Professional Documents

Culture Documents

2011 Well Servicing Practice Test KEY

2011 Well Servicing Practice Test KEY

Uploaded by

Boedi SyafiqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2011 Well Servicing Practice Test KEY

2011 Well Servicing Practice Test KEY

Uploaded by

Boedi SyafiqCopyright:

Available Formats

Chevron

WellCAP®

IADC Well Control Accreditation Program

Supervisor Level

Coil Tubing, Snubbing, & Wireline

KEY Test 1A - Course 2

Practice Test

Name:

Test Date:

Score:

Note: Each question is 2 points

C2 T1A K WS Page 1 of 14 Rev. 05/11/2010

C2 T1A K WS Page 2 of 14 Rev. 05/11/2010

1. What is the purpose of the ball check valve used in a wireline lubricator stuffing box?

a. To automatically catch the wire in case it parts

b. To keep the wireline in tension when working against well pressure

c. To automatically seal off the wellbore if the wireline breaks and is blown out of the well

d. To engage the counter rotating chains

2. What is needed to control pressure on wireline?

a. A lubricator assembly with stuffing box / grease injector

b. A circulating swage

c. A full open safety valve

d. All of the above

3. While pressure testing the lubricator, you notice a small leak. What should be done?

a. Immediately tighten the connection under pressure.

b. If the leak is small continue the operation

c. Bleed off the test pressure and retest at a faster rate

d. Bleed off the test pressure and repair the leak

4. Why are the lower rams in a double Wireline valve inverted?

a. The lower ram is a test ram. It aids in testing the lubricator prior to opening up to the

wellbore.

b. To seal pressure from below.

c. As an aid to maintenance of the upper wireline valve

d. To seal against wellbore pressure by injecting grease between the closed upper and

lower rams

5. What is the purpose of the guide tube used on snubbing units?

a. It provides a guide to lay down pipe.

b. It provides a marker for safe parking

c. It prevents lateral movement of pipe to prevent buckling

d. It is used to guide the tubing up to the workbasket

C2 T1A K WS Page 3 of 14 Rev. 05/11/2010

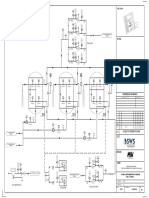

6. Using the given illustration, identify item number 1.

a. Wireline clamp

b. Line Wiper

c. Wireline valve

d. Tool trap

7. Using the given illustration, identify item number 9.

a. Ball check valve

b. Bleed-off valve

c. Heavy weight indicator

d. Lubricator section

8. Using the given illustration, identify item number 4.

a. Pump-in sub

b. Grease return line

c. Master valve

d. Crown valve

C2 T1A K WS Page 4 of 14 Rev. 05/11/2010

9. You are running 11/4” coiled tubing inside 27/8” production tubing cleaning out bridges with 12

ppg brine. Reservoir pressure data below the bridge is not reliable. The well kicks, from the

perforations at 10000’, and you shut in with a stabilized tubing pressure of 700 psi. What kill

weight fluid is needed?

a. 11.0 ppg

b. 11.4 ppg

c. 12.0 ppg 700 psi / 0.052 / 10000’ = 1.35 ppg + 12 ppg = 13.4 ppg

d. 13.4 ppg

10. An “N” nipple should be run in addition to one, or preferably two, __________________ when

snubbing.

Answer: Float/ Check/ BPV (all are correct responses)

11. The advantage of using small tubing (hydraulic workover operation) over coil tubing of the same

size can be:

a. Higher circulation rate

b. Greater tensile strength collapse and burst pressure

c. Run in and out of hole faster than coil tubing

d. All of the above

12. While coming out of the hole with coil tubing under pressure, a hole is discovered in the tubing

between the stripper and the injector. After stopping the pumps the flow continues. Which of the

following action should be taken first?

a. Run in hole and place hole in tubing below the stripper

b. Notify supervisor and/or company man

c. Close the shear ram immediately

d. None of the above

13. How many bending cycles and bending events is the coiled tubing exposed to in a round trip?

a. 6 bending cycles & 3 bending events

b. 3 bending cycles & 6 bending events

c. 8 bending cycles & 4 bending events

d. 8 bending cycles & 6 bending events

C2 T1A K WS Page 5 of 14 Rev. 05/11/2010

14. When reeling coiled tubing from a pressurized well, what is the main function of the stripper

assembly?

a. Provide pressure seal around coiled tubing during pipe movement

b. Provide lateral support to the coiled tubing to prevent buckling

c. Regulates pulling or injecting force on the coiled tubing when moving the pipe

d. Provides a means of supporting coiled tubing when shearing the pipe

15. What is the maximum acceptable limit for ovality of coiled tubing (per API)?

a. 2%

b. 4%

c. 5%

d. 8%

16. Running coiled tubing while pumping at high pressures ________ the number of bend cycles

before the coiled tubing fatigues.

a. Increases

b. Decreases

c. Has no effect on

d. Will increase the yield strength and therefore will increase

17. The term “balance point” is used in snubbing terminology. What does this refer to?

a. A method used for weighing mud

b. A phrase not used in snubbing operations

c. The process of running in the hole with no problems

d. The situation that exists when the effective weight of the snubbing string is equal to the

well bore force and the friction through the preventer

18. The lift force of a jack equals:

a. The well pressure multiplied by the hydraulic pressure

b. The effective area on the snub side multiplied by the well pressure

c. The hydraulic pressure multiplied by the effective area of the piston

d. The well pressure multiplied by the piston area

C2 T1A K WS Page 6 of 14 Rev. 05/11/2010

19. Why do we need a stuffing box using slickline?

a. To seal around the cable when it’s not moving.

b. To contain the well pressure.

c. For pressure testing.

d. All of the above

20. What is the purpose of guy cables on a snubbing unit?

a. Maximize bending stress on well equipment

b. Has no effect on bending stress that may occur

c. Lowers bending stress on well equipment

d. Initiate any bending stress needed on equipment

21. What should you do first if a stripper rubber fails in a snubbing unit?

a. Install a full open stabbing valve in the open position, then close

b. Adjust hydraulic pressure

c. Pull out of hole immediately and repair the stripper

d. Close the lower stripper ram and the traveling slips

22. A well has a shut in pressure of 2000 psi. The tubing to be run has an outside diameter of 1.2

inches, and is 1.32 lbs/ft. Ignoring friction and buoyancy, approximately how much tubing

will have to be run in the hole to reach the balance point?

a. 3065 ft 1.2’’2 x 0.7854 x 2000 psi = 2262 lbs

b. 1714 ft 2262 lbs / 1.32 lbs/ft = 1714’

c. 3400 ft

d. 4125 ft

23. When stripping into a well against well pressure, a certain amount of fluid will have to be bled

from the well. This amount of fluid bled should be based on what calculation?

a. Total cross section area of the casing

b. Open ended displacement of the tube of the pipe being stripped

c. Displacement of the casing wall thickness

d. Closed ended pipe displacement

C2 T1A K WS Page 7 of 14 Rev. 05/11/2010

24. Which of the following is NOT a function of the coiled tubing injector assembly?

a. Providing thrust to snub the tubing into the well against pressure and well bore friction

b. Inject fluid into the coiled tubing

c. Controlling the rate of lowering the tubing into the well

d. Supporting the full weight of the tubing when it’s pulled from the well while maintaining

operating speed

25. What is the standard arrangement for a quad coiled tubing BOP stack, starting at the top?

a. Pipe, slip, cutter, blind

b. Slip, pipe, blind, cutter

c. Blind, shear, slip, pipe

d. Blind, slip, shear, pipe

26. Which of the following is most true concerning ovality of coiled tubing

a. Ovality issues are very rare with coiled tubing because there are no connections in the string

b. Can significantly decrease collapse pressure rating

c. Not a major concern as long as pipe rams and stripper test ok

d. Ovality need not be measured after start of job

27. In a coiled tubing unit, which of the following is NOT true concerning slip rams?

a. Used to support the tubing weight when realigning or shearing pipe

b. Are pressure sealing

c. Teeth should accommodate both pipe light and pipe heavy situations

d. Will damage the coiled tubing when operated

28. 1¼” coil tubing work string is at the end of the production string and a 15 barrel gain is noticed.

Assume that all of the gain is in the 31/2” I.D. production tubing annulus. What is the length of

the bubble?

a. 382 ft

b. 1445 ft (3.5’’2 – 1.25’’2) / 1029.4 = 0.0104 bbl/ft

c. 580 ft 15 bbl / 0.0104 bbl/ft = 1445’

d. 940 ft

C2 T1A K WS Page 8 of 14 Rev. 05/11/2010

29. If you have 8000’ of coiled tubing in the hole, and 4000’ of coiled tubing on the reel. The

capacity of the coiled tubing is 0.000699 bbl/ft. How many strokes do you need to pump to

displace fluid to the end of the coil tubing if the pump output is 0.049 bbls/stk?

a. 80 stks

b. 100 stks

c. 128 stks

d. 171 stks 8000’ + 4000’ = 12000’ x 0.000699 bbl/ft = 8.4 bbl

8.4 bbl / 0.049 bbl/stk = 171 stks

30. Which of the following is a good reason for using braided line instead of slickline?

a. It costs less

b. Fishing operations

c. Swabbing operations

d. b and c

31. What type of connections should there be between the coiled tubing stack and the tree?

a. Threaded

b. Welded

c. Flanged

d. Any of the above as long as sufficient guy wires are installed

32. Coiled tubing buckling is a major concern with which type of stripper?

a. Top-entry stripper

b. Side-entry stripper

c. Radial stripper

d. Coiled tubing buckling is very rare and may be disregarded

33. How much force is developed against the coiled tubing, if 700 psi trapped below a 4" I.D. BOP

stack with 2” coiled tubing inside the rams?

a. 3296 lbs

b. 2198 lbs 2’’2 x 0.7854 x 700 psi = 2198 lbs

c. 1613 lbs

d. 837 lbs

C2 T1A K WS Page 9 of 14 Rev. 05/11/2010

The following information is provided to assist in answering questions 34 and 35.

Casing depth: 9200’ TVD/MD, 7” O.D., 6.004” I.D.

Tubing depth: 9000’ TVD/MD, 23/8” O.D., 1.995” I.D.

Packer depth: 9000’ TVD/MD

Coil Tubing: 11/4” O.D., 1.06” I.D.

Top of perforation: 9010’ TVD/MD

Fluid in well: 8.7 ppg

Formation pressure: 2960 psi (Ignore the weight of nitrogen gas.)

34. To what depth will the fluid need to be displaced with nitrogen to enable perforating with a 300

psi negative differential (under balance)?

a. 2870 ft

b. 2909 ft 2960 psi – 300 psi = 2660 psi / 0.052 / 8.7 ppg = 5880’

c. 3130 ft 9010’ – 5880’ = 3130’

d. None of the above

35. In reaching the displacement depth, how many barrels of fluid would have to be displaced from

the tubing when pumping nitrogen and running coil tubing?

a. 2.5 bbl

b. 7.2 bbl

c. 9.0 bbl

d. 12.2 bbl 1.995’’2 / 1029.4 = 0.0039 bbl/ft x 3130’ = 12.2 bbl

36. With 3600 psi of well pressure, what pressure setting will be required on two jacks (5” cylinders,

3 ½” rods) to snub 2 3/8” tubing into the well? Assume 3,000 lbs of friction must be overcome

to strip through ram preventers.

a. 947 psi

b. 940 psi

c. 903 psi 2.375’’2 x 0.7854 = 4.43’’2 x 3600 psi = 15949 lbs + 3000 lbs = 18949 lbs

d. 752 psi (5’’2 - 3.5’’2) x 0.7854 = 10.01’’2

18949 lbs / 10.01’’2 / 2 jacks = 947 psi

37. What is the primary purpose of the window in a HWO snubbing unit?

a. Provides access to repair or replace the stationary slips

b. Is used to adjust the overall height of the HWO

c. Provides the means to perform maintenance on the tubing stripper

d. Provides access to the string so tools that cannot pass through the guide tube can be

installed

C2 T1A K WS Page 10 of 14 Rev. 05/11/2010

38. When stripping into a well under pressure, what is the effect on casing pressure during the

process of running pipe? (Assume that you are not bleeding while stripping)

a. Casing pressure is decreasing due to the tubing weight

b. Casing pressure is increasing due to the pump pressure

c. Casing pressure increases due to the displacement of the tubing being run in the well

d. Casing pressure increase due to the weight of the fluid in the casing

39. When calculating snub force, the following factors must be considered:

a. Buoyed weight of the pipe

b. O.D. of the pipe

c. Pressure in the well bore below the BOP’s

d. All of the above

40. While snubbing out of the hole, you are circulating across the stack. You are pulling 2 7/8” flush

joint production tubing. Each joint is 30’ in length. For each 5 joints that you pull, what should

be the fluid volume pumped to maintain constant bottom hole pressure. (Ignoring influx

migration or expansion.)

a. 0.8 bbls

b. 1.0 bbls

c. 1.2 bbls 2.875’’2 / 1029.4 = 0.008029 bbl/ft

d. 1.25 bbls 5 joints x 30 ft/joint = 150’ x 0.008029 bbl/ft = 1.2 bbl

41. The workstring is being stripped into the well "ram-to-ram". A tool joint is immediately above

the bottom set of rams and the top rams have just been closed. What must be done before the

bottom rams can be opened?

a. The tool joint must be lowered onto the rams to force them open

b. Well bore pressures must be bled off to prevent surging

c. Fluid must be pumped or bled into the stack between the rams to equalize the pressure

between the stack and the well bore

d. The annular preventer must be closed as a back-up device

C2 T1A K WS Page 11 of 14 Rev. 05/11/2010

42. During wireline operations, it is possible to:

a. Equalize pressure across closed rams through an equalizing valve

b. Swab in a kick

c. Open or close sleeves and ports

d. all the above

43. Disregarding friction through the slickline stuffing box, what would be the minimum weight of

the tool string that has to be run to overcome wellbore forces using 0.092 wire? The shut-in

surface pressure is 4500 psi.

a. 200 lbs

b. 63 lbs

c. 30 lbs

d. 27 lbs 0.0922 x 0.7853 x 4500 psi = 29.9 lbs

44. You are snubbing into a well, under pressure, with a standard bottom hole assembly of two back

pressure valves and an “N” nipple above them. You get a back flow through the snubbing string

and after pumping an “N” nipple plug you cannot get it to seal. What might be the problem?

a. A hole between back pressure valves in the snubbing string

b. A hole above the lower back pressure valve in the snubbing string

c. A hole above the “N” nipple in the snubbing string

d. A leaking stripper rubber

45. During coiled tubing operations, which type of stripper assembly is recommended as a backup in

high pressure applications?

a. Radial

b. Side door

c. Top entry

d. A stripper assembly is not used for high pressure applications

46. In coiled tubing operations, the majority of bending stresses occurs:

a. Between the reel and guide arch

b. At the mechanical footage counter

c. In the upper gripping blocks

d. At the injector goose or guide arch neck

C2 T1A K WS Page 12 of 14 Rev. 05/11/2010

47. What kind of valve should be installed in the tubing hanger when removing a tree?

a. Back pressure valve

b. Two way check valve

c. SCSSV

d. Gate valve

48. What parameter is used to determine size of flow tube for wireline operations?

a. Pressure in well

b. O.D. of wireline

c. Fluid in well

d. Grease injection rate

49. When do you use the packoff during a braided wire pressure control job?

a. When the tools need to be made up in the rig floor

b. To wipe the excess grease off the wireline

c. To help obtain a seal when you have lost the grease seal

d. When the cable is going to be stationary for a long period of time

50. The amount of snub or lift force that a snubbing jack generates is effected by:

a. The cross sectional area of the hydraulic piston

b. The length of the hydraulic piston

c. The amount of hydraulic pressure available

d. a and c

C2 T1A K WS Page 13 of 14 Rev. 05/11/2010

SCORE SHEET FOR TRAINERS

QUESTIONS POINTS TOTAL

MISSED MISSED SCORE

0 0 100

1 2 98

2 4 96

3 6 94

4 8 92

5 10 90

6 12 88

7 14 86

8 16 84

9 18 82

10 20 80

11 22 78

12 24 76

13 26 74

14 28 72

15 30 70

16 32 68

17 34 66

18 36 64

19 38 62

20 40 60

21 42 58

22 44 56

23 46 54

24 48 52

25 50 50

26 52 48

27 54 46

28 56 44

29 58 42

30 60 40

31 62 38

32 64 36

33 66 34

34 68 32

. . .

. . .

. . .

. . .

50 100 0

C2 T1A K WS Page 14 of 14 Rev. 05/11/2010

You might also like

- Valve Inspection ChecklistDocument1 pageValve Inspection ChecklistMohamed Afsal100% (12)

- IADC Wellsharp HomeworkDocument13 pagesIADC Wellsharp HomeworkalloriadNo ratings yet

- Completion Pre Course ExerciseDocument11 pagesCompletion Pre Course Exerciseeng200720070% (1)

- SOPDocument12 pagesSOPMas KuncritNo ratings yet

- 966H Hydraulic SchematicsDocument2 pages966H Hydraulic SchematicsEslamAldenAbdo100% (1)

- Rig Hub Routine Service Handbook Ver 4.1Document183 pagesRig Hub Routine Service Handbook Ver 4.1Boedi Syafiq100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 22 - IWCF Review Questions 2014 - MSA PDFDocument9 pages22 - IWCF Review Questions 2014 - MSA PDFFoued NasriNo ratings yet

- Schlum Well Control PresentationDocument118 pagesSchlum Well Control PresentationMuhammad Tahir0% (1)

- Type of Blower Wheels and ApplicationsDocument3 pagesType of Blower Wheels and ApplicationskumarNo ratings yet

- IADC 77 DRILLING Pretest 2 (Without A)Document15 pagesIADC 77 DRILLING Pretest 2 (Without A)Ariq Dicky100% (3)

- Wireline ExerciseDocument21 pagesWireline Exerciseomar shahat0% (1)

- Well Control Questions and Answers Part 1Document6 pagesWell Control Questions and Answers Part 1Rizwan Farid100% (1)

- Workover 1 Soal - 8 APR21.revDocument17 pagesWorkover 1 Soal - 8 APR21.revputujuliandikaNo ratings yet

- Iadc Drilling 1.10.20. - (77) W.outDocument14 pagesIadc Drilling 1.10.20. - (77) W.outsendi100% (1)

- WL - TopicsDocument22 pagesWL - TopicsMohamed100% (1)

- WL Excercies 3&4Document12 pagesWL Excercies 3&4Mohamed Elabbasy0% (1)

- GTS P&P ExersiceDocument132 pagesGTS P&P ExersiceMessere HubenakNo ratings yet

- 23 - IWCF SO Sample QuestionsDocument6 pages23 - IWCF SO Sample QuestionsRichard ReiersenNo ratings yet

- Coiled Tubing EnglishDocument18 pagesCoiled Tubing EnglishmissaouiNo ratings yet

- Oil Well Kicks Questions and Answers Part1Document7 pagesOil Well Kicks Questions and Answers Part1Rizwan FaridNo ratings yet

- IWCF Comb. Supv Equip. 02Document24 pagesIWCF Comb. Supv Equip. 02andrzema100% (3)

- 01 - Drill 16'' Hole Section & POOHDocument3 pages01 - Drill 16'' Hole Section & POOHDrilling Engineering ChannelNo ratings yet

- 28 - IWCF Study GuideDocument7 pages28 - IWCF Study GuideBabi LakhdariNo ratings yet

- Well Control ExerciseمهمDocument133 pagesWell Control ExerciseمهمAsad babil BabilNo ratings yet

- Well Service IWCF Test and AnswersDocument33 pagesWell Service IWCF Test and Answersseyyid ali lylNo ratings yet

- Lecture2-Well CompletionDocument43 pagesLecture2-Well CompletionRamy MaamounNo ratings yet

- Oilwell Drilling 8Document3 pagesOilwell Drilling 8chuksNo ratings yet

- Student Study GuideDocument34 pagesStudent Study Guidecyrel carl molo100% (1)

- Tutorial Sheet No.3: Leak Off Test and MAASPDocument14 pagesTutorial Sheet No.3: Leak Off Test and MAASPali jabbarNo ratings yet

- Falcon Latest Well Intrevention With GlosoryDocument440 pagesFalcon Latest Well Intrevention With GlosorySachin SahooNo ratings yet

- Principles and Procedures: Rev.3 - November 2003Document144 pagesPrinciples and Procedures: Rev.3 - November 2003Ibnu Rusdi SolomammaNo ratings yet

- Hard Shut-In Procedure - Drilling Fixed RigDocument6 pagesHard Shut-In Procedure - Drilling Fixed RigLetterio MammolitiNo ratings yet

- LD2 Drilling Practices & Lessons Learned - A.boubeniaDocument8 pagesLD2 Drilling Practices & Lessons Learned - A.boubeniaAli BoubeniaNo ratings yet

- Test Principles and Procedures1Document15 pagesTest Principles and Procedures1eng20072007No ratings yet

- Omar Drilling Supervisor CV.Document5 pagesOmar Drilling Supervisor CV.cgmqf89286No ratings yet

- Essential Tips For Well Control Success: Aberdeen Drilling SchoolsDocument4 pagesEssential Tips For Well Control Success: Aberdeen Drilling SchoolsCerón Niño SantiagoNo ratings yet

- Workover Kill Fluid Density CalculationDocument3 pagesWorkover Kill Fluid Density CalculationSanny Astari100% (1)

- Lesson 8b Introduction To UBDDocument57 pagesLesson 8b Introduction To UBDbon1ngNo ratings yet

- Well Control Course Workbook 2001 Q1 PDFDocument96 pagesWell Control Course Workbook 2001 Q1 PDFdvbnjfdNo ratings yet

- Quiz AITDocument4 pagesQuiz AITazizsarshoghNo ratings yet

- P & P AnswerDocument143 pagesP & P AnswerOmerNo ratings yet

- P and P (EDC) PDFDocument62 pagesP and P (EDC) PDFAli mohammad50% (2)

- Well Control MethodsDocument89 pagesWell Control MethodsMustafa Naithel100% (1)

- CO Excercies 3&4Document47 pagesCO Excercies 3&4Waleed Barakat Maria100% (1)

- Driller Module Workbook 5 Sedco Forex Modular Training ProgramDocument3 pagesDriller Module Workbook 5 Sedco Forex Modular Training ProgramKaleem UllahNo ratings yet

- Dokumen - Tips Equipment Iwcf CourseDocument42 pagesDokumen - Tips Equipment Iwcf CourseFranklinNo ratings yet

- Chevron: Wellcap Plus Practice Test Surface/SubseaDocument13 pagesChevron: Wellcap Plus Practice Test Surface/SubseaBoedi SyafiqNo ratings yet

- 1 CompletionDesignDocument38 pages1 CompletionDesignMikko Delos ReyesNo ratings yet

- Shell Wireline Downhole Tools ToolkitDocument21 pagesShell Wireline Downhole Tools ToolkitLuqman ZamanNo ratings yet

- Exercise 1Document16 pagesExercise 1adeelsnNo ratings yet

- Well Control ConstantsDocument6 pagesWell Control Constantschubby_hippoNo ratings yet

- Iwcf Exercise STC 1Document149 pagesIwcf Exercise STC 1ali jabbar100% (1)

- Coiled Tubing Calculation Homework HandoutDocument6 pagesCoiled Tubing Calculation Homework HandouthafsaNo ratings yet

- Well Completion (1) Model AnswerDocument4 pagesWell Completion (1) Model Answermissaoui0% (1)

- 13 3-8" Cementing Program ChecklistDocument2 pages13 3-8" Cementing Program ChecklistYougchu LuanNo ratings yet

- Assignment Co OperationsDocument20 pagesAssignment Co Operationsyasirism100% (2)

- WellsafeDocument34 pagesWellsafeHendra Jurbon0% (1)

- Pemex Short Course: Offshore DrillingDocument67 pagesPemex Short Course: Offshore Drillingdriller22100% (1)

- Quiz 4 A-Choose The Correct Answer :: AnswersDocument2 pagesQuiz 4 A-Choose The Correct Answer :: Answersazareiforoush100% (1)

- 07-Hoan Thien Gieng Optimize PDFDocument93 pages07-Hoan Thien Gieng Optimize PDFGiang Nguyen NinhNo ratings yet

- Basics Downhole ConfigurationsDocument13 pagesBasics Downhole ConfigurationsAthaurrohman Alfaina ShidiqNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- SEC 05 Simulator Proficiency GuidelineDocument1 pageSEC 05 Simulator Proficiency GuidelineBoedi SyafiqNo ratings yet

- Simulator Proficiency GuidelinesDocument4 pagesSimulator Proficiency GuidelinesBoedi SyafiqNo ratings yet

- 2010 Workover Completion Practice Test2Document12 pages2010 Workover Completion Practice Test2Boedi SyafiqNo ratings yet

- Well Control Preparation Class Homework #5: Name: Badge: DateDocument6 pagesWell Control Preparation Class Homework #5: Name: Badge: DateBoedi SyafiqNo ratings yet

- Accumulator - Yancheng RuihuaDocument26 pagesAccumulator - Yancheng RuihuaBoedi SyafiqNo ratings yet

- DEMCODocument26 pagesDEMCOBoedi SyafiqNo ratings yet

- Driller's MethodDocument19 pagesDriller's MethodBoedi SyafiqNo ratings yet

- Annular RongShengDocument5 pagesAnnular RongShengBoedi SyafiqNo ratings yet

- 11AX 12th Edition Addendum 2 Purch Guidelines R2 20131004Document5 pages11AX 12th Edition Addendum 2 Purch Guidelines R2 20131004Boedi SyafiqNo ratings yet

- Coiled TubingDocument87 pagesCoiled TubingBoedi Syafiq100% (1)

- ComplicationsDocument11 pagesComplicationsBoedi SyafiqNo ratings yet

- Hydraulic: Hose & FittingsDocument40 pagesHydraulic: Hose & FittingsBoedi Syafiq100% (1)

- Basic ConceptsDocument23 pagesBasic ConceptsBoedi SyafiqNo ratings yet

- Bullheading: Workover Well Control Guide (Vol 15,1994 Ed.) - Section HDocument11 pagesBullheading: Workover Well Control Guide (Vol 15,1994 Ed.) - Section HBoedi SyafiqNo ratings yet

- Prediction of Shear Ram BOP Cutting Force Via Finite Element AnalysisDocument11 pagesPrediction of Shear Ram BOP Cutting Force Via Finite Element AnalysisBoedi SyafiqNo ratings yet

- Chevron: Wellcap Plus Practice Test Surface/SubseaDocument15 pagesChevron: Wellcap Plus Practice Test Surface/SubseaBoedi Syafiq100% (1)

- Activity & Briefing On Simulation Test: A. Prior To DrillingDocument2 pagesActivity & Briefing On Simulation Test: A. Prior To DrillingBoedi SyafiqNo ratings yet

- Townsend 2008 Catalog (BESMINDO)Document97 pagesTownsend 2008 Catalog (BESMINDO)Boedi SyafiqNo ratings yet

- Chevron: Wellcap Plus Practice Test Surface/SubseaDocument13 pagesChevron: Wellcap Plus Practice Test Surface/SubseaBoedi SyafiqNo ratings yet

- Well Control Preparation Class Final-Test: Name: Badge: DateDocument16 pagesWell Control Preparation Class Final-Test: Name: Badge: DateBoedi SyafiqNo ratings yet

- Townsend Type 82 (Besmindo)Document21 pagesTownsend Type 82 (Besmindo)Boedi SyafiqNo ratings yet

- Pilot Operated Safety Valves Type 95 Anderson Greenwood (Tyco) PDFDocument16 pagesPilot Operated Safety Valves Type 95 Anderson Greenwood (Tyco) PDFdhaneshbhorNo ratings yet

- Titan CF Filter Manual 2014Document4 pagesTitan CF Filter Manual 2014Yareli de la CruzNo ratings yet

- Spare Parts Proposal Kit: Boyles C5CDocument6 pagesSpare Parts Proposal Kit: Boyles C5CRafael Castillo LimachiNo ratings yet

- BKH / Bkhp420 2-Way Ball Valve Stainless Steel: Available Sizes ConnectionsDocument4 pagesBKH / Bkhp420 2-Way Ball Valve Stainless Steel: Available Sizes ConnectionsManikandan MNo ratings yet

- Steam Condenser Definition Working Types and Advantages Mechanical BoosterDocument9 pagesSteam Condenser Definition Working Types and Advantages Mechanical Boostersaiampolu194No ratings yet

- Flex Spiral Wound GasketsDocument49 pagesFlex Spiral Wound GasketsJomer J Simpson100% (1)

- PMS Series Hand Pumps PDFDocument3 pagesPMS Series Hand Pumps PDFTran DucNo ratings yet

- Brayton Cycle: Avellana, OcceñaDocument54 pagesBrayton Cycle: Avellana, OcceñaMarcial Jr. MilitanteNo ratings yet

- Man#251 Rev BDocument10 pagesMan#251 Rev Bjuan dalmassoNo ratings yet

- 148 - Ic-P&id-06 (Filters)Document1 page148 - Ic-P&id-06 (Filters)Fun TonNo ratings yet

- ValvesDocument1 pageValvesnikhilNo ratings yet

- Frs Du 5056 CDocument18 pagesFrs Du 5056 Crajindo1No ratings yet

- 106Document1 page106ahm3d16n100% (1)

- Reciprocating PUMPSDocument15 pagesReciprocating PUMPSRyan LincayNo ratings yet

- Assam Petrochemicals LimitedDocument14 pagesAssam Petrochemicals Limitedhimanshu gogoiNo ratings yet

- Piping Slide ChartDocument36 pagesPiping Slide Charttandk1989100% (2)

- Isolation Methodology Ensures Safe, Flexible Facilities - Oil & Gas JournalDocument16 pagesIsolation Methodology Ensures Safe, Flexible Facilities - Oil & Gas JournalSEGUNNo ratings yet

- Cylinder Head Valves: 3612 and 3616 EnginesDocument4 pagesCylinder Head Valves: 3612 and 3616 EnginesFredy QuistialNo ratings yet

- Coiled TubingT Downhole Hydraulics OS-HPCT-D010Document17 pagesCoiled TubingT Downhole Hydraulics OS-HPCT-D010Amina MekkakiaNo ratings yet

- Atex A1-020-03-En PDFDocument8 pagesAtex A1-020-03-En PDFherrerafaridNo ratings yet

- Piping Design CriteriaDocument20 pagesPiping Design Criteriasuman_ghosh6798No ratings yet

- Flow of Incompressible Fluids in Conduits & Thin LayersDocument22 pagesFlow of Incompressible Fluids in Conduits & Thin LayerssaimaabdulrasheedNo ratings yet

- 02 110 BPS Foam Pump Skid With Foam Pump and RC ControllerDocument8 pages02 110 BPS Foam Pump Skid With Foam Pump and RC Controllerarachman297988No ratings yet

- CRR Corrosion Resistance Ratio ValuesDocument1 pageCRR Corrosion Resistance Ratio ValuesabdulafoajjawiNo ratings yet

- Duct System Design AssignmentDocument7 pagesDuct System Design AssignmentTharanga PereraNo ratings yet

- Visual Checklist - Pump & Compressor PDFDocument2 pagesVisual Checklist - Pump & Compressor PDFWiratama TambunanNo ratings yet

- Actuators: Version 2 EE IIT, Kharagpur 1Document34 pagesActuators: Version 2 EE IIT, Kharagpur 1Khaled MahranNo ratings yet