Professional Documents

Culture Documents

Manual Boiler Feed IND 6

Manual Boiler Feed IND 6

Uploaded by

Hicham Idrisi0 ratings0% found this document useful (0 votes)

7 views1 pageThe document discusses boiler house components, focusing on deaerators. It provides details on:

1) Deaerators are tanks used in steam boiler systems to reduce oxygen and carbonic acid levels in boiler feed water to protect against corrosion.

2) Thermal deaerators heat water to around 221°F using steam to remove air through an air vent valve, maintaining a total pressure of 1.2 bar absolute.

3) Vacuum deaerators use an ejector pump to create a vacuum and boil water over 140°F to remove air. This type is commonly used in steam turbine applications.

Original Description:

Manual-Boiler-Feed-IND-11

Original Title

Manual-Boiler-Feed-IND-6

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses boiler house components, focusing on deaerators. It provides details on:

1) Deaerators are tanks used in steam boiler systems to reduce oxygen and carbonic acid levels in boiler feed water to protect against corrosion.

2) Thermal deaerators heat water to around 221°F using steam to remove air through an air vent valve, maintaining a total pressure of 1.2 bar absolute.

3) Vacuum deaerators use an ejector pump to create a vacuum and boil water over 140°F to remove air. This type is commonly used in steam turbine applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views1 pageManual Boiler Feed IND 6

Manual Boiler Feed IND 6

Uploaded by

Hicham IdrisiThe document discusses boiler house components, focusing on deaerators. It provides details on:

1) Deaerators are tanks used in steam boiler systems to reduce oxygen and carbonic acid levels in boiler feed water to protect against corrosion.

2) Thermal deaerators heat water to around 221°F using steam to remove air through an air vent valve, maintaining a total pressure of 1.2 bar absolute.

3) Vacuum deaerators use an ejector pump to create a vacuum and boil water over 140°F to remove air. This type is commonly used in steam turbine applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

grundfos boiler feed manual grundfos boiler house components

Boiler house components Deaerator

The most important task for the deaerator is to

Deaerator reduce the oxygen (O2) and carbonic acid (H2CO3)

Deaerator and condenser tanks are only used in steam levels in boiler feed water to protect the boiler against

boiler systems and not in hot water and hot oil boilers corrosion. It is possible to reduce the oxygen and

as fluid is always in its liquid form. The construction carbonic acid levels to approx. < 0.02 mg/l of O2 and 0

of these two types of tanks is almost identical, but mg/l of CO2, depending on the deaerator construction.

as their names indicate, they are used for different

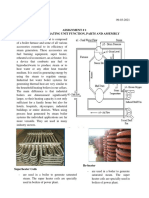

Fig. 9: Deaerator

purposes. Air vent

Two primary principles are used with this form of Condensate

tank design; thermal and vacuum. The tank design

used depends on the type of boiler being used.

Each principle also has different pump construction Vent Trayed section Deaerator

requirements.

Aeration steam

Thermal principle

A tank using the thermal principle is connected to the

Glass Feed tank

atmosphere. This design is normally used in smaller level Liquid level

plants. Here, steam is used to maintain the tank gauge

water temperature at around 221°F, which removes

Heating steam

air from the water. The air vent valve mounted on the

Deaerator or condenser needs an opening pressure

of approx. 0.2 bar. This provides a total pressure of 1.2

bar absolute. This means that the water will boil at a

Drain Rollers

temperature higher than the usual 212˚F which is the Deaerated water to

normal boiling temperature in atmospheric pressure. boiler feed water pump

See also the vapour pressure table at the back of this

manual. Besides the air vent valve, a vacuum breaker Internal steam distributor piping

valve has also been mounted to ensure that vacuum Internal perforated pipe (water distributor)

never occurs in this tank type. If the vacuum valve

Perforated trays

was not mounted, vacuum could occur when cold

Low pressure steam

make-up water was added to the tank.

Boiler feed water (Recycled condensate and make-up water)

Vacuum principle

Here an ejector pump is used to create a vacuum in Over the last years it has become more and more

the tank. This causes the water to start boiling even normal just to use hot wells or water tanks with a

at lower temperature than typical 140°F. This in turn water temperature of approx. 176°F instead of the

removes air from the water. This principle is normally deareators to get the oxygen out of the water. Instead

used in steam turbine applications. of boiling the water in these tanks chemicals are

dosed to remove the oxygen.

10 11

You might also like

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewFrom EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewRating: 5 out of 5 stars5/5 (1)

- Pressurized Deaerator Spec PDFDocument9 pagesPressurized Deaerator Spec PDFkosmc123No ratings yet

- Deareator Training Topic OCT 2022Document17 pagesDeareator Training Topic OCT 2022mizharmuisstNo ratings yet

- Deaerator Working Principle: What Is Deaeration?Document4 pagesDeaerator Working Principle: What Is Deaeration?Freddy Mendoza CoronelNo ratings yet

- AdcaTraining-2-Rev 02 53b126afc413aDocument40 pagesAdcaTraining-2-Rev 02 53b126afc413ajoaquin torrano veraNo ratings yet

- Deaerator PapgingDocument36 pagesDeaerator PapgingPrudhvi Raj100% (2)

- Condenser & BoilerDocument33 pagesCondenser & BoilerShaun Patrick Albao100% (2)

- Condenser Functions of Condensers: Plant Maintenance Work and Service - PracticeDocument18 pagesCondenser Functions of Condensers: Plant Maintenance Work and Service - PracticeTHEOPHILUS ATO FLETCHER100% (1)

- FinalDocument77 pagesFinalAnup MinjNo ratings yet

- I A L R: Ntroduction ND Iterature EviewDocument42 pagesI A L R: Ntroduction ND Iterature Eviewyfyfkfuf100% (1)

- DeaeratorDocument6 pagesDeaerator9kkn7rsdm8No ratings yet

- Chapter One: CondenserDocument10 pagesChapter One: Condenserشاكر العاقل100% (1)

- Feed Water Tanks PDFDocument4 pagesFeed Water Tanks PDFAleksei SukhovNo ratings yet

- Ijett V4i5p58 PDFDocument4 pagesIjett V4i5p58 PDFAndirazakNo ratings yet

- Steam CondensersDocument59 pagesSteam CondensersBLACK GAMINGNo ratings yet

- Water Tube BoilersDocument5 pagesWater Tube Boilerssyakirz_1100% (1)

- Introduction To BoilersDocument219 pagesIntroduction To BoilersTsako ManganyeNo ratings yet

- Deaerator Principle & ApplicationDocument3 pagesDeaerator Principle & Applicationarvidkumar87060100% (1)

- Boiler Performance ImproveDocument5 pagesBoiler Performance Improvehwang2No ratings yet

- Skills Workshop: For Condensing BoilersDocument3 pagesSkills Workshop: For Condensing BoilersKailas NimbalkarNo ratings yet

- Acitivity No.1 Group 3Document17 pagesAcitivity No.1 Group 3johnfelixcollectionNo ratings yet

- Water Circulation SystemDocument24 pagesWater Circulation SystemRaga Lasya100% (1)

- Tps in IoclDocument4 pagesTps in IoclanirNo ratings yet

- Boiler Feedwater: A. DeaerationDocument11 pagesBoiler Feedwater: A. DeaerationRaja TNo ratings yet

- Lec 13 Boliers CH - Eng L.AboudDocument25 pagesLec 13 Boliers CH - Eng L.AboudAnas DarwishNo ratings yet

- Primary-Secondary-Tertiary Pumping PDFDocument32 pagesPrimary-Secondary-Tertiary Pumping PDFMinh TranNo ratings yet

- Boiler Efficiency & ImprovementsDocument32 pagesBoiler Efficiency & ImprovementsIndian Tech.No ratings yet

- Assignment # 1 Steam Generating Unit Function, Parts and AssemblyDocument8 pagesAssignment # 1 Steam Generating Unit Function, Parts and AssemblyJohannis ReyNo ratings yet

- Superheaters and ReheaterDocument16 pagesSuperheaters and ReheaterBudi Norton100% (1)

- Chapter 5 Steam CondenserDocument40 pagesChapter 5 Steam CondenserHabtamu Tkubet Ebuy100% (1)

- Presentation By: 3 Year Mech-D 17985A077 17985A078 17985A079 17985A083 17985A084 17985A088 17985A092 17985A095 17985A098Document15 pagesPresentation By: 3 Year Mech-D 17985A077 17985A078 17985A079 17985A083 17985A084 17985A088 17985A092 17985A095 17985A098pranav100% (1)

- ASTW Smell Removal BrochureDocument12 pagesASTW Smell Removal BrochureWilki SantanderNo ratings yet

- Steam Condesers Note 2Document7 pagesSteam Condesers Note 2diksahu wfeeNo ratings yet

- Chapter 4. Steam Jet Refrigeration SystemsDocument14 pagesChapter 4. Steam Jet Refrigeration SystemsMicah SileshiNo ratings yet

- Experimental Study On Heat Recovery From Continuous Blow Down Water and Reduced Feed Water Consumption by Utilizing It in CFBC BoilerDocument5 pagesExperimental Study On Heat Recovery From Continuous Blow Down Water and Reduced Feed Water Consumption by Utilizing It in CFBC BoilerIan B. YtomNo ratings yet

- Blowdown Systems EG 9 - 2 PDFDocument4 pagesBlowdown Systems EG 9 - 2 PDFcvolkan1No ratings yet

- Ammonia AbsorptionDocument5 pagesAmmonia Absorptionfarzad100% (1)

- Steam Condenser: Me 420 - Me Laboratory 2Document74 pagesSteam Condenser: Me 420 - Me Laboratory 2daan100% (1)

- 1 210 Desuperheaters Spirax SarcoDocument7 pages1 210 Desuperheaters Spirax SarcoWADENo ratings yet

- Manual Boiler Feed IND 8 PDFDocument1 pageManual Boiler Feed IND 8 PDFHicham IdrisiNo ratings yet

- Boiler Feed PumpDocument32 pagesBoiler Feed PumpAli Bari100% (2)

- Absorption Refrigeration - AKMDocument19 pagesAbsorption Refrigeration - AKMTahmid HossainNo ratings yet

- Considerations in Designing Sour Water StrippersDocument6 pagesConsiderations in Designing Sour Water StrippersHanan AmarkiNo ratings yet

- Utility Assignment: Reboiler Arranged By: I Made Vidya Prawira Satrio 21030117190076 Awindya Candrasmurti 21030117190176Document7 pagesUtility Assignment: Reboiler Arranged By: I Made Vidya Prawira Satrio 21030117190076 Awindya Candrasmurti 21030117190176I Made Vidya Prawira SatrioNo ratings yet

- Deaerating Boiler FeedwaterDocument4 pagesDeaerating Boiler Feedwaterritesh sharmaNo ratings yet

- Blowdown in Boiler - Boiler Blowdown Calculation Formula & Calculator...Document7 pagesBlowdown in Boiler - Boiler Blowdown Calculation Formula & Calculator...حسين مهديNo ratings yet

- Steam26b Condensing PDFDocument3 pagesSteam26b Condensing PDFAnonymous Q9i062VNo ratings yet

- BKLT DeaeratorDocument24 pagesBKLT Deaeratormalikgaurav01No ratings yet

- Vapour AbsorptionDocument15 pagesVapour AbsorptionSatheesh ChandranNo ratings yet

- Manual Boiler Feed IND 5 PDFDocument1 pageManual Boiler Feed IND 5 PDFHicham IdrisiNo ratings yet

- Thermal Degassing Fundamentals R4i1 enDocument6 pagesThermal Degassing Fundamentals R4i1 enAnonymous v5uipHNo ratings yet

- Chapter SixDocument25 pagesChapter SixADEFRIS BELACHEWNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Aquaponics in Winter: How to Heat Your Aquaponic Garden in Cold ClimateFrom EverandAquaponics in Winter: How to Heat Your Aquaponic Garden in Cold ClimateNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Manual Boiler Feed IND 28 PDFDocument1 pageManual Boiler Feed IND 28 PDFHicham IdrisiNo ratings yet

- Manual Boiler Feed IND 21Document1 pageManual Boiler Feed IND 21Hicham IdrisiNo ratings yet

- Manual Boiler Feed IND 18 PDFDocument1 pageManual Boiler Feed IND 18 PDFHicham IdrisiNo ratings yet

- Manual-Boiler-Feed-IND (1) - 15-18 PDFDocument4 pagesManual-Boiler-Feed-IND (1) - 15-18 PDFHicham IdrisiNo ratings yet

- Manual Boiler Feed IND 1Document1 pageManual Boiler Feed IND 1Hicham IdrisiNo ratings yet

- Manual Boiler Feed IND 19 PDFDocument1 pageManual Boiler Feed IND 19 PDFHicham IdrisiNo ratings yet

- Manual Boiler Feed IND 13 PDFDocument1 pageManual Boiler Feed IND 13 PDFHicham IdrisiNo ratings yet

- Manual Boiler Feed IND 15 PDFDocument1 pageManual Boiler Feed IND 15 PDFHicham IdrisiNo ratings yet

- Manual Boiler Feed IND 7 PDFDocument1 pageManual Boiler Feed IND 7 PDFHicham IdrisiNo ratings yet

- 201-Intercom Alphatron AlphaCall MF InstallOper Manual 3-6-2008 PDFDocument22 pages201-Intercom Alphatron AlphaCall MF InstallOper Manual 3-6-2008 PDFHicham IdrisiNo ratings yet

- Manual Boiler Feed IND 3 PDFDocument1 pageManual Boiler Feed IND 3 PDFHicham IdrisiNo ratings yet

- The Ultimate Guide To Riding The Trans-Siberian Railway - Kara and NateDocument88 pagesThe Ultimate Guide To Riding The Trans-Siberian Railway - Kara and NateHicham IdrisiNo ratings yet

- Manual Boiler Feed IND 10 PDFDocument1 pageManual Boiler Feed IND 10 PDFHicham IdrisiNo ratings yet

- 2 Days in Berlin - A Guide To The Perfect Weekend in Berlin (Itinerary)Document20 pages2 Days in Berlin - A Guide To The Perfect Weekend in Berlin (Itinerary)Hicham IdrisiNo ratings yet

- Advanced Training For Oil Tanker Cargo Operations - Model Course 1.02Document238 pagesAdvanced Training For Oil Tanker Cargo Operations - Model Course 1.02Hicham Idrisi100% (3)

- 3 Days in Berlin (Budget Guide + Itinerary)Document20 pages3 Days in Berlin (Budget Guide + Itinerary)Hicham IdrisiNo ratings yet

- Comfort Handbook - Lowres PDFDocument474 pagesComfort Handbook - Lowres PDFHicham IdrisiNo ratings yet

- Sopep PlanDocument36 pagesSopep PlanHicham IdrisiNo ratings yet