Professional Documents

Culture Documents

Microcontroller Based Distribution Transformer Protection

Microcontroller Based Distribution Transformer Protection

Uploaded by

Gemechu WareOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microcontroller Based Distribution Transformer Protection

Microcontroller Based Distribution Transformer Protection

Uploaded by

Gemechu WareCopyright:

Available Formats

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

DEDICATION

This project work may not get to its final destination without the strong

guidance of our advisor Mr. Vijay saradhi and Mr. Hayilemariam other willing

power engineering instructors mentioned in acknowledgement part and our

friends who motivate us to do our best. So, we would like to dedicate this work

for power engineering stream.

G5-ELECTRICAL POWER Page i

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

ACKNOWLEDGEMENT

First and foremost, we would like to thank the Almighty God for His guidance throughout our

studies in the Arbaminch University and the completion of this project. And also we would like

to express our gratitude to our advisor, Mr. Vijaysaradhi and Mr. Hayilemariam who gave us the

opportunity to have such a practical based knowledge related to software applications and our

field of study in terms of communication with other persons, ability to develop new skills and

cooperation with others so as to share experiences and knowledge.

G5-ELECTRICAL POWER Page ii

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

ABSTRACT

Microcontroller based distribution transformer protection system is taken to mean the use of

advanced technologies in order to determine equipment condition, and potentially predict failure.

This project is essential to prevent faults that are costly to repair and result loss of service. It is

used to protect and ensure the integrity, reliability and functionality of distribution transformers.

It has a great advantage to improve durability of the distribution transformers which are installed

with a high cost and human effort.

This project consists of measuring the current consumed by the transformer using current

transformer (CT) and temperature of the transformer by temperature sensor. The measured

signals of each line currents will be conditioned using rectification and voltage regulation in

order to make suitable for microcontroller input. Then after the temperature conditioning current

signal of the transformer continuously detected at every moment by the microcontroller.

At the initial moment the microcontroller sends turn on signal to the relay meanwhile the relay

switch then power will flow from the source to the load through transformer. The

microcontroller will take some delay time for the sake of system stabilization and LCD displays

a normal condition code N. If the system operates at normal condition no action will be taken,

but if there is any fault happen the microcontroller take an action to disconnect the input side of

the transformer and display the status fault condition including system condition on the LCD at

the same time. Then after a few delay time it re-closes the input line again, if the fault is cleared

system continuous normally. But if the fault persists system will be stay disconnected and fault

status will be indicated again on the LCD display.

G5-ELECTRICAL POWER Page iii

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

List of figure

Figure 1 Air Core Type Transformers ........................................................................................ 5

Figure 2 Iron Core Type Transformer ....................................................................................... 5

Figure 3 Allegro Microsystems ACCS712 Series ...................................................................... 7

Figure 4 Current sensor functional block diagram ................................................................... 9

Figure 5 Relay ............................................................................................................................... 9

Figure 6 Lcd................................................................................................................................. 12

Figure 7 over Current Flow ....................................................................................................... 13

Figure 8 Over current Protection Relay ................................................................................... 15

Figure 9 A block diagram representation of microcontroller Protection System for DF .... 18

Figure 10 Microcontroller-LCD interface as done in the simulation software ..................... 19

Figure 11 Microcontroller-LED connection3 ........................................................................... 20

Figure 12 Microcontroller-relay interface as done on the simulation software. ................... 22

Figure 13 Microcontroller-sensor interface as done on the simulation software.................. 22

Figure 14 Microcontroller-sensor interface as done on the simulation software.................. 23

Figure 16 LCD Display ............................................................................................................... 27

Figure 17 Led interface .............................................................................................................. 28

G5-ELECTRICAL POWER Page iv

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

Table of Contents

CHAPTER ONE ........................................................................................................................................... 1

1. INTRODUCTION .................................................................................................................................... 1

1.1 BACKGROUND ................................................................................................................................ 1

1.2 Objective ............................................................................................................................................. 2

1.3 Problem of statement .......................................................................................................................... 3

1.4 Scope of project .................................................................................................................................. 3

CHAPTER TWO .......................................................................................................................................... 4

2 LITERATURE REVIEW .......................................................................................................................... 4

2.1 Definition of Transformer ................................................................................................................... 4

2.2 Principle of Transformer ..................................................................................................................... 4

2.3 Basic Theory of Transformer .............................................................................................................. 4

2.4 Main Constructional Parts of Transformer ......................................................................................... 6

2.5 Causes of fault in transformer ............................................................................................................. 7

2.6 Current sensor ..................................................................................................................................... 7

2.7 Relay ................................................................................................................................................... 9

2.8 Microcontroller ................................................................................................................................. 10

2.9 LCD (liquid crystal display) ............................................................................................................. 11

2.10 Overloading..................................................................................................................................... 12

2.11 Over Current ................................................................................................................................... 13

2.12 Over current protection ................................................................................................................... 14

2.13 Transformer over heating ................................................................................................................ 15

2.14 Temperature Sensor ........................................................................................................................ 15

CHAPTER THREE .................................................................................................................................... 17

METHODOLOGY AND DESIGN ............................................................................................................ 17

3.1 Methodologies................................................................................................................................... 17

3.2 Design ............................................................................................................................................... 18

3.4 Warning devices and relay control.................................................................................................... 19

3.5 SOFTWARE DESIGN ..................................................................................................................... 23

3.6 Analytical Method and Technique .................................................................................................... 24

CHAPTER FOUR....................................................................................................................................... 26

RESULTS AND DISCUSSION ................................................................................................................. 26

4.1 Simulated results ............................................................................................................................... 26

G5-ELECTRICAL POWER Page v

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

4.2 Analysis............................................................................................................................................. 27

4.3 Evaluation of accuracy ...................................................................................................................... 28

CHAPTER FIVE ........................................................................................................................................ 29

CONCLUSIONS AND RECOMMANDETION ........................................................................................ 29

5.1 Conclusions ....................................................................................................................................... 29

5.2 limitations and Future recommendations .......................................................................................... 30

References ................................................................................................................................................... 31

Appendix ..................................................................................................................................................... 32

G5-ELECTRICAL POWER Page vi

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

ACRONYMS AND ABBREVIATIONS

PIC Programmable Intelligent Controller

LCD Liquid crystal Display

GND Ground

LED Light emitting diode

MOS Metal oxide semiconductor

GSM Global System for Mobile

CT Current transformer

RAM Random access memory

ROM Read only memory

AC Alternating Current

DC Direct Current

ADC Analogue to Digital Converter

CPU Central Processing Unit

IC Integrated circuit

G5-ELECTRICAL POWER Page vii

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

CHAPTER ONE

1. INTRODUCTION

1.1 BACKGROUND

Different type of protections is installed to protect the equipment in an electric power system.

Their task is to disconnect failed or overloaded equipment or parts of the system to avoid

unnecessary damages on equipment and personnel. The purpose is also to limit the impact of

failures on the parts of the system that have not failed.

An intensive development of protections based on modern information technology is going on

both regarding hardware and software. On the hardware side microprocessors have been used

over a long time to implement different functions in the protections, and with the recent

developments more and more complicated functions can be implemented in a reliable way.

In general the functions which earlier were handled with separate relays are increasingly being

integrated with other functional units for control and supervision

The summary here is concentrated on general principles for protections. A protection for an

electric power system comprises the following parts:

Measurement device with current- and/or voltage transformers and other sensors

measuring the relevant quantities.

Relay which when certain conditions are fulfilled sends signals to a circuit breaker or

another switching device.

This relay was earlier a separate unit, but can in modern protections be a part of a larger

unit for protection, supervision and control.

Power supply systems which shall secure the power supply to the protection system, even

with faults in the system. The requirements on a protection system are that they should be

dependable, secure, selective, sensitive, and fast.

Dependability:- means that the protection should react and do its action when a fault

occurs for which it is designed to react for. To achieve desired dependability double or

even triple sets of certain parts of the protection of signal paths might be needed.

Malfunctions can be divided into”not occurring” operations (which are actions that were

supposed to happen but did not) and +”unwanted” operations (which are actions that

G5-ELECTRICAL POWER Page 1

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

happened although they should not have). Normally not occurring operations are more

serious malfunctions than unwanted ones.

Security:-means that the protection should not react when no fault occurs or when a fault

for which it is not intended to react occurs.

Selectivity:- implies that not more than necessary pieces of equipment and apparatuses

are disconnected to isolate a fault.

Sensitivity:- is needed to detect failures which cause small fault currents, e.g. high

impedance faults. This implies that the risk for miss operations increases at “small”

disturbances, e.g. at energization of transformers, or at high load operation but normal

operation.

The protection should react fast to secure that damages on persons and equipment are

prevented or limited

1.2 Objective

The main objective of this project is to protect distribution transformer by using microcontroller

based protection system , to get fast response, better isolation and accurate detection of the fault,

to improve the reliability of the power system supply and to protect overloaded equipment or

parts of the system as well as to avoid unnecessary damages on equipment and personnel.

This system overcomes the other drawbacks in the existing systems such as maintenance and

response time. To achieve this following must be done.

a) Design and build overheating and over current relay using PIC microcontroller and a current

sensor

b) Development, analysis and calibration of the current sensor and temperature sensor.

c) Development of the ADC program to convert the analogue sensor output to equivalent digital

form within the PIC microcontroller.

d) Development of the LCD program to display the sensed levels.

e) Development of warning (audio and visual) and relay control system program.

G5-ELECTRICAL POWER Page 2

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

1.3 Problem of statement

In our country there are so many problems faced on distribution transformer in different way

such as damage of equipment and personnel due to short circuit, overload, overheating and

ground fault Additionally EEPCO spends much money for purchasing new transformer. Because

the existing protection system have the following character.

It used HRC fuses.

It does not have fast processing speeds

It required more maintenance due to some moving parts in the equipment.

So by observing this problem we are motivated to suggest and contribute a solution to our scope

of knowledge Therefore we are designed microcontroller based distribution transformer

protection system.

1.4 Scope of project

The scope of this project is to protect distribution transformer from burning out due to short

circuit, overload, overheating and ground fault on medium voltage and low voltage system such

as 33kV, 15kV and 400 voltages respectively for transformer ratings 25kVA, 50kVA, 100kVA,

200kVA, 315kVA, 500kVA, 630kVA, 800kVA and 1250kVA.

G5-ELECTRICAL POWER Page 3

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

CHAPTER TWO

2 LITERATURE REVIEW

2.1 Definition of Transformer

Electrical transformer is a static device which transforms electrical energy from one circuit

to another without any direct electrical connection and with the help of mutual induction

between two windings. It transforms power from one circuit to another without changing its

frequency but may be in different voltage.

2.2 Principle of Transformer

The working principle of transformer is very simple. It depends upon Faraday’s law of

electromagnetic induction. Actually, mutual induction between two or more winding is

responsible for transformation action in an electrical transformer.

According to these Faraday’s laws, "Rate of change of flux linkage with respect to time is

directly proportional to the induced EMF in a conductor or coil".

2.3 Basic Theory of Transformer

Say you have one winding which is supplied by an alternating electrical source. The alternating

current through the winding produces a continually changing flux or alternating flux that

surrounds the winding. If any other winding is brought nearer to the previous one, obviously

some portion of this flux will link with the second. As this flux is continually changing in its

amplitude and direction, there must be a change in flux linkage in the second winding or coil.

According to Faraday’s law of electromagnetic induction, there must be an EMF induced in the

second. If the circuit of the later winding is closed, there must be a current flowing through it.

This is the simplest form of electrical power transformer and this is the most basic of working

principle of transformer. The winding which takes electrical power from the source, is generally

known as primary winding of transformer

G5-ELECTRICAL POWER Page 4

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

Figure 1 Air Core Type Transformers

The winding which gives the desired output voltage due to mutual induction in the transformer,

is commonly known as secondary winding of transformer.

Figure 2 Iron Core Type Transformer

The above mentioned form of transformer is theoretically possible but not practically, because in

open air very tiny portion of the flux of the first winding will link with second; so the current that

G5-ELECTRICAL POWER Page 5

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

flows through the closed circuit of later, will be so small in amount that it will be difficult to

measure.

The rate of change of flux linkage depends upon the amount of linked flux with the second

winding. So, it is desired to be linked to almost all flux of primary winding to the secondary

winding. This is effectively and efficiently done by placing one low reluctance path common to

both of the winding. This low reluctance path is core of transformer, through which maximum

number of flux produced by the primary is passed through and linked with the secondary

winding.

𝐸=𝑁𝑑∕ɸ𝑑𝑡

𝐸=𝑁∗𝜔∗ɸ𝑚𝑎𝑥∗cos𝜔𝑡

𝐸𝑚𝑎𝑥=𝑁∗𝜔∗ɸ𝑚𝑎𝑥

𝐸𝑟𝑚𝑠=𝑁∗𝜔∗ɸmax√2=2𝜋∗𝑓∗𝑁∗ɸ𝑚𝑎𝑥/√2

𝐸𝑟𝑚𝑠=4.44∗𝑓∗𝑁∗ɸ𝑚𝑎𝑥

Where:

𝑓 - Is the flux frequency in Hertz, =𝜔/2𝜋

𝛮 - The number of coil windings.

ɸ - Is the flux density in Webber’s

2.4 Main Constructional Parts of Transformer

The three main parts of a transformer are:

1. Primary winding of transformer - which produces magnetic flux when it is connected to

electrical source.

2. Magnetic Core of transformer - the magnetic flux produced by the primary winding, that will

pass through this low reluctance path linked with secondary winding and create a closed

magnetic circuit.

3. Secondary Winding of transformer – the flux, produced by primary winding, passes through

the core, will link with the secondary winding. This winding also wounds on the same core and

gives the desired output of the transformer.

G5-ELECTRICAL POWER Page 6

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

2.5 Causes of fault in transformer

There are many faults that can occur in a transformer owing to a variety of reasons as follows

a) Winding and core fault is the most frequent type of fault in a transformer. This can be

attributed to weakening of conductor insulation. Phase faults rarely occur in the transformer, they

may however occur at the terminals of that are found within the transformer protection zone.

b) Most power transformers use oil for cooling and insulation, oil leakage can also be a cause of

fault in a transformer.

c) The inrush current that occurs momentarily when a transformer is energized can also be

treated as a fault unless conditions are set for its detection.

d) Inter-turn faults may occur and cause rise in hot spots within the transformer winding.

e) Transformer may experience over fluxing which may be as a result of transformer operating at

low frequency at rated voltage. Over fluxing may also be caused by overvoltage operation at

rated frequency.

f) Sustained overload can also be a cause of fault in a transformer

2.6 Current sensor

This is a device that detects electric AC or DC current flowing in a conductor and gives out a

corresponding signal (analogue voltage/current/digital pulse). The detected signal can be used for

various purposes like measuring the amount of current in the conductor, controlling of another

device etc.

Figure 3 Allegro Microsystems ACCS712 Series

G5-ELECTRICAL POWER Page 7

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

The current sensor used in this project is Allegro ACS712ELCTR-30A-T. It is popularly used in

diverse applications in motor control, electric vehicles and in power distribution. It has the

following features :-

Low-noise analogue signal path

Device bandwidth is set via the new FILTER pin

5 μs output rise time in response to step input current

80 kHz bandwidth

Total output error 1.5% at TA= 25°C

Small footprint, low-profile SOIC8 package1.2 mΩ internal conductor resistance

2.1 kVRMS minimum isolation voltage from pins 1-4 to pins 5-8

5.0 V, single supply operation

66 mV/A output sensitivity

Output voltage proportional to AC or DC currents

Factory-trimmed for accuracy

Extremely stable output offset voltage

Nearly zero magnetic hysteresis

Ratiometric output from supply voltage

The Allegro ACS712ELCTR-30A-T has a low-offset linear Hall sensor circuit that has a

conduction path made of copper located next to the die. A magnetic field is caused by the current

flowing through the copper conductor. This magnetic field is detected by the integrated Hall IC

which converts it into a voltage proportional to the magnetic flux. A current of 1A flowing in a

conductor produces 66mV. The close proximity of the magnetic signal to the Hall transducer

optimizes the device accuracy. To attain precision, in terms of voltage produced, a low-offset

chopper-stabilized Bi-CMOS Hall IC is used. It is programmed for accuracy at the factory

The sensor measures a maximum of 30A from the load current. This serves as its primary

current. The sensor output voltage is fed into the microcontroller as the analogue input.

G5-ELECTRICAL POWER Page 8

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

Figure 4 Current sensor functional block diagram

2.7 Relay

A relay is an electrically operated switch. It uses electromagnetic force to close or open contact.

The relay employed in this project can be operated as normally closed or normally open. For this

system, the normally closed mode was used. The relay circuit is illustrated in figure below . The

relay was used to de-energize the contactor coil in case of a fault thus isolating the transformer

from the system.

Figure 5 Relay

G5-ELECTRICAL POWER Page 9

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

2.7.1 Contactor

When a relay is used to switch a large amount of electrical power through its contacts, it is

referred to as a contractor. Contactors basically have several contacts, and which are usually (but

not always) normally-open, so that power to the load is shut off when the coil is de-energized

2.7.2 Functional requirement of a protection relay

In order for a protection relay to operate effectively, it must have the following qualities.

a) Reliability: power protection relays should remain inoperative always as long as a fault does

not occur. But when a fault occurs, they should respond as quickly as possible.

b) Selectivity: it must only operate on the section that has experienced a fault to avoid

unnecessary power outs due to wrong detections. It should also respond only when a fault

occurs.

c) Sensitivity: The relaying equipment should be highly sensitive so that it can be relied on to

provide the required detection.

d) Speed: the relaying equipment must operate at the required speed. It should not delay so as to

give time for system equipment to get destroyed. It should also not be too fast to cause undesired

operation.

2.8 Microcontroller

There are two branches in the ongoing evolution of the microprocessor. One branch supports

CPUs for the personal computer and workstation industry, where the main constraints are high

speed and large word size (32 and 64 bits). The other branch includes development of the

microcontroller, which is a single IC containing specialized circuits and functions that are

applicable to mechatronic system design. It contains a microprocessor, memory, I/O capabilities,

and other on-chip resources. It is basically a microcomputer on a single IC. Examples of

microcontrollers’ are Microchip’s PIC, Motorola’s 68HC11, and Intel’s 8096. Factors that have

driven development of the microcontroller are low cost, versatility, ease of programming, and

small size. Microcontrollers are attractive in mechatronic system design since their small size

and broad functionality allow them to be physically embedded in a system to perform all of the

G5-ELECTRICAL POWER Page 10

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

necessary control functions. Microcontrollers are used in a wide array of applications including

home appliances, entertainment equipment, telecommunication equipment, automobiles, trucks,

airplanes, toys, and office equipment. All these products involve devices that require some sort

of intelligent control based on various inputs. For example, the microcontroller in a microwave

oven monitors the control panel for user input, updates the graphical displays when necessary,

and controls the timing and cooking functions. In an automobile, there are many microcontrollers

to control various sub systems, including cruise control, antilock braking, ignition control,

keyless entry, and environmental control, and air and fuel flow. An office fax machine controls

actuators to feed paper, uses photo sensors to scan a page, sends or receives data on a phone line,

and provides a user interface complete with menu-driven controls. A toy robot dog has various

sensors to detect inputs from its environment (e.g., bumping into obstacles, being patted on the

head, light and dark, voice commands), and a non board microcontroller actuates motors to

mimic actual dog behavior (e.g., bark ,sit, and walk) based on this input. All of these powerful

and interesting devices are controlled by microcontrollers and the software running on them.

2.9 LCD (liquid crystal display)

A liquid-crystal display (LCD) is a flat panel display, electronic visual display, or video display

that uses the light modulating properties of liquid crystals. Liquid crystals do not emit light

directly.

LCDs are available to display arbitrary images (as in a general-purpose computer display) or

fixed images which can be displayed or hidden, such as preset words, digits, and 7-segment

displays as in a digital clock. They use the same basic technology, except that arbitrary images

are made up of a large number of small pixels, while other displays have larger elements.

LCDs are used in a wide range of applications including computer monitors, televisions,

instrument panels, aircraft cockpit displays, and signage. They are common in consumer devices

such as video players, gaming devices, clocks, watches, calculators, and telephones, and have

replaced cathode ray tube (CRT) displays in most applications. They are available in a wider

range of screen sizes than CRT and plasma displays, and since they do not use phosphors, they

do not suffer image burn-in. LCD sari, however, susceptible to image persistence.

G5-ELECTRICAL POWER Page 11

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

The LCD screen is more energy efficient and can be disposed of more safely than a CRT. Its low

electrical power consumption enables it to be used in battery-powered electronic equipment. It is

an electronically modulated optical device made up of any number of segments filled with liquid

crystals and arrayed in front of a light source (backlight) or reflector to produce images in color

or monochrome. The LCD can be operated either in 4-bit or 8-bit interface. 8bit interface makes

use of all the pins while 4-bit mode uses only 4 data lines plus the other remaining pins. In this

project, 8-bit mode is used.

Figure 6 Lcd

2.10 Overloading

A transformer is normally rated to operate continuously at a maximum temperature based on an

assumed ambient. No sustained overload is usually permissible for this condition. At lower

ambient it is often possible to allow short periods of overload but no hard and fast rules apply,

regarding the magnitude and duration of the overload .The only certain factor is that the winding

must not overheat to the extent that the insulation is cooked, thereby accelerating ageing. A

winding temperature of 95 °C is considered to be the normal maximum working value Systems

Protection.

G5-ELECTRICAL POWER Page 12

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

2.11 Over Current

Figure 7 over Current Flow

The National Electrical Code defines over current as any current in excess of the rated current of

equipment or the capacity of a conductor. It may result from overload, short circuit, or ground

fault. Current flow in a conductor always generates heat. The greater the current flow, the hotter

the conductor. Excess heat is damaging to electrical components. For that reason, conductors

have a rated continuous current carrying capacity or amp city. Over current protection devices

are used to protect conductors from excessive current flow. These protective devices are

G5-ELECTRICAL POWER Page 13

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

designed to keep the flow of current in a circuit at a safe level to prevent the circuit conductors

from overheating

2.12 Over current protection

Over current protection scheme ensures that the transformer is protected from momentary excess

current caused by overload, power surge etc.

In electric power system, over current refers to a situation where more than current intended

flows through a conductor. This leads to excessive heat generation and thus the risk of causing

fire or causing destruction to electrical equipment. Over current is caused by short circuit,

overloading or wrong design.

Over current protection protects the transformers against currents that rise beyond its rated value.

Over current relay isolates the transformer in case of a fault in the system. This relay is the focus

of this project. It can be implemented using analogue circuitry or digitally using

microcontrollers. This project seeks to apply microcontroller and appropriate software program

to design an over current relay. The diagram below illustrates an over current relay scheme.

G5-ELECTRICAL POWER Page 14

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

Over current Protection Relay

Figure 8 Over current Protection Relay

2.13 Transformer over heating

The rating of a transformer is based on the temperature rise above an assumed maximum

ambient temperature; under this condition no sustained overload is usually permissible. At a

lower ambient temperature some degree of sustained overload can be safely applied. Short-term

overloads are also permissible to an extent dependent on the previous loading conditions.

The only certain statement is that the winding must not overheat; a temperature of about 95°C is

considered to be the normal maximum working value beyond which a further rise of 8°C-10°C,

if sustained, will halve the insulation life of the unit. Protection against overload is therefore

based on winding temperature, which is usually measured by a thermal image technique.

Protection is arranged to trip the transformer if excessive temperature is reached. The trip signal

is usually routed via a digital input of a protection relay on one side of the transformer, with both

alarm and trip facilities made available through programmable logic in the relay. Inter tripping

between the relays on the primary side of the transformer is usually applied to ensure total

disconnection transformer.

2.14 Temperature Sensor

Temperature is one of the most commonly measured variables and it is therefore not surprising

that there are many ways of sensing it. Heat is transferred by three methods: convection,

G5-ELECTRICAL POWER Page 15

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

conduction, and radiation. Temperature sensing can be done either through direct contact with

the heating source, or remotely, without direct contact with the source using radiated energy

instead.

Accurate temperature measurements are required in many other measurements systems such as

process control and instrumentation applications. In most cases, because of low level non-linear

outputs, the sensor output must be properly conditioned and amplified before further processing

can occur.

Except for IC sensors, all temperature sensors have nonlinear transfer functions. In the past,

complex analog conditioning circuits were designed to correct for the sensor nonlinearity. These

circuits often required manual calibration and precision resistors to achieve the desired accuracy.

Today these sensor outputs may be digitized directly by high resolution ADCs. Linearization and

calibration is then performed digitally, thereby reducing cost and complexity.

2.14.1 General Description temperature sensor

The LM35 series are precision integrated-circuit temperature sensors, whose output voltage is

linearly proportional to the Celsius (Centigrade) temperature. The LM35 thus has an advantage

over linear temperature sensors calibrated in

Kelvin, as the user is not required to subtract a large constant voltage from its output to obtain

convenient Centigrade scaling. The LM35 does not require any external calibration or trimming

to provide typical accuracies of ±1∕4°C at room temperature and ±3∕4°C over a full −55 to

+150°C temperature range. Low cost is assured by trimming and calibration at the wafer level.

The LM35’s low output impedance, linear output, and precise inherent calibration make

interfacing to readout or control circuitry especially easy. It can be used with single power

supplies, or with plus and minus supplies. As it draws only 60 μA from its supply, it has very

low self-heating, less than 0.1°C in still air. The LM35 is rated to operate over a −55° to +150°C

temperature range, while the LM35C is rated for a −40° to +110°C range (−10° with improved

accuracy). The LM35 series is available packaged in hermetic TO-46 transistor packages, while

the LM35C, LM35CA, and LM35D are also available in the plastic TO-92 transistor package.

The LM35D is also available in an 8-lead surface mount small outline package and a plastic TO-

220 package

G5-ELECTRICAL POWER Page 16

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

CHAPTER THREE

METHODOLOGY AND DESIGN

3.1 Methodologies

Transformers are typically the most common application where proper over current, over load

and overheating protections are required and utilized to provide the necessary protection to

facilities, electrical systems, equipment, and most importantly electrical workers and other

involved personnel. As a result, it is vitally important that there is at least a basic understanding

of how transformers and their related electrical systems can be properly protected.

The methodology of this project consists of measuring the current consumed by the transformer

using current sensor (CS) and temperature of the transformer by temperature sensor.At the initial

moment the microcontroller sends turn on signal to the relay meanwhile the relay connect the

power for turning on the switch then power will flow from the source to the load through

transformer. The microcontroller will take some delay time for the sake of system stabilization

and LCD displays a normal condition codes. If the system operates at normal condition no action

will be taken, but if there is any fault happen the microcontroller take an action to disconnect the

output side of the transformer and display the status fault condition including system condition

on the LCD at the same time.if the fault persists system will be stay disconnected and fault status

will be indicated again on the LCD display.

Before looking the details of designing this project, it is best to start with brief review of the

system design. Figure 9 shows the complete system design. The whole idea of this project is to

isolate the faulty conditions from over load Current and overheating by controlling the SSR

using microcontroller

G5-ELECTRICAL POWER Page 17

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

Figure 9 A block diagram representation of microcontroller Protection System for DF

3.2 Design

The ultimate objective of this project is to design an automatic over current relay that uses

microcontroller to read transformer currents and automatically isolate the transformer from the

power system in case of a fault. This design is therefore based on the programmable Interrupt

Controller (PIC microcontroller) as the main control element in the system. The design of this

system has been divided into the following sections;

Hardware design

Software design

3.3 Hardware Design

The PIC16F877A microcontroller has been used as the main device in the development of this

system. Based on the number of input/output pins and the other functional features it was

G5-ELECTRICAL POWER Page 18

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

selected for use in this project. The 20 pins of the microcontroller have been distributed for use

as follows

3.3.1 Interfacing LCD to the microcontroller

The LM016L LCD display device has been employed in the system implementation. The LCD

operates as a medium for communicating the amount of current flowing in the electric conductor

at any given time. The logical process that avails the readings takes place within the

microcontroller using a program and displayed on the LCD. The LCD operates in 8-bit mode, so

8 pins from the microcontroller have been connected to the 8 data pins on the LCD. Since

PORTC of the PIC16F877A is 8-bit wide, it is used for this purpose. So, RB2- RB5 pins of PIC

microcontroller have been connected to D4-D7 of the LCD as illustrated in the following:-

LCD1

LCD2

LM041L

RV1

RV4

VDD

VSS

VEE

RW

RS

D0

D1

D2

D3

D4

D5

D6

D7

50%

E

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1k

U1

U4

13 33

OSC1/CLKIN RB0/INT

14 34

OSC2/CLKOUT RB1

35

RB2

2 36

RA0/AN0 RB3/PGM

3 37

RA1/AN1 RB4

4 38

RA2/AN2/VREF-/CVREF RB5

5 39

RA3/AN3/VREF+ RB6/PGC

6 40

RA4/T0CKI/C1OUT RB7/PGD

7

RA5/AN4/SS/C2OUT

15

RC0/T1OSO/T1CKI

8 16

RE0/AN5/RD RC1/T1OSI/CCP2

9 17

RE1/AN6/W R RC2/CCP1

10 18

RE2/AN7/CS RC3/SCK/SCL

23

RC4/SDI/SDA

1 24

MCLR/Vpp/THV RC5/SDO

25

RC6/TX/CK

26

RC7/RX/DT

19

RD0/PSP0

20

RD1/PSP1

21

RD2/PSP2

22

RD3/PSP3

27

RD4/PSP4

28

RD5/PSP5

29

RD6/PSP6

30

RD7/PSP7

PIC16F877A

Figure 10 Microcontroller-LCD interface as done in the simulation software

The register select (RS) pin has been connected to pin 33 (RB0) on the microcontroller. Enable

pin has been connected to RB1 (pin 33). At all times, the R/W line is connected to ground (kept

low) since data in this case is always written into the LCD. A potentiometer of 10KΩ has been

used to vary the brightness contrast of the LCD.

3.4 Warning devices and relay control

3.4.1 LEDs

In order to indicate the state of the power line, two Light emitting diodes have been used. One

LED emits red light and the other one green light. The green LED is set to blink when the current

flowing through the power system is at a normal level. The red LED should blink at an interval

of half a second whenever the current build up approaches the overload level through to the point

G5-ELECTRICAL POWER Page 19

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

when the relay gets energized. This acts as a visual warning when a fault occurs. The green LED

has been connected to the pin RD7 (pin 30) via a current limiting resistor (220Ω) to ground. The

Red LED has been connected to pin RD6 (pin 29) also through a current limiting resistor (220Ω)

to ground. The microcontroller pins can give a maximum of 5.3V. LEDs typically have a

forward voltage drop ranging between 1.8V and 3.3V subject to the LED color. The value for red

LED is about 1.8V. The forward voltage drop is a function of the LED color frequency.

For the LED to light, it needs around 20mA of current. The calculation below justifies the

resistor values chosen for the design of this system.

According to Ohms law, resistance is a function of voltage and current, as shown below.

𝑅 = 𝑉𝑠−𝑉𝑓

𝐼𝑠

𝑅 = (5.3−1.8) ∗ 1000

20

=175Ω

𝑉𝑠=𝑠𝑢𝑝𝑝𝑙𝑦 𝑣𝑜𝑙𝑡𝑎𝑔𝑒 𝑓𝑟𝑜𝑚 𝑡𝑒 𝑝𝑖𝑛 𝑡𝑜 𝑡𝑒 𝐿𝐸𝐷,

𝑉𝑓=𝑓𝑜𝑟𝑤𝑎𝑟𝑑 𝑣𝑜𝑙𝑡𝑎𝑔𝑒 𝑑𝑟𝑜𝑝,

𝐼𝑠=𝐿𝐸𝐷𝑐𝑢𝑟𝑟𝑒𝑛𝑡

175Ω is not a standard resistor value, so a value close to it can be chosen. In order to ensure that

the current sourced is as little as possible, the 220Ω resistor has been chosen such that the

maximum current sourced becomes; 5.3−1.8220=16𝑚𝐴

U1

U4

13 33

OSC1/CLKIN RB0/INT

14 34

OSC2/CLKOUT RB1

35

RB2

2 36

RA0/AN0 RB3/PGM

3 37

RA1/AN1 RB4

4 38

RA2/AN2/VREF-/CVREF RB5

5 39

RA3/AN3/VREF+ RB6/PGC

6 40

RA4/T0CKI/C1OUT RB7/PGD

7

RA5/AN4/SS/C2OUT

15

RC0/T1OSO/T1CKI

8 16

RE0/AN5/RD RC1/T1OSI/CCP2

9 17

RE1/AN6/WR RC2/CCP1

10 18

RE2/AN7/CS RC3/SCK/SCL

23

RC4/SDI/SDA

1 24

MCLR/Vpp/THV RC5/SDO

25

RC6/TX/CK

26

RC7/RX/DT

19

RD0/PSP0

20

RD1/PSP1

21 D2

D1

RD2/PSP2

22

R1

R4

RD3/PSP3

27 220

RD4/PSP4

28 LED-RED

RD5/PSP5

29 D3

D5

RD6/PSP6

30

R2

R6

RD7/PSP7

220

PIC16F877A LED-GREEN

Figure 11 Microcontroller-LED connection3

G5-ELECTRICAL POWER Page 20

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

4.2 Audio Alert

In order to provide an audio warning in case of a transformer overload, a piezoelectric buzzer has

been used. The buzzer rating is between 2V-5V with a current rating of approximately 9mA. In

order to achieve the 9mA rating, a resistor of value R= 5V/9mA = 550Ω is required. A standard

560Ω resistor has been used. In order to allow for varied range of buzzers to be used, a

Darlington transistor is used as a switch. It is connected to pin RB6 of the microcontroller. The

microcontroller produces 5V that drives the transistor thus allowing current flow in the transistor.

The buzzer is connected between the transistor VDD and the collector. It goes on whenever the

microcontroller pin controlling it is set to high. This results due to an instance of a fault

occurring in the system which is unsuitable for the transformer. This piezoelectric buzzer serves

to give a warning to users to cease overloading the transformer or for a mitigation process to be

conducted.

3.4.3 Relay/contactor control

An electromagnetic relay has been employed as a switch to isolate the transformer from the

power system in case a fault occurs. The rating of the relay used is in the model system is 12V.

Due to the fact that the relay might draw a current of higher value than what the microcontroller

can sink or source, a Darlington transistor is used as a switch to run it. It is connected between

the transistor VDD and the Darlington transistor collector. When fault current is detected, the

RB6 pin of the microcontroller is set high. This produces current that drives the Darlington

transistor. The transistor in turn completes the relay coil circuit. The relay is energized through

the principle of electromagnetic induction. It in turn de-energizes the contactor to isolate the

transformer from the system. The relay is used alongside a contactor because; a power

transformer uses high currents that the 5V relay cannot sustain. The relay sends signals to the

contactor which in turn disconnects the circuit and isolates the transformer from the power

system.

G5-ELECTRICAL POWER Page 21

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

RL1

RL2

TR1

TR2 12V

+88.8

AC Amps

+88.8

1k

61%

AC Volts

RV3

RV5

TRAN-2P2S

R5

R8 D10

D7 B1

B2

100k +88.8 12V

DIODE Volts

4

U3

U6

GND IP-

VCC IP+

ACS755XCB-100

VIOUT

Q3

Q5

1

2N1711

U1

U4

13 33

OSC1/CLKIN RB0/INT

14 34

OSC2/CLKOUT RB1

35

RB2

2 36

RA0/AN0 RB3/PGM

3 37

RA1/AN1 RB4

4 38

RA2/AN2/VREF-/CVREF RB5

5 39

RA3/AN3/VREF+ RB6/PGC

6 40

RA4/T0CKI/C1OUT RB7/PGD

7

RA5/AN4/SS/C2OUT

15

RC0/T1OSO/T1CKI

8 16

RE0/AN5/RD RC1/T1OSI/CCP2

9 17

RE1/AN6/WR RC2/CCP1

10 18

RE2/AN7/CS RC3/SCK/SCL

23

RC4/SDI/SDA

1 24

MCLR/Vpp/THV RC5/SDO

25

RC6/TX/CK

26

RC7/RX/DT

19

RD0/PSP0

20

RD1/PSP1

21

RD2/PSP2

22

RD3/PSP3

27

RD4/PSP4

28

RD5/PSP5

29

RD6/PSP6

30

RD7/PSP7

PIC16F877A

Figure 12 Microcontroller-relay interface as done on the simulation software.

3.4.4 Sensor interfacing to the microcontroller

Since the microcontroller can take a maximum of 5.3V DC input, it cannot be connected directly

to an AC line with high voltages. A current transformer and anACS75x series sensor has been

used. The current transformer stepped down the line current to measurable level some Ampère.

The current sensor converts the current to a maximum of 5V. The current transformer is

connected to the current sensor.The sensor output is connected to the microcontroller. The figure

4.4 illustrates this process

RL1

TR1 12V

+88.8

AC Amps

+88.8

1k

61%

AC Volts

RV3

TRAN-2P2S

R5 D10 B1

100k +88.8 12V

DIODE Volts

5

U3

GND IP-

VCC IP+

ACS755XCB-100

VIOUT

Q3

2

2N1711

U1

13 33

OSC1/CLKIN RB0/INT

14 34

OSC2/CLKOUT RB1

35

RB2

2 36

RA0/AN0 RB3/PGM

3 37

RA1/AN1 RB4

4 38

RA2/AN2/VREF-/CVREF RB5

5 39

RA3/AN3/VREF+ RB6/PGC

6 40

RA4/T0CKI/C1OUT RB7/PGD

7

RA5/AN4/SS/C2OUT

15

RC0/T1OSO/T1CKI

8 16

RE0/AN5/RD RC1/T1OSI/CCP2

9 17

RE1/AN6/W R RC2/CCP1

10 18

RE2/AN7/CS RC3/SCK/SCL

23

RC4/SDI/SDA

1 24

MCLR/Vpp/THV RC5/SDO

25

RC6/TX/CK

26

RC7/RX/DT

19

RD0/PSP0

20

RD1/PSP1

21

RD2/PSP2

22

RD3/PSP3

27

RD4/PSP4

28

RD5/PSP5

29

RD6/PSP6

30

RD7/PSP7

PIC16F877A

Figure 13 Microcontroller-sensor interface as done on the simulation software

G5-ELECTRICAL POWER Page 22

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

3.5 SOFTWARE DESIGN

For the microcontroller to operate, it must be programmed, and thus the software design. Software design

is divided into four parts as follows;

LCD Program

Analogue to Digital conversion

Protection program

The main program guide

The flow chart below illustrates the way the program worked. It was used as a guide while

writing the code for the microcontroller..

Flow chart of the program

Figure 14 Microcontroller-sensor interface as done on the simulation software

G5-ELECTRICAL POWER Page 23

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

3.6 Analytical Method and Technique

3.6.1 Selection of Transformer

The purpose of our project is to protect the distribution transformer for our design we use available in

the machine lab, which can represent an actual distribution transformer in smaller size. From the

name plate of transformer we got the rated value of the transformer that help us to select other system

components of the project.

𝑭𝒓𝒐𝒎𝒏𝒂𝒎𝒆𝒑𝒍𝒂𝒕𝒆𝒓𝒂𝒕𝒊𝒏𝒈

𝑆=2.5𝑘𝑉𝐴

𝑃𝑟𝑖𝑚𝑎𝑟𝑦𝑣𝑜𝑙𝑡𝑎𝑔𝑒 v1=220𝑉𝐷𝑒𝑙𝑡𝑎𝑐𝑜𝑛𝑛𝑒𝑐𝑡𝑖𝑜𝑛

𝑃𝑟𝑖𝑚𝑎𝑟𝑦𝑐𝑢𝑟𝑟𝑒𝑛𝑡I1=6.5𝐴

𝑒𝑐𝑜𝑛𝑑𝑎𝑟𝑦𝑣𝑜𝑙𝑡𝑎𝑔𝑒V2=190𝑉𝑆𝑡𝑎𝑟𝑐𝑜𝑛𝑛𝑒𝑐𝑡𝑖𝑜𝑛

𝑆𝑒𝑐𝑜𝑛𝑑𝑎𝑟𝑦𝑐𝑢𝑟𝑟𝑒𝑛𝑡I2=7.5𝐴

3.6.2 Analytical analysis

Where - a is transformation ratios we can calculate from the given rated value of both the

primary and secondary current values are:-

G5-ELECTRICAL POWER Page 24

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

G5-ELECTRICAL POWER Page 25

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

CHAPTER FOUR

RESULTS AND DISCUSSION

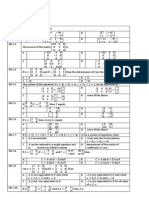

4.1 Simulated results

Protection System at normal condition (no fault happened on the system)

RL1

RL2

TR1

TR2 12V

+0.25

AC Amps

+154

1k

61%

AC Volts

RV3

RV5

LCD1

LCD2

LM041L

TRAN-2P2S

R5

R8 D10

D7 B1

B2

100k +12.0 12V

DIODE Volts

RV1

RV4

VDD

VSS

VEE

RW

RS

D0

D1

D2

D3

D4

D5

D6

D7

50%

E

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

U3

U6 1k

GND IP-

VCC IP+

ACS755XCB-100

VIOUT

Q3

Q5

2

2N1711

U1

U4

13 33

RV2

RV6 OSC1/CLKIN RB0/INT

14 34

OSC2/CLKOUT RB1

35

RB2

2 36

RA0/AN0 RB3/PGM

3 37

58%

RA1/AN1 RB4

4 38

RA2/AN2/VREF-/CVREF RB5

5 39

RA3/AN3/VREF+ RB6/PGC

6

RA4/T0CKI/C1OUT RB7/PGD

40 R3

R7 BUZ2

BUZ1

1k 7

RA5/AN4/SS/C2OUT D4

D6 560

220

+2.90 15 DIODE

U2

U5 RC0/T1OSO/T1CKI

Volts 1 8 16

RE0/AN5/RD RC1/T1OSI/CCP2

9 17

RE1/AN6/WR RC2/CCP1 BUZZER

10 18

RE2/AN7/CS RC3/SCK/SCL

23

93.0

94.0 RC4/SDI/SDA

1 24

MCLR/Vpp/THV RC5/SDO

25

RC6/TX/CK

2 26

VOUT RC7/RX/DT

19

RD0/PSP0

RD1/PSP1

20

D2

D1 Q1

Q2

Q4

Q6

3 LM35 21

+0.93

+0.94 RD2/PSP2

22

R1

R4 2N1711

BU806

Volts RD3/PSP3

27 220

RD4/PSP4

28 LED-RED

RD5/PSP5

29 D3

D5

RD6/PSP6

30

R2

R6

RD7/PSP7

220

PIC16F877A LED-GREEN

Protection System at abnormal condition (Fault occurred on the system)

RL1

RL2

TR1

TR2 12V

+0.25

0.00

AC Amps

+154

1k

61%

AC Volts

RV3

RV5

LCD1

LCD2

LM041L

TRAN-2P2S

R5

R8 D10

D7 B1

B2

100k +12.0 12V

DIODE Volts

RV1

RV4

VDD

VSS

VEE

RW

RS

D0

D1

D2

D3

D4

D5

D6

D7

50%

E

5

1

2

3

4

5

6

7

8

9

10

11

12

13

U3

U6 1k

14

IP-

VCC IP+

ACS755XCB-100

VIOUT

GND

Q3

Q5

2

2N1711

U1

U4

13 33

RV2

RV6 OSC1/CLKIN RB0/INT

14 34

OSC2/CLKOUT RB1

35

RB2

2 36

RA0/AN0 RB3/PGM

3 37

58%

61%

RA1/AN1 RB4

4 38

RA2/AN2/VREF-/CVREF RB5

5 39

RA3/AN3/VREF+ RB6/PGC

6

RA4/T0CKI/C1OUT RB7/PGD

40 R3

R7 BUZ2

BUZ1

1k 7

RA5/AN4/SS/C2OUT D4

D6 560

220

+2.90

+3.05 15 DIODE

U2

U5 RC0/T1OSO/T1CKI

Volts 1 8 16

RE0/AN5/RD RC1/T1OSI/CCP2

9 17

RE1/AN6/WR RC2/CCP1 BUZZER

10 18

RE2/AN7/CS RC3/SCK/SCL

23

93.0

96.0 RC4/SDI/SDA

1 24

MCLR/Vpp/THV RC5/SDO

25

RC6/TX/CK

2 26

VOUT RC7/RX/DT

19

RD0/PSP0

RD1/PSP1

20

D2

D1 Q1

Q2

Q4

Q6

3 LM35 21

+0.93

+0.96 RD2/PSP2

22

R1

R4 2N1711

BU806

Volts RD3/PSP3

27 220

RD4/PSP4

28 LED-RED

RD5/PSP5

29 D3

D5

RD6/PSP6

30

R2

R6

RD7/PSP7

220

PIC16F877A LED-GREEN

G5-ELECTRICAL POWER Page 26

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

4.2 Analysis

The state of the relay,LED and buzzer as current increases. A decrease in load resistance makes

current circulating in the primary side of the transformer to increase.

It Is observed that as the current circulating in the transformer increases, the sensor output also

increases. This is illustrated in the Little resistance means that the load has increased thus more

current is drawn from the transformer.

More resistance limits current flow, signifying reduced load. So as resistance is reduced by

varying the rheostat, current increases up to a point where the relay trips the circuit. This

confirms that the system has been designed well and thus it is able to read and record the current

as it changes, and operate the switches at optimum current levels.

The ADC gave satisfactory results as expected. The input value from the sensor matches well

with the displayed value on the LCD. For example “fault current” displayed on the LCD

corresponds to (<= 3V) from the sensor.

1k

61%

RV3

LCD1

LM041L

RV1

VDD

VSS

VEE

RW

RS

D0

D1

D2

D3

D4

D5

D6

D7

50%

E

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1k

Figure 15 LCD Display

Finally, it is observed that when the current is varied up to the pre-set level, of 15.015A, the

relay, buzzer and the red LED are triggered. The buzzer sounds an alarm notifying the operators

of the fault, the relay isolates the transformer from the system, the red LED blinks to signify that

the current level is too much for the transformer to supply. The LCD displays a notification that

there is an OVERCURRENT FAULT. The observations are as follow.

G5-ELECTRICAL POWER Page 27

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

33

RB0/INT

34

RB1

35

RB2

36

RB3/PGM

37

RB4

38

RB5

39

RB6/PGC

RB7/PGD

40 R3 BUZ2

D4 560

15 DIODE

OSO/T1CKI

16

1OSI/CCP2

17

RC2/CCP1 BUZZER

18

3/SCK/SCL

23

C4/SDI/SDA

24

RC5/SDO

25

RC6/TX/CK

26

RC7/RX/DT

19

RD0/PSP0

RD1/PSP1

20

D2 Q1

Q2

21 R1 2N1711

BU806

RD2/PSP2

22

RD3/PSP3

27 220

RD4/PSP4

28 LED-RED

RD5/PSP5

29 D3

RD6/PSP6

30

R2

RD7/PSP7

220

LED-GREEN

Figure 16 Led interface

From the observations, the system achieves the function of an over-current relay that

automatically detects over current fault and uses a microcontroller to record the fault, isolate the

transformer from the affected zone and report the fault occurrence so that the system operator is

aware that there is a problem. The advantage of this system over analogue over current relay is

that it automatically recloses once the fault is cleared. The level of accuracy of the system is also

super as compared to analogue operated over-current relay.

4.3 Evaluation of accuracy

Relatively compare with the currently existing protection method used by utility company, the

Microcontroller protection system of this project is fast responding to any faults which damage

the transformer than the existing one.

The existing protection system uses drop out fuse and HRC Fuse these protection equipment has

larger time delay so this type of protection system is not reliable and accurate.

G5-ELECTRICAL POWER Page 28

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

CHAPTER FIVE

CONCLUSIONS AND RECOMMANDETION

5.1 Conclusions

The main objective if this project has been to design and implement a system that uses a

microcontroller to protect a power transformer. This objective was achieved as the system works

effectively. As the current circulating in the transformer coil varies, the LCD displays the

readings. The relay is able to operate and isolate the transformer in case of an over current fault.

The relay is the main switching element in the system. When energized, it opens its contacts and

de-energizes the contactor thus isolating the transformer to safety in case of adverse current

conditions. The other peripheral devices act as means of sending warning messages in case a

fault occurs.

This system if put to use in distribution transformer protection can serve the purpose with greater

advantages than the analogue over current relay. The admirable fact about it is the accuracy with

which it closes and recloses during either normal operation or fault occurrence. It also has the

possible to improve the reliability of the existing power system in our country. This project can

reduce the economic loss incurred due to burnt transformers. It can reduce the time required for

maintaining and replacing of the distribution transformer.

G5-ELECTRICAL POWER Page 29

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

5.2 limitations and Future recommendations

Transformer protection is a very crucial engineering principle. It is clear that the demand for

electricity is increasing fast with increasing population and economic growth. This demands that

more sophisticated transformer protection methods be used in the future in order to maintain a

stable electrical power supply as will be demanded by the growing economy.

Based n the work done in this project, the future may demand that some improvements be made.

Some of the limitations faced in the design and future solutions include;

a) The current sensor does not offer a 100% sensing speed as needs some time do sense and

transfer the signal to the microcontroller. A device with a faster sensing speed should be

established.

b) Instead of using the relay as a switch, a semiconductor switching device such as a thyristor

should be used.

c) Another limitation is that whereas the relay automatically recloses its contacts, the contactor

used has to be restarted physically by an operator. Using a circuit that automatically recloses the

system would be a great solution.

d) The Utility Company has to better focus on improving the control system of distribution

transformer and replace the manual HRC fuses protection by the microcontroller based

protection system.

e) Lastly, the method of relaying the information to an operator in a control room far from the

sub-station has not been explored in this project due to time constraint. An area for future study

is how the system can automatically send a message to a control center and notify the engineers

of the exact location of a faulted transformer.

G5-ELECTRICAL POWER Page 30

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

References

2. El-Hawary, M. E. Electrical Power Systems: Design and Analysis. s.l. : John Wiley & Sons,

1995.

3. Yeshwant G. Paithankar, S. R. Bhide. Fundamentals of Power System Protection. s.l. :

2010, 2010. 3.

5. Billings, Keith H., Switchmode Power Supply Handbook – 2nd ed., McGraw-Hill, New York,

1999.

6. McLyman, Colonel Wm. T., Transformer and Inductor Design Handbook, Marcel Dekker,

New York, 1978.

G5-ELECTRICAL POWER Page 31

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

Appendix

Programing code

//.............................

sbit LCD_RS at RB0_bit;

sbit LCD_EN at RB1_bit;

sbit LCD_D4 at RB2_bit;

sbit LCD_D5 at RB3_bit;

sbit LCD_D6 at RB4_bit;

sbit LCD_D7 at RB5_bit;

sbit LCD_RS_Direction at TRISB0_bit;

sbit LCD_EN_Direction at TRISB1_bit;

sbit LCD_D4_Direction at TRISB2_bit;

sbit LCD_D5_Direction at TRISB3_bit;

sbit LCD_D6_Direction at TRISB4_bit;

sbit LCD_D7_Direction at TRISB5_bit;

// Text to be displayed char

text1 []="SYSTEM IS NORMAL"; //Characters to be displayed

char text2 []="TRANSFORMER OVER LOAD"; //Characters to be displayed

//..........................

unsigned int adc_rd;

unsigned int voltage;

unsigned long ADRead;

unsigned int vDisp[3];

unsigned char Display[7];

int adc_value = 0;

G5-ELECTRICAL POWER Page 32

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

int tempreture = 0;

const float factor = 0.488;

void adcFcn()

ADRead = (ADC_Get_Sample(0) * 500) >> 10;

vDisp[0] = ADRead / 100;

vDisp[1] = (ADRead / 10) % 10;

vDisp[2] = ADRead % 10;

Display[1] = vDisp[0] + 48;

Display[2] = vDisp[1] + 48;

Display[3] = vDisp[2] + 48;

LCD_Chr(1, 8, Display[0]);

LCD_Chr(1, 9, Display[1]);

LCD_Chr(1, 10, Display[2]);

LCD_Chr(1, 11, Display[3]);

LCD_Chr(1, 12, Display[4]);

LCD_Chr(1, 13, Display[5]);

//LCD_Out(1, 8, ); // 'Show temperature

delay_ms(200); //200ms delay for waiting

void main() {

ADCON1 = 0x80; // A/D voltage reference is

VCC

TRISA = 0xFF; // All port A pins are

configured as inputs

//....................................

G5-ELECTRICAL POWER Page 33

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

PORTB = 0;

TRISB = 0;

LCD_Init();

Lcd_Out(2,1,"G5-ELEC PROJECT");

Lcd_Out(3,4,"0N");

lcd_cmd(_lcd_cursor_off);

Delay_ms(2000);

lcd_cmd(_lcd_cursor_off);

lcd_cmd(_lcd_clear); // Write the first message in the

first line

Lcd_Out(2,2," TRANSFORMER");

delay_ms(2000);

lcd_cmd(_lcd_clear);

lcd_cmd(_lcd_cursor_off);

lcd_cmd(_lcd_cursor_off);

lcd_cmd(_lcd_clear); // Write the first message in the first

line

Lcd_Out(2,2," PROTECTION");

Delay_ms(2000);

lcd_cmd(_lcd_cursor_off);

lcd_cmd(_lcd_clear); // Write the first message in the first

line

Lcd_Out(2,2," SYSTEM CHEACK");

delay_ms(2000);

LCD_Cmd(_LCD_CURSOR_OFF);

LCD_Cmd(_LCD_CLEAR); // Define the first message

G5-ELECTRICAL POWER Page 34

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

//LCD_Cmd(_LCD_CURSOR_OFF);

//LCD_Cmd(_LCD_CLEAR);

//LCD_Out(1, 1, "Temp:");

//Display = "+125 'C";

// endless loop start here..........................................

while (1)

adc_value = ADC_read(0);

tempreture = adc_value*factor; // convert the voltage to tempreture equivalent

if(tempreture <=95)

LCD_Out(1,1,"OIL TEMP NORMAL");

delay_ms(3000);

//LCD_Cmd(_LCD_CURSOR_OFF);

//LCD_Cmd(_LCD_CLEAR);

else{

LCD_Out(1, 1, "OIL TEMP OVER HE");

delay_ms(3000);

//LCD_Cmd(_LCD_CURSOR_OFF);

//LCD_Cmd(_LCD_CLEAR);

//................................

TRISD.f3 = 0; // set direction to be output

TRISD.F0 =0;

TRISD.F6=0;

G5-ELECTRICAL POWER Page 35

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

PORTD.F3=0X00;

PORTD.F0;0X00;

Delay_ms(1000); // 1 second delay

PORTD = 0xFF; // Turn ON LEDs on PORT

Delay_ms(1000); // 1 second delay

adc_rd = ADC_Read(1);

voltage= adc_rd;

if(voltage <= 613)

lcd_out(2,1,"NORMAL CURRENT");

delay_ms(3000);

else{

lcd_out(3,1,"TRA OVER LOAD");

delay_ms(5000);

lcd_cmd(_lcd_cursor_off);

lcd_cmd(_lcd_clear);

lcd_out(3,1,"OVER CURRENT");

delay_ms(500);

lcd_out(4,1,"LOAD DISCONNECT");

delay_ms(2000);

lcd_cmd(_lcd_cursor_off);

lcd_cmd(_lcd_clear);

TRISD.f3 = 0; // set direction to be output

TRISD.F0 =0;

G5-ELECTRICAL POWER Page 36

MICROCONTROLLER BASED DISTRIBUTION TRANSFORMER PROTECTION June , 2016

TRISD.F6=0;

PORTD.F3=0X00;

PORTD.F0;0X00;

Delay_ms(1000); // 1 second delay

PORTD = 0xFF; // Turn ON LEDs on PORTD

Delay_ms(1000); // 1 second delay

G5-ELECTRICAL POWER Page 37

You might also like

- Industrial Automation Technologies (Chanchal Dey (Editor) Sunit Kumar Sen (Editor) )Document376 pagesIndustrial Automation Technologies (Chanchal Dey (Editor) Sunit Kumar Sen (Editor) )Ed Carlo Ramis100% (1)

- Sma Sunny Tripower 15000tl 20000tl 25000tl Operating ManualDocument56 pagesSma Sunny Tripower 15000tl 20000tl 25000tl Operating ManualSadikNo ratings yet

- Manual AC-M1 (Rev1)Document62 pagesManual AC-M1 (Rev1)HushanjiNo ratings yet

- Ilker Drilling ProgrammeDocument71 pagesIlker Drilling Programmerıdvan duranNo ratings yet

- University of Gondar Instituet of Technology Department of Electrical and Computer Engineering Stream of Industrial ControlDocument53 pagesUniversity of Gondar Instituet of Technology Department of Electrical and Computer Engineering Stream of Industrial ControlTegegne YimerNo ratings yet

- Final Draft of Pfi On 2005e-1Document41 pagesFinal Draft of Pfi On 2005e-1Addisu TadesseNo ratings yet

- Acknowledgment: Arduino Based Design & Controling of Office Applianc SystemDocument64 pagesAcknowledgment: Arduino Based Design & Controling of Office Applianc SystemAbiy FissheaNo ratings yet

- Automatic Three Phase Changer-1Document28 pagesAutomatic Three Phase Changer-1kidus ameroNo ratings yet

- Capstone Final Report FinalxxxDocument56 pagesCapstone Final Report Finalxxxmathynil41No ratings yet

- My FileDocument57 pagesMy FileAsim iqbal438No ratings yet

- Dsp-Ohmni: C-EG30EM Instruction Manual V2, June 2020Document50 pagesDsp-Ohmni: C-EG30EM Instruction Manual V2, June 2020Carlos CamayoNo ratings yet

- Intern Report and ProjectDocument58 pagesIntern Report and ProjectassayegedifbduNo ratings yet

- Sharingan ThesisDocument69 pagesSharingan Thesisprince asadNo ratings yet

- Shambel Dagnew 0904686 2. Shikur Worku 2202/08 3. Kassahun Marew 0903126 4. Mulatu Dessalegn 0904062 Advised By: Girma M. (MSC.)Document42 pagesShambel Dagnew 0904686 2. Shikur Worku 2202/08 3. Kassahun Marew 0903126 4. Mulatu Dessalegn 0904062 Advised By: Girma M. (MSC.)Dawit Adane KebedeNo ratings yet

- Position Feedback For Motor Control Using Magnetic SensorDocument17 pagesPosition Feedback For Motor Control Using Magnetic SensorPablo TapiaNo ratings yet

- LightSYS2 - Installation and Programming ManualDocument260 pagesLightSYS2 - Installation and Programming ManualSittiphong OUNSAVANHNo ratings yet

- CT2440ARINC: Broadcast Microwave ServicesDocument42 pagesCT2440ARINC: Broadcast Microwave Servicesfrancisco saez moraNo ratings yet

- Foot-Step Generator ReportDocument26 pagesFoot-Step Generator ReportsurafelNo ratings yet

- Learning Based Model Predictive Control (LBMPC) For Optimum Control of Asynchronous MotorDocument91 pagesLearning Based Model Predictive Control (LBMPC) For Optimum Control of Asynchronous MotordfdafdsfasdgNo ratings yet

- FILE 20220531 131930 MA WATERFLUX3070 V2 en 161207 4001410207 R07Document80 pagesFILE 20220531 131930 MA WATERFLUX3070 V2 en 161207 4001410207 R07muoi dinhNo ratings yet

- DC Motor Control by Using PicDocument53 pagesDC Motor Control by Using PicjabezNo ratings yet

- AcuRev 1310 User ManualDocument109 pagesAcuRev 1310 User ManualFeriferi FerencNo ratings yet

- my project - نسخةDocument143 pagesmy project - نسخةAnas SadiqNo ratings yet

- Schneider Electric UPSDocument501 pagesSchneider Electric UPSduyhamhoc162No ratings yet

- Password Based Circuit Breaker Using Pic MicrocontrollerDocument43 pagesPassword Based Circuit Breaker Using Pic Microcontrollermstudent327No ratings yet

- 13.0 MMC HardwareManualDocument156 pages13.0 MMC HardwareManualggntb64fckNo ratings yet

- CoreUSXGMII HBDocument26 pagesCoreUSXGMII HBQuenii ZNo ratings yet

- Industrial ElectronicsDocument154 pagesIndustrial ElectronicsSayantika PanNo ratings yet

- Manual Mvi46 MCMDocument108 pagesManual Mvi46 MCMDiego FernandesNo ratings yet

- University of Dar Es Salaam: Design and Implementation of Speed Control Circuit of Multiple MotorDocument33 pagesUniversity of Dar Es Salaam: Design and Implementation of Speed Control Circuit of Multiple MotorMatele de GilesNo ratings yet

- A Review On AC and DC Technology in MicrogridsDocument24 pagesA Review On AC and DC Technology in Microgridshafiz858No ratings yet

- Final Project Report Mobile Phone JammerDocument19 pagesFinal Project Report Mobile Phone JammerFarine TripoliNo ratings yet

- Vol - 8 Guidelines For Outdoor Installations - 11-10-2023Document36 pagesVol - 8 Guidelines For Outdoor Installations - 11-10-2023lokesh medhaNo ratings yet

- Sma STP 110-60 Core2Document84 pagesSma STP 110-60 Core2Manuel UrdanetaNo ratings yet

- Ncube Brian T Final Year ProjectDocument61 pagesNcube Brian T Final Year ProjectBrian NcubeNo ratings yet

- Analog System Lab 2024Document38 pagesAnalog System Lab 2024vishu shankarNo ratings yet

- Samir I. Abood, John Fuller - Power System Protection and Relaying. Computer-Aided Design Using SCADA Technology-CRC Press (2024)Document405 pagesSamir I. Abood, John Fuller - Power System Protection and Relaying. Computer-Aided Design Using SCADA Technology-CRC Press (2024)nhattruongimpeNo ratings yet

- Masterys BC: Installation and Operating ManualDocument48 pagesMasterys BC: Installation and Operating ManualGervasio SimaoNo ratings yet

- Sungrow Inverter - UM - 202010 - SG2-8K G2 Premium User Manual - V1.5Document79 pagesSungrow Inverter - UM - 202010 - SG2-8K G2 Premium User Manual - V1.5johnto1999No ratings yet

- GB Green Power 2.0 Masterys GP 60 80 Operating ManualDocument52 pagesGB Green Power 2.0 Masterys GP 60 80 Operating Manualperformer 237No ratings yet

- Final PaperDocument63 pagesFinal PaperObsa TesemaNo ratings yet

- Sunny Tripower CORE1 (STP 50-40) : Operating ManualDocument114 pagesSunny Tripower CORE1 (STP 50-40) : Operating ManualMonster LifeNo ratings yet

- MN04020003EDocument204 pagesMN04020003EElderJoaoNo ratings yet

- Design and Simulation of Protection System in Switched Mode Power SupplyDocument60 pagesDesign and Simulation of Protection System in Switched Mode Power SupplyFarbod Jz.No ratings yet

- C 453em SigmaDocument30 pagesC 453em Sigmachaakam99No ratings yet

- 1MAC306892-MB C IEC 104 Comm Protocol, ABBDocument40 pages1MAC306892-MB C IEC 104 Comm Protocol, ABBAlexander GinNo ratings yet

- SMA Sunnyboy 3 3.6 4 5 6 Operating ManualDocument98 pagesSMA Sunnyboy 3 3.6 4 5 6 Operating ManualEmmanuel F. JusayNo ratings yet

- Final ThesisDocument52 pagesFinal ThesisQaiser MehmoodNo ratings yet

- Implementation of A Low-Cost Three-Phase Electronic Watt-Hour Meter Using The MSP430F67641Document59 pagesImplementation of A Low-Cost Three-Phase Electronic Watt-Hour Meter Using The MSP430F67641Rangel FlavioNo ratings yet

- PLCC Based Load SchedulingDocument24 pagesPLCC Based Load SchedulingSheeba CNo ratings yet

- MFC 400 Manual PDFDocument132 pagesMFC 400 Manual PDFTrường ThạchNo ratings yet

- Knowledge in Detail Mechatronic in Theory and Practice 2Document29 pagesKnowledge in Detail Mechatronic in Theory and Practice 2Osama AhmedNo ratings yet

- Sunny Tripower CORE1 (STP 50-40) : Operating ManualDocument118 pagesSunny Tripower CORE1 (STP 50-40) : Operating ManualMohamed MourtagaNo ratings yet