Professional Documents

Culture Documents

System PDF Files - 1. UL and cUL Systems - wl7025 - DL

System PDF Files - 1. UL and cUL Systems - wl7025 - DL

Uploaded by

Emanuel PastlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System PDF Files - 1. UL and cUL Systems - wl7025 - DL

System PDF Files - 1. UL and cUL Systems - wl7025 - DL

Uploaded by

Emanuel PastlCopyright:

Available Formats

Classified by

Underwiters Laboratories, Inc.

to ANSI/UL 1479 (ASTM E814) and CAN/ULC S115

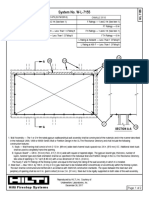

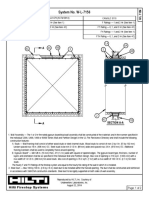

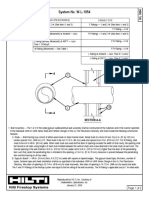

System No. W-L-7025

ANSI/UL1479 (ASTM E814) CAN/ULC S115

F Ratings - 1 and 2 Hr (See Item 1) F Ratings - 1 and 2 Hr (See Item 1)

T Rating - 1/2 Hr FT Rating - 1/2 Hr

L Rating At Ambient - Less Than 1 CFM/sq ft FH Ratings - 1 and 2 Hr (See Item 1)

L Rating At 400 F - Less Than 1 CFM/sq ft FTH Rating - 1/2 Hr

L Rating At Ambient - Less Than 5.1 L/s/m3

L Rating At 204 C- Less Than 5.1 L/s/m3

1A

A 1A

3B 3C

3B

1B

A

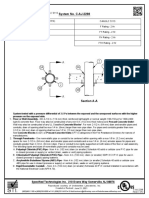

2 Section A-A

1. Wall Assembly - The 1 or 2 hr fire-rated gypsum wallboard/stud wall assembly shall be constructed of the materials and in

the manner described in the individual U400, V400 or W 400 Series Wall or Partition Design in the UL Fire Resistance

Directory and shall include the following construction features:

A. Studs - Wall framing shall consist of min 3-1/2 in. (89 mm) wide steel channel studs spaced max 24 in. (610 mm) OC.

Additional steel studs shall be used to completely frame the opening.

B. Gypsum Board* - 5/8 in. (16 mm) thick, 4 ft (1.22 m) wide with square or tapered edges. The gypsum board type,

thickness, number of layers, fastener type and sheet orientation shall be as specified in the individual Design in the UL

Fire Resistance Directory. Max area of opening is 73.7 sq ft (6.85 m2) with a max dimension of 104 in. (2.64 m).

The hourly F and FH Ratings of the firestop system are equal to the hourly fire rating of the wall assembly in

which it is installed.

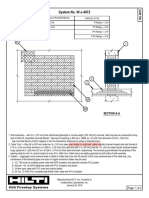

2. Steel Duct - Max 100 in. by 100 in. (2.54 by 2.54 m) No. 26 gauge (or heavier) galv steel duct to be installed either

concentrically or eccentrically within the firestop system. The space between the steel duct and periphery of opening shall be

min 0 in. ( 0 mm, point contact) to max 2 in. (51 mm). Steel duct to be rigidly supported on both sides of the wall assembly.

2A. Coated Ducts* - As an alternate to Item 2, max 60 by 60 in. (1524 by 1524 mm) steel duct coated with BW11 coating

material. Duct sections shall be assembled using bolted flanges or SMACNA approved Transverse Joint Reinforcements.

Annular space between duct and periphery of opening shall be shall be min 0in. (point contact) to max 2 in. (51 mm). Duct to

be rigidly supported on both sides wall assembly.

FIRESPRAY INTERNATIONAL LTD - FLAMEBAR BW11 fire rated ductwork

Specified Technologies Inc. 210 Evans Way Somerville, NJ 08876

Reproduced courtesy of Underwriters Laboratories, Inc.

Created or Revised: July 24, 2017 R

STI ® (800)992-1180 · (908)526-8000 · FAX (908)231-8415 · E-Mail:techserv@stifirestop.com · Website:www.stifirestop.com

W-L-7025

PAGE 1 OF 2

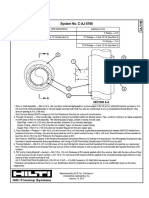

3. Firestop System - The firestop system shall consist of the following:

A. Packing Material - (Optional, Not Shown) - Polyethylene backer rod, mineral wool batt insulation or fiberglass batt

insulation friction fitted into annular space. Packing material to be recessed from both surfaces of wall as required to

accommodate the required thickness of fill material.

B. Fill, Void or Cavity Material* - Sealant - Min 5/8 in. (16 mm) thickness of fill material applied within the annulus, flush

with both surfaces of wall. Min 1/4 in. (6 mm) diam bead of fill material shall be applied at the point contact location

between the steel duct and the gypsum board. For 2 hr Rated walls when LC150 or LE600 Sealant is used, fill material

thickness installed to full depth of gypsum board layers on each side of wall assembly.

SPECIFIED TECHNOLOGIES INC - SpecSeal Series SSS Sealant, SpecSeal LCI Sealant, SpecSeal LCI Sealant,

SpecSeal LC150 Sealant or SpecSeal LE 600 Sealant.

C. Steel Retaining Angles - Min No. 16 gauge (0.059 in. or 15 mm) galv steel angles sized to lap steel duct a min of 2 in. (51

mm) and to lap wall surfaces a min of 1 in. (25 mm). Angles attached to steel duct on both sides of wall with min No. 10 by

1/2 in. (13 mm) long steel sheet metal screws located a max of 1 in. (25 mm) from each end of steel duct and spaced a

max of 6 in. (152 mm) OC.

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL

Certification (such as Canada), respectively.

Specified Technologies Inc. 210 Evans Way Somerville, NJ 08876

Reproduced courtesy of Underwriters Laboratories, Inc.

Created or Revised: July 24, 2017 R

STI ® (800)992-1180 · (908)526-8000 · FAX (908)231-8415 · E-Mail:techserv@stifirestop.com · Website:www.stifirestop.com

W-L-7025

PAGE 2 OF 2

You might also like

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- Max 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyDocument2 pagesMax 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyvikaspisalNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFEmanuel PastlNo ratings yet

- Sistema UL HWD0079 Junta 2 Hrs DrywallDocument2 pagesSistema UL HWD0079 Junta 2 Hrs DrywallRaul Fernando Villarreal VargasNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- Approval Document ASSET DOC LOC 939Document2 pagesApproval Document ASSET DOC LOC 939andy_ramblaNo ratings yet

- C Aj 2586 PDFDocument1 pageC Aj 2586 PDFEmanuel PastlNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- WL7223Document1 pageWL7223Juvenal GutierrezNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2320Document1 pageSystem PDF Files - 1. UL and cUL Systems - fc2320Emanuel PastlNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- Approval Document ASSET DOC LOC 716Document2 pagesApproval Document ASSET DOC LOC 716fazil yoosufNo ratings yet

- System No. C-AJ-2898Document2 pagesSystem No. C-AJ-2898darwish.hiltiNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj8113 - DLDocument4 pagesSystem PDF Files - 1. UL and cUL Systems - Caj8113 - DLEmanuel PastlNo ratings yet

- HI TECH Corrugate Pipe BroucherDocument30 pagesHI TECH Corrugate Pipe BroucherarsssyNo ratings yet

- HILTI - Approval-document-ASSET-DOC-LOC-722Document1 pageHILTI - Approval-document-ASSET-DOC-LOC-722david messierNo ratings yet

- Stopping StuffDocument28 pagesStopping StuffaNo ratings yet

- Approval Document ASSET DOC LOC 953Document2 pagesApproval Document ASSET DOC LOC 953andy_ramblaNo ratings yet

- Chain Link Fence and Gates 32-31-13Document14 pagesChain Link Fence and Gates 32-31-13melvinkorahNo ratings yet

- HW-D-0038 - 1 of 1: 3M Fire Protection ProductsDocument1 pageHW-D-0038 - 1 of 1: 3M Fire Protection Productskirollos HabibNo ratings yet

- BIS Hume PipeDocument7 pagesBIS Hume PipeShiv Pratap SinghNo ratings yet

- LPS v1Document3 pagesLPS v1mdhasan40751No ratings yet

- Approval Document ASSET DOC LOC 99Document1 pageApproval Document ASSET DOC LOC 99Amir IqbalNo ratings yet

- BXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQDocument6 pagesBXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQEmanuel Ciprian CiucurNo ratings yet

- Duct Bank InformationDocument19 pagesDuct Bank InformationGaneshNo ratings yet

- W L 1176Document1 pageW L 1176shama093No ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- Installation ManualDocument40 pagesInstallation ManualHenryMenacho100% (1)

- WL1167Document1 pageWL1167Juvenal GutierrezNo ratings yet

- Ul HWD 0209Document2 pagesUl HWD 0209jlledwinestebanNo ratings yet

- W-L-1054 Pipe Through Gyp Board AssemblyDocument2 pagesW-L-1054 Pipe Through Gyp Board AssemblyJason StelleNo ratings yet

- YORK-AHUDocument11 pagesYORK-AHUTienNguyenNo ratings yet

- CAJ1317Document1 pageCAJ1317Luis AlbertoNo ratings yet

- Minara District A, Stage 2: Badrah DevelopmentDocument4 pagesMinara District A, Stage 2: Badrah DevelopmentCody TillmanNo ratings yet

- Approval Document ASSET DOC LOC 257Document3 pagesApproval Document ASSET DOC LOC 257Omar DDCNo ratings yet

- Abrazaderas para Tubos MMDocument7 pagesAbrazaderas para Tubos MMMarcos Ariel Caceres PozasNo ratings yet

- 1 Electrical N/A: Group Item No. Item Code (If Any)Document9 pages1 Electrical N/A: Group Item No. Item Code (If Any)ApexBD01No ratings yet

- SECTION 08 90 00 Louvers and VentsDocument10 pagesSECTION 08 90 00 Louvers and VentsJuanPaoloYbañezNo ratings yet

- Summary of Modifications/Changes in This UpdateDocument11 pagesSummary of Modifications/Changes in This UpdateAnonymous vh1f95o8No ratings yet

- RMCON Catalogue Min MinDocument20 pagesRMCON Catalogue Min MinSaptarshi RoyNo ratings yet

- Firestop Application Handbook (Macau) - Part-5 PDFDocument25 pagesFirestop Application Handbook (Macau) - Part-5 PDFSharoon S raoNo ratings yet

- Enquiry - Extranal LightDocument12 pagesEnquiry - Extranal Lightrkpatel40No ratings yet

- System No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRDocument2 pagesSystem No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- Marine Switchboards Main and AuxDocument15 pagesMarine Switchboards Main and AuxBharatiyulam100% (3)

- Itaan Pharma Offer For HVAC - R0 - 27.05.22 (1) - 15Document2 pagesItaan Pharma Offer For HVAC - R0 - 27.05.22 (1) - 15Srikanth ChagantipatiNo ratings yet

- Holti System No. C-AJ-8143Document3 pagesHolti System No. C-AJ-8143S. Priscila Castillo V.No ratings yet

- Lapp LeRoy Catalog C-1 12-01-2017 PDFDocument14 pagesLapp LeRoy Catalog C-1 12-01-2017 PDFdeltaNo ratings yet

- Flume 1 84inchParshallSpecDocument3 pagesFlume 1 84inchParshallSpecnupurNo ratings yet

- Champ FMV NR Floodlights 6L: Industry Best For Ease of InstallationDocument4 pagesChamp FMV NR Floodlights 6L: Industry Best For Ease of InstallationMartin MartinezNo ratings yet

- 05 31 00milDocument7 pages05 31 00milJerico NamucoNo ratings yet

- Lighting Poles and StandardsDocument5 pagesLighting Poles and StandardsCharles ChismNo ratings yet

- Bahra BusbarDocument4 pagesBahra BusbarSalmanNo ratings yet