Professional Documents

Culture Documents

Betontop Tec Eng

Betontop Tec Eng

Uploaded by

PedroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Betontop Tec Eng

Betontop Tec Eng

Uploaded by

PedroCopyright:

Available Formats

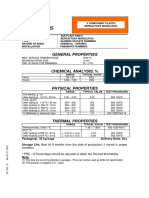

DATA SHEET

betontop

Rev. 05 dated 12 / 10 / 2022

B E TONTOP

cod. IW-BETONTOP

Fibre-inofcd conetra ofr lwo thicknes flors 2

( . 5 - 60 ) cm

DESCRIPTION

BETONTOP is a multifunctional product formulated for the creation of low thickness concrete

flatwork from 2,5 to 6 cm.

BETONTOP is composed of a mixture based on siliceous aggregates, fibres, super plasticising

additives, anti-shrinkage and anti-efflorescence agents. Sand and aggregates are added to the

concentrated product on site.

FIELDS OF USE

• Restoration of internal and external concrete flatwork

• Low thickness stamped concrete

• Industrial floors

• Herringbone ramps

• Decorative flooring

MIXTURE PROPERTIES

• Excellent workability, similar to that of traditional concrete

• High resistance to freeze-thaw cycles compared to traditional concrete.

• Greater resistance to compression and flexion.

• Reduced quantity of water and consequent increase in performance.

• Homogeneity of result.

• No additions other than sand and aggregates to be made.

• Easy to use.

TECHNICAL INFORMATION

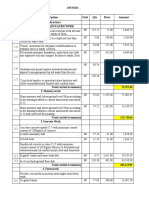

DESCRIPTION STANDARD VALUE

Pull off Ideal Bond + Betontop on a concrete background UNI EN 1542 2,00 N\mm2

Slump (quantity of water as per technical data sheet) UNI EN 206 S3

Volumetric Mass (Fresh) UNI EN 1235/6 2.350 kg\m3

Compression Resistance after 1 day UNI EN 12390/3 13 Mpa

Compression Resistance after 7 days UNI EN 12390/3 31,7 Mpa

Compression Resistance after 28 days UNI EN 12390/3 43,7 Mpa

Flexural Resistance after 28 gg UNI EN 12390/5 5,5 Mpa

Hydraulic shrinkage after 7 gg UNI EN 6555 120 µn\m

Hydraulic shrinkage after 28 gg UNI EN 6555 300 µn\m

IDEAL WORK SRL 1/4

Via Kennedy, 52 - Vallà di Riese Pio X – 31030 TV, Italy - P. Iva 03293380261 • www.idealwork.it – T +39 0423 4535

DATA SHEET

betontop

The technical data of the tests may vary if the aggregates, type of cement and water-cement ratio

are changed.

Based on these results, the screed made with BETONTOP Ideal Work was found to be, in accordance

with UNI 11104 and UNU EN 206 \ 1, suitable for the following exposure classes:

• XC4 (external floors subject to dry and wet cycles);

• XA1 (floors subject to weak chemical attack);

• XF3 (external floors subject to freeze-thaw cycles).

APPLICATION

PREPARATION OF THE SUBSTRATE

The surface to be treated must be free from oil stains, waxes, paints, resins and any other products

that may hinder the penetration of the binder.

A base slab of at least 1.0 Mpa for pull-off strength is required.

The concrete substrate must be previously scarified or processed with TEXTURE-BROOM or similar

during casting.

Before application, wash thoroughly with a high-power pressure washer.

Wet the surface to be treated with water

APPLICATION OF THE IDEALBINDER-MIX PRIMER

Mix IDEALBINDER thoroughly and mix with cold water in a proportion of 1:3.

Then add to the solution 2 parts by weight of cement to a part of liquid and then spread the mixture

evenly with a broom.

The substrate must contain the appropriate number of control joints which, in the subsequent

casting, must be respected.

Any cracks must be previously repaired with Epoxy-Coat.

IDEAL WORK SRL 2/4

Via Kennedy, 52 - Vallà di Riese Pio X – 31030 TV, Italy - P. Iva 03293380261 • www.idealwork.it – T +39 0423 4535

DATA SHEET

betontop

MIXTURE AND CONSUMPTION

BETONTOP can be mixed directly in the mixer with cement, sand and aggregates. Basic proportions

are:

1 Part BETONTOP

1 Part Sand 0-6 mm

2 Parts Cement Grey 425

7 Parts Aggregate 5-15 mm (the size may vary depending on the thickness)

Water / cement ratio not higher than 0.48 (11-12 L per 25 Kg bag)

The parts are expressed in Kg.

To obtain the best mix, insert the components into the mixer in the following order: aggregates, 50%

of the total water, Betontop, cement, 30% of the water, sand and the remaining 20% water.

Aggregates must be washed and cleaned prior to use.

This formulation can be varied according to the aggregate size and site requirements. Consult the

Ideal Work technical service for more information.

Indicative consumptions for a 1 cm thick mixture made using the basic formulation:

BETONTOP 2 Kg per m²

CEMENT 4 Kg per m²

SAND 0-6 mm 2 Kg per m²

GHIAIA 5-15 mm 4 Kg per m²

Working temperature between 5°C and 28°C.

LOW THICKNESS FLOORS

Once the mix is applied, BETONTOP is worked as normal concrete casting. It is therefore possible to

apply the hardener, then release agent and print the surface (low thickness moulded floor) or apply

the IDEAL FLOOR hardener to create a normal industrial floor, a decorative surface or a herringbone

ramp using mechanical trowels and hand tools.).

JOINTS AND CURING

The existing joints on the mother slab must be respected and therefore must also be reflected in

the new adhered surface. The new surface will always follow the movement of the existing. For this

reason, the joints must be cut as soon as possible after installation of the BETONTOP.

Like all concrete floors, it is necessary to provide adequate curing with water-based IW CURE or

solvent-based CURING. Consult the Ideal Work technical service for more information.

IDEAL WORK SRL 3/4

Via Kennedy, 52 - Vallà di Riese Pio X – 31030 TV, Italy - P. Iva 03293380261 • www.idealwork.it – T +39 0423 4535

DATA SHEET

betontop

RELATED PRODUCTS

• IW-EC

• IW-CURE

• CURING

• Cement-Scud protective shield

• IDEALBINDER10 - IDEALBINDER25

Consult the respective data sheets.

PACKAGING / STORAGE / DISPOSAL

BETONTOP is supplied in 25 Kg bags.

Stored in a dry place in its original packaging, it has a minimum shelf life of 12 months.

PRECAUTIONS

Please consult safety data sheets before use.

IMPORTANT

The manufacturer disclaims any responsibility for the achievement of the services declared for the system and for the success of the work if

it is not used in accord with its instructions. The manufacturer disclaims any responsibility for the achievement of the services declared for

the system and for the success of the work if it is performed even partially in contrast with these guidelines or with products not covered by

them.

The manufacturer also declines any responsibility for the aesthetic aspect of the flooring which depends on the installation methods,

working times and climatic conditions of the site. The applicator must take these into account when scheduling and applying the materials

supplied by the manufacturer.

The applicator notes that Ideal Work is in no way responsible for the suitability of the solution chosen in relation to:

A) Substrate suitability, climatic conditions or any other external parameter which may affect the performance of the Ideal Work products

being used.

B) The stresses to which Ideal Work products may be put under operation.

It also notes that the indications provided by Ideal Work in its technical documentation are to be considered a necessary condition but do

not in any way relieve the contractor of the responsibilities and technical evaluations of the applicator. The data can be changed at any time.

Also note that the products are intended for professional use only.

IDEAL WORK SRL 4/4

Via Kennedy, 52 - Vallà di Riese Pio X – 31030 TV, Italy - P. Iva 03293380261 • www.idealwork.it – T +39 0423 4535

You might also like

- Company Profile PT - Sanwa Prefab TechnologyDocument23 pagesCompany Profile PT - Sanwa Prefab TechnologyNug Larso100% (1)

- 9235 Waterproofing Membrane: Advantages and CertificationsDocument5 pages9235 Waterproofing Membrane: Advantages and CertificationsatharkNo ratings yet

- Lanko Grout 280 Eco BrochureDocument2 pagesLanko Grout 280 Eco BrochureMrgsrzNo ratings yet

- Microsoft Word - MasterInject 1320 User GuideDocument11 pagesMicrosoft Word - MasterInject 1320 User GuideMaamar BergerNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Topfloor Tec EngDocument3 pagesTopfloor Tec EngPedroNo ratings yet

- Iw Ec Tec EngDocument2 pagesIw Ec Tec EngPedroNo ratings yet

- Lixio Tec EngDocument5 pagesLixio Tec EngPedroNo ratings yet

- Idealbinder Tec EngDocument2 pagesIdealbinder Tec EngPedroNo ratings yet

- TD Self-LevellingDocument6 pagesTD Self-LevellingMeliany SariNo ratings yet

- HARD SKY EN STAMPED CONCRETE Installation Instruction5a0e7630f320eDocument3 pagesHARD SKY EN STAMPED CONCRETE Installation Instruction5a0e7630f320eAyça Bayram OzcanlarNo ratings yet

- Ideal Water Tec EngDocument3 pagesIdeal Water Tec EngPedroNo ratings yet

- Tec 311 MC: Non-Shrink Fluid Micro ConcreteDocument2 pagesTec 311 MC: Non-Shrink Fluid Micro Concretemanikandan4strl100% (1)

- WP - Brochure - Sika Davco Bitkote - 3 - Jan - 20Document2 pagesWP - Brochure - Sika Davco Bitkote - 3 - Jan - 20Ade KurniawanNo ratings yet

- Sika Monotop - 122fDocument3 pagesSika Monotop - 122fHamza SiddiqueNo ratings yet

- TDS Consol Grout 600 MFDocument2 pagesTDS Consol Grout 600 MFPEP GUDANGNo ratings yet

- Nitotile Fix ProDocument2 pagesNitotile Fix ProtalatzahoorNo ratings yet

- Sika MonoTop 438 R - Micro Concrete - PDS PDFDocument4 pagesSika MonoTop 438 R - Micro Concrete - PDS PDFKrish ChandNo ratings yet

- FB 12 STC 025 en 03 - Struttura Raso Fino - RF 248 - EngDocument4 pagesFB 12 STC 025 en 03 - Struttura Raso Fino - RF 248 - EngrogirosNo ratings yet

- Consol Grout 600 MF PDFDocument2 pagesConsol Grout 600 MF PDFKhaerul SidikNo ratings yet

- Emcekrete 0 A: Routing ConcreteDocument2 pagesEmcekrete 0 A: Routing Concretesunil kumarNo ratings yet

- SikaMonoTop 3020 en CORP 08 2020 1 1Document4 pagesSikaMonoTop 3020 en CORP 08 2020 1 1Mohamed Osama AshmawyNo ratings yet

- Nitoseal 290Document4 pagesNitoseal 290Venkata RaoNo ratings yet

- Sika Geotextile 500gDocument3 pagesSika Geotextile 500gKumarRamNo ratings yet

- Sikagrout 215 New - Pds en PDFDocument3 pagesSikagrout 215 New - Pds en PDFDeny Anarista SitorusNo ratings yet

- S IKADocument4 pagesS IKAQuevara AntonNo ratings yet

- Sikagrout® 215 (New) : Product Data SheetDocument3 pagesSikagrout® 215 (New) : Product Data SheetWan Fikri DarmawanNo ratings yet

- Sika® Microcrete®-218: Product Data SheetDocument3 pagesSika® Microcrete®-218: Product Data SheetthowchinNo ratings yet

- Sikagrout FM - Pds en PDFDocument3 pagesSikagrout FM - Pds en PDFANDI SETIAWANNo ratings yet

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutDocument3 pagesMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolNo ratings yet

- Nafufill KM 250Document2 pagesNafufill KM 250Richard AmoahNo ratings yet

- FLOOR-PRO 601 LIQUID FLOOR HARDENER Is A One-ComponentDocument3 pagesFLOOR-PRO 601 LIQUID FLOOR HARDENER Is A One-ComponentmrafigNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewAlex Tri WijayantoNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewPeralatan Divisi3No ratings yet

- Sikagrout®-215 (New) : Product Data SheetDocument3 pagesSikagrout®-215 (New) : Product Data SheetWahyu MahaendraNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 Newmanuel rgNo ratings yet

- Repair-Mortar Tec EngDocument2 pagesRepair-Mortar Tec EngPedroNo ratings yet

- Sikagrout®-214 Ae: Product Data SheetDocument3 pagesSikagrout®-214 Ae: Product Data Sheetmohammed rinshinNo ratings yet

- SikaMonoTop 2003finish en (06 2023) 2Document3 pagesSikaMonoTop 2003finish en (06 2023) 2Ghiorghica AndreiNo ratings yet

- E-Mix - Flowment 550 PDFDocument4 pagesE-Mix - Flowment 550 PDFngNo ratings yet

- Properties:: F9200 Is A Ready-To-Use Dryblend Mortar Based On Cement, Which HardensDocument3 pagesProperties:: F9200 Is A Ready-To-Use Dryblend Mortar Based On Cement, Which HardensMuhsin KhanNo ratings yet

- Sika Monotop®-610: Product Data SheetDocument3 pagesSika Monotop®-610: Product Data SheetViet LeNo ratings yet

- Floor Levelling CompoundDocument2 pagesFloor Levelling CompoundandrijapopovicNo ratings yet

- PDS SikaGrout-215P PDFDocument3 pagesPDS SikaGrout-215P PDFDeny PutraNo ratings yet

- Nitotile XS GroutDocument33 pagesNitotile XS GroutAhmad SamyNo ratings yet

- Izon L : Technical Data Sheet: Izonil Hard - Renovation and Waterproof Plaster (Revision - February 2018)Document4 pagesIzon L : Technical Data Sheet: Izonil Hard - Renovation and Waterproof Plaster (Revision - February 2018)AcingEdogawaNo ratings yet

- SdadsadasDocument3 pagesSdadsadasTwink Arcane 9No ratings yet

- Sikagrout 215 M - Pds en PDFDocument3 pagesSikagrout 215 M - Pds en PDFPrabowo SandiNo ratings yet

- Sikagrout 215 M Pds enDocument3 pagesSikagrout 215 M Pds enAdiprabowo WicaksonoNo ratings yet

- Tec 302 HF (UAE) : Highly Fluid Expansive Bedding GroutDocument3 pagesTec 302 HF (UAE) : Highly Fluid Expansive Bedding Groutmanikandan4strlNo ratings yet

- Techno XT TechnicalDocument4 pagesTechno XT TechnicalniroNo ratings yet

- Sika Monotop 412myDocument4 pagesSika Monotop 412mysaifulsabdinNo ratings yet

- Ideal Hard Tec EngDocument4 pagesIdeal Hard Tec EngPedroNo ratings yet

- Sikatop - 122Document3 pagesSikatop - 122YOSAFAT YUDHA GUNTORONo ratings yet

- UP210 Lime/cement Basecoat Render: Data Sheet Sept 2014Document3 pagesUP210 Lime/cement Basecoat Render: Data Sheet Sept 2014Francesco FanaraNo ratings yet

- Tec 305 HF: Highly Fluid Non-Shrink Cementitious GroutDocument2 pagesTec 305 HF: Highly Fluid Non-Shrink Cementitious Groutmanikandan4strlNo ratings yet

- TDS Pidifin 2K Eng Rev.09 23 07 19Document3 pagesTDS Pidifin 2K Eng Rev.09 23 07 19Sumit SinhaNo ratings yet

- Cera Tec EngDocument2 pagesCera Tec EngPedroNo ratings yet

- Fib Tec EngDocument3 pagesFib Tec EngPedroNo ratings yet

- Idealpu78-Matt Tec EngDocument2 pagesIdealpu78-Matt Tec EngPedroNo ratings yet

- Acido Tec EngDocument4 pagesAcido Tec EngPedroNo ratings yet

- Adam Q070: Q070005XNA Q070004XNADocument2 pagesAdam Q070: Q070005XNA Q070004XNAPedroNo ratings yet

- Cure Tec EngDocument2 pagesCure Tec EngPedroNo ratings yet

- Topfloor Tec EngDocument3 pagesTopfloor Tec EngPedroNo ratings yet

- Polyfibra Tec EngDocument2 pagesPolyfibra Tec EngPedroNo ratings yet

- Ideal Malta05 Tec EngDocument3 pagesIdeal Malta05 Tec EngPedroNo ratings yet

- Repair-Mortar Tec EngDocument2 pagesRepair-Mortar Tec EngPedroNo ratings yet

- Ideal Stuck10s Tec EngDocument2 pagesIdeal Stuck10s Tec EngPedroNo ratings yet

- Seal Col Tec EngDocument2 pagesSeal Col Tec EngPedroNo ratings yet

- Ideal Strong Tec EngDocument1 pageIdeal Strong Tec EngPedroNo ratings yet

- Idealpu-Wb Primer - Tec - EngDocument2 pagesIdealpu-Wb Primer - Tec - EngPedroNo ratings yet

- Mt-Primer Tec EngDocument2 pagesMt-Primer Tec EngPedroNo ratings yet

- Ideal Water Tec EngDocument3 pagesIdeal Water Tec EngPedroNo ratings yet

- Ideal Color80 Tec EngDocument2 pagesIdeal Color80 Tec EngPedroNo ratings yet

- Iw Ec Tec EngDocument2 pagesIw Ec Tec EngPedroNo ratings yet

- Ideal Hard Tec EngDocument4 pagesIdeal Hard Tec EngPedroNo ratings yet

- Mangiapolvere Tec EngDocument1 pageMangiapolvere Tec EngPedroNo ratings yet

- Filtene 06 - Tec - EngDocument2 pagesFiltene 06 - Tec - EngPedroNo ratings yet

- Colo-Re Tec EngDocument3 pagesColo-Re Tec EngPedroNo ratings yet

- Cement-Scud-Gel Tec EngDocument1 pageCement-Scud-Gel Tec EngPedroNo ratings yet

- Guaina Tec EngDocument1 pageGuaina Tec EngPedroNo ratings yet

- Colour Mix Tec EngDocument2 pagesColour Mix Tec EngPedroNo ratings yet

- Idealbinder Tec EngDocument2 pagesIdealbinder Tec EngPedroNo ratings yet

- Ideal Floor Tec EngDocument3 pagesIdeal Floor Tec EngPedroNo ratings yet

- Idealpu-Wb-Opacizzante Tec EngDocument2 pagesIdealpu-Wb-Opacizzante Tec EngPedroNo ratings yet

- Acido Provertical Tec EngDocument2 pagesAcido Provertical Tec EngPedroNo ratings yet

- Barriera Cem Tec EngDocument3 pagesBarriera Cem Tec EngPedroNo ratings yet

- The Mechanism of Work-HardeningDocument6 pagesThe Mechanism of Work-HardeningManish PandeyNo ratings yet

- Miramer M2372 TDS - Rev3.1Document1 pageMiramer M2372 TDS - Rev3.1Adesh GurjarNo ratings yet

- Basic Principles of PSC-July2019Document119 pagesBasic Principles of PSC-July2019kesharinareshNo ratings yet

- S - 8 Composites Composition, Classification & PolymerisationDocument36 pagesS - 8 Composites Composition, Classification & PolymerisationShaliniNo ratings yet

- JY7903 Series Oil-Resistant Sealing GreaseDocument2 pagesJY7903 Series Oil-Resistant Sealing GreaseilkerkozturkNo ratings yet

- Brochure Solare XDocument12 pagesBrochure Solare XChana 'eLecter' ChuLumNo ratings yet

- Composite MaterialsDocument22 pagesComposite MaterialsayseNo ratings yet

- Reference Information: Copper TubeDocument9 pagesReference Information: Copper TubeFitsum BulloNo ratings yet

- Sheet Waterproofing Membrane: 1. Product Name 2. Product DescriptionDocument4 pagesSheet Waterproofing Membrane: 1. Product Name 2. Product DescriptionsevargasparinNo ratings yet

- The Sub-Grade and Sub-Base of Concrete PavementDocument16 pagesThe Sub-Grade and Sub-Base of Concrete PavementPatrick TaylorNo ratings yet

- Failure Analysis of Paints and CoatingDocument8 pagesFailure Analysis of Paints and Coatingdhruvi0% (1)

- Duroflex 1K: Product Data SheetDocument4 pagesDuroflex 1K: Product Data SheetVaittianathan MahavapillaiNo ratings yet

- List of Is Codes For Cement and ConcreteDocument6 pagesList of Is Codes For Cement and ConcreteAnand.5No ratings yet

- Sast3884 01Document1 pageSast3884 01Jan JanNo ratings yet

- Bearing Strength of Concrete Containing Polystyrene AggregateDocument10 pagesBearing Strength of Concrete Containing Polystyrene AggregateMunyaNo ratings yet

- PaintDocument21 pagesPaintPRAVEEN VARMANo ratings yet

- Chain: Service & Inspection ManualDocument12 pagesChain: Service & Inspection ManualAndi KastrawanNo ratings yet

- FENICE SL-Colors 1556025224Document4 pagesFENICE SL-Colors 1556025224wishraj7No ratings yet

- Item Description Unit Qty Rate Amount A. Substructure: 1. Excavation and Eatrh WorkDocument9 pagesItem Description Unit Qty Rate Amount A. Substructure: 1. Excavation and Eatrh WorkSurafel WonduNo ratings yet

- Steel Section AISC360-10Document4 pagesSteel Section AISC360-10osman_sultan100% (1)

- Filter Element OverviewDocument6 pagesFilter Element Overviewmona zhangNo ratings yet

- 1 s2.0 S1350630722000541 MainDocument15 pages1 s2.0 S1350630722000541 Mainkaren Daniela chaparro perezNo ratings yet

- Maksal TubesDocument4 pagesMaksal TubesHaji AliNo ratings yet

- Festerbond Tds enDocument3 pagesFesterbond Tds endocumentacion.epinsaNo ratings yet

- Compre 15-16 Sem1 With Soln (Charsichoco)Document4 pagesCompre 15-16 Sem1 With Soln (Charsichoco)Jasdeep SinghNo ratings yet

- Ace Plast Ram C Revised July 2016Document1 pageAce Plast Ram C Revised July 2016pulakjaiswal85No ratings yet

- Alucoworld E CatalogueDocument22 pagesAlucoworld E CatalogueRicardo Miguel Ayllon CamachoNo ratings yet

- Boost Your Sustainability Profile: Sovermol - Natural Oil-Based, Performance Driven PolyolsDocument8 pagesBoost Your Sustainability Profile: Sovermol - Natural Oil-Based, Performance Driven Polyolssriatul2006No ratings yet

- 2.1 Ficha Técnica Aluminio CorrugadoDocument3 pages2.1 Ficha Técnica Aluminio CorrugadogercubNo ratings yet