν1.f ck .t.A k 4

TRd,max TRd,max = 23470 kNm

cotθ tanθ Max. Spacing of Transv. Reinf. based on Torsion:

Required Reinforcement for Torsion

u s2_max = 1120

TEd tanθ s _ min , b, h mm

At sw .s v Atsw 2 8

2 0.87fy v .A k = 38 mm

Smax = Smaller of S1_max and S2_max Smax = 600 mm

Required Reinforcement for Combined Shear & Torsion

Sact = 200 mm < Smax = 600 mm

A T Av sw 2At sw A sw,min AT 2

= 591 mm

Since Sact < Smax, OK!

Avpvd = 1407 > AT = 591

Since the Provided Reinforcement is greater than the Required, OK! Check for Clear Spacing of Main Reinforcement

Adequacy of Section for Combined Shear & Torsion Table 7.3N Maximum Bar Spacing for Crack Control

Steel Stress, fs Bar Clear Spacing, s Number of Bars in Layer 1

TEd VEd

1.0 160 MPa 300 mm N = 20 pcs

TRd,max VRd,max

200 MPa 250 mm

240 MPa 200 mm Allowable Crack Width

0.23 < 1.0 Section is Adequate, OK!

280 MPa 150 mm wk,allow = 0.30 mm

Additional Longitudinal Torsional Reinforcement 320 MPa 100 mm

360 MPa 50 mm

TEd u k

A SL . .cotθ ASL = 10382 mm2 The stress of rebar at service, 's shall be calculated using the principle of cracked section,

2A k 0.87fy L

see next page for detailed calculation of 's. 's = 68 N/mm2

Required Reinforcement for Bending

f σ 68 N/mm2 160 N/mm2

As B As b As t AsB = 15880 mm2

Maximum Clear Spacing of Main Reinforcement

Required Reinforcement for Bending & Torsion

for fs = 160 N/mm2 smax = 300 mm

As rqd As B A SL Asrqd = 26262 mm2

Minimum Clear Spacing of Main Reinforcement c' = 130 mm

Provided Reinforcement for Bending & Torsion c" = 130 mm

s d or 20 smin = 32 mm

As T As pvd db = 32 mm

AsT = 48240 mm2

Actual Clear Spacing of Main Reinforcement

AsT = 48240 > Asrqd = 26262 s b c c" ⁄ N 1 d sact = 138 mm

Since the Provided Reinforcement is greater than the Required, OK! Since, Smin < Sact < Smax, OK!

Reference Code: SS EN 1992-1-1:2008 Design of Concrete Structures Page 2 of 3

PROJECT TITLE LOCATION

MARK:

MEMBER DESIGN FOR BENDING

RC SHEAR & TORSION

TG FOUNDATION Singapore

MEMBER GX1A

KEPPEL LNTP PROJECT DATE -

In Accordance with SS EN 1992-1-1:2008

RC Beam Design_Ver.03

CHECK FOR CRACK Design Notes

Design Parameters where:

1.0 for pure tension

Maximum Service Axial Load (COMP.) NEd = 608 kN kc σc = 0.40

0.4.1 1.0 for Bending Axial

Maximum Service Moment MEd = 2,356 kN-m

2

*

k1. h/h .f ct,eff

Mean Conc. Tensile Strength, fct,eff = fctm fct,eff = 2.8 N/mm

2

Modulus of Elasticity of Steel Es = 200000 N/mm

N Ed

Modulus of Elasticity of Concrete Ecm = 32300 N/mm

2 σc c = 0.0717 N/mm2

b.h

Width of Beam b = 3490 mm

Depth of Beam h = 2430 mm h for h 1000mm

Effective Depth of Beam d = 2330 mm h* h* = 1000 mm

2

1000 for h 1000mm

Provided Area of Rebars As = 16080 mm

Concrete Covering cc = 119 mm 1.5 if N Ed is a compressiv e force

Diameter of Main Bar = 32 mm k1 2h * k1 = 1.5

if N Ed is a tensile force

3h

Required Minimum Reinforcement for Crack Control

k c .k.f ct,eff .A ct 2 1.0 for webs with h 300mm

A s,min As,min = 1271 mm for webs with h 800mm k = 0.65

σs k 0.65

intermedia te values may be interpolat ed

Provided Reinforcement As,prvd = 16080 mm2

Since the Required Minimum Reinforcement < Provided Reinforcement, OK! A b. 2.5 h d Act = 872500 mm2

Calculation of Neutral Axis of Cracked Section σ s f yk s = 500 N/mm

2

b.x 2

α' e .A s .d x x = 531 mm e

Es e = 6.2

2 E cm

E

'e s

E c, eff

'e = 17.03

ρ p,eff A s ξ12 A 'p /A c,eff A'p = 0

p,eff = 0.0184

Calculation of Rebar Stress at Service Limit Ac,eff = 872500 mm2

A c,eff b.h c,eff

M Ed

σ s' 's = 68 N/mm

2

2.5(h - d) = 250

x

A s . d h c,eff min . (h - x)/3 = 633 hc,eff = 250 mm

3

h/2 = 1215

Calculation of Crack Width

0.6 for short term loading kt = 0.4

f ct,eff kt

σ's k t . .1 α e .ρ p,eff 0.4 for long term loading

ρ p,eff σ's

ε sm ε cm 0.6 = 0.0002

Es Es 0.8 for high bond bars k1 = 0.8

k1

k .k .k . 1.6 for plain bars

s r,max k 3 .c c 1 2 4 = 700 mm

ρ p,eff

0.5 for bending k2 = 0.5

k

Actual Crack Width 1.0 for pure tension

w k s r,max .ε sm ε cm wk = 0.14 mm k3 and k4 can be found in National Annex k3 = 3.4

and Recommended values are:

Allowable Crack Width wk,allow = 0.30 mm k4 = 0.425

E cm

Since Actual Crack Width is lesser than the Allowable Crack Width, OK! E c, eff Ec,eff = 11745 N/mm2

1 , t o

, t o = 1.75 (Creep Coefficient, See Fig. 3.1

of EN NEN 1992-1)

C28/35

Procedure How to Read the Graph

Concrete Class: Class N

Concrete Age: 28 Days

28 Days

h > 1500mm

1.75

Reference Code: SS EN 1992-1-1:2008 Design of Concrete Structures Page 3 of 3

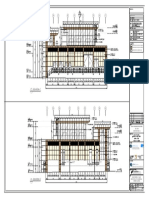

PROJECT TITLE LOCATION

MARK:

MEMBER DESIGN FOR BENDING

RC SHEAR & TORSION

TG FOUNDATION Singapore

MEMBER GX1A

KEPPEL LNTP PROJECT DATE -

In Accordance with SS EN 1992-1-1:2008

RC Beam Design_Ver.03

INPUT PARAMETERS MINOR AXIS

Beam Properties

MEMBER DIAGRAM SUMMARY OF REBAR

Width of Beam b = 2430 mm

Depth of Beam h = 3490 mm TOP 10 - D32

MAIN BAR

Minimum Concrete cover cc = 114 mm b BOT 10 - D32

Effective Depth of Beam at Top dT = 3360 mm LEFT 20 - D32

d' SIDE BAR

Effective Depth of Beam at Bottom dB = 3360 mm RIGHT 20 - D32

Y

Outer 2 - D16

SHEAR BAR

Material Strengths Inner 2 - D16

dB

f ck N/mm2 SPACING sv =

h

Comp. Strength of Concrete (C28/35) = 28 Z dT 200 mm

Yield Strength of Main Rebar (G500) fyk = 500 N/mm2 EDGE DISTANCE TO CENTER OF REBAR

Yield Strength of Shear bars (G500) fykv = 500 N/mm2 TOP BAR d' = 130 mm

d" BOTTOM d" = 130 mm

Loading Data (See ANNEXURE B) c' c" LEFT SIDE c' = 135 mm

Ultimate Bending Moment (Top) MuT = 4730 kNm RIGHT SIDE c" = 100 mm

Ultimate Bending Moment (Bottom) MuB = 6876 kNm

Ultimate Torsion TEd = 1933 kNm Provided Main Bar

Ultimate Shear Force VEf = 1476 kN Top Bar 10 - D32 Astpvd = 8040 mm2

Bottom Bar 10 - D32 Asbpvd = 8040 mm2

Limit of Reinforcements Side Bar (Left) 20 - D32 AssLpvd = 16080 mm2

Side Bar (Right) 20 - D32 AssRpvd = 16080 mm2

As max

※ Maximum Steel Ratio ρ max 0.04 = 0.04 Aspvd = 48240 mm2

b.d

Provided Shear bar

Max. Steel Area (TOP) As max ρ max .b.d T = 326592 mm2 Outer Bar 2 - D16 Avo = 402 mm2

Inner Bar 2 - D16 Avi = 402 mm2

Max. Steel Area (BOT) As max ρ max .b.d B = 326592 mm 2

Total 4 - D16 Avprd = 804 mm2

Spacing of Shear Bar sv = 200 mm

0.26f ctm

※ Minimum Steel Ratio ρ min = 0.0015

f yk

Material Partial Factors Mean Conc. Tensile Strength

Min. Steel Area (TOP) As _ ρ . b. d = 12248 mm2

Concrete c = 1.50

Min. Steel Area (BOT) As _ ρ . b. d = 12248 mm2 Steel s = 1.15 fctm = 2.8 N/mm2

CHECK THE CAPACITY OF TOP BAR CHECK THE CAPACITY OF BOTTOM BAR

Mu T Mu B

Resistance K 0.167 = 0.006 < 0.167 OK Resistance K 0.167 = 0.009 < 0.167 OK

b.d T2 .f ck b.d 2B .f ck

K K

Moment Arm z dT.0.5 0.25 = 3342 mm Moment Arm z dB.0.5 0.25 = 3333 mm

1.134 1.134

Mu t Mu B

Required Steel Area Ast = 3256 mm2 Required Steel Area Asb = 4745 mm2

(f yk / s ).z (f yk / s ).z

Provided Steel Area Astpvd (10-D32) = 8040 mm2 OK Provided Steel Area Asbpvd (10-D32) = 8040 mm2 OK

8040 < 326592 OK 8040 < 326592 OK

Ast pvd Asb pvd

Actual Reinf. Ratio ρ act 0.0010 < max OK Actual Reinf. Ratio ρ act 0.001 < max OK

b.d T b.d B

Ast f ⁄γ Ast f ⁄γ

Depth of Comp. Block s = 91 mm Depth of Comp. Block s = 91 mm

0.85 f ⁄γ · b 0.85 f ⁄γ · b

To ensure yielding of Tension Steel, x 0.617dT = 2073 mm To ensure yielding of Tension Steel, x 0.617d T = 2073 mm

s s

Depth of Neutral Axis x = 114 mm Depth of Neutral Axis x = 114 mm

0.8 0.8

114 mm < 2073 mm OK 114 mm < 2073 mm OK

s s

Moment Capacity Mn Ast f ⁄γ d = 11586 kNm Moment Capacity Mn Asb f ⁄γ d = 11586 kNm

2 2

Mn = 11586 > MuT = 4730 OK Mn = 11586 > MuB = 6876 OK

Reference Code: SS EN 1992-1-1:2008 Design of Concrete Structures Page 1 of 3

PROJECT TITLE LOCATION

MARK:

MEMBER DESIGN FOR BENDING

RC SHEAR & TORSION

TG FOUNDATION Singapore

MEMBER GX1A

KEPPEL LNTP PROJECT DATE -

In Accordance with SS EN 1992-1-1:2008

RC Beam Design_Ver.03

CHECK FOR COMBINED SHEAR & TORSION Design Notes

Design Parameters Section Properties for Torsion:

b.h

Width of Beam b = 2430 mm Equivalent thickness of Concrete t t = 716 mm

2.b h

Minimum Effective Depth of Beam d = 3360 mm Cross-section

Maximum Ultimate Shear VEf = 1476 kN

Maximum Ultimate Torsion TEd = 1933 kN-m Area of Equivalent Hollow box A k b t . h t Ak = 5E+06 mm2

2

Yield Strength of transv Rebar fyv = 500 N/mm within centerline

2

Yield Strength of Longt'l Torsion Rebar fyL = 500 N/mm

Spacing of Transverse Rebar sv = 200 mm Perimeter of Equivalent Hollow u k 2b h 2t uk = 8976 mm2

Box cross-section

VEf

Actual Angle of Inclination θ a 0.5sin 1. 45

o

0.18b.d.1 f ck /250 .f ck Torsional Factor, 1: ν1 0.61 f ck /250 1 = 0.533

a = 1 deg

Angle of Crack Inclination = 22 deg < 45 deg OK

Usual Angle of Crack Inclination u = 22 deg

Max. Angle of Crack Inclination max = 45 deg Since the Angle of Crack Inclination < 45 deg, therefore, OK!

Maximum Design Shear Force Additional Horizontal Tensile Force due to Shear

0.36b.d.1 f ck /250 .f ck

VRd,max VRd,max = 25384 kN Ftd 0.5VEd .cotθ Ftd = 1,827 KN

cotθ tanθ

Design Shear Force The additional longitudinal tensile force is provided by extending the

curtailment point of the longitudinal reinforcement

VEd VEf VEd = 1476 kN

Minimum Reinforcement for Shear & Torsion:

Required Shear Rebar

0.08 f ck

VEd . tan θ A sw,min b.s v Asw,min = 412 mm2

Av sw .s v Avsw = 92 mm

2 f yv

0.78.f yv .d

Max. Spacing of Transv. Reinf. based on Shear:

Maximum Design Torsion 3d

s1_max or 600 mm s1_max = 600 mm

1.33ν1.f ck .t.A k 4

TRd,max TRd,max = 23470 kNm

cotθ tanθ Max. Spacing of Transv. Reinf. based on Torsion:

Required Reinforcement for Torsion

u s2_max = 1120

TEd tanθ s _ min , b, h mm

At sw .s v Atsw 2 8

2 0.87fy v .A k = 38 mm

Smax = Smaller of S1_max and S2_max Smax = 600 mm

Required Reinforcement for Combined Shear & Torsion

Sact = 200 mm < Smax = 600 mm

A T Av sw 2At sw A sw,min AT 2

= 412 mm

Since Sact < Smax, OK!

Avpvd = 804 > AT = 412

Since the Provided Reinforcement is greater than the Required, OK! Check for Clear Spacing of Main Reinforcement

Adequacy of Section for Combined Shear & Torsion Table 7.3N Maximum Bar Spacing for Crack Control

Steel Stress, fs Bar Clear Spacing, s Number of Bars in Layer 1

TEd VEd

1.0 160 MPa 300 mm N = 12 pcs

TRd,max VRd,max

200 MPa 250 mm

240 MPa 200 mm Allowable Crack Width

0.14 < 1.0 Section is Adequate, OK!

280 MPa 150 mm wk,allow = 0.30 mm

Additional Longitudinal Torsional Reinforcement 320 MPa 100 mm

360 MPa 50 mm

TEd u k

A SL . .cotθ ASL = 10382 mm2 The stress of rebar at service, 's shall be calculated using the principle of cracked section,

2A k 0.87fy L

see next page for detailed calculation of 's. 's = 43 N/mm2

Required Reinforcement for Bending

f σ 43 N/mm2 160 N/mm2

As B As b As t AsB = 8001 mm 2

Maximum Clear Spacing of Main Reinforcement

Required Reinforcement for Bending & Torsion 2

for fs = 160 N/mm smax = 300 mm

As rqd As B A SL Asrqd = 18383 mm2

Minimum Clear Spacing of Main Reinforcement c' = 135 mm

Provided Reinforcement for Bending & Torsion c" = 100 mm

s d or 20 smin = 32 mm

As T As pvd db = 32 mm

AsT = 48240 mm2

Actual Clear Spacing of Main Reinforcement

AsT = 48240 > Asrqd = 18383 s b c c" ⁄ N 1 d sact = 168 mm

Since the Provided Reinforcement is greater than the Required, OK! Since, Smin < Sact < Smax, OK!

Reference Code: SS EN 1992-1-1:2008 Design of Concrete Structures Page 2 of 3

PROJECT TITLE LOCATION

MARK:

MEMBER DESIGN FOR BENDING

RC SHEAR & TORSION

TG FOUNDATION Singapore

MEMBER GX1A

KEPPEL LNTP PROJECT DATE -

In Accordance with SS EN 1992-1-1:2008

RC Beam Design_Ver.03

CHECK FOR CRACK Design Notes

Design Parameters where:

1.0 for pure tension

Maximum Service Axial Load (COMP.) NEd = 928 kN kc σc = 0.40

0.4.1 1.0 for Bending Axial

k1.h/h .f ct,eff

Maximum Service Moment MEd = 1091 kN-m *

2

Mean Conc. Tensile Strength, fct,eff = fctm fct,eff = 2.8 N/mm

2

Modulus of Elasticity of Steel Es = 200000 N/mm

N Ed

Modulus of Elasticity of Concrete Ecm = 32300 N/mm

2 σc c = 0.1094 N/mm2

b.h

Width of Beam b = 2430 mm

Depth of Beam h = 3490 mm h for h 1000mm

Effective Depth of Beam d = 3360 mm h* h* = 1000 mm

2

1000 for h 1000mm

Provided Area of Rebars As = 8040 mm

Concrete Covering cc = 114 mm 1.5 if N Ed is a compressiv e force

Diameter of Main Bar = 32 mm k1 2h * k1 = 1.5

if N Ed is a tensile force

3h

Required Minimum Reinforcement for Crack Control

k c .k.f ct,eff .A ct 2 1.0 for webs with h 300mm

A s,min As,min = 1150 mm for webs with h 800mm k = 0.65

σs k 0.65

2

intermedia te values may be interpolat ed

Provided Reinforcement As,prvd = 8040 mm

Since the Required Minimum Reinforcement < Provided Reinforcement, OK! A b. 2.5 h d Act = 789750 mm2

Calculation of Neutral Axis of Cracked Section σ s f yk s = 500 N/mm

2

b.x 2

α' e .A s .d x x = 562 mm e

Es e = 6.2

2 E cm

E

'e s

E c, eff

'e = 17.03

ρ p,eff A s ξ12 A 'p /A c,eff A'p = 0

p,eff = 0.0102

Calculation of Rebar Stress at Service Limit Ac,eff = 789750 mm2

A c,eff b.h c,eff

M Ed

σ s' 's = 43 N/mm

2

2.5(h - d) = 325

x

A s . d h c,eff min . (h - x)/3 = 976 hc,eff = 325 mm

3

h/2 = 1745

Calculation of Crack Width

0.6 for short term loading kt = 0.4

f ct,eff kt

σ's k t . .1 α e .ρ p,eff 0.4 for long term loading

ρ p,eff σ's

ε sm ε cm 0.6 = 0.0001

Es Es 0.8 for high bond bars k1 = 0.8

k1

k .k .k . 1.6 for plain bars

s r,max k 3 .c c 1 2 4 = 921 mm

ρ p,eff

0.5 for bending k2 = 0.5

k

Actual Crack Width 1.0 for pure tension

w k s r,max .ε sm ε cm wk = 0.09 mm k3 and k4 can be found in National Annex k3 = 3.4

and Recommended values are:

Allowable Crack Width wk,allow = 0.30 mm k4 = 0.425

E cm

Since Actual Crack Width is lesser than the Allowable Crack Width, OK! E c, eff Ec,eff = 11745 N/mm2

1 , t o

, t o = 1.75 (Creep Coefficient, See Fig. 3.1

of EN NEN 1992-1)

C28/35

Procedure How to Read the Graph

Concrete Class: Class N

Concrete Age: 28 Days

28 Days

h > 1500mm

1.75

Reference Code: SS EN 1992-1-1:2008 Design of Concrete Structures Page 3 of 3

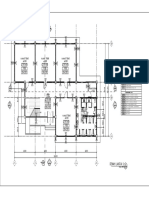

You might also like

- Design Sheet: View A Load Case= Nodal ID = α F F F Precast BeamDocument5 pagesDesign Sheet: View A Load Case= Nodal ID = α F F F Precast BeamGanesh PrabuNo ratings yet

- Design of ColumnsDocument6 pagesDesign of ColumnsGlenn Enrico AmoloNo ratings yet

- Design of Beam For Shear & TorsionDocument4 pagesDesign of Beam For Shear & TorsionGlenn Enrico AmoloNo ratings yet

- MUR860Document2 pagesMUR860rumburac_13No ratings yet

- Pegatron BOSTON BS BS-TK Colay REV 1.0 - Toshiba Satellite C670Document77 pagesPegatron BOSTON BS BS-TK Colay REV 1.0 - Toshiba Satellite C670Serwis MagazynNo ratings yet

- (Esquema) Ba41-00809a (Gce) Ba41-00810a (Nanya) Hainan3 - Ext Rev1.0Document53 pages(Esquema) Ba41-00809a (Gce) Ba41-00810a (Nanya) Hainan3 - Ext Rev1.0Keven silvaNo ratings yet

- Part - 1 Structural Drawing 20201221Document5 pagesPart - 1 Structural Drawing 20201221Aung Thit LwîñNo ratings yet

- Rev 01 Part - 1 Structural Drawing 202012225Document6 pagesRev 01 Part - 1 Structural Drawing 202012225Aung Thit LwîñNo ratings yet

- HPC Bridge Views SummaryDocument16 pagesHPC Bridge Views SummaryWaheed AhmadNo ratings yet

- 5.FSD C22048 Ele 102Document1 page5.FSD C22048 Ele 102mhazarath murariNo ratings yet

- D PRXDocument1 pageD PRXDiana ArredondoNo ratings yet

- RECT - Uni-Axial Column Capacity ACI 318-08 R3Document3 pagesRECT - Uni-Axial Column Capacity ACI 318-08 R3Glenn Enrico AmoloNo ratings yet

- CIRC - Uni-Axial Column Capacity ACI 318-08 R2Document2 pagesCIRC - Uni-Axial Column Capacity ACI 318-08 R2Glenn Enrico AmoloNo ratings yet

- Architectural & Structural-Driver's LoungeDocument14 pagesArchitectural & Structural-Driver's Loungejoseph mtalemwaNo ratings yet

- Prototype Asrama MartapuraDocument9 pagesPrototype Asrama MartapuraAndika PermataNo ratings yet

- D D D D D D: SN54ABT640, SN74ABT640 Octal Bus Transceivers With 3-State OutputsDocument8 pagesD D D D D D: SN54ABT640, SN74ABT640 Octal Bus Transceivers With 3-State OutputsStuxnetNo ratings yet

- 6b42b - Compal - LA A913p - r0.1 - 2013 Dell Latitude 5550 1Document57 pages6b42b - Compal - LA A913p - r0.1 - 2013 Dell Latitude 5550 1Carlos ArévaloNo ratings yet

- THAIOIL - BEAM TO BEAM - FIN PLATE - BOLTED - 001 - Rev ADocument10 pagesTHAIOIL - BEAM TO BEAM - FIN PLATE - BOLTED - 001 - Rev ACivil StructureNo ratings yet

- XA33-20-TX: Polarisation Gain HBW Elec Downtilt Frequency Cross Polarised Single Band Antenna Xpol +45 - 45Document1 pageXA33-20-TX: Polarisation Gain HBW Elec Downtilt Frequency Cross Polarised Single Band Antenna Xpol +45 - 45ИмяNo ratings yet

- 21Document4 pages21Sarah Mae GarciaNo ratings yet

- Strap FootingDocument2 pagesStrap FootingLloyd Ki'sNo ratings yet

- Spreadsheets To BS 8110: Advisory Group ECBP Typical Floor To BS8110 RMW 11-Jun-2020 123 CHG - R68Document23 pagesSpreadsheets To BS 8110: Advisory Group ECBP Typical Floor To BS8110 RMW 11-Jun-2020 123 CHG - R68Hossen LeopoldNo ratings yet

- BBS 24+523 - 322Document29 pagesBBS 24+523 - 322Aejaz Ur RahmanNo ratings yet

- Samsung Cambridge r1 SchematicsDocument76 pagesSamsung Cambridge r1 SchematicsYaroslav NikonovNo ratings yet

- Project Name: Two and A Half Storey Residential Building: Date: 20/dec/2020Document1 pageProject Name: Two and A Half Storey Residential Building: Date: 20/dec/2020Aung Thit LwîñNo ratings yet

- Construction PlanDocument4 pagesConstruction Planzamree BMNo ratings yet

- Steel Embedeed Type M (2ND Floor)Document7 pagesSteel Embedeed Type M (2ND Floor)nofrizar nofriNo ratings yet

- Design of CorbalDocument47 pagesDesign of CorbalHussam JumahNo ratings yet

- STR 8Document1 pageSTR 8Syahrul RomadhonNo ratings yet

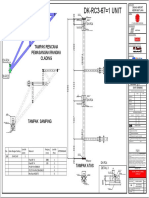

- DK-RC3-67 1 UNIT: Tampak Rencana Pemasangan Rangka CladingDocument1 pageDK-RC3-67 1 UNIT: Tampak Rencana Pemasangan Rangka CladingRobert EffendiNo ratings yet

- 23ho-139me-D-01 - Rev.a1 - Tube Bundle General ArrangementDocument1 page23ho-139me-D-01 - Rev.a1 - Tube Bundle General ArrangementIkatan Alumni GumuruhNo ratings yet

- CN 05Document3 pagesCN 05GousePeerzadeNo ratings yet

- 300 WW 14T2 1 009 Bk1.shaDocument1 page300 WW 14T2 1 009 Bk1.shaABDERRAZZAKNo ratings yet

- C 9403Document2 pagesC 9403christian culladoNo ratings yet

- RTKF Porip - General InfoDocument11 pagesRTKF Porip - General InfomaggamNo ratings yet

- 4.FSD C22048 Ele 101Document1 page4.FSD C22048 Ele 101mhazarath murariNo ratings yet

- Cantilever SlabDocument7 pagesCantilever Slabankit kadamNo ratings yet

- Dce DW ST BLG C Col 1st 2nd 029bDocument1 pageDce DW ST BLG C Col 1st 2nd 029bMidhun Babu NTNo ratings yet

- Design Information: 1. Type of Structure 3. Reference CodesDocument8 pagesDesign Information: 1. Type of Structure 3. Reference CodesWin ThanNo ratings yet

- Splitline 52Document10 pagesSplitline 52Antoni WangNo ratings yet

- Ppd-Zamboanga 3 Storey Warehouse - Rev00 - 20.12.2022Document16 pagesPpd-Zamboanga 3 Storey Warehouse - Rev00 - 20.12.2022Thinh LuongNo ratings yet

- Base Plate External Pipe Rack PK 12bDocument2 pagesBase Plate External Pipe Rack PK 12bDass DassNo ratings yet

- PM3 Dwall Option 20240109Document1 pagePM3 Dwall Option 20240109Tâm TrầnNo ratings yet

- THAIOIL - DOUBLE SHEAR CLEAT ANGLE - BOLTED - 005 - Rev ADocument11 pagesTHAIOIL - DOUBLE SHEAR CLEAT ANGLE - BOLTED - 005 - Rev ACivil StructureNo ratings yet

- Dell 5400 EDC41 LA-G891PDocument103 pagesDell 5400 EDC41 LA-G891PDariusz SmętekNo ratings yet

- Connection Design WSM Rev.00Document53 pagesConnection Design WSM Rev.00leroytuscanoNo ratings yet

- 01 - Doors and Windows ScheduleDocument1 page01 - Doors and Windows ScheduleKarlomarco ParedesNo ratings yet

- Flange Design As Per PedDocument10 pagesFlange Design As Per Pedvaibhavd123No ratings yet

- E9d6f Compal La-A691p r1.0 SchematicsDocument53 pagesE9d6f Compal La-A691p r1.0 Schematicsjoe wiillsonNo ratings yet

- Tampak Gondola Tower 2Document1 pageTampak Gondola Tower 2Triez zhedhlieNo ratings yet

- Shop Drawing 1st Submission 20211005Document10 pagesShop Drawing 1st Submission 20211005roy leungNo ratings yet

- 9.14M Wide RoadDocument18 pages9.14M Wide RoadPriodeep Chowdhury100% (2)

- 2 Expansion Joint DetailDocument1 page2 Expansion Joint Detailbenjamin swokaNo ratings yet

- Batemans BayDocument1 pageBatemans BayAnonymous riBDrDGiNo ratings yet

- Alvarez Engr. Catibayan: Riser Diagram 1 3Document1 pageAlvarez Engr. Catibayan: Riser Diagram 1 3Grizzly BearNo ratings yet

- AD534Document12 pagesAD534Vaibhav GaurNo ratings yet

- محطة ساقية ابو شعرةDocument187 pagesمحطة ساقية ابو شعرةAhmed TalaatNo ratings yet

- A B C D E F G H: Lake House Family Club - East BuildingDocument1 pageA B C D E F G H: Lake House Family Club - East BuildingrfaizalnurandyNo ratings yet