Professional Documents

Culture Documents

Datasheet - 77 - Te Tns n043n 00

Datasheet - 77 - Te Tns n043n 00

Uploaded by

Fernando MoraisCopyright:

Available Formats

You might also like

- Recent Master Plumber Board Exam Problems PDFDocument97 pagesRecent Master Plumber Board Exam Problems PDFJhonna Trinidad89% (9)

- Henk Automotive GuideDocument52 pagesHenk Automotive Guidetripathi prashantNo ratings yet

- IMI Maxseal ICO3S 1-2, 3-Way, 174 PdiDocument2 pagesIMI Maxseal ICO3S 1-2, 3-Way, 174 PdiHamed YadegariNo ratings yet

- BLU R - ChinaDocument1 pageBLU R - ChinaShishan AhmadNo ratings yet

- Info Material ListDocument3 pagesInfo Material Listelvis007No ratings yet

- Immersion Temperature Sensors: Integral Mounting Connection, Welded ThermowellsDocument1 pageImmersion Temperature Sensors: Integral Mounting Connection, Welded ThermowellsMarco Antonio Flores lopezNo ratings yet

- Nitrogen Gas Charging Kits Brochure PDFDocument12 pagesNitrogen Gas Charging Kits Brochure PDFluisedonossaNo ratings yet

- O-4 Sensor DwyerDocument1 pageO-4 Sensor DwyernhungtruongNo ratings yet

- Ps TsapxxxDocument1 pagePs TsapxxxEko SetiawanNo ratings yet

- Littelfuse - Thermistor Threaded USP10981 - DatasheetDocument1 pageLittelfuse - Thermistor Threaded USP10981 - DatasheetbcostiucNo ratings yet

- Thies - Safety Valves 356 - 357Document4 pagesThies - Safety Valves 356 - 357Piero Graffigna Pruzzo100% (2)

- Pentair Pilot Enclosures For Non-Hazardous LocationDocument6 pagesPentair Pilot Enclosures For Non-Hazardous LocationEdson MirandaNo ratings yet

- USUR1000 Series UL Recognized Ring Lug Thermistor Assembly: DescriptionDocument3 pagesUSUR1000 Series UL Recognized Ring Lug Thermistor Assembly: DescriptionCesar GutierrezNo ratings yet

- Catalog-I PS81Document2 pagesCatalog-I PS81Marcos ZanfolinNo ratings yet

- Technical Data: Relative Humidity SensorDocument4 pagesTechnical Data: Relative Humidity Sensorjesus yndriagoNo ratings yet

- PECO Raintight Weather Resistant Line Voltage ThermostatDocument2 pagesPECO Raintight Weather Resistant Line Voltage Thermostatmhagerty513No ratings yet

- E t8n00 HP DesbloqueadoDocument2 pagesE t8n00 HP DesbloqueadoJaime RodriguezNo ratings yet

- Rele de Proteccion DGPT2 2Document8 pagesRele de Proteccion DGPT2 2WALTERNo ratings yet

- Dre 120Document4 pagesDre 120Gesiel SoaresNo ratings yet

- Zoeller 202Document2 pagesZoeller 202angelalvaraguilNo ratings yet

- 28 NB Pulse Jet Solenoid Valve: FeaturesDocument2 pages28 NB Pulse Jet Solenoid Valve: FeaturesNatarajan RavisankarNo ratings yet

- CT112558 ImDocument12 pagesCT112558 ImFranklin LibreNo ratings yet

- IS ValvesR2Document14 pagesIS ValvesR2noelia lopez razukNo ratings yet

- Flame Guard ProductsDocument16 pagesFlame Guard ProductsRajkumar TomerNo ratings yet

- Stego HG140 400V 2017 enDocument1 pageStego HG140 400V 2017 enJulek VargaNo ratings yet

- Bearing Embedment RTD: Features / BenefitsDocument1 pageBearing Embedment RTD: Features / BenefitscaseyNo ratings yet

- Issued For Tender - ARCH - 2023.11.06Document4 pagesIssued For Tender - ARCH - 2023.11.06Youngjae YJ Theodore SongNo ratings yet

- Omnigrad TST410: RTD ThermometerDocument4 pagesOmnigrad TST410: RTD ThermometerTCP.MT.2014 TCP.MT.2014No ratings yet

- For Air Indirectly Solenoid Actuated Diaphragm Valves Internal Thread 3/4" NPT To 2 1/2" NPTDocument2 pagesFor Air Indirectly Solenoid Actuated Diaphragm Valves Internal Thread 3/4" NPT To 2 1/2" NPTTrong Hung NguyenNo ratings yet

- Goetze 2781 Datasheet enDocument4 pagesGoetze 2781 Datasheet enrosiNo ratings yet

- Pressure Vacuum Relief Valve Flame Arrester 102Document3 pagesPressure Vacuum Relief Valve Flame Arrester 102vikramNo ratings yet

- Flexible DuctDocument4 pagesFlexible DuctMohammed RayanNo ratings yet

- Liquid Level IndicatorDocument8 pagesLiquid Level Indicatorhiren_mistry55No ratings yet

- 03 - Thermostat & Accessories - EmailDocument24 pages03 - Thermostat & Accessories - EmailTanveer AzizNo ratings yet

- RotaryDocument10 pagesRotaryVEERAMANINo ratings yet

- John Crane Type 32 SealDocument4 pagesJohn Crane Type 32 SealhichamNo ratings yet

- Explosion-Proof Differential Pressure Switch: SERIES 1950Document2 pagesExplosion-Proof Differential Pressure Switch: SERIES 1950Alex RamirezNo ratings yet

- Ekc111rd 5fl402Document2 pagesEkc111rd 5fl402Pedro LuisNo ratings yet

- Variety For Industrial Production Rooms: Küba DZ ProductionDocument2 pagesVariety For Industrial Production Rooms: Küba DZ ProductiongemagdyNo ratings yet

- Datasheet - 77 - Te DFG A 04 4 3 00Document1 pageDatasheet - 77 - Te DFG A 04 4 3 00pedro pabloNo ratings yet

- Omnigrad TST410: RTD ThermometerDocument4 pagesOmnigrad TST410: RTD Thermometermetanoia88No ratings yet

- Catalogo Tecnico PresostatoDocument32 pagesCatalogo Tecnico PresostatoRonulfo GutierrezNo ratings yet

- Commercial Heavy Duty Water Heater With Surface Mount ThermostatsDocument4 pagesCommercial Heavy Duty Water Heater With Surface Mount Thermostatsfirefightermanta31No ratings yet

- 1N4728A PanJitInternationalDocument5 pages1N4728A PanJitInternationalPablo AllosiaNo ratings yet

- Data Sheet: 1N4728A 1N4764ADocument5 pagesData Sheet: 1N4728A 1N4764AAnkitNo ratings yet

- Applications / Markets: 260gf +100/-50gf 350gf +100/-50gfDocument3 pagesApplications / Markets: 260gf +100/-50gf 350gf +100/-50gfArdi PutraNo ratings yet

- Terman - WTI - MSRT150-WDocument9 pagesTerman - WTI - MSRT150-Waimiza100% (2)

- Ds tr10 4 en UsDocument2 pagesDs tr10 4 en UsMuhammad Haroon AsgharNo ratings yet

- Uponor A2870100 Data SheetDocument1 pageUponor A2870100 Data SheetJohnNo ratings yet

- POLYTETRAFLUOROETHYLENE - MAIZEY PTFE - 2021 - EmailDocument2 pagesPOLYTETRAFLUOROETHYLENE - MAIZEY PTFE - 2021 - EmailGustavNo ratings yet

- European Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Document2 pagesEuropean Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Julio César Herrera MontoyaNo ratings yet

- Dwyer - Te-Dfg PDFDocument2 pagesDwyer - Te-Dfg PDFLucas PenalvaNo ratings yet

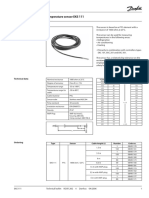

- Atlantic Water HeaterDocument2 pagesAtlantic Water Heaterratheesh0117No ratings yet

- Ele Vir Flush Ring 160 0001 To 0008Document16 pagesEle Vir Flush Ring 160 0001 To 0008rahul o gNo ratings yet

- Mks Series 10Document25 pagesMks Series 10Kamatsho BarcelonaNo ratings yet

- MeasurIT KTek BETA Switches 0803Document32 pagesMeasurIT KTek BETA Switches 0803cwiejkowskaNo ratings yet

- A.O. Smith DEL 6 DEN 52 SpecificationsDocument4 pagesA.O. Smith DEL 6 DEN 52 SpecificationsJonalou ArominNo ratings yet

- Led Flood Light: SpecificationDocument5 pagesLed Flood Light: Specificationdanny avilaNo ratings yet

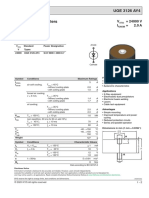

- UGE3126AY4Document2 pagesUGE3126AY4jose luis jimenezNo ratings yet

- NorthStar - Bateria - Hoja Técnica - NSB125REDTTDocument2 pagesNorthStar - Bateria - Hoja Técnica - NSB125REDTTSilvio MosciaroNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Rates Analysis For Aliens W.ODocument23 pagesRates Analysis For Aliens W.ORAVIKUMAR KONKATINo ratings yet

- En 10253 3Document50 pagesEn 10253 3Thanh Nguyen VanNo ratings yet

- Concrete Batching Plant CatalogueDocument17 pagesConcrete Batching Plant CatalogueSelf ConceptNo ratings yet

- Problems 13.1: Difficulties Associated With The Partially Melted ZoneDocument2 pagesProblems 13.1: Difficulties Associated With The Partially Melted ZoneSayyidah FarhanaNo ratings yet

- Ruredil XF54 Schedatecnica 1215ENDocument3 pagesRuredil XF54 Schedatecnica 1215ENSeid HodzicNo ratings yet

- Safety Valves and Double Stop ValvesDocument24 pagesSafety Valves and Double Stop ValvesRahul PatilNo ratings yet

- Senior Welding Inspector: Multiple Choice Questions Paper 1: Name: . . DateDocument6 pagesSenior Welding Inspector: Multiple Choice Questions Paper 1: Name: . . DateFuaz SukaryaNo ratings yet

- Bend Strength of Complete Closed-Type Carbon Fiber-Reinforced Polymer Stirrups With Rectangular SectionDocument11 pagesBend Strength of Complete Closed-Type Carbon Fiber-Reinforced Polymer Stirrups With Rectangular SectionSayan MahapatraNo ratings yet

- Wooden Slats Updated DetailDocument1 pageWooden Slats Updated DetailSebastian AbordoNo ratings yet

- Superstrut Metal FramingDocument83 pagesSuperstrut Metal FramingAdam SonNo ratings yet

- Concrete Blocks For Thermal Insulation in Hot ClimateDocument8 pagesConcrete Blocks For Thermal Insulation in Hot ClimateaduquegoNo ratings yet

- MAGGIOLINA - INSTRUCTIONS Roof TopDocument24 pagesMAGGIOLINA - INSTRUCTIONS Roof TopSuhi TeoNo ratings yet

- Metallic Implant MaterialsDocument39 pagesMetallic Implant MaterialsRecep VatanseverNo ratings yet

- CANAL ESTIMATE TemplateDocument3 pagesCANAL ESTIMATE TemplateEdison G. CaluzaNo ratings yet

- Mapei - TLC Shah Alam Warehouse 271022Document3 pagesMapei - TLC Shah Alam Warehouse 271022John EweNo ratings yet

- Adweataqaaddctranscoaadcal MirfaDocument328 pagesAdweataqaaddctranscoaadcal MirfaClark HonradoNo ratings yet

- Unit VDocument52 pagesUnit Vsai keerthiNo ratings yet

- Nexans 54379Document4 pagesNexans 54379Barbara OrtigozaNo ratings yet

- SAES-L-610 PDF Download - Nonmetallic Piping in Oily Water Services - PDFYARDocument6 pagesSAES-L-610 PDF Download - Nonmetallic Piping in Oily Water Services - PDFYARZahidRafiqueNo ratings yet

- Spray-Applied Fireproofing: Isolatek Type II Cafco Blaze-Shield IIDocument2 pagesSpray-Applied Fireproofing: Isolatek Type II Cafco Blaze-Shield IIAnonyNo ratings yet

- Mensuration & Calculation For Plumbing by Daleon PDFDocument101 pagesMensuration & Calculation For Plumbing by Daleon PDFmanny daleon100% (1)

- Aalco Stainless Steel Tube TubeDocument18 pagesAalco Stainless Steel Tube Tubearun100% (1)

- Solopanel - Datasheet - ENDocument2 pagesSolopanel - Datasheet - ENSamwel Mwangi MuriithiNo ratings yet

- Effect of Rolling ParametersDocument18 pagesEffect of Rolling Parameters19Y210 - JEEVA ENo ratings yet

- SEHI Catch Up Plan 26102019Document2 pagesSEHI Catch Up Plan 26102019Keith CuberoNo ratings yet

- Rising Damp in Buildings With SolutionsDocument6 pagesRising Damp in Buildings With SolutionsAjin SharmaNo ratings yet

- Pakistan Steel MillDocument24 pagesPakistan Steel MillMuhammad OsafNo ratings yet

Datasheet - 77 - Te Tns n043n 00

Datasheet - 77 - Te Tns n043n 00

Uploaded by

Fernando MoraisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet - 77 - Te Tns n043n 00

Datasheet - 77 - Te Tns n043n 00

Uploaded by

Fernando MoraisCopyright:

Available Formats

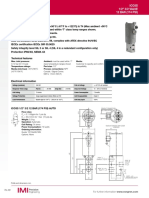

®

TEMPERATURE

SERIES TE-I

IMMERSION TEMPERATURE SENSORS BALL CHAIN CONNECTOR

Ø3.310

BALL CHAIN CONNECTOR

2X

Integral Mounting Connection, Welded Thermowells 2X

Ø0.875

Ø3.310

Ø0.875

PROBE

YEAR LIMITED

WARRANTY

VIDEO ON

LENGTH*

LI

NE

0.125 0.125

2.201 GASKET 2.813 GASKET

TE-ITG TE-ITW GENERAL PURPOSE WEATHERPROOF

TE-ITG TE-ITW

The Series TE-I Immersion Style Temperature Sensors accurately measure water SPECIFICATIONS

temperature inside chilled and hot water loops in HVAC systems. Thermowells are Accuracy: Thermistor temperature sensor: ±0.22°C @ 25°C (±0.4°F @ 77°F); RTD

required to protect the electrical connection from the process water and to allow temperature sensor DIN Class A: ±0.15°C @ 0°C (±0.28°F @ 32°F).

replacement of the sensors without draining the system. Temperature Limits: Operating: -40 to 302°F (-40 to 150°C).

Sensor Curves: See page reference u below.

FEATURES/BENEFITS Housing Material: Meets UL, 94 V-0 polycarbonate plastic.

• Integral 1/2˝ NPSM connection for direct mounting to a thermowell Thermowell Material: 304 SS.

• 1/4 turn housing cover with chain to prevent dropping Thermowell Connections: Internal = 1/2˝ NPSM; External = 1/2˝ NPT.

• Multiple conduit knockouts for easy installation positioning Weight: 5.3 oz (150.3 g).

• General purpose or weatherproof enclosure

options MODEL CHART

• Terminal connection eliminates need for

wire nuts Example TE -ITG -A 25 4 4 -00 TE-ITG-A2544-00

Series TE Duct and immersion building automation temperature sensor

APPLICATIONS Mounting ITG Immersion in general purpose housing

• Chiller or boiler loops Configuration ITW Immersion in NEMA 4X housing

• Building automation Sensor Type A 10k Ω type III thermistor

B 10k Ω type II thermistor

C 3k Ω thermistor

D Pt100 Ω RTD

E Pt1000 Ω RTD

F 20k Ω thermistor

Q 10k Ω type III with 11k Ω shunt

Probe Length* 25 2.5˝

04 4˝

06 6˝

08 8˝

12 12˝

18 18˝

Probe Diameter 4 1/4˝

5 1/4˝ double encapsulated

Termination 4 4˝ flying leads terminal block

uResistance vs. Temperature Table: See page 148 Fittings 00 None (integral)

(Series TE-OND/RND/OSA) *Actual probe length is approximately 0.75˝ longer than listed probe length to ensure maximum immersion into thermowells.

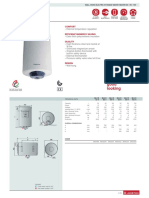

TE-TNS

THERMOWELLS

R 1/8

Temperature Sensors

2X BREAK Ø1-1/8 [28.55] X 30°

A SEE BELOW FOR [R2.29]

THREAD DETAIL Ø1/4

1-3/4 1/4 [7.11]

Thermowells for Building Automation Temperature Sensors A

1-1/8 HEX [28.55]

3/4 [19.05]

[44.45] [6.35]

INSERTION

YEAR LIMITED

WARRANTY

1-3/4 INSERTION LENGTH

[45.21] LENGTH Ø1-1/16 Ø7/8 Ø5/8

VIDEO ON [26.68] Ø3/4 [19.05] A [21.34] [15.88]

Machined thermowell A

LI

NE

WELDED A [1/2 NPT]

[SEALED] 1-1/8 A [3/4 NPT] [1/4 NPT]

1/2˝ NPSM [1/2 NPT]

INTERNAL 1/2˝ NPT OR [28.58] 1/2 X 3/4 NPT 1/4 X 1/2 NPT

Fabricated (welded) thermowell THREAD BSPT THREAD SERIES THERMOWELL SERIES THERMOWELL

The Series TE-TNS Stainless Steel Thermowells are used to separate the instrument SPECIFICATIONS

from the surrounding media. When used with the Series TE and TE-I Immersion Maximum Pressure: Fabricated: 140 psi; Machined: 304 SS: 3700 psi; 316 SS:

Temperature Sensors, further protection is offered from aggressive media, high 5500 psi.

pressures, and flow rates while allowing for quick and easy installation of temperature Maximum Temperature: Fabricated: 1000°F (538°C); Machined: 1200°F (648°C).

sensors without having to drain process media. Construction: Fabricated (welded) or machined model specific.

Thermowells are offered in both 304 and 316 stainless steel allowing for superior

corrosion resistance. Fabricated, or welded, thermowells are constructed from a MODEL CHART

tube that is closed at the tip by a welded solid tip. Solid-machined thermowells are

manufactured from barstock. Connection

Model Material Length Construction (Internal/External)

FEATURES/BENEFITS APPLICATIONS TE-TNS-N254N-12 304 SS 2.5˝ Machined 1/2˝ NPT / 3/4˝ NPT

• Configurable materials and sizes • Building automation TE-TNS-N254N-14 304 SS 2.5˝ Machined 1/4˝ NPT / 1/2˝ NPT

• Fabricated (welded) or machined construction • Chiller or boiler loops TE-TNS-N044N-14 304 SS 4˝ Machined 1/4˝ NPT / 1/2˝ NPT

• 1/2˝ or 3/4˝ NPT process connections • Chemical industry or process TE-TNS-N044N-12 304 SS 4˝ Machined 1/2˝ NPT / 3/4˝ NPT

technology TE-TNS-N064N-14 304 SS 6˝ Machined 1/4˝ NPT / 1/2˝ NPT

TE-TNS-N064N-12 304 SS 6˝ Machined 1/2˝ NPT / 3/4˝ NPT

TE-TNS-N094N-14 304 SS 9˝ Machined 1/4˝ NPT / 1/2˝ NPT

MODEL CHART TE-TNS-N094N-12 304 SS 9˝ Machined 1/2˝ NPT / 3/4˝ NPT

Example TE-TNS -N 9 5N -14 TE-TNS-N095N-14 TE-TNS-N124N-14 304 SS 12˝ Machined 1/4˝ NPT / 1/2˝ NPT

Series TE-TNS Stainless steel thermowell TE-TNS-N124N-12 304 SS 12˝ Machined 1/2˝ NPT / 3/4˝ NPT

TE-TNS-N045N-14 316 SS 4˝ Machined 1/4˝ NPT / 1/2˝ NPT

Thread Type N NPT TE-TNS-N045N-12 316 SS 4˝ Machined 1/2˝ NPT / 3/4˝ NPT

Length 25 2.5˝ TE-TNS-N065N-14 316 SS 6˝ Machined 1/4˝ NPT / 1/2˝ NPT

04 4˝ TE-TNS-N065N-12 316 SS 6˝ Machined 1/2˝ NPT / 3/4˝ NPT

06 6˝ TE-TNS-N095N-14 316 SS 9˝ Machined 1/4˝ NPT / 1/2˝ NPT

09 9˝ TE-TNS-N095N-12 316 SS 9˝ Machined 1/2˝ NPT / 3/4˝ NPT

12 12˝ TE-TNS-N125N-14 316 SS 12˝ Machined 1/4˝ NPT / 1/2˝ NPT

18 18˝ TE-TNS-N125N-12 316 SS 12˝ Machined 1/2˝ NPT / 3/4˝ NPT

Material & 3N 304 SS fabricated (welded) TE-TNS-N253N-00 304 SS 2.5˝ Fabricated 1/2˝ NPSM / 1/2˝ NPT

Construction 4N 304 SS machined TE-TNS-N043N-00 304 SS 4˝ Fabricated 1/2˝ NPSM / 1/2˝ NPT

5N 316 SS machined TE-TNS-N063N-00 304 SS 6˝ Fabricated 1/2˝ NPSM / 1/2˝ NPT

Connection 00 1/2˝ NPSM / 1/2˝ NPT TE-TNS-N083N-00 304 SS 8˝ Fabricated 1/2˝ NPSM / 1/2˝ NPT

(Internal & External) 12 1/2˝ NPT / 3/4˝ NPT TE-TNS-N123N-00 304 SS 12˝ Fabricated 1/2˝ NPSM / 1/2˝ NPT

14 1/4˝ NPT / 1/2˝ NPT TE-TNS-N183N-00 304 SS 18˝ Fabricated 1/2˝ NPSM / 1/2˝ NPT

DWYER INSTRUMENTS, INC. | dwyer-inst.com 147

You might also like

- Recent Master Plumber Board Exam Problems PDFDocument97 pagesRecent Master Plumber Board Exam Problems PDFJhonna Trinidad89% (9)

- Henk Automotive GuideDocument52 pagesHenk Automotive Guidetripathi prashantNo ratings yet

- IMI Maxseal ICO3S 1-2, 3-Way, 174 PdiDocument2 pagesIMI Maxseal ICO3S 1-2, 3-Way, 174 PdiHamed YadegariNo ratings yet

- BLU R - ChinaDocument1 pageBLU R - ChinaShishan AhmadNo ratings yet

- Info Material ListDocument3 pagesInfo Material Listelvis007No ratings yet

- Immersion Temperature Sensors: Integral Mounting Connection, Welded ThermowellsDocument1 pageImmersion Temperature Sensors: Integral Mounting Connection, Welded ThermowellsMarco Antonio Flores lopezNo ratings yet

- Nitrogen Gas Charging Kits Brochure PDFDocument12 pagesNitrogen Gas Charging Kits Brochure PDFluisedonossaNo ratings yet

- O-4 Sensor DwyerDocument1 pageO-4 Sensor DwyernhungtruongNo ratings yet

- Ps TsapxxxDocument1 pagePs TsapxxxEko SetiawanNo ratings yet

- Littelfuse - Thermistor Threaded USP10981 - DatasheetDocument1 pageLittelfuse - Thermistor Threaded USP10981 - DatasheetbcostiucNo ratings yet

- Thies - Safety Valves 356 - 357Document4 pagesThies - Safety Valves 356 - 357Piero Graffigna Pruzzo100% (2)

- Pentair Pilot Enclosures For Non-Hazardous LocationDocument6 pagesPentair Pilot Enclosures For Non-Hazardous LocationEdson MirandaNo ratings yet

- USUR1000 Series UL Recognized Ring Lug Thermistor Assembly: DescriptionDocument3 pagesUSUR1000 Series UL Recognized Ring Lug Thermistor Assembly: DescriptionCesar GutierrezNo ratings yet

- Catalog-I PS81Document2 pagesCatalog-I PS81Marcos ZanfolinNo ratings yet

- Technical Data: Relative Humidity SensorDocument4 pagesTechnical Data: Relative Humidity Sensorjesus yndriagoNo ratings yet

- PECO Raintight Weather Resistant Line Voltage ThermostatDocument2 pagesPECO Raintight Weather Resistant Line Voltage Thermostatmhagerty513No ratings yet

- E t8n00 HP DesbloqueadoDocument2 pagesE t8n00 HP DesbloqueadoJaime RodriguezNo ratings yet

- Rele de Proteccion DGPT2 2Document8 pagesRele de Proteccion DGPT2 2WALTERNo ratings yet

- Dre 120Document4 pagesDre 120Gesiel SoaresNo ratings yet

- Zoeller 202Document2 pagesZoeller 202angelalvaraguilNo ratings yet

- 28 NB Pulse Jet Solenoid Valve: FeaturesDocument2 pages28 NB Pulse Jet Solenoid Valve: FeaturesNatarajan RavisankarNo ratings yet

- CT112558 ImDocument12 pagesCT112558 ImFranklin LibreNo ratings yet

- IS ValvesR2Document14 pagesIS ValvesR2noelia lopez razukNo ratings yet

- Flame Guard ProductsDocument16 pagesFlame Guard ProductsRajkumar TomerNo ratings yet

- Stego HG140 400V 2017 enDocument1 pageStego HG140 400V 2017 enJulek VargaNo ratings yet

- Bearing Embedment RTD: Features / BenefitsDocument1 pageBearing Embedment RTD: Features / BenefitscaseyNo ratings yet

- Issued For Tender - ARCH - 2023.11.06Document4 pagesIssued For Tender - ARCH - 2023.11.06Youngjae YJ Theodore SongNo ratings yet

- Omnigrad TST410: RTD ThermometerDocument4 pagesOmnigrad TST410: RTD ThermometerTCP.MT.2014 TCP.MT.2014No ratings yet

- For Air Indirectly Solenoid Actuated Diaphragm Valves Internal Thread 3/4" NPT To 2 1/2" NPTDocument2 pagesFor Air Indirectly Solenoid Actuated Diaphragm Valves Internal Thread 3/4" NPT To 2 1/2" NPTTrong Hung NguyenNo ratings yet

- Goetze 2781 Datasheet enDocument4 pagesGoetze 2781 Datasheet enrosiNo ratings yet

- Pressure Vacuum Relief Valve Flame Arrester 102Document3 pagesPressure Vacuum Relief Valve Flame Arrester 102vikramNo ratings yet

- Flexible DuctDocument4 pagesFlexible DuctMohammed RayanNo ratings yet

- Liquid Level IndicatorDocument8 pagesLiquid Level Indicatorhiren_mistry55No ratings yet

- 03 - Thermostat & Accessories - EmailDocument24 pages03 - Thermostat & Accessories - EmailTanveer AzizNo ratings yet

- RotaryDocument10 pagesRotaryVEERAMANINo ratings yet

- John Crane Type 32 SealDocument4 pagesJohn Crane Type 32 SealhichamNo ratings yet

- Explosion-Proof Differential Pressure Switch: SERIES 1950Document2 pagesExplosion-Proof Differential Pressure Switch: SERIES 1950Alex RamirezNo ratings yet

- Ekc111rd 5fl402Document2 pagesEkc111rd 5fl402Pedro LuisNo ratings yet

- Variety For Industrial Production Rooms: Küba DZ ProductionDocument2 pagesVariety For Industrial Production Rooms: Küba DZ ProductiongemagdyNo ratings yet

- Datasheet - 77 - Te DFG A 04 4 3 00Document1 pageDatasheet - 77 - Te DFG A 04 4 3 00pedro pabloNo ratings yet

- Omnigrad TST410: RTD ThermometerDocument4 pagesOmnigrad TST410: RTD Thermometermetanoia88No ratings yet

- Catalogo Tecnico PresostatoDocument32 pagesCatalogo Tecnico PresostatoRonulfo GutierrezNo ratings yet

- Commercial Heavy Duty Water Heater With Surface Mount ThermostatsDocument4 pagesCommercial Heavy Duty Water Heater With Surface Mount Thermostatsfirefightermanta31No ratings yet

- 1N4728A PanJitInternationalDocument5 pages1N4728A PanJitInternationalPablo AllosiaNo ratings yet

- Data Sheet: 1N4728A 1N4764ADocument5 pagesData Sheet: 1N4728A 1N4764AAnkitNo ratings yet

- Applications / Markets: 260gf +100/-50gf 350gf +100/-50gfDocument3 pagesApplications / Markets: 260gf +100/-50gf 350gf +100/-50gfArdi PutraNo ratings yet

- Terman - WTI - MSRT150-WDocument9 pagesTerman - WTI - MSRT150-Waimiza100% (2)

- Ds tr10 4 en UsDocument2 pagesDs tr10 4 en UsMuhammad Haroon AsgharNo ratings yet

- Uponor A2870100 Data SheetDocument1 pageUponor A2870100 Data SheetJohnNo ratings yet

- POLYTETRAFLUOROETHYLENE - MAIZEY PTFE - 2021 - EmailDocument2 pagesPOLYTETRAFLUOROETHYLENE - MAIZEY PTFE - 2021 - EmailGustavNo ratings yet

- European Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Document2 pagesEuropean Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Julio César Herrera MontoyaNo ratings yet

- Dwyer - Te-Dfg PDFDocument2 pagesDwyer - Te-Dfg PDFLucas PenalvaNo ratings yet

- Atlantic Water HeaterDocument2 pagesAtlantic Water Heaterratheesh0117No ratings yet

- Ele Vir Flush Ring 160 0001 To 0008Document16 pagesEle Vir Flush Ring 160 0001 To 0008rahul o gNo ratings yet

- Mks Series 10Document25 pagesMks Series 10Kamatsho BarcelonaNo ratings yet

- MeasurIT KTek BETA Switches 0803Document32 pagesMeasurIT KTek BETA Switches 0803cwiejkowskaNo ratings yet

- A.O. Smith DEL 6 DEN 52 SpecificationsDocument4 pagesA.O. Smith DEL 6 DEN 52 SpecificationsJonalou ArominNo ratings yet

- Led Flood Light: SpecificationDocument5 pagesLed Flood Light: Specificationdanny avilaNo ratings yet

- UGE3126AY4Document2 pagesUGE3126AY4jose luis jimenezNo ratings yet

- NorthStar - Bateria - Hoja Técnica - NSB125REDTTDocument2 pagesNorthStar - Bateria - Hoja Técnica - NSB125REDTTSilvio MosciaroNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Rates Analysis For Aliens W.ODocument23 pagesRates Analysis For Aliens W.ORAVIKUMAR KONKATINo ratings yet

- En 10253 3Document50 pagesEn 10253 3Thanh Nguyen VanNo ratings yet

- Concrete Batching Plant CatalogueDocument17 pagesConcrete Batching Plant CatalogueSelf ConceptNo ratings yet

- Problems 13.1: Difficulties Associated With The Partially Melted ZoneDocument2 pagesProblems 13.1: Difficulties Associated With The Partially Melted ZoneSayyidah FarhanaNo ratings yet

- Ruredil XF54 Schedatecnica 1215ENDocument3 pagesRuredil XF54 Schedatecnica 1215ENSeid HodzicNo ratings yet

- Safety Valves and Double Stop ValvesDocument24 pagesSafety Valves and Double Stop ValvesRahul PatilNo ratings yet

- Senior Welding Inspector: Multiple Choice Questions Paper 1: Name: . . DateDocument6 pagesSenior Welding Inspector: Multiple Choice Questions Paper 1: Name: . . DateFuaz SukaryaNo ratings yet

- Bend Strength of Complete Closed-Type Carbon Fiber-Reinforced Polymer Stirrups With Rectangular SectionDocument11 pagesBend Strength of Complete Closed-Type Carbon Fiber-Reinforced Polymer Stirrups With Rectangular SectionSayan MahapatraNo ratings yet

- Wooden Slats Updated DetailDocument1 pageWooden Slats Updated DetailSebastian AbordoNo ratings yet

- Superstrut Metal FramingDocument83 pagesSuperstrut Metal FramingAdam SonNo ratings yet

- Concrete Blocks For Thermal Insulation in Hot ClimateDocument8 pagesConcrete Blocks For Thermal Insulation in Hot ClimateaduquegoNo ratings yet

- MAGGIOLINA - INSTRUCTIONS Roof TopDocument24 pagesMAGGIOLINA - INSTRUCTIONS Roof TopSuhi TeoNo ratings yet

- Metallic Implant MaterialsDocument39 pagesMetallic Implant MaterialsRecep VatanseverNo ratings yet

- CANAL ESTIMATE TemplateDocument3 pagesCANAL ESTIMATE TemplateEdison G. CaluzaNo ratings yet

- Mapei - TLC Shah Alam Warehouse 271022Document3 pagesMapei - TLC Shah Alam Warehouse 271022John EweNo ratings yet

- Adweataqaaddctranscoaadcal MirfaDocument328 pagesAdweataqaaddctranscoaadcal MirfaClark HonradoNo ratings yet

- Unit VDocument52 pagesUnit Vsai keerthiNo ratings yet

- Nexans 54379Document4 pagesNexans 54379Barbara OrtigozaNo ratings yet

- SAES-L-610 PDF Download - Nonmetallic Piping in Oily Water Services - PDFYARDocument6 pagesSAES-L-610 PDF Download - Nonmetallic Piping in Oily Water Services - PDFYARZahidRafiqueNo ratings yet

- Spray-Applied Fireproofing: Isolatek Type II Cafco Blaze-Shield IIDocument2 pagesSpray-Applied Fireproofing: Isolatek Type II Cafco Blaze-Shield IIAnonyNo ratings yet

- Mensuration & Calculation For Plumbing by Daleon PDFDocument101 pagesMensuration & Calculation For Plumbing by Daleon PDFmanny daleon100% (1)

- Aalco Stainless Steel Tube TubeDocument18 pagesAalco Stainless Steel Tube Tubearun100% (1)

- Solopanel - Datasheet - ENDocument2 pagesSolopanel - Datasheet - ENSamwel Mwangi MuriithiNo ratings yet

- Effect of Rolling ParametersDocument18 pagesEffect of Rolling Parameters19Y210 - JEEVA ENo ratings yet

- SEHI Catch Up Plan 26102019Document2 pagesSEHI Catch Up Plan 26102019Keith CuberoNo ratings yet

- Rising Damp in Buildings With SolutionsDocument6 pagesRising Damp in Buildings With SolutionsAjin SharmaNo ratings yet

- Pakistan Steel MillDocument24 pagesPakistan Steel MillMuhammad OsafNo ratings yet