Professional Documents

Culture Documents

Analysis of Properties of Concrete Using Dried Banana Peel Powder As Admixture

Analysis of Properties of Concrete Using Dried Banana Peel Powder As Admixture

Uploaded by

Rameg EtakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis of Properties of Concrete Using Dried Banana Peel Powder As Admixture

Analysis of Properties of Concrete Using Dried Banana Peel Powder As Admixture

Uploaded by

Rameg EtakCopyright:

Available Formats

[Gadgihalli et. al., Vol.5 (Iss.

11): November, 2017] ISSN- 2350-0530(O), ISSN- 2394-3629(P)

DOI: https://doi.org/10.29121/granthaalayah.v5.i11.2017.2367

Science

ANALYSIS OF PROPERTIES OF CONCRETE USING DRIED BANANA

PEEL POWDER AS ADMIXTURE

Vishal Gadgihalli *1, MeenaY.R 2, Sindhu Shankar 1, Raghavendra Prasad Havanje

Dinakar 3

*1

UG Student, Department of civil engineering, Jain University, Bangalore, India

2

Assistant Professor, Department of civil engineering, Jain University, Bangalore, India

3

Research Assistant, Department of civil engineering, Jain University, Bangalore, India

Abstract

Ingredients other than cement, water& aggregates that import a specific quality to either

plastic(fresh)mix or the hardened concrete (ASTMC 496) is called concrete admixture. In this

paper analysis of properties of concrete using banana peel as admixture is studied and verified

the strength of concrete and temperature emitted due to chemical reaction to the normal Portland

cement. As banana’s peel is rich in natural fiber and it is well known source of potassium. The

flexural strength of concrete by using banana peel powder as admixture has increased, but

considerable lesser compressive strength has increased. The percentage of transmission

temperature and reduction time of temperature has decreased; hence it is clear that the

exothermal reaction in concrete has been reduced by using dried banana peel powder as

admixture.

Keywords: Grudhrasi; Unique Combination of Ayurvedic Herbal Kwatha; Agnikarma.

Cite This Article: Vishal Gadgihalli, MeenaY.R, Sindhu Shankar and Raghavendra Prasad

Havanje Dinakar. (2017). “ANALYSIS OF PROPERTIES OF CONCRETE USING DRIED

BANANA PEEL POWDER AS ADMIXTURE.” International Journal of Research

- Granthaalayah, 5(11), 351-354. https://doi.org/10.29121/granthaalayah.v5.i11.2017.2367.

1. Introduction

Banana’s peel was one of the massive construction material used as an admixture in historical

construction industries. As banana are popular most consumed and worldwide produced fruit,

Because of removal of bananas peel, a significant amount of kitchen waste is generated[1][2],

which is very rich in fiber content, About 30-35% of total mass of fibers and carbohydrates.

Mineral content in a banana peel is primarily consistent of potassium (78.10mg/g) and

manganese (76.20mg/g). Other minerals present are sodium, calcium and iron at 24.30, 19.20 &

0.61mg/g respectively. Bananas peels has numerous application, for water purification, [3] to

produce ethanol [4], cellulose, [5] lactase, [6] as fertilizer [7] and in composting. Although

banana peel has these meritorious uses, these are considered as vegetable waste.

Http://www.granthaalayah.com ©International Journal of Research - GRANTHAALAYAH [351]

[Gadgihalli et. al., Vol.5 (Iss.11): November, 2017] ISSN- 2350-0530(O), ISSN- 2394-3629(P)

DOI: 10.5281/zenodo.1117183

As average mass of peel of banana is about 25 to 20% of total mass of banana, as 145million

tones of Banana is consumed in worldwide hence amount of banana peel will be approximately

40million tones. The main drawback of banana peel is they undergo biodegradation quickly, as

banana peel is fresh their co-efficient of friction on a linoleum surface was measured as just 0.07,

But when these banana peel dries or bio-degrades its co-efficient of friction gradually increases.

The author has experimented by keeping banana peel exposed to sunlight for 5days, which

increases surface tension and co-efficient of friction. These peels are used as admixture to

experience different results. As banana contains potassium this may help in enhancing reduction

of temperature transmission and temperature absorbing properties of concrete.

2. Methodology

The banana peel is collected from different sources. As banana undergoes bio-degradation to

avoid it peels are dried under sunlight for 2days. After complete drying the peels are powdered

carefully. Obtained powder is packed in aluminum sheets or polythene cover helps in protecting

powder from atmospheric moisture. While mixing the powder must be free from lumps.

An empty spaced cube with bottom, size of 10*10*10cmcasted using concrete with peel

powder concrete and walls of thickness 1cm. Water of 100 0c was filled in empty cube and the

time consumed for reduction of temperature of water to 40 0c were noted down. This gives the

time consumed by cube to reduce inner temperature of 1000c of water to 400c.

An empty cube casted by using peel powder concrete size 10*10*10 was inserted into another

larger empty cube casted using plane cement concrete size of 15*15*10cm. 3cm sufficient space

was left between two cubes was filled with Water of 100c and top side of cube was closed by lid.

Water temperature was noted down after 8mins for 1,3,7,21,23 and 28 days of similar casted

samples. The difference between the water temperature noted after 8min and the temperature at

room temperature gives the amount of heat transmitted through the walls of inner cube.

3. Results and Discussions

Compressive strength

30

25

Compressive strength

20

15

10

5

0

M20 M20 M30 M30

DAY 1 2.18 1.79 3.19 2.86

DAY7 10.73 10.59 16.85 16.81

DAY14 14.16 14.09 21.48 21.53

DAY21 17.56 17.64 25.28 25.37

DAY28 19.71 19.84 27.72 27.9

Days

DAY 1 DAY7 DAY14 DAY21 DAY28

Http://www.granthaalayah.com ©International Journal of Research - GRANTHAALAYAH [352]

[Gadgihalli et. al., Vol.5 (Iss.11): November, 2017] ISSN- 2350-0530(O), ISSN- 2394-3629(P)

DOI: 10.5281/zenodo.1117183

flexural strength

9

8

flexural strength

7

6

5

4

3

2

1

0

M20 M20 M30 M30

DAY 1 0.92 0.78 1.09 0.82

DAY7 4.06 4.23 5.83 5.96

DAY14 4.69 4.88 6.41 6.6

DAY21 5.08 5.35 7.23 7.54

DAY28 5.78 6.21 8.17 8.43

Days

DAY 1 DAY7 DAY14 DAY21 DAY28

Transmission temperature

3.54

Transmission temperature

2.53

1.52

0.51

0

M20 M20 M30 M30

DAY 1 3.34 2.89 3.56 3.29

DAY7 2.14 1.62 2.32 2.21

DAY14 1.91 1.51 2.13 1.88

DAY21 1.82 1.64 1.89 1.73

DAY28 1.37 1.2 1.39 1.17

Days

DAY 1 DAY7 DAY14 DAY21 DAY28

Reduction time

60

50

Reduction time

40

30

20

10

0

M20 M20 M30 M30

DAY 1 49.18 48.29 51.49 50.23

DAY7 44.15 43.11 45.22 43.17

DAY14 41.54 39.45 43.08 42.09

DAY21 39.16 37.06 41.08 39.32

DAY28 34.13 33.29 38.48 37.04

Days

DAY 1 DAY7 DAY14 DAY21 DAY28

Http://www.granthaalayah.com ©International Journal of Research - GRANTHAALAYAH [353]

[Gadgihalli et. al., Vol.5 (Iss.11): November, 2017] ISSN- 2350-0530(O), ISSN- 2394-3629(P)

DOI: 10.5281/zenodo.1117183

4. Conclusions

From fig(3), it can be observed that M20 & M30 grade of concrete with banana peel powder

transmitted less temperature (1.20c)&(1.170c) compared to the normal concrete

(1.370c)&(1.390c). Temperature transmittance capacity found more or less same for all grades.

About 12.41% and 15.82% of heat transmitted property has reduced by M20 and M30 grade of

concrete respectively.

In fig (4) shows, the time taken by each sample to cool down from 100 0c to 400c. present study

reveals that banana peel dried powder added concrete cube takes very less that is 33min 29sec &

37min 4sec comparatively to the normal concrete that is 34min 13 sec and 38min 48sec by M20

&M30 grade of concrete respectively for 28days, That is 2.46% and 3.78% time faster compared

to normal concrete . Hence it says the temperature liberated during chemical reaction may be less

by using peel powder as admixture.

Fig (1) &fig (2) shows, there is no considerable change in the compressive strength & tensile

strength, in all grades of concrete.

Hence banana peel can be used as admixture where temperature due to exothermal reaction place

an important role to exothermal reaction place an important role and to be reduced un

construction.

References

[1] Derived from: “FAOSTAT”. Food and agriculture organization of United Nations. The data for

bananas and plantations for 2011 were combined as the two are distinguishing by some countries

but combined under “bananas” by others.

[2] G.M. Babatunde; “Availability of banana and plantain products for animal feeding”. In:

D.Machin, S.Nyvoid: Roots, tubers, plantains and bananas in animal feeding. Proceedings of the

FAO Expert Consultation held in CIAT, Cali, Colombia FAO ANIMAL PRODUCTION AND

HEALTH PAPER 95, FAO, Rome,1992

[3] A.Chaparadza, JM Hossenloppl; adsorption Kinetics, isotherms and thermodynamics of atrazine

removal using a banana peel based sorbent. Water-Science technology, 65(5), 2012, PP.940-947.

[4] HS Oberoi, PV Vadlani, L. Saida, S. Bansal; ethanol production from banana peel using

statistically optimized simultaneous scarification and fermentation process. Waste management

31(7), 2011, pp1576-1584.

[5] Hai-Yan Sun, Li Juanhua, Pingjuan Zhao Ming Peng; Banana peel. Novel substrates for cellulose

production under solid state fermentation African Journal of Biotechnology 10(77), 2011,

pp.1788.

[6] V.Vivekanand, P.Dwivedi, N.Pareek, RP Singh; Banana Peel: potential substrates for laccase

production by Aspergillus Fumigatus VKJ2.4.5 in solid-state Fermentation. Applied Bio-

Chemistry and Bio-Technology 165(1), 2011, pp. 204-220.

[7] “How to use banana peels in your gardens”. Frugal Chicken 2015-07-05. Retrieved 2015-07-06.

*Corresponding author.

E-mail address: g.vishal1912@ gmail.com

Http://www.granthaalayah.com ©International Journal of Research - GRANTHAALAYAH [354]

You might also like

- NBC1103 Phase 4 Report TemplateDocument11 pagesNBC1103 Phase 4 Report TemplategurjotNo ratings yet

- Steel Pipes Pipe Schedule ChartDocument1 pageSteel Pipes Pipe Schedule Chartbadesharamk100% (4)

- ST P Maths 3A Answers OriginalDocument127 pagesST P Maths 3A Answers OriginalMmm83% (24)

- The Fusion Marketing Bible: Fuse Traditional Media, Social Media, & Digital Media to Maximize MarketingFrom EverandThe Fusion Marketing Bible: Fuse Traditional Media, Social Media, & Digital Media to Maximize MarketingRating: 5 out of 5 stars5/5 (2)

- 9 - Urban & Rural Development in BangladeshDocument21 pages9 - Urban & Rural Development in BangladeshMd Omar Kaiser MahinNo ratings yet

- Properties of ConcreteDocument3 pagesProperties of ConcretekklisaNo ratings yet

- Memanjang Tipe Panjang Tinggi Luas Kusen Luas Dinding: MelintangDocument3 pagesMemanjang Tipe Panjang Tinggi Luas Kusen Luas Dinding: MelintangAfishyNellyArifiantyNo ratings yet

- Data Analysis (PLC) 2021Document3 pagesData Analysis (PLC) 2021SHAHARATULNo ratings yet

- Basic College Mathematics 2nd Edition Miller Solutions ManualDocument8 pagesBasic College Mathematics 2nd Edition Miller Solutions Manualknackishfantigue.63von100% (28)

- Blank Jenis Sampah SeptemberDocument25 pagesBlank Jenis Sampah Septemberharisonsisong21No ratings yet

- Math-6 (TM)Document80 pagesMath-6 (TM)Rey Xerxes Alejandro DizonNo ratings yet

- Lab Scale Analysis of Boric Acid As Fire Retardant For Wooden MaterialDocument5 pagesLab Scale Analysis of Boric Acid As Fire Retardant For Wooden MaterialMechanical GecNo ratings yet

- LG001 Csa Cal 026Document89 pagesLG001 Csa Cal 026Iman RahmatullahNo ratings yet

- A Study On Replacement of Cement With Rice Husk AshDocument5 pagesA Study On Replacement of Cement With Rice Husk AshIAEME PublicationNo ratings yet

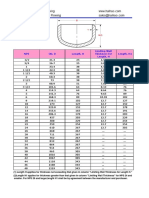

- Tunnel Lenth 3500 M Tunnel Diameter Inside Area (m2) Wetted Perimeter (M)Document26 pagesTunnel Lenth 3500 M Tunnel Diameter Inside Area (m2) Wetted Perimeter (M)Prayas SubediNo ratings yet

- Augmentin DuoDocument2 pagesAugmentin Duojunaid hashmiNo ratings yet

- Equipment Report Cecef-021120 202308Document4 pagesEquipment Report Cecef-021120 202308Ermias BeyeneNo ratings yet

- EVS Weather ReportDocument5 pagesEVS Weather Reportvishesh.aswal23No ratings yet

- Together We Build A Better FutureDocument29 pagesTogether We Build A Better FutureShintia AndrianiNo ratings yet

- Prediction of Compressive Strength of Concrete From Early Age Test ResultDocument8 pagesPrediction of Compressive Strength of Concrete From Early Age Test Resultlutfatul MuchlisohNo ratings yet

- 3 Grove GMK 3050Document3 pages3 Grove GMK 3050Mostafa MohamedNo ratings yet

- School PLAN2Document1 pageSchool PLAN2Osama AbdellatefNo ratings yet

- Diagram R-XDocument5 pagesDiagram R-Xseri astinaNo ratings yet

- Competition Data For Bis1cDocument6 pagesCompetition Data For Bis1cJesse UngerNo ratings yet

- Plastic Concrete TestDocument8 pagesPlastic Concrete TestSlan ClanNo ratings yet

- MCM - Final RoughDocument41 pagesMCM - Final RoughNaveen NatarajanNo ratings yet

- Weight of Building MaterialDocument3 pagesWeight of Building MaterialBud MannNo ratings yet

- 3IJCSEIERDFEB20193Document6 pages3IJCSEIERDFEB20193TJPRC PublicationsNo ratings yet

- Pipe Sizes According To Schedule Input Value Unit: Pipe Table - Extracted From Asme B36.1Document6 pagesPipe Sizes According To Schedule Input Value Unit: Pipe Table - Extracted From Asme B36.1Richard ObinnaNo ratings yet

- FascinatingDocument24 pagesFascinatingAnmbiya QadirNo ratings yet

- Plastic Concrete Compression Strength and Elasticity Modulus Changes During TimeDocument8 pagesPlastic Concrete Compression Strength and Elasticity Modulus Changes During TimeKhlif NadaNo ratings yet

- 2-1-1 050-BC275-0000 Force Reference ChartDocument1 page2-1-1 050-BC275-0000 Force Reference ChartJulian TorresNo ratings yet

- Block ContaminacionDocument12 pagesBlock ContaminacionkiaraNo ratings yet

- SKIPPERDocument1 pageSKIPPERatulkkabadiNo ratings yet

- Equipment Report Cecef-021120 202310Document4 pagesEquipment Report Cecef-021120 202310Ermias BeyeneNo ratings yet

- HDPE Pipe Dimensions and Pressure Ratings1 - P.E.S CoDocument2 pagesHDPE Pipe Dimensions and Pressure Ratings1 - P.E.S CoJGon100% (1)

- Aspersor 5022Document1 pageAspersor 5022Marvin David Gonzalez AmadorNo ratings yet

- Areas TributariasDocument12 pagesAreas TributariasDolores AristaNo ratings yet

- M HCS 933 10 9 P 00Document2 pagesM HCS 933 10 9 P 00fernandoraiasaNo ratings yet

- Technical Section: DIN 79 Square Tolerance, For Shafts and Square BoresDocument1 pageTechnical Section: DIN 79 Square Tolerance, For Shafts and Square BoresVelibor StokicNo ratings yet

- Absen Giat Binku 2023Document3 pagesAbsen Giat Binku 2023IsmawatiNo ratings yet

- Anchor Bolt: Table J3.2 AISC ASD Table J3.2 AISC ASDDocument15 pagesAnchor Bolt: Table J3.2 AISC ASD Table J3.2 AISC ASDballisnothingNo ratings yet

- AccuracyDocument2 pagesAccuracyabdul haji daudNo ratings yet

- Plasco Brochure HDPEDocument2 pagesPlasco Brochure HDPEhaitham655766No ratings yet

- General Directions:: Guide For InterpretationDocument10 pagesGeneral Directions:: Guide For InterpretationMary Grace Ortega-Dela RosaNo ratings yet

- Extended Answers SBDocument60 pagesExtended Answers SBademaibraimova849No ratings yet

- Cp505a-12 Crown Molding User Guide - Form 969Document2 pagesCp505a-12 Crown Molding User Guide - Form 969billNo ratings yet

- 2-1 Practice - BDocument2 pages2-1 Practice - BStanley50% (2)

- Haihao CapDocument1 pageHaihao CapDeden SobirinNo ratings yet

- 4KB Zaqya Herfisyah Diagram PengendalianDocument17 pages4KB Zaqya Herfisyah Diagram PengendalianZaqya HerfisyahNo ratings yet

- Metric, Socket Head Shoulder Screws, (Stripper Bolt), Class 12.9, Black Oxide (Unground Surfaces)Document2 pagesMetric, Socket Head Shoulder Screws, (Stripper Bolt), Class 12.9, Black Oxide (Unground Surfaces)khairulyuslizarNo ratings yet

- Total 371,893,460.0 0 100.0 0Document2 pagesTotal 371,893,460.0 0 100.0 0Osamafaktafinish NdruruNo ratings yet

- Equipment Report Cecef-021120 202309Document4 pagesEquipment Report Cecef-021120 202309Ermias BeyeneNo ratings yet

- Calculate RFSDocument10 pagesCalculate RFSDnNo ratings yet

- Job Satisfaction StatisticsDocument4 pagesJob Satisfaction StatisticsJoy GinesNo ratings yet

- Cube Test Format 28 DaysDocument14 pagesCube Test Format 28 DaysAmarendra KojjaNo ratings yet

- Source: Adapted From MSS Standard SP-69Document1 pageSource: Adapted From MSS Standard SP-69Shappan Abd AllhaNo ratings yet

- Study and Experimental Analysis On BitumenDocument7 pagesStudy and Experimental Analysis On BitumenIJRASETPublicationsNo ratings yet

- Denah Bazar 2022Document1 pageDenah Bazar 2022Candra RadityaNo ratings yet

- Data Hasil Ground VibrationDocument6 pagesData Hasil Ground VibrationPipinRioSianturiNo ratings yet

- Flood Pulsing in Wetlands: Restoring the Natural Hydrological BalanceFrom EverandFlood Pulsing in Wetlands: Restoring the Natural Hydrological BalanceNo ratings yet

- Banana Peel Utilization As The Green Corotion Inhibitor of Iron in NaCl MediumDocument7 pagesBanana Peel Utilization As The Green Corotion Inhibitor of Iron in NaCl MediumRameg EtakNo ratings yet

- Extraction of Saba Banana PeelDocument7 pagesExtraction of Saba Banana PeelRameg EtakNo ratings yet

- Structural Performance of Concrete Reinforced With Banana and Orange PDFDocument19 pagesStructural Performance of Concrete Reinforced With Banana and Orange PDFRameg EtakNo ratings yet

- Innovative Uses of Recycle Waste Materials As An Artificial Concrete Reef For Estuarine EcosystemDocument7 pagesInnovative Uses of Recycle Waste Materials As An Artificial Concrete Reef For Estuarine EcosystemRameg EtakNo ratings yet

- Short Procedure Engineering Chemistry SASTRA UniversityDocument13 pagesShort Procedure Engineering Chemistry SASTRA UniversitystarNo ratings yet

- Intro To 21 StepsDocument28 pagesIntro To 21 StepsZoey SanNo ratings yet

- 273 Pocket Theatre Training ActivityDocument1 page273 Pocket Theatre Training Activityxxxxxx100% (1)

- What Should PDFDocument20 pagesWhat Should PDFCarlos Charlotte SalvadorNo ratings yet

- Osteoarthritis in Both Hands Meant Neil Snelson of NRS Sports Therapy in Sheffield Was Considering A Change From CareerDocument2 pagesOsteoarthritis in Both Hands Meant Neil Snelson of NRS Sports Therapy in Sheffield Was Considering A Change From CareerAlexandra HartNo ratings yet

- Soal UAS01Document8 pagesSoal UAS01Ferdinandus TengaNo ratings yet

- Giftedstudents RecommendationsDocument4 pagesGiftedstudents Recommendationsapi-301904910No ratings yet

- Earnings Statementimportant - Keep For Your Records: E-MailDocument1 pageEarnings Statementimportant - Keep For Your Records: E-MailJuanNo ratings yet

- TR MassageTherapy NCIIDocument91 pagesTR MassageTherapy NCIIRebu Leno Rnlptlmtcssi100% (2)

- Module 3 G10 (Q4)Document4 pagesModule 3 G10 (Q4)Meco ChicaNo ratings yet

- Spondilitis TB AnakDocument36 pagesSpondilitis TB Anaktry intan kartini50% (2)

- MODEL PROJECT REPORT For Broiler Farming On Contract SystemDocument42 pagesMODEL PROJECT REPORT For Broiler Farming On Contract SystemVijay Kumar83% (12)

- Oman Rainfall PDFDocument13 pagesOman Rainfall PDFConifer YuNo ratings yet

- Icsh Hemostasis Critical ValuesDocument12 pagesIcsh Hemostasis Critical Valuescitometria prolabNo ratings yet

- Flexible Link: Busduct SystemDocument1 pageFlexible Link: Busduct Systemeeng gilangNo ratings yet

- Frescolat MGAMenthone Glyceryl Acetal SDSDocument9 pagesFrescolat MGAMenthone Glyceryl Acetal SDSMihaNo ratings yet

- Daftar Pustaka: Historical and Perennial Issues, 349Document2 pagesDaftar Pustaka: Historical and Perennial Issues, 349Adelina JoseNo ratings yet

- What Is A Restriction EnzymeDocument10 pagesWhat Is A Restriction EnzymenaveenNo ratings yet

- Central Directory IndividualsDocument486 pagesCentral Directory IndividualsJerich0 VentureNo ratings yet

- Sound Proof Canopy Model:: Industrial RangeDocument1 pageSound Proof Canopy Model:: Industrial Rangesales3 iaescoNo ratings yet

- IdiPAZ 2017 - Instituto de Investigación, Hospital Universitario La Paz - MadridDocument167 pagesIdiPAZ 2017 - Instituto de Investigación, Hospital Universitario La Paz - MadridMagdalena Alejandra PIERA50% (2)

- MODUL PRAKTEK Dental MaterialDocument11 pagesMODUL PRAKTEK Dental MaterialPutri Amalia MahsunNo ratings yet

- 411UDAC Battery Calculation: Secondary Power Source RequirementsDocument1 page411UDAC Battery Calculation: Secondary Power Source RequirementsFire ChileNo ratings yet

- Get The Analysis of Biological Data Third Edition Whitlock PDF Full ChapterDocument24 pagesGet The Analysis of Biological Data Third Edition Whitlock PDF Full Chapteralmunanghi100% (6)

- Nippon Wall Putty A-100: Water BasedDocument3 pagesNippon Wall Putty A-100: Water BasedNippon Paint PakistanNo ratings yet

- Nisekoi Yomeiri English Text (WIP)Document86 pagesNisekoi Yomeiri English Text (WIP)Jan Dominic GUCORNo ratings yet

- Dental ProblemsDocument18 pagesDental ProblemsRenellie Quiñonez TrimidalNo ratings yet

- 1078 HysterH36 21 J3y.00 48.00XM (S) 12Document16 pages1078 HysterH36 21 J3y.00 48.00XM (S) 12Arturo Rengifo100% (1)

- Textile Testing International Total Testing Solutions Inc.: Vendor InformationDocument4 pagesTextile Testing International Total Testing Solutions Inc.: Vendor InformationJawad IqbalNo ratings yet