Professional Documents

Culture Documents

System PDF Files - 1. UL and cUL Systems - fc2320

System PDF Files - 1. UL and cUL Systems - fc2320

Uploaded by

Emanuel PastlCopyright:

Available Formats

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- Product Specification: Leminar Air-Conditioning Industries LLCDocument8 pagesProduct Specification: Leminar Air-Conditioning Industries LLCMaher Al LobnanyNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- C Aj 2586 PDFDocument1 pageC Aj 2586 PDFEmanuel PastlNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- Max 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyDocument2 pagesMax 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyvikaspisalNo ratings yet

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlNo ratings yet

- WL7223Document1 pageWL7223Juvenal GutierrezNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFEmanuel PastlNo ratings yet

- C-AJ-2813 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2813 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- CAJ1317Document1 pageCAJ1317Luis AlbertoNo ratings yet

- HW-D-0038 - 1 of 1: 3M Fire Protection ProductsDocument1 pageHW-D-0038 - 1 of 1: 3M Fire Protection Productskirollos HabibNo ratings yet

- Installation Instructions: Supplied As A Complete Fire-Rated Enclosure To Ensure ComplianceDocument1 pageInstallation Instructions: Supplied As A Complete Fire-Rated Enclosure To Ensure ComplianceAnonymous 59kfV93pf4No ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- System No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRArulNo ratings yet

- Detailed Specification PE Casing Jacket With Standard UIP System 1) GeneralDocument3 pagesDetailed Specification PE Casing Jacket With Standard UIP System 1) GeneralMina MagdyNo ratings yet

- DesignSpec FR1200 MultiBoxDocument1 pageDesignSpec FR1200 MultiBoxrbucholzNo ratings yet

- TROSTEN Mechanical Specification - AHUDocument6 pagesTROSTEN Mechanical Specification - AHUBalaji JenarthananNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- System No. C-AJ-2898Document2 pagesSystem No. C-AJ-2898darwish.hiltiNo ratings yet

- System No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDocument2 pagesSystem No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDatNo ratings yet

- 09 51 00asiDocument17 pages09 51 00asiAngelica Dela CruzNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- Technical Data: 1. DescriptionDocument18 pagesTechnical Data: 1. DescriptionitaloNo ratings yet

- Rockwool BoardsDocument12 pagesRockwool BoardsMohammed AwwadNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- Fire Barrier & Cavity Systems Stop Fires!: KillerDocument4 pagesFire Barrier & Cavity Systems Stop Fires!: KillerMedhat ElhagrasiNo ratings yet

- System No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Document2 pagesSystem No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Lea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- DampersDocument25 pagesDampersmpwasaNo ratings yet

- LP Solidstart Ewp SpecificationsDocument10 pagesLP Solidstart Ewp SpecificationsRodrigo CandeoNo ratings yet

- System No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRArulNo ratings yet

- Isover New Build Residential Solutions Guide Separating FloorsDocument7 pagesIsover New Build Residential Solutions Guide Separating FloorsChristian HutterNo ratings yet

- IIG Mineral Wool Spec SheetDocument2 pagesIIG Mineral Wool Spec SheetNaresh PaneruNo ratings yet

- XHEZ.C-AJ-7029 - UL Product IqDocument3 pagesXHEZ.C-AJ-7029 - UL Product Iqfazil yoosufNo ratings yet

- Ameron FRP Fittings 7000MDocument8 pagesAmeron FRP Fittings 7000MNatchimuthu Durai BalanNo ratings yet

- FM Design 628 (FB-4003)Document2 pagesFM Design 628 (FB-4003)raviNo ratings yet

- 644-034 - Pexco, Davidson Traffic Control Products - FG 300 Model EFX - High-Performance Surface Mount PostDocument3 pages644-034 - Pexco, Davidson Traffic Control Products - FG 300 Model EFX - High-Performance Surface Mount PostfelipesvazNo ratings yet

- Cellecta Sound Proofing Solutions GuideDocument24 pagesCellecta Sound Proofing Solutions Guidejamiecellecta2012No ratings yet

- System No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRDocument2 pagesSystem No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- Ready® Sleeve Firestop Sleeve: Product Description ApplicationsDocument2 pagesReady® Sleeve Firestop Sleeve: Product Description ApplicationsMohamed Rafi MNo ratings yet

- Flume 1 84inchParshallSpecDocument3 pagesFlume 1 84inchParshallSpecnupurNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- Specs TARKETT - VCTIIDocument1 pageSpecs TARKETT - VCTIIFede PerezNo ratings yet

- WL1167Document1 pageWL1167Juvenal GutierrezNo ratings yet

- CAJ1427Document1 pageCAJ1427mr. mydNo ratings yet

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Document5 pagesEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783No ratings yet

- White Book C04 Partitions Section 3Document180 pagesWhite Book C04 Partitions Section 3Chris FindlayNo ratings yet

- Atco - Hoja Tecnica PDFDocument2 pagesAtco - Hoja Tecnica PDFAlison ThompsonNo ratings yet

- FlameOFF Fire Barrier PaintDocument2 pagesFlameOFF Fire Barrier PaintmurdicksNo ratings yet

- Boq Ductable AirconditionerDocument3 pagesBoq Ductable AirconditionerAPNIT MISHRANo ratings yet

- Rockwool Fire Barrier SystemsDocument8 pagesRockwool Fire Barrier Systemsaag0475No ratings yet

- Super Firetemp: Fire Protection SystemsDocument6 pagesSuper Firetemp: Fire Protection SystemstimetemasekNo ratings yet

- Fire Technical Manual-ElectricalDocument14 pagesFire Technical Manual-ElectricalWissam AlameddineNo ratings yet

- PVC c900 HP Water PipeDocument8 pagesPVC c900 HP Water Pipeyeli878No ratings yet

- Soundlag 4525C - BrochureDocument4 pagesSoundlag 4525C - BrochureGaynorNo ratings yet

System PDF Files - 1. UL and cUL Systems - fc2320

System PDF Files - 1. UL and cUL Systems - fc2320

Uploaded by

Emanuel PastlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System PDF Files - 1. UL and cUL Systems - fc2320

System PDF Files - 1. UL and cUL Systems - fc2320

Uploaded by

Emanuel PastlCopyright:

Available Formats

Classified by

Underwiters Laboratories, Inc.

to ASTM/UL1479 (ASTM E814)

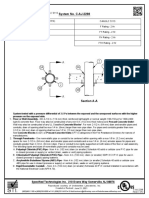

System No. F-C-2320

F Rating - 1 Hr

T Rating - 1 Hr

2

1A 3

1C 1B

1. Floor-Ceiling Assembly - The 1 hr fire-rated solid or trussed lumber joist floor-ceiling assembly shall be constructed of the

materials and in the manner specified in the individual L500 Series Floor-Ceiling Designs in the UL Fire Resistance Directory.

The general construction features of the floor-ceiling assembly are summarized below:

A. Flooring System - Lumber or plywood subfloor with finish floor of lumber, plywood or Floor Topping Mixture* as specified

in the individual Floor-Ceiling Design. Rectangular cutout in flooring to accommodate the bathtub drain piping (Item 2) to be

max 8 by 12 in. (203 by 305 mm). Cutout to be patched on underside of subfloor using one layer of min 3/4 in. (19 mm)

thick plywood or min 5/8 in. (16 mm) thick gypsum wallboard (Item 1C) sized to lap min 2 in. (51 mm) beyond each edge of

rectangular cutout. Diam of opening hole-sawed through patch to accommodate drain piping (Item 2) to be 1 in. (25 mm)

larger than outside diam of drain piping and positioned such that drain piping is centered in opening. Patch split into two

pieces at opening hole-sawed for bathtub drain piping. Two pieces positioned around drain piping, with cut edges tightly

butted, and screw-attached to underside of subfloor with 1-1/4 in. (32 mm) long Type S steel screws spaced max 6 in. (152

mm) OC.

B. Wood Joists* - Nom 10 in. (254 mm) deep (or deeper) lumber, steel or combination lumber and steel joists, trusses or

Structural Wood Members* with bridging as required and with ends firestopped.

C. Gypsum Board* - Nom 4 ft (1.22 m) wide by 5/8 in. (16 mm) thick, attached as described in the individual Floor-Ceiling

Design.

2. Drain Piping - Nom 1-1/2 in. (38 mm) diam (or smaller) Schedule 40 cellular or solid core polyvinyl chloride (PVC) or

acrylonitrile butadiene styrene (ABS) pipe and drain fittings cemented together and provided with PVC or ABS bathtub

waste/overflow fittings. The annular space shall be a min 3/8 in. (10 mm) to max 5/8 in. (16 mm).

3. Fill, Void or Cavity Material* - Sealant - Min 5/8 in. (16 mm) depth of fill material applied within annular space, flush with both

surfaces of plywood or gypsum wallboard patch.

SPECIFIED TECHNOLOGIES INC - Type WF300 Caulk

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification

(such as Canada), respectively.

Specified Technologies Inc. 210 Evans Way Somerville, NJ 08876

Reproduced courtesy of Underwriters Laboratories, Inc.

Created or Revised: January 23, 2014

STI

R

F-C-2320

® (800)992-1180 · (908)526-8000 · FAX (908)231-8415 · E-Mail:techserv@stifirestop.com · Website:www.stifirestop.com PAGE 1 OF 1

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- Product Specification: Leminar Air-Conditioning Industries LLCDocument8 pagesProduct Specification: Leminar Air-Conditioning Industries LLCMaher Al LobnanyNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- C Aj 2586 PDFDocument1 pageC Aj 2586 PDFEmanuel PastlNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- Max 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyDocument2 pagesMax 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyvikaspisalNo ratings yet

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlNo ratings yet

- WL7223Document1 pageWL7223Juvenal GutierrezNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFEmanuel PastlNo ratings yet

- C-AJ-2813 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2813 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- CAJ1317Document1 pageCAJ1317Luis AlbertoNo ratings yet

- HW-D-0038 - 1 of 1: 3M Fire Protection ProductsDocument1 pageHW-D-0038 - 1 of 1: 3M Fire Protection Productskirollos HabibNo ratings yet

- Installation Instructions: Supplied As A Complete Fire-Rated Enclosure To Ensure ComplianceDocument1 pageInstallation Instructions: Supplied As A Complete Fire-Rated Enclosure To Ensure ComplianceAnonymous 59kfV93pf4No ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- System No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRArulNo ratings yet

- Detailed Specification PE Casing Jacket With Standard UIP System 1) GeneralDocument3 pagesDetailed Specification PE Casing Jacket With Standard UIP System 1) GeneralMina MagdyNo ratings yet

- DesignSpec FR1200 MultiBoxDocument1 pageDesignSpec FR1200 MultiBoxrbucholzNo ratings yet

- TROSTEN Mechanical Specification - AHUDocument6 pagesTROSTEN Mechanical Specification - AHUBalaji JenarthananNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- System No. C-AJ-2898Document2 pagesSystem No. C-AJ-2898darwish.hiltiNo ratings yet

- System No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDocument2 pagesSystem No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDatNo ratings yet

- 09 51 00asiDocument17 pages09 51 00asiAngelica Dela CruzNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- Technical Data: 1. DescriptionDocument18 pagesTechnical Data: 1. DescriptionitaloNo ratings yet

- Rockwool BoardsDocument12 pagesRockwool BoardsMohammed AwwadNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- Fire Barrier & Cavity Systems Stop Fires!: KillerDocument4 pagesFire Barrier & Cavity Systems Stop Fires!: KillerMedhat ElhagrasiNo ratings yet

- System No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Document2 pagesSystem No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Lea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- DampersDocument25 pagesDampersmpwasaNo ratings yet

- LP Solidstart Ewp SpecificationsDocument10 pagesLP Solidstart Ewp SpecificationsRodrigo CandeoNo ratings yet

- System No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRArulNo ratings yet

- Isover New Build Residential Solutions Guide Separating FloorsDocument7 pagesIsover New Build Residential Solutions Guide Separating FloorsChristian HutterNo ratings yet

- IIG Mineral Wool Spec SheetDocument2 pagesIIG Mineral Wool Spec SheetNaresh PaneruNo ratings yet

- XHEZ.C-AJ-7029 - UL Product IqDocument3 pagesXHEZ.C-AJ-7029 - UL Product Iqfazil yoosufNo ratings yet

- Ameron FRP Fittings 7000MDocument8 pagesAmeron FRP Fittings 7000MNatchimuthu Durai BalanNo ratings yet

- FM Design 628 (FB-4003)Document2 pagesFM Design 628 (FB-4003)raviNo ratings yet

- 644-034 - Pexco, Davidson Traffic Control Products - FG 300 Model EFX - High-Performance Surface Mount PostDocument3 pages644-034 - Pexco, Davidson Traffic Control Products - FG 300 Model EFX - High-Performance Surface Mount PostfelipesvazNo ratings yet

- Cellecta Sound Proofing Solutions GuideDocument24 pagesCellecta Sound Proofing Solutions Guidejamiecellecta2012No ratings yet

- System No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRDocument2 pagesSystem No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- Ready® Sleeve Firestop Sleeve: Product Description ApplicationsDocument2 pagesReady® Sleeve Firestop Sleeve: Product Description ApplicationsMohamed Rafi MNo ratings yet

- Flume 1 84inchParshallSpecDocument3 pagesFlume 1 84inchParshallSpecnupurNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- Specs TARKETT - VCTIIDocument1 pageSpecs TARKETT - VCTIIFede PerezNo ratings yet

- WL1167Document1 pageWL1167Juvenal GutierrezNo ratings yet

- CAJ1427Document1 pageCAJ1427mr. mydNo ratings yet

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Document5 pagesEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783No ratings yet

- White Book C04 Partitions Section 3Document180 pagesWhite Book C04 Partitions Section 3Chris FindlayNo ratings yet

- Atco - Hoja Tecnica PDFDocument2 pagesAtco - Hoja Tecnica PDFAlison ThompsonNo ratings yet

- FlameOFF Fire Barrier PaintDocument2 pagesFlameOFF Fire Barrier PaintmurdicksNo ratings yet

- Boq Ductable AirconditionerDocument3 pagesBoq Ductable AirconditionerAPNIT MISHRANo ratings yet

- Rockwool Fire Barrier SystemsDocument8 pagesRockwool Fire Barrier Systemsaag0475No ratings yet

- Super Firetemp: Fire Protection SystemsDocument6 pagesSuper Firetemp: Fire Protection SystemstimetemasekNo ratings yet

- Fire Technical Manual-ElectricalDocument14 pagesFire Technical Manual-ElectricalWissam AlameddineNo ratings yet

- PVC c900 HP Water PipeDocument8 pagesPVC c900 HP Water Pipeyeli878No ratings yet

- Soundlag 4525C - BrochureDocument4 pagesSoundlag 4525C - BrochureGaynorNo ratings yet