Professional Documents

Culture Documents

1 OBD2 Terms

1 OBD2 Terms

Uploaded by

yagaCopyright:

Available Formats

You might also like

- Automotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedFrom EverandAutomotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedRating: 4 out of 5 stars4/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- OT680 UsermanualDocument23 pagesOT680 Usermanualmauricio0% (1)

- Audi A4 Quattro 2.0L 4-Cyl. 4V Turbo EngineDocument203 pagesAudi A4 Quattro 2.0L 4-Cyl. 4V Turbo EngineNP0% (1)

- Jeep Chrysler Diagnostic Trouble CodesDocument55 pagesJeep Chrysler Diagnostic Trouble CodesDanilo Barrios100% (6)

- OEM Ford 7.3 Litre Diesel OBD II DiagnosticsDocument26 pagesOEM Ford 7.3 Litre Diesel OBD II DiagnosticsTigxMig75% (8)

- GS500 Manual enDocument35 pagesGS500 Manual enJovica MilicevicNo ratings yet

- ManualDocument29 pagesManualAlfredo SotoNo ratings yet

- INstrument Cluster Test PDFDocument122 pagesINstrument Cluster Test PDFryanhartery100% (1)

- Perkins 1103 and 1104 EnginesDocument136 pagesPerkins 1103 and 1104 EnginesAnonymous yjK3peI797% (30)

- Nissan Frontier Service Manual Engine Control SystemDocument338 pagesNissan Frontier Service Manual Engine Control SystemDaniel Aguirre100% (4)

- 1-Nguyen Ly Cua OBD (English)Document9 pages1-Nguyen Ly Cua OBD (English)Thanh Tùng HuỳnhNo ratings yet

- 05 - DriveabilityDocument71 pages05 - DriveabilityEdgardo RivasNo ratings yet

- Audi A4 Quattro 3.0 Liter 6-Cyl. 5V Fuel Injection & IgnitionDocument259 pagesAudi A4 Quattro 3.0 Liter 6-Cyl. 5V Fuel Injection & IgnitionNPNo ratings yet

- Safety Precautions in An Automotive Workshop by SamiiDocument76 pagesSafety Precautions in An Automotive Workshop by Samiijocasam2000No ratings yet

- On Board Diagnostics (OBD) MonitorsDocument5 pagesOn Board Diagnostics (OBD) MonitorsJosé AntonioNo ratings yet

- Obdii Motorists092005Document1 pageObdii Motorists092005Osama RaNo ratings yet

- STYPEDocument309 pagesSTYPEZulia AmbarNo ratings yet

- Bosch ECU On-Board DiagnosticsDocument98 pagesBosch ECU On-Board DiagnosticsRafael Hubner100% (3)

- 2009-12-27 171410 XtypeDocument98 pages2009-12-27 171410 XtypeDeni WardiniNo ratings yet

- Powertrain DTC SummaryDocument71 pagesPowertrain DTC SummaryplanelNo ratings yet

- GS500 Manual FinalDocument50 pagesGS500 Manual FinalTreloepistimonn TreloepistimonnNo ratings yet

- Xtype Power Train DTC SummariesDocument53 pagesXtype Power Train DTC Summariescardude45750No ratings yet

- Obd 1Document14 pagesObd 1jevelezsoft100% (4)

- Manual JP701, EU702, US703&FR704 - 1.01Document69 pagesManual JP701, EU702, US703&FR704 - 1.01bmw316No ratings yet

- p0420 Catalyst ErrorDocument7 pagesp0420 Catalyst Errordion132100% (2)

- P 2229Document3 pagesP 2229Doug SmileyNo ratings yet

- OBD II System MonitorsDocument22 pagesOBD II System Monitorsjre123No ratings yet

- MD801 Manual V1.00-100421Document80 pagesMD801 Manual V1.00-100421Nelson TinocoNo ratings yet

- 11 Onboard Diagnostics OBD For DieselsDocument40 pages11 Onboard Diagnostics OBD For DieselsMuhamad HakimNo ratings yet

- GS400 ManualDocument29 pagesGS400 ManualDuvel Arago0% (1)

- 2TR-FE Engine Control SystemDocument4 pages2TR-FE Engine Control SystemFernando Condori Calle80% (5)

- Autel MS309 - Manual - V1.01Document27 pagesAutel MS309 - Manual - V1.01xuzebin100% (3)

- Code Meanings:-: DTC CodesDocument14 pagesCode Meanings:-: DTC Codestatami99No ratings yet

- GS300 ManualDocument46 pagesGS300 ManualDuvel AragoNo ratings yet

- MSA5T0123A27477Document1 pageMSA5T0123A27477Razvan MateiNo ratings yet

- 4Hk1 6HK1 Engine Diagnostic and Drivability Student PDF (035 040) PDFDocument6 pages4Hk1 6HK1 Engine Diagnostic and Drivability Student PDF (035 040) PDFluigi100% (1)

- SensorsDocument21 pagesSensorsTristan Reyes100% (1)

- Ata 77 - Engine Indicating CorDocument23 pagesAta 77 - Engine Indicating CorIdrisNo ratings yet

- Manual JP701, EU702, US703&FR704 - 1.01Document69 pagesManual JP701, EU702, US703&FR704 - 1.01jacques_arnal3664No ratings yet

- Volvo 850 ODB A1 Automatic Transmission DiagnosticDocument9 pagesVolvo 850 ODB A1 Automatic Transmission DiagnosticBartłomiej KilianNo ratings yet

- Mode Generic Title Toyota/Lexus Title: Coolant TempDocument6 pagesMode Generic Title Toyota/Lexus Title: Coolant TempMohamed Wahieb100% (1)

- 0002-000-2461-Pids Supplement PDFDocument42 pages0002-000-2461-Pids Supplement PDFRaulVazquez100% (1)

- Ls1 ManualDocument113 pagesLs1 ManualMTNo ratings yet

- Preparing For An OBD11 TestDocument9 pagesPreparing For An OBD11 Testashk89No ratings yet

- Land Rover-Freelander 2005Document85 pagesLand Rover-Freelander 2005Anderson Duarte100% (1)

- Obdii EngDocument92 pagesObdii EngjaeszNo ratings yet

- Instrument Cluster: SECTION 413-01A: Instrument Cluster - Conventional 2001 F-150 Workshop Manual Diagnosis and TestingDocument45 pagesInstrument Cluster: SECTION 413-01A: Instrument Cluster - Conventional 2001 F-150 Workshop Manual Diagnosis and Testingsqhu100% (2)

- Kia Code RetrievalDocument2 pagesKia Code Retrievalandreisim80100% (1)

- Engine PerformanceDocument965 pagesEngine Performance5cubero5No ratings yet

- Chrysler Town and Country - Caravan - Voyager - 1998 Emission ControlDocument10 pagesChrysler Town and Country - Caravan - Voyager - 1998 Emission ControleephantomNo ratings yet

- Lesson 5: Denso-Common Rail System: ObjectivesDocument27 pagesLesson 5: Denso-Common Rail System: ObjectivesSenghakPhally100% (1)

- Sistema de Control Electronico CatDocument9 pagesSistema de Control Electronico CatNava RobertoNo ratings yet

- Air Conditioning Climate Control Manual Climate ControlDocument138 pagesAir Conditioning Climate Control Manual Climate ControlSuncica BulatovicNo ratings yet

- 1999-2004 Discovery2 RR 38A Bosch GS8.87 TCMDocument13 pages1999-2004 Discovery2 RR 38A Bosch GS8.87 TCMBernard TrippNo ratings yet

- MS409 Manual V1.01Document46 pagesMS409 Manual V1.01zayarmyint_uNo ratings yet

- Ford OBDOBD2 CodesDocument25 pagesFord OBDOBD2 Codesfabiobonadia100% (1)

- Ford OBDOBD2 Codes PDFDocument25 pagesFord OBDOBD2 Codes PDFfabiobonadiaNo ratings yet

- 4 AfeDocument36 pages4 AfeJuan ContrerasNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Cycle Infrastructure DesignDocument92 pagesCycle Infrastructure DesignTony CarrollNo ratings yet

- Er300 Affagf Eu Parts List PDFDocument99 pagesEr300 Affagf Eu Parts List PDFOliver0% (1)

- Tata Nano Case StudyDocument9 pagesTata Nano Case StudyShilpa Sehrawat0% (1)

- Speed and Delay Study On National HighwayDocument20 pagesSpeed and Delay Study On National HighwayAshutosh Arun100% (1)

- Peugeot Citroen 3rg IndustrialDocument72 pagesPeugeot Citroen 3rg IndustrialcoqacolaNo ratings yet

- Cat Serial Number PrefixesDocument4 pagesCat Serial Number Prefixestuffmach100% (5)

- Cable Caterpillar PDFDocument2 pagesCable Caterpillar PDFLhoussain Bourda100% (1)

- DB ICE To London ProjectDocument3 pagesDB ICE To London ProjectRailway 20No ratings yet

- 777F PDFDocument79 pages777F PDFsergio roa100% (2)

- Ce T63 Transportation Engineering - Ii Unit - IDocument12 pagesCe T63 Transportation Engineering - Ii Unit - IMugilan SNo ratings yet

- Rear Axle Beam ReplacementDocument5 pagesRear Axle Beam ReplacementRomy M100% (1)

- Classic 500Document86 pagesClassic 500Rodrigo FischNo ratings yet

- Bernese Oberland Railway PDFDocument7 pagesBernese Oberland Railway PDFluizzzfNo ratings yet

- Highway Engineering MCQDocument11 pagesHighway Engineering MCQAbhijeet GholapNo ratings yet

- Gtu Weightage Acet Sem-Vii 2022Document3 pagesGtu Weightage Acet Sem-Vii 2022Jyotin KateshiaNo ratings yet

- Toyota Harrier Main Specification Sheet PDFDocument1 pageToyota Harrier Main Specification Sheet PDFsampathNo ratings yet

- Cummins CRDocument40 pagesCummins CRАлексей Миронов100% (8)

- Brake Checklist A4 L enDocument1 pageBrake Checklist A4 L enNantha Kumara Periasamy100% (1)

- Manual CRV 2012Document384 pagesManual CRV 2012Rene SalathielNo ratings yet

- 4045TF150 ADocument2 pages4045TF150 ADouglas SobralNo ratings yet

- Diagrama Nissan Pinout Del ECM QR25DE 2Document17 pagesDiagrama Nissan Pinout Del ECM QR25DE 2Jose CifuentesNo ratings yet

- What Is A Maglev Train?Document3 pagesWhat Is A Maglev Train?Jhenson SiiNo ratings yet

- Desember Daily BreakdownDocument7 pagesDesember Daily BreakdownIqmal WahabNo ratings yet

- Hiace Owners ManualDocument240 pagesHiace Owners ManualJonathan Bebego100% (1)

- Report 5701311953851337357Document3 pagesReport 5701311953851337357Pane DileNo ratings yet

- Bullet 350 BS6 ManualDocument72 pagesBullet 350 BS6 ManualAshwin PrakashNo ratings yet

- SPINNER 2014 Catalogue PDFDocument18 pagesSPINNER 2014 Catalogue PDFGoodBikesNo ratings yet

- Transportation Engineering IDocument45 pagesTransportation Engineering IMohsinNo ratings yet

1 OBD2 Terms

1 OBD2 Terms

Uploaded by

yagaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 OBD2 Terms

1 OBD2 Terms

Uploaded by

yagaCopyright:

Available Formats

AMT-200

OBD2 Terms

Catalyst Monitor - Non Continuous

Checks the three-way cat by comparing the upstream and downstream O2 sensor signals.

A Non Continuous monitor that will run once per trip given the appropriate enabling conditions.

Comprehensive component Monitor – Continuous Monitor

The system check of the sensor inputs. This includes all types of electrical faults and rationality

checks of sensor inputs.

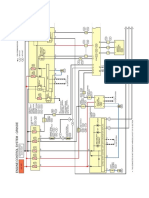

Diagnostic Trouble codes

Second Digit indicates SAE or

Code structure: Manufacturer Specific

0 – SAE generic

First Digit indicates the System 1 – Manufacture specific

P – Powertrain 2 – SAE generic

B – Body 3 – P30xx-P33xxManufacture specific

C – Chassis 3 - P34xx-P39xx Generic

U - Network 3 - “C” “B” “U” generic

PO301

Third Digit indicates Specific System 4th & 5th Digits indicates fault code

1 – Air/Fuel Induction number (00-99) see charts

2 – Fuel Injection

3 – Ignition or Misfire

4 – Auxiliary Emission Controls

5 – Vehicle speed, Idle Controls, Auxiliary input

6 – Computer Inputs and Outputs

7 – Transmission

8 – Transmission

A – Hybrid propulsion

Example:

PO301 – Powertrain, SAE, Ignition Misfire, Cylinder #1

Code Types:

A Codes – (one-trip detection)

Misfire detection, Fuel Control and Comprehensive Component monitors. Hard DTC,

MIL on and Freeze Frame data stored.

B Codes – (two-trip detection)

First failure sets a pending code. Second consecutive failure in similar conditions results

in hard DTC, MIL on and Freeze Frame data stored.

C & D Codes – Non emissions related

Does not turn on the MIL, stores a DTC, may turn on other indicator lamps, may store a

failure record.

Drive Cycle - see Trip

EGR Monitor – Non Continuous

Verifies EGR operation by opening EGR and looking for the predicted results. A Non

Continuous monitor that will run once per trip given the appropriate enabling conditions.

Enabling Conditions

The specific operating conditions that must be meet for a monitor to run.

EVAP Monitor – Non Continuous

Checks evaporative system for leaks and verifies air flow in the system. Must be able to detect a

leak as small as .020 in the system. A Non Continuous monitor that will run once per trip given

the appropriate enabling conditions.

Freeze Frame Data

The vehicle operating conditions under which the DTC was set. Freeze Frame data is only

required to be stored for emissions related failures. Data may be overwritten by a DTC with

higher priority.

Fuel System Monitor – Continuous Monitor

The PCM check of the O2 sensor signals and Fuel Trim. MIL will turn on if PCM cannot

maintain fuel control.

MIL

The malfunction indicator lamp MIL will turn on anytime the vehicle could exceed 1.5 times the

allowable exhaust emissions.

Misfire Monitor – Continuous Monitor

The PCM must verify cylinder firing. Usually done with CKP sensor. PCM looks for changes

in rotational speed indicating a misfire.

Type A - Severe misfire excessive misfires in 200 revolutions.

MIL flashing, Hard DTC, Freeze Frame Data Stored

Type B - Excessive misfires in 1000 – 3200 revolutions.

Pending DTC and Freeze Frame first trip

MIL on, hard DTC, Freeze Frame second trip.

Monitors

The self-tests performed by the vehicle mandated by legislation pertaining to ODB2.

There are three continuous monitors:

Comprehensive Component

Misfire

Fuel Control

Non-continuous monitors:

EGR HO2S Catalyst

EVAP AIR Others

Oxygen Sensor Monitor – Non Continuous

Checks sensors output signal and heater circuit. A Non Continuous monitor that will run once

per trip given the appropriate enabling conditions.

Readiness Status

OBD2 systems must indicate the status of its monitors.

Ready – indicates monitor has run and passed

Failed – indicates monitor has run and failed

Pending – indicates monitor has not run

TRIP

A TRIP or Drive Cycle is where the enabling conditions are met for at least one non-continuous

monitor to run.

A global TRIP or compete Drive Cycle is where enabling conditions have been meet for all

monitor to run.

Warm-Up Cycle

Key-on engine operation where the coolant temp rises at least 40 degrees and goes above 160

degrees.

You might also like

- Automotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedFrom EverandAutomotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedRating: 4 out of 5 stars4/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- OT680 UsermanualDocument23 pagesOT680 Usermanualmauricio0% (1)

- Audi A4 Quattro 2.0L 4-Cyl. 4V Turbo EngineDocument203 pagesAudi A4 Quattro 2.0L 4-Cyl. 4V Turbo EngineNP0% (1)

- Jeep Chrysler Diagnostic Trouble CodesDocument55 pagesJeep Chrysler Diagnostic Trouble CodesDanilo Barrios100% (6)

- OEM Ford 7.3 Litre Diesel OBD II DiagnosticsDocument26 pagesOEM Ford 7.3 Litre Diesel OBD II DiagnosticsTigxMig75% (8)

- GS500 Manual enDocument35 pagesGS500 Manual enJovica MilicevicNo ratings yet

- ManualDocument29 pagesManualAlfredo SotoNo ratings yet

- INstrument Cluster Test PDFDocument122 pagesINstrument Cluster Test PDFryanhartery100% (1)

- Perkins 1103 and 1104 EnginesDocument136 pagesPerkins 1103 and 1104 EnginesAnonymous yjK3peI797% (30)

- Nissan Frontier Service Manual Engine Control SystemDocument338 pagesNissan Frontier Service Manual Engine Control SystemDaniel Aguirre100% (4)

- 1-Nguyen Ly Cua OBD (English)Document9 pages1-Nguyen Ly Cua OBD (English)Thanh Tùng HuỳnhNo ratings yet

- 05 - DriveabilityDocument71 pages05 - DriveabilityEdgardo RivasNo ratings yet

- Audi A4 Quattro 3.0 Liter 6-Cyl. 5V Fuel Injection & IgnitionDocument259 pagesAudi A4 Quattro 3.0 Liter 6-Cyl. 5V Fuel Injection & IgnitionNPNo ratings yet

- Safety Precautions in An Automotive Workshop by SamiiDocument76 pagesSafety Precautions in An Automotive Workshop by Samiijocasam2000No ratings yet

- On Board Diagnostics (OBD) MonitorsDocument5 pagesOn Board Diagnostics (OBD) MonitorsJosé AntonioNo ratings yet

- Obdii Motorists092005Document1 pageObdii Motorists092005Osama RaNo ratings yet

- STYPEDocument309 pagesSTYPEZulia AmbarNo ratings yet

- Bosch ECU On-Board DiagnosticsDocument98 pagesBosch ECU On-Board DiagnosticsRafael Hubner100% (3)

- 2009-12-27 171410 XtypeDocument98 pages2009-12-27 171410 XtypeDeni WardiniNo ratings yet

- Powertrain DTC SummaryDocument71 pagesPowertrain DTC SummaryplanelNo ratings yet

- GS500 Manual FinalDocument50 pagesGS500 Manual FinalTreloepistimonn TreloepistimonnNo ratings yet

- Xtype Power Train DTC SummariesDocument53 pagesXtype Power Train DTC Summariescardude45750No ratings yet

- Obd 1Document14 pagesObd 1jevelezsoft100% (4)

- Manual JP701, EU702, US703&FR704 - 1.01Document69 pagesManual JP701, EU702, US703&FR704 - 1.01bmw316No ratings yet

- p0420 Catalyst ErrorDocument7 pagesp0420 Catalyst Errordion132100% (2)

- P 2229Document3 pagesP 2229Doug SmileyNo ratings yet

- OBD II System MonitorsDocument22 pagesOBD II System Monitorsjre123No ratings yet

- MD801 Manual V1.00-100421Document80 pagesMD801 Manual V1.00-100421Nelson TinocoNo ratings yet

- 11 Onboard Diagnostics OBD For DieselsDocument40 pages11 Onboard Diagnostics OBD For DieselsMuhamad HakimNo ratings yet

- GS400 ManualDocument29 pagesGS400 ManualDuvel Arago0% (1)

- 2TR-FE Engine Control SystemDocument4 pages2TR-FE Engine Control SystemFernando Condori Calle80% (5)

- Autel MS309 - Manual - V1.01Document27 pagesAutel MS309 - Manual - V1.01xuzebin100% (3)

- Code Meanings:-: DTC CodesDocument14 pagesCode Meanings:-: DTC Codestatami99No ratings yet

- GS300 ManualDocument46 pagesGS300 ManualDuvel AragoNo ratings yet

- MSA5T0123A27477Document1 pageMSA5T0123A27477Razvan MateiNo ratings yet

- 4Hk1 6HK1 Engine Diagnostic and Drivability Student PDF (035 040) PDFDocument6 pages4Hk1 6HK1 Engine Diagnostic and Drivability Student PDF (035 040) PDFluigi100% (1)

- SensorsDocument21 pagesSensorsTristan Reyes100% (1)

- Ata 77 - Engine Indicating CorDocument23 pagesAta 77 - Engine Indicating CorIdrisNo ratings yet

- Manual JP701, EU702, US703&FR704 - 1.01Document69 pagesManual JP701, EU702, US703&FR704 - 1.01jacques_arnal3664No ratings yet

- Volvo 850 ODB A1 Automatic Transmission DiagnosticDocument9 pagesVolvo 850 ODB A1 Automatic Transmission DiagnosticBartłomiej KilianNo ratings yet

- Mode Generic Title Toyota/Lexus Title: Coolant TempDocument6 pagesMode Generic Title Toyota/Lexus Title: Coolant TempMohamed Wahieb100% (1)

- 0002-000-2461-Pids Supplement PDFDocument42 pages0002-000-2461-Pids Supplement PDFRaulVazquez100% (1)

- Ls1 ManualDocument113 pagesLs1 ManualMTNo ratings yet

- Preparing For An OBD11 TestDocument9 pagesPreparing For An OBD11 Testashk89No ratings yet

- Land Rover-Freelander 2005Document85 pagesLand Rover-Freelander 2005Anderson Duarte100% (1)

- Obdii EngDocument92 pagesObdii EngjaeszNo ratings yet

- Instrument Cluster: SECTION 413-01A: Instrument Cluster - Conventional 2001 F-150 Workshop Manual Diagnosis and TestingDocument45 pagesInstrument Cluster: SECTION 413-01A: Instrument Cluster - Conventional 2001 F-150 Workshop Manual Diagnosis and Testingsqhu100% (2)

- Kia Code RetrievalDocument2 pagesKia Code Retrievalandreisim80100% (1)

- Engine PerformanceDocument965 pagesEngine Performance5cubero5No ratings yet

- Chrysler Town and Country - Caravan - Voyager - 1998 Emission ControlDocument10 pagesChrysler Town and Country - Caravan - Voyager - 1998 Emission ControleephantomNo ratings yet

- Lesson 5: Denso-Common Rail System: ObjectivesDocument27 pagesLesson 5: Denso-Common Rail System: ObjectivesSenghakPhally100% (1)

- Sistema de Control Electronico CatDocument9 pagesSistema de Control Electronico CatNava RobertoNo ratings yet

- Air Conditioning Climate Control Manual Climate ControlDocument138 pagesAir Conditioning Climate Control Manual Climate ControlSuncica BulatovicNo ratings yet

- 1999-2004 Discovery2 RR 38A Bosch GS8.87 TCMDocument13 pages1999-2004 Discovery2 RR 38A Bosch GS8.87 TCMBernard TrippNo ratings yet

- MS409 Manual V1.01Document46 pagesMS409 Manual V1.01zayarmyint_uNo ratings yet

- Ford OBDOBD2 CodesDocument25 pagesFord OBDOBD2 Codesfabiobonadia100% (1)

- Ford OBDOBD2 Codes PDFDocument25 pagesFord OBDOBD2 Codes PDFfabiobonadiaNo ratings yet

- 4 AfeDocument36 pages4 AfeJuan ContrerasNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Cycle Infrastructure DesignDocument92 pagesCycle Infrastructure DesignTony CarrollNo ratings yet

- Er300 Affagf Eu Parts List PDFDocument99 pagesEr300 Affagf Eu Parts List PDFOliver0% (1)

- Tata Nano Case StudyDocument9 pagesTata Nano Case StudyShilpa Sehrawat0% (1)

- Speed and Delay Study On National HighwayDocument20 pagesSpeed and Delay Study On National HighwayAshutosh Arun100% (1)

- Peugeot Citroen 3rg IndustrialDocument72 pagesPeugeot Citroen 3rg IndustrialcoqacolaNo ratings yet

- Cat Serial Number PrefixesDocument4 pagesCat Serial Number Prefixestuffmach100% (5)

- Cable Caterpillar PDFDocument2 pagesCable Caterpillar PDFLhoussain Bourda100% (1)

- DB ICE To London ProjectDocument3 pagesDB ICE To London ProjectRailway 20No ratings yet

- 777F PDFDocument79 pages777F PDFsergio roa100% (2)

- Ce T63 Transportation Engineering - Ii Unit - IDocument12 pagesCe T63 Transportation Engineering - Ii Unit - IMugilan SNo ratings yet

- Rear Axle Beam ReplacementDocument5 pagesRear Axle Beam ReplacementRomy M100% (1)

- Classic 500Document86 pagesClassic 500Rodrigo FischNo ratings yet

- Bernese Oberland Railway PDFDocument7 pagesBernese Oberland Railway PDFluizzzfNo ratings yet

- Highway Engineering MCQDocument11 pagesHighway Engineering MCQAbhijeet GholapNo ratings yet

- Gtu Weightage Acet Sem-Vii 2022Document3 pagesGtu Weightage Acet Sem-Vii 2022Jyotin KateshiaNo ratings yet

- Toyota Harrier Main Specification Sheet PDFDocument1 pageToyota Harrier Main Specification Sheet PDFsampathNo ratings yet

- Cummins CRDocument40 pagesCummins CRАлексей Миронов100% (8)

- Brake Checklist A4 L enDocument1 pageBrake Checklist A4 L enNantha Kumara Periasamy100% (1)

- Manual CRV 2012Document384 pagesManual CRV 2012Rene SalathielNo ratings yet

- 4045TF150 ADocument2 pages4045TF150 ADouglas SobralNo ratings yet

- Diagrama Nissan Pinout Del ECM QR25DE 2Document17 pagesDiagrama Nissan Pinout Del ECM QR25DE 2Jose CifuentesNo ratings yet

- What Is A Maglev Train?Document3 pagesWhat Is A Maglev Train?Jhenson SiiNo ratings yet

- Desember Daily BreakdownDocument7 pagesDesember Daily BreakdownIqmal WahabNo ratings yet

- Hiace Owners ManualDocument240 pagesHiace Owners ManualJonathan Bebego100% (1)

- Report 5701311953851337357Document3 pagesReport 5701311953851337357Pane DileNo ratings yet

- Bullet 350 BS6 ManualDocument72 pagesBullet 350 BS6 ManualAshwin PrakashNo ratings yet

- SPINNER 2014 Catalogue PDFDocument18 pagesSPINNER 2014 Catalogue PDFGoodBikesNo ratings yet

- Transportation Engineering IDocument45 pagesTransportation Engineering IMohsinNo ratings yet