Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

14 viewsData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDF

Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDF

Uploaded by

Sachin KumarThis document provides the technical specifications for a 3/4" socket welded ball valve. It lists details such as the valve manufacturer, size, material specifications for components like the body, ball, and seals. It also outlines requirements for testing, painting, and that charpy v-notch testing shall be conducted at 0°C with minimum absorbed energies. The valve will be used for natural gas in a pipeline modification project.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- User Design Spec - Rev1Document5 pagesUser Design Spec - Rev1John NashNo ratings yet

- DataSheet 2 More 300# BV - FB - BW - NT-77 PDFDocument1 pageDataSheet 2 More 300# BV - FB - BW - NT-77 PDFSachin KumarNo ratings yet

- Data Sheet 2 More 300# PV - RF - NT-79 PDFDocument1 pageData Sheet 2 More 300# PV - RF - NT-79 PDFSachin KumarNo ratings yet

- Data Sheet 2 Less 800# PV - SW - LT-76Document1 pageData Sheet 2 Less 800# PV - SW - LT-76Sachin KumarNo ratings yet

- Data Sheet 2 Less 800# PV - SW - NT-77Document1 pageData Sheet 2 Less 800# PV - SW - NT-77Sachin KumarNo ratings yet

- Sample DS-1Document1 pageSample DS-1Sachin KumarNo ratings yet

- Sample DSDocument1 pageSample DSSachin KumarNo ratings yet

- 2009 BV SocketWelded DatasheetDocument2 pages2009 BV SocketWelded DatasheetAqib Khan VCSPNo ratings yet

- Rev 01 Mud Gas Separator of Oil ServiceDocument3 pagesRev 01 Mud Gas Separator of Oil ServiceKanti LakhankarNo ratings yet

- CF-1000 SCMH-Approved With Minor CommentsDocument3 pagesCF-1000 SCMH-Approved With Minor CommentsUmer KhanNo ratings yet

- Mazda Limited: Terms and ConditionsDocument3 pagesMazda Limited: Terms and ConditionsrezarossNo ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocument11 pagesDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- Piping Class Specification - CNE-001-2006-E-08-M-L-10126Document20 pagesPiping Class Specification - CNE-001-2006-E-08-M-L-10126Mubashir fareedNo ratings yet

- VMS PDFDocument1 pageVMS PDFritoh8657No ratings yet

- 1664189682389-2ba010110 Cced25030Document1 page1664189682389-2ba010110 Cced25030ylc956867No ratings yet

- Spec 6a E21 en Add3Document16 pagesSpec 6a E21 en Add3LiLiNo ratings yet

- 2/2 Way Direct Acting Solenoid Valve: Uflow AutomationDocument4 pages2/2 Way Direct Acting Solenoid Valve: Uflow AutomationkarthikNo ratings yet

- Datasheet For Ball Valve123Document1 pageDatasheet For Ball Valve123valveNo ratings yet

- DS-01 - LR BendsDocument1 pageDS-01 - LR BendsMecon LtdNo ratings yet

- Boiler 2 Furnace Tube Thickness and LifeDocument1 pageBoiler 2 Furnace Tube Thickness and LifegandungwNo ratings yet

- DS-02 - LR BendsDocument1 pageDS-02 - LR BendsMecon LtdNo ratings yet

- WN SA-105 B16 5 TT Rev0Document2 pagesWN SA-105 B16 5 TT Rev0Aço SalgueiroNo ratings yet

- Datasheet For Ball ValveDocument1 pageDatasheet For Ball ValvevalveNo ratings yet

- Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Document4 pagesGlobe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Ammanda ErnawanNo ratings yet

- CS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3Document2 pagesCS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3PRADEEP GAIKWADNo ratings yet

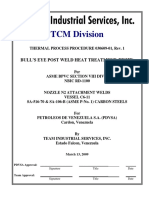

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document11 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- Technical Notes and Specifications Part CDocument29 pagesTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- Nuberg Technical Specification SheetDocument5 pagesNuberg Technical Specification SheetSmart ChannelNo ratings yet

- Spec ListDocument27 pagesSpec ListArun CPNo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document12 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- Data Sheet Item 2Document3 pagesData Sheet Item 2Bagus SigitNo ratings yet

- Valve DatasheetDocument9 pagesValve DatasheetArunkumarNo ratings yet

- 9952T 1311 F0001 PD2 A CDocument169 pages9952T 1311 F0001 PD2 A CBarbara HowellNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- VMS - 3Document1 pageVMS - 3ritoh8657No ratings yet

- Special Notes On ValvesDocument101 pagesSpecial Notes On ValvesamithcivilNo ratings yet

- 123HAN BPS 02 - Rev.2Document1 page123HAN BPS 02 - Rev.2ABDUL RAHMAN ALI MIRNo ratings yet

- 026 To 033test ReportsDocument40 pages026 To 033test ReportsRahul MoottolikandyNo ratings yet

- EDG-2301-DTA-007 Rev 0 (DRAFT) Weld Overlay Linepipe Data Sheet-2Document15 pagesEDG-2301-DTA-007 Rev 0 (DRAFT) Weld Overlay Linepipe Data Sheet-2barrygideonNo ratings yet

- Conexiones 3 SCH 160Document29 pagesConexiones 3 SCH 160RodolfoNo ratings yet

- Validacion Software Conexiones 3 SCH 160Document29 pagesValidacion Software Conexiones 3 SCH 160RodolfoNo ratings yet

- Especificacion B2AS1Document9 pagesEspecificacion B2AS1Jorge TagleNo ratings yet

- 1441793840reactor Datasheet 10kl ss316Document3 pages1441793840reactor Datasheet 10kl ss316Adrian StoicescuNo ratings yet

- Specification - 2023 02 01 09 02 41Document10 pagesSpecification - 2023 02 01 09 02 41Chinnaraj SNo ratings yet

- TDCDocument6 pagesTDCalex hutaurukNo ratings yet

- Qaswa - 100 ABFV 17.06.21Document1 pageQaswa - 100 ABFV 17.06.21FLOW VALVE AUTOMATIONNo ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- 1.0 Data Sheet For Sight Glass 1.1 General Requirements: Minimum (HOLD 2)Document1 page1.0 Data Sheet For Sight Glass 1.1 General Requirements: Minimum (HOLD 2)ABDUL KADHARNo ratings yet

- VD-SRU-V-004-100-Rev ADocument51 pagesVD-SRU-V-004-100-Rev ASYedZYnAleNo ratings yet

- Seim Deviazioni Api Iii Edizione 676Document1 pageSeim Deviazioni Api Iii Edizione 676hohnzimhlnrftumftrNo ratings yet

- Data Sheet-Ball ValveDocument2 pagesData Sheet-Ball ValveJatin Vadhera VCSP100% (1)

- Datasheet Valve ПДНГ 0440 22Document3 pagesDatasheet Valve ПДНГ 0440 22Ngoc Huyen NguyenNo ratings yet

- Heat Exchanger SpecificationsDocument1 pageHeat Exchanger SpecificationsPankaj PandeyNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- DT & DP - Flange Rating and Pipe Sizing R2 PDFDocument11 pagesDT & DP - Flange Rating and Pipe Sizing R2 PDFroyNo ratings yet

- 10in 1500 MOV DatasheetDocument1 page10in 1500 MOV DatasheetkarthikNo ratings yet

- QC Procedure ApprovedDocument6 pagesQC Procedure ApprovedSachin KumarNo ratings yet

- Mail From RashidDocument1 pageMail From RashidSachin KumarNo ratings yet

- Qap-Bv, PV, GVDocument10 pagesQap-Bv, PV, GVSachin KumarNo ratings yet

- Approved Doc - LR BendsDocument21 pagesApproved Doc - LR BendsSachin KumarNo ratings yet

- TN 03 QapDocument5 pagesTN 03 QapSachin KumarNo ratings yet

- Gsr476e PDFDocument16 pagesGsr476e PDFSachin KumarNo ratings yet

- G.A Drawing of 6''#150 IjDocument1 pageG.A Drawing of 6''#150 IjSachin KumarNo ratings yet

- G.A. Drawing of 4'' #300 IJDocument1 pageG.A. Drawing of 4'' #300 IJSachin KumarNo ratings yet

- Gsr541e PDFDocument16 pagesGsr541e PDFSachin KumarNo ratings yet

- 750 (E) PDFDocument2 pages750 (E) PDFSachin KumarNo ratings yet

- 274Document2 pages274Sachin KumarNo ratings yet

- Mail From Sinha SirDocument1 pageMail From Sinha SirSachin KumarNo ratings yet

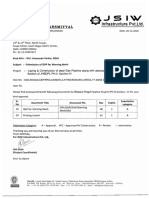

- Jsiw - PHPL 1B - Qap - WM - Aan - 09.02.2017Document7 pagesJsiw - PHPL 1B - Qap - WM - Aan - 09.02.2017Sachin Kumar100% (1)

- Sample DS-1Document1 pageSample DS-1Sachin KumarNo ratings yet

- Policy Circular No. 86-2015Document7 pagesPolicy Circular No. 86-2015Sachin KumarNo ratings yet

- QAP - CIPL - WARNING MESH - 09.01.2019 (Revised)Document3 pagesQAP - CIPL - WARNING MESH - 09.01.2019 (Revised)Sachin KumarNo ratings yet

- Standard Guide For Selection and Use of Liquid Coating Encapsulation Products For Leaded Paint in BuildingsDocument9 pagesStandard Guide For Selection and Use of Liquid Coating Encapsulation Products For Leaded Paint in BuildingsSachin KumarNo ratings yet

- D 6743 - 01 - Rdy3ndmtukveDocument5 pagesD 6743 - 01 - Rdy3ndmtukveSachin KumarNo ratings yet

- D 6745 - 01 - Rdy3nduDocument6 pagesD 6745 - 01 - Rdy3nduSachin KumarNo ratings yet

- Standard Guide For Selecting Techniques For Treating Uncertainty and Risk in The Economic Evaluation of Buildings and Building SystemsDocument17 pagesStandard Guide For Selecting Techniques For Treating Uncertainty and Risk in The Economic Evaluation of Buildings and Building SystemsSachin KumarNo ratings yet

- D 1211 - 97 - RdeymteDocument3 pagesD 1211 - 97 - RdeymteSachin KumarNo ratings yet

- PLL PROJ ME KKBMPL SEC VII HO 52 Invitation For Conciliation Under Cl. 59.1.7.2 of SCCDocument54 pagesPLL PROJ ME KKBMPL SEC VII HO 52 Invitation For Conciliation Under Cl. 59.1.7.2 of SCCSachin KumarNo ratings yet

- MNGL - CRV - ApprovedDocument1 pageMNGL - CRV - ApprovedSachin KumarNo ratings yet

- Sample DSDocument1 pageSample DSSachin KumarNo ratings yet

- Amip65894613 - 2015 01 08 - 12 08 17Document3 pagesAmip65894613 - 2015 01 08 - 12 08 17Sachin KumarNo ratings yet

- Your Reliance Communications BillDocument4 pagesYour Reliance Communications BillSachin KumarNo ratings yet

- Pipeline Endseal Tape 20151013Document10 pagesPipeline Endseal Tape 20151013Sachin KumarNo ratings yet

- Draft-IMS PPPDocument49 pagesDraft-IMS PPPSachin KumarNo ratings yet

- PLAN FOR PIPE STORAGE ModelDocument1 pagePLAN FOR PIPE STORAGE ModelSachin KumarNo ratings yet

- Your Reliance GSM Mobile No. 8882833959Document6 pagesYour Reliance GSM Mobile No. 8882833959Sachin KumarNo ratings yet

Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDF

Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDF

Uploaded by

Sachin Kumar0 ratings0% found this document useful (0 votes)

14 views1 pageThis document provides the technical specifications for a 3/4" socket welded ball valve. It lists details such as the valve manufacturer, size, material specifications for components like the body, ball, and seals. It also outlines requirements for testing, painting, and that charpy v-notch testing shall be conducted at 0°C with minimum absorbed energies. The valve will be used for natural gas in a pipeline modification project.

Original Description:

Original Title

3. Data Sheet 2 less 800#-BV_FB_SW_NT-76.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides the technical specifications for a 3/4" socket welded ball valve. It lists details such as the valve manufacturer, size, material specifications for components like the body, ball, and seals. It also outlines requirements for testing, painting, and that charpy v-notch testing shall be conducted at 0°C with minimum absorbed energies. The valve will be used for natural gas in a pipeline modification project.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDF

Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDF

Uploaded by

Sachin KumarThis document provides the technical specifications for a 3/4" socket welded ball valve. It lists details such as the valve manufacturer, size, material specifications for components like the body, ball, and seals. It also outlines requirements for testing, painting, and that charpy v-notch testing shall be conducted at 0°C with minimum absorbed energies. The valve will be used for natural gas in a pipeline modification project.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

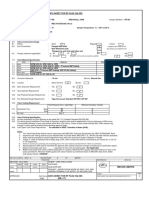

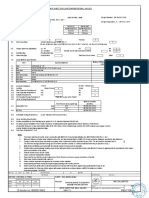

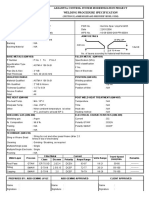

DATA SHEET FOR SOCKET WELDED BALL VALVE

1.0 Valve Manufacturer :

2.0 Valve Size (NB), mm (inch) : 3/4" NB ANSI Rating : 800# Design Standard: BS EN ISO 17292

3.0 MECON's Technical Specification No. :

4.0 Connecting Pipeline Design Pressure,Bar : 92 Design Temperature, °C : -29°C to +65°C Service : Natural Gas

5.0 Connecting Pipe Specification :

5.1 Diameter (OD), mm : 26.7 mm (for 3/4")

5.2 Material : A106 Gr. B

5.3 Wall Thickness, mm : 5.6 mm (for 3/4")

6.0 Valve Construction Design

6.1. Configuration : Reduced Bore Full Bore √

6.2. End Connections : Socket Welded as per ASME B16.11

100mm Extension Pups in ASTM A106 Gr.B , Sch. 160 (for 3/4")

6.3.1 Flanges (wherever applicable) : RF FF RTJ NA √

6.3.2 Flange Face Finish Serrated Smooth (125 to 200 microinches AARH) NA √

6.4 Ball Mounting : Floating Ball

7.0 Valve Material Specification

Part Specified Material Material Offered (Equivalent or superior)

7.1 Body ASTM A105

7.2 Ball 13% Cr Steel

7.3 Body Seat RPTFE/ DELRIN

7.4 Gland 13% Cr Steel

7.5 Stem (No Casting) 13% Cr Steel

7.6 Body Seal Grafoil

7.7 Stem Seal Grafoil

7.8 Body Studs/Nuts ASTM A193 Gr. B7/ A194 Gr. 2H

8.0 Corrosion Allowance : 1.5 mm Service : Natural Gas

9.0 Location : Above Ground √ Buried

10.0 Stem Extension Requirement : Yes No √

11.0 Gear Operator Requirement : Yes No √

12.0 Gas Operated Actuator Requirement : Yes No √

13.0 Fire Resistant Design Requirement : Type-Test as per API 607 / API 6FA

14.0 Valve Testing Requirement

Test Pressure (min.)

2

Minimum Duration (Minutes)

(kg/cm (g))

14.1 Hydrostatic Test Body 210 2

Seat 155 2

14.2 Air Test 5.6 - 7 2

15.0 Anti-Static Testing Requirement : As per BS EN ISO 17292

16.0 Valve Painting Specification

16.1 Surface preparation by Short Blasting as per grade SA 2 1/2, Swedish Standard SIS-055 909.

16.2 For above ground installation-Three coats of corrosion resistant paint shall be applied with minimum thickness of 300 micron

( Permissible thickness in each coat shall be within 80 to 120 micron). Colour of paint shade shall be RAL-7038, however any change in colour

shall be finalized during drawing approval stage.

17.0 Lock Open/ Lock Close/Normally Close Requirement : As indicated in P&ID /Schedule of Rates (SOR).

Notes:

1. Charpy V-notch test for body, ball, body seat, gland, stem & studs/nuts shall be conducted as per A370. The test shall be conducted at 0°C.

The minimum average absorbed energy per set of three specimen shall be 27 J with an individual minimum per specimen of 22 J.

2. Material test certificates and hydrostatic test reports shall be furnished prior to despatch.

3. Detailed dimensional drawings showing cross-section with part numbers and materials shall be submitted for Purchaser's approval

prior to manufacture of the valves.

4. Valves shall have ball position indicator.

5. Stops shall be provided for positive alignment of ball with ports and ensure proper installation of handle.

6. Each valve shall be provided with a wrench.

7. Valves shall be inspected and approved by Purchaser before despatch.

8. Gland packing assembly shall permit repair of gland packing under full line pressure.

9. Inspection and Testing shall be as per attached QAP, this datasheet, API 598, other relevant standards&clause no. 6.0&7.0 of

TS No.: MEC/TS/05/21/002,Rev. 1,Ed. 1.

REV. NO. DATE ZONE DESCRIPTIONS BY APPRD

REFERENCES DRG. NO.

SECTION CLIENT : GAIL (India) Limited

NAME DATE CHKD DATE SUPPLIER :

DSGN Sachin 12.05.2015 Harsh 12.05.2015 SUB SUPPLIER : MECON LIMITED

DRWN PROJECT : MODIFICATION WORK AT GSFC, IOCL AND

UNDERA TERMINAL FOR SUPPLY OF NATURAL GAS

TECHNICAL SPECIFICATION & SCALE : REV

APPROVED Anil Kumar DATA SHEET FOR BALL VALVES DATA SHEET NO.:MEC/23PL/05/28/M/001/DS/BV/76 0

DGM (NB < 2'')

You might also like

- User Design Spec - Rev1Document5 pagesUser Design Spec - Rev1John NashNo ratings yet

- DataSheet 2 More 300# BV - FB - BW - NT-77 PDFDocument1 pageDataSheet 2 More 300# BV - FB - BW - NT-77 PDFSachin KumarNo ratings yet

- Data Sheet 2 More 300# PV - RF - NT-79 PDFDocument1 pageData Sheet 2 More 300# PV - RF - NT-79 PDFSachin KumarNo ratings yet

- Data Sheet 2 Less 800# PV - SW - LT-76Document1 pageData Sheet 2 Less 800# PV - SW - LT-76Sachin KumarNo ratings yet

- Data Sheet 2 Less 800# PV - SW - NT-77Document1 pageData Sheet 2 Less 800# PV - SW - NT-77Sachin KumarNo ratings yet

- Sample DS-1Document1 pageSample DS-1Sachin KumarNo ratings yet

- Sample DSDocument1 pageSample DSSachin KumarNo ratings yet

- 2009 BV SocketWelded DatasheetDocument2 pages2009 BV SocketWelded DatasheetAqib Khan VCSPNo ratings yet

- Rev 01 Mud Gas Separator of Oil ServiceDocument3 pagesRev 01 Mud Gas Separator of Oil ServiceKanti LakhankarNo ratings yet

- CF-1000 SCMH-Approved With Minor CommentsDocument3 pagesCF-1000 SCMH-Approved With Minor CommentsUmer KhanNo ratings yet

- Mazda Limited: Terms and ConditionsDocument3 pagesMazda Limited: Terms and ConditionsrezarossNo ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocument11 pagesDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- Piping Class Specification - CNE-001-2006-E-08-M-L-10126Document20 pagesPiping Class Specification - CNE-001-2006-E-08-M-L-10126Mubashir fareedNo ratings yet

- VMS PDFDocument1 pageVMS PDFritoh8657No ratings yet

- 1664189682389-2ba010110 Cced25030Document1 page1664189682389-2ba010110 Cced25030ylc956867No ratings yet

- Spec 6a E21 en Add3Document16 pagesSpec 6a E21 en Add3LiLiNo ratings yet

- 2/2 Way Direct Acting Solenoid Valve: Uflow AutomationDocument4 pages2/2 Way Direct Acting Solenoid Valve: Uflow AutomationkarthikNo ratings yet

- Datasheet For Ball Valve123Document1 pageDatasheet For Ball Valve123valveNo ratings yet

- DS-01 - LR BendsDocument1 pageDS-01 - LR BendsMecon LtdNo ratings yet

- Boiler 2 Furnace Tube Thickness and LifeDocument1 pageBoiler 2 Furnace Tube Thickness and LifegandungwNo ratings yet

- DS-02 - LR BendsDocument1 pageDS-02 - LR BendsMecon LtdNo ratings yet

- WN SA-105 B16 5 TT Rev0Document2 pagesWN SA-105 B16 5 TT Rev0Aço SalgueiroNo ratings yet

- Datasheet For Ball ValveDocument1 pageDatasheet For Ball ValvevalveNo ratings yet

- Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Document4 pagesGlobe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Ammanda ErnawanNo ratings yet

- CS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3Document2 pagesCS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3PRADEEP GAIKWADNo ratings yet

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document11 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- Technical Notes and Specifications Part CDocument29 pagesTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- Nuberg Technical Specification SheetDocument5 pagesNuberg Technical Specification SheetSmart ChannelNo ratings yet

- Spec ListDocument27 pagesSpec ListArun CPNo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document12 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- Data Sheet Item 2Document3 pagesData Sheet Item 2Bagus SigitNo ratings yet

- Valve DatasheetDocument9 pagesValve DatasheetArunkumarNo ratings yet

- 9952T 1311 F0001 PD2 A CDocument169 pages9952T 1311 F0001 PD2 A CBarbara HowellNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- VMS - 3Document1 pageVMS - 3ritoh8657No ratings yet

- Special Notes On ValvesDocument101 pagesSpecial Notes On ValvesamithcivilNo ratings yet

- 123HAN BPS 02 - Rev.2Document1 page123HAN BPS 02 - Rev.2ABDUL RAHMAN ALI MIRNo ratings yet

- 026 To 033test ReportsDocument40 pages026 To 033test ReportsRahul MoottolikandyNo ratings yet

- EDG-2301-DTA-007 Rev 0 (DRAFT) Weld Overlay Linepipe Data Sheet-2Document15 pagesEDG-2301-DTA-007 Rev 0 (DRAFT) Weld Overlay Linepipe Data Sheet-2barrygideonNo ratings yet

- Conexiones 3 SCH 160Document29 pagesConexiones 3 SCH 160RodolfoNo ratings yet

- Validacion Software Conexiones 3 SCH 160Document29 pagesValidacion Software Conexiones 3 SCH 160RodolfoNo ratings yet

- Especificacion B2AS1Document9 pagesEspecificacion B2AS1Jorge TagleNo ratings yet

- 1441793840reactor Datasheet 10kl ss316Document3 pages1441793840reactor Datasheet 10kl ss316Adrian StoicescuNo ratings yet

- Specification - 2023 02 01 09 02 41Document10 pagesSpecification - 2023 02 01 09 02 41Chinnaraj SNo ratings yet

- TDCDocument6 pagesTDCalex hutaurukNo ratings yet

- Qaswa - 100 ABFV 17.06.21Document1 pageQaswa - 100 ABFV 17.06.21FLOW VALVE AUTOMATIONNo ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- 1.0 Data Sheet For Sight Glass 1.1 General Requirements: Minimum (HOLD 2)Document1 page1.0 Data Sheet For Sight Glass 1.1 General Requirements: Minimum (HOLD 2)ABDUL KADHARNo ratings yet

- VD-SRU-V-004-100-Rev ADocument51 pagesVD-SRU-V-004-100-Rev ASYedZYnAleNo ratings yet

- Seim Deviazioni Api Iii Edizione 676Document1 pageSeim Deviazioni Api Iii Edizione 676hohnzimhlnrftumftrNo ratings yet

- Data Sheet-Ball ValveDocument2 pagesData Sheet-Ball ValveJatin Vadhera VCSP100% (1)

- Datasheet Valve ПДНГ 0440 22Document3 pagesDatasheet Valve ПДНГ 0440 22Ngoc Huyen NguyenNo ratings yet

- Heat Exchanger SpecificationsDocument1 pageHeat Exchanger SpecificationsPankaj PandeyNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- DT & DP - Flange Rating and Pipe Sizing R2 PDFDocument11 pagesDT & DP - Flange Rating and Pipe Sizing R2 PDFroyNo ratings yet

- 10in 1500 MOV DatasheetDocument1 page10in 1500 MOV DatasheetkarthikNo ratings yet

- QC Procedure ApprovedDocument6 pagesQC Procedure ApprovedSachin KumarNo ratings yet

- Mail From RashidDocument1 pageMail From RashidSachin KumarNo ratings yet

- Qap-Bv, PV, GVDocument10 pagesQap-Bv, PV, GVSachin KumarNo ratings yet

- Approved Doc - LR BendsDocument21 pagesApproved Doc - LR BendsSachin KumarNo ratings yet

- TN 03 QapDocument5 pagesTN 03 QapSachin KumarNo ratings yet

- Gsr476e PDFDocument16 pagesGsr476e PDFSachin KumarNo ratings yet

- G.A Drawing of 6''#150 IjDocument1 pageG.A Drawing of 6''#150 IjSachin KumarNo ratings yet

- G.A. Drawing of 4'' #300 IJDocument1 pageG.A. Drawing of 4'' #300 IJSachin KumarNo ratings yet

- Gsr541e PDFDocument16 pagesGsr541e PDFSachin KumarNo ratings yet

- 750 (E) PDFDocument2 pages750 (E) PDFSachin KumarNo ratings yet

- 274Document2 pages274Sachin KumarNo ratings yet

- Mail From Sinha SirDocument1 pageMail From Sinha SirSachin KumarNo ratings yet

- Jsiw - PHPL 1B - Qap - WM - Aan - 09.02.2017Document7 pagesJsiw - PHPL 1B - Qap - WM - Aan - 09.02.2017Sachin Kumar100% (1)

- Sample DS-1Document1 pageSample DS-1Sachin KumarNo ratings yet

- Policy Circular No. 86-2015Document7 pagesPolicy Circular No. 86-2015Sachin KumarNo ratings yet

- QAP - CIPL - WARNING MESH - 09.01.2019 (Revised)Document3 pagesQAP - CIPL - WARNING MESH - 09.01.2019 (Revised)Sachin KumarNo ratings yet

- Standard Guide For Selection and Use of Liquid Coating Encapsulation Products For Leaded Paint in BuildingsDocument9 pagesStandard Guide For Selection and Use of Liquid Coating Encapsulation Products For Leaded Paint in BuildingsSachin KumarNo ratings yet

- D 6743 - 01 - Rdy3ndmtukveDocument5 pagesD 6743 - 01 - Rdy3ndmtukveSachin KumarNo ratings yet

- D 6745 - 01 - Rdy3nduDocument6 pagesD 6745 - 01 - Rdy3nduSachin KumarNo ratings yet

- Standard Guide For Selecting Techniques For Treating Uncertainty and Risk in The Economic Evaluation of Buildings and Building SystemsDocument17 pagesStandard Guide For Selecting Techniques For Treating Uncertainty and Risk in The Economic Evaluation of Buildings and Building SystemsSachin KumarNo ratings yet

- D 1211 - 97 - RdeymteDocument3 pagesD 1211 - 97 - RdeymteSachin KumarNo ratings yet

- PLL PROJ ME KKBMPL SEC VII HO 52 Invitation For Conciliation Under Cl. 59.1.7.2 of SCCDocument54 pagesPLL PROJ ME KKBMPL SEC VII HO 52 Invitation For Conciliation Under Cl. 59.1.7.2 of SCCSachin KumarNo ratings yet

- MNGL - CRV - ApprovedDocument1 pageMNGL - CRV - ApprovedSachin KumarNo ratings yet

- Sample DSDocument1 pageSample DSSachin KumarNo ratings yet

- Amip65894613 - 2015 01 08 - 12 08 17Document3 pagesAmip65894613 - 2015 01 08 - 12 08 17Sachin KumarNo ratings yet

- Your Reliance Communications BillDocument4 pagesYour Reliance Communications BillSachin KumarNo ratings yet

- Pipeline Endseal Tape 20151013Document10 pagesPipeline Endseal Tape 20151013Sachin KumarNo ratings yet

- Draft-IMS PPPDocument49 pagesDraft-IMS PPPSachin KumarNo ratings yet

- PLAN FOR PIPE STORAGE ModelDocument1 pagePLAN FOR PIPE STORAGE ModelSachin KumarNo ratings yet

- Your Reliance GSM Mobile No. 8882833959Document6 pagesYour Reliance GSM Mobile No. 8882833959Sachin KumarNo ratings yet