Professional Documents

Culture Documents

021 Hydrotesting

021 Hydrotesting

Uploaded by

Manzoor AhmadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

021 Hydrotesting

021 Hydrotesting

Uploaded by

Manzoor AhmadCopyright:

Available Formats

International Agent Group

Calibration, NDT, Trading, Inspection, Testing,

QMS Consultancy, IT Solutions and Contracting

Doc. No. :

Procedure for Hydrotesting Rev. 00 Jun , 2015

INAT/MECH/LCP-021

STANDARD TESTING PROCEDURE

FOR

HYDRO TESTING

Prepared by

Muhammad Azam Signature Date : Jun-2015

Reviewed by

Ruel Lucopia Signature Date : Jun-2015

Approved by

Manzoor Ahmed Signature Date : Jun-2015

Controlled Copy No: Uncontrolled Copy:

Issued to:

This document is the property of INAT, and is issued only for persons or entity as written on this

manual. It is not to be retransmitted, printed or copied without prior written permission of company

Issue 00, Dec 2012 Page 1 of 4

International Agent Group

Calibration, NDT, Trading, Inspection, Testing,

QMS Consultancy, IT Solutions and Contracting

Doc. No. :

Procedure for Hydrotesting Rev. 00 Jun , 2015

INAT/MECH/LCP-021

Table of Contents

Sr. No. Title Page No(s).

1.0 Scope 03

2.0 Normative references 03

3.0 Reference standard 03

4.0 Acceptance Criteria 03

5.0 Preliminary Operations 03

6.0 Procedure 03~04

7.0 Appendices 04

Issue 00, Dec 2012 Page 2 of 4

International Agent Group

Calibration, NDT, Trading, Inspection, Testing,

QMS Consultancy, IT Solutions and Contracting

Doc. No. :

Procedure for Hydrotesting Rev. 00 Jun , 2015

INAT/MECH/LCP-021

1.0 Scope

This method defines the procedures for Hydro testing.

2.0 Normative references

ASME B31.3

ASME B31.4

SAES-A-004

SAES-A-007

SAES-L-150

3.0 Reference Standard

3.1 Pressure Indicator (Digital/Dial) with a valid certificate of calibration either traceable to

international or national standard laboratory in accordance with an industrial code or a

regulation shall be used as a standard for calibration.

4.0 Acceptance Criteria

4.1 The Acceptance for drop in pressure shall be as per Client specifications. Otherwise, it

shall be rejected if the drop in pressure is more than 5% of nominal pressure within one

hour.

5.0 Preliminary Operations

5.1 The details of item under test received for Testing shall be entered in the

calibration/testing job form.

5.2 It shall be ensured that the item shall be free from physical defect or damage.

5.3 The item shall be inspected and marked in relevant block of equipment’s primary

inspection section of calibration/Testing data sheet form.

6.0 Procedure

6.1 The Pressure Indicator & item shall be maintained at same place for 1hours minimum.

6.2 Connect the item with the Pressure Indicator accordingly.

6.3 Apply the pressure with the pressure source.

6.4 The Applied pressure should be 1.5 times more than the working pressure of the item

which is under test.

6.5 Hold the applied pressure for 30 minutes at least.

6.6 Leakage must be observed from any point/fittings.

6.7 In case of leakage in the system just Unpressurized the system and Remove the

Leakage if there is any.

6.8 Apply the pressure again and check for the leakage again. If not found than check the

item under test for any de-shape or deformation.

6.9 If deformation/defect or de-shape is found reject the item, otherwise item is pass.

Issue 00, Dec 2012 Page 3 of 4

International Agent Group

Calibration, NDT, Trading, Inspection, Testing,

QMS Consultancy, IT Solutions and Contracting

Doc. No. :

Procedure for Hydrotesting Rev. 00 Jun , 2015

INAT/MECH/LCP-021

6.10 Observation shall be mention on the data sheet.

6.11 Calibration/Testing certificate form shall be issued for Hydro testing as per

calibration/Hydro testing data sheet form.

6.12 A calibration/Testing sticker containing/ having following information shall be affixed on

the Hydro tested item.

a) Item code

b) Calibrated/tested on

c) Next calibration/Testing date

7.0 Appendices

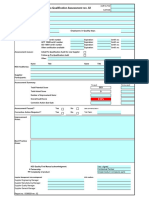

Job Form Call/001

Data Sheet Form Call/013

Test Certificate Call/002

Issue 00, Dec 2012 Page 4 of 4

You might also like

- Cleaning Validation ProtocolDocument21 pagesCleaning Validation Protocolmarkandey gupta100% (7)

- Solutions Manual Brief Course in Mathematical Statistics 1st Edition TanisDocument3 pagesSolutions Manual Brief Course in Mathematical Statistics 1st Edition Tanisstephensimon3297No ratings yet

- Validation Master PlanDocument56 pagesValidation Master PlanMd Nazim Uddin100% (7)

- Standard Calibration Procedure Gauss Meter Doc. No. Call/SCP/002 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Gauss Meter Doc. No. Call/SCP/002 Rev. 00 May 01, 2015Ajlan KhanNo ratings yet

- Quality ManualDocument73 pagesQuality Manualmechtek 20No ratings yet

- This Study Resource Was: Session 7: VeritasDocument7 pagesThis Study Resource Was: Session 7: VeritasPagod100% (1)

- 6.QSP Non-Conformity & Corrective ActionDocument3 pages6.QSP Non-Conformity & Corrective Actiontrivesh100% (1)

- Supplier Quality AgreementDocument5 pagesSupplier Quality AgreementSampda100% (1)

- 009-Control ValveDocument4 pages009-Control ValveManzoor AhmadNo ratings yet

- 003-Pressure Switch PDFDocument4 pages003-Pressure Switch PDFManzoor AhmadNo ratings yet

- 002 Pressure Calibration, Master Gauges and Pressure Indicator PDFDocument9 pages002 Pressure Calibration, Master Gauges and Pressure Indicator PDFManzoor AhmadNo ratings yet

- 001-Dead Weight TesterDocument4 pages001-Dead Weight TesterManzoor Ahmad100% (1)

- T&D-HSE-PRC-0060 Non Conformity and Corrective Action ProcedureDocument10 pagesT&D-HSE-PRC-0060 Non Conformity and Corrective Action ProcedureDamalieNo ratings yet

- Standard Calibration Procedure Densitometer Doc. No. Call/SCP/032 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Densitometer Doc. No. Call/SCP/032 Rev. 00 May 01, 2015Ajlan Khan100% (2)

- Standard Calibration Procedure Pressure Gauge Doc. No. Call/SCP/014 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Pressure Gauge Doc. No. Call/SCP/014 Rev. 00 May 01, 2015Ajlan KhanNo ratings yet

- Standard Calibration Procedure Pick Glass Doc. No. Call/SCP/010 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Pick Glass Doc. No. Call/SCP/010 Rev. 00 May 01, 2015Ajlan KhanNo ratings yet

- 004 - Gas Analyzer Cal ProcedureDocument3 pages004 - Gas Analyzer Cal ProcedureManzoor AhmadNo ratings yet

- QSP 07 CAPA Rev 1Document4 pagesQSP 07 CAPA Rev 1kmvimal36No ratings yet

- Standard Calibration Procedure Hydrometer Doc. No. Call/SCP/033 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Hydrometer Doc. No. Call/SCP/033 Rev. 00 May 01, 2015Ajlan Khan100% (1)

- 013-Torque Wrenches and Torue MetersDocument12 pages013-Torque Wrenches and Torue MetersManzoor AhmadNo ratings yet

- 019-Compression Load CellDocument3 pages019-Compression Load CellManzoor AhmadNo ratings yet

- 008-Pressure TransmitterDocument4 pages008-Pressure TransmitterManzoor AhmadNo ratings yet

- 031-Conductivity MeterDocument4 pages031-Conductivity MeterAjlan KhanNo ratings yet

- Single Gas Detector (Msa Altair Pro)Document10 pagesSingle Gas Detector (Msa Altair Pro)MANIVASAGANNo ratings yet

- 005 ManometerDocument4 pages005 ManometerManzoor AhmadNo ratings yet

- Standard Calibration Procedure Dial Gauge Doc. No. Call/SCP/007 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Dial Gauge Doc. No. Call/SCP/007 Rev. 00 May 01, 2015Ajlan KhanNo ratings yet

- KSA-POP-010-General Guidelines For Sampling For Laboratory TestingDocument7 pagesKSA-POP-010-General Guidelines For Sampling For Laboratory TestingASHJANNo ratings yet

- 034-Measuring CylinderDocument4 pages034-Measuring CylinderAjlan KhanNo ratings yet

- 035-Volumetric MeasuresDocument4 pages035-Volumetric MeasuresAjlan KhanNo ratings yet

- 022 PmiDocument5 pages022 PmiManzoor AhmadNo ratings yet

- Standard Calibration Procedure Weighing Scale Doc. No. Call/SCP/019 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Weighing Scale Doc. No. Call/SCP/019 Rev. 00 May 01, 2015Ajlan KhanNo ratings yet

- Single Gas Detector (Msa Altair)Document10 pagesSingle Gas Detector (Msa Altair)MANIVASAGANNo ratings yet

- (QSP-QA-08) Process For Internal Rejection HandelingDocument4 pages(QSP-QA-08) Process For Internal Rejection HandelingMUNENDRA SHAKYANo ratings yet

- Standard Calibration Procedure Micron Air Doc. No. Call/SCP/018 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Micron Air Doc. No. Call/SCP/018 Rev. 00 May 01, 2015Ajlan KhanNo ratings yet

- 023-Temperature GaugeDocument4 pages023-Temperature GaugeAjlan KhanNo ratings yet

- TUV SUD - PT Procedure Rev.05Document13 pagesTUV SUD - PT Procedure Rev.05HassanNo ratings yet

- Control of Monitoring, Inspection, and Measuring Equipment - Rev. 01Document11 pagesControl of Monitoring, Inspection, and Measuring Equipment - Rev. 01moytabura96100% (1)

- 004-Decade Resistance BoxDocument4 pages004-Decade Resistance BoxAjlan KhanNo ratings yet

- TEMPLATE FOR PROCESS VALIDATION PROTOCOL - Pharmaceutical GuidanceDocument6 pagesTEMPLATE FOR PROCESS VALIDATION PROTOCOL - Pharmaceutical GuidancePackaging Development BernofarmNo ratings yet

- 003-Megger - Insulation TesterDocument4 pages003-Megger - Insulation TesterAjlan Khan100% (1)

- Liquid Penetrant Examination ProcedureDocument15 pagesLiquid Penetrant Examination ProcedureANH TAI MAI100% (1)

- OQ Protocol Air ShowerDocument6 pagesOQ Protocol Air Showerziauddin bukhari0% (1)

- 022-Temperature CalibratorDocument4 pages022-Temperature CalibratorAjlan Khan100% (1)

- 16 Fribility Test Appratus 016Document3 pages16 Fribility Test Appratus 016ASHOK KUMAR LENKANo ratings yet

- Internal Audit CAR RecordDocument11 pagesInternal Audit CAR RecordAkki SaudiNo ratings yet

- Quality Mannul-NABL-AAPL - (SSP) 11092015Document69 pagesQuality Mannul-NABL-AAPL - (SSP) 11092015Varsha ZambareNo ratings yet

- 009-Measuring Tape - Steel RuleDocument4 pages009-Measuring Tape - Steel RuleAjlan KhanNo ratings yet

- Nabl 126Document31 pagesNabl 126Gazal GuptaNo ratings yet

- 09 - Tata Power Safety - Audit - ProcedureDocument9 pages09 - Tata Power Safety - Audit - ProcedureloganathanNo ratings yet

- Procedure For Corrective Action and Preventive ActionDocument11 pagesProcedure For Corrective Action and Preventive Actionsohankumar.mahaleNo ratings yet

- 013-Pressure CalibratorDocument4 pages013-Pressure CalibratorAjlan KhanNo ratings yet

- PPEPL-SOP-04 Procedure For Corrective ActionDocument3 pagesPPEPL-SOP-04 Procedure For Corrective ActionRaja RehaNo ratings yet

- Incoming VTM Material Inspection Procedure - RevisedDocument6 pagesIncoming VTM Material Inspection Procedure - RevisedMusyoka Urbanus100% (1)

- Sop 1 Recommended Standard Operating Procedure For Preparation of Calibration CertificatesDocument6 pagesSop 1 Recommended Standard Operating Procedure For Preparation of Calibration CertificatessmalnifNo ratings yet

- MSA Altair 2XDocument10 pagesMSA Altair 2XMANIVASAGANNo ratings yet

- Non Conformance ProcedureDocument3 pagesNon Conformance ProcedureBharamu Patil33% (3)

- Internal Audit Check SheetDocument14 pagesInternal Audit Check SheetJOAI BITANA100% (1)

- J910-DT03-P0ZEN-040004 SQCP-0103 (Matrix For Quality Program) - Rev.0 (AWC)Document6 pagesJ910-DT03-P0ZEN-040004 SQCP-0103 (Matrix For Quality Program) - Rev.0 (AWC)Budi SetiawanNo ratings yet

- 016-Vacuum Gauge - IndicatorDocument4 pages016-Vacuum Gauge - IndicatorAjlan KhanNo ratings yet

- Supplier Pre-Qualification Assessment Form - Rev.02Document18 pagesSupplier Pre-Qualification Assessment Form - Rev.02cpsinasNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- 004 - Gas Analyzer Cal ProcedureDocument3 pages004 - Gas Analyzer Cal ProcedureManzoor AhmadNo ratings yet

- 009-Control ValveDocument4 pages009-Control ValveManzoor AhmadNo ratings yet

- 013-Torque Wrenches and Torue MetersDocument12 pages013-Torque Wrenches and Torue MetersManzoor AhmadNo ratings yet

- 022 PmiDocument5 pages022 PmiManzoor AhmadNo ratings yet

- 019-Compression Load CellDocument3 pages019-Compression Load CellManzoor AhmadNo ratings yet

- 008-Pressure TransmitterDocument4 pages008-Pressure TransmitterManzoor AhmadNo ratings yet

- 003-Pressure Switch PDFDocument4 pages003-Pressure Switch PDFManzoor AhmadNo ratings yet

- 002 Pressure Calibration, Master Gauges and Pressure Indicator PDFDocument9 pages002 Pressure Calibration, Master Gauges and Pressure Indicator PDFManzoor AhmadNo ratings yet

- 005 ManometerDocument4 pages005 ManometerManzoor AhmadNo ratings yet

- 001-Dead Weight TesterDocument4 pages001-Dead Weight TesterManzoor Ahmad100% (1)

- 004-Vacuum Gauge - IndicatorDocument4 pages004-Vacuum Gauge - IndicatorManzoor AhmadNo ratings yet

- SR International School Bareilly Holiday HomeworkDocument4 pagesSR International School Bareilly Holiday Homeworkafnazopkfplanl100% (1)

- ppt3 Descriptive2 (23-24)Document74 pagesppt3 Descriptive2 (23-24)alexzandrei.rara937No ratings yet

- Equivalent MaterialDocument1 pageEquivalent Materialmuhammadf SardarNo ratings yet

- Meteodyn Complex Terrain Modeling CFD Software Bolund Hill Round Robin TestDocument18 pagesMeteodyn Complex Terrain Modeling CFD Software Bolund Hill Round Robin TestMeteodyn_UrbawindNo ratings yet

- File PDFDocument5 pagesFile PDFAljon AvilaNo ratings yet

- Belden 9842 Data SheetDocument2 pagesBelden 9842 Data SheetFranklin GuillenNo ratings yet

- Dsto TR 2757Document41 pagesDsto TR 2757Muhammet özbekNo ratings yet

- Appendices Appendix A Data GatheringDocument6 pagesAppendices Appendix A Data GatheringLoi BuchornoNo ratings yet

- Budget of Work in General Biology 1Document5 pagesBudget of Work in General Biology 1Elma SolibagaNo ratings yet

- Hot Springs in Peninsula Malaysia: January 2010Document6 pagesHot Springs in Peninsula Malaysia: January 2010Arjunaidi JamaludinNo ratings yet

- Reasons For Conducting Literature ReviewDocument4 pagesReasons For Conducting Literature Reviewfvhvmqqj100% (1)

- Cultural Marxism in The Works of BurroughsDocument1 pageCultural Marxism in The Works of BurroughsChandrapal S BhaskerNo ratings yet

- E C O - P R I N T I N G - 2 0 2 3 - Compressed - Compressed PDFDocument32 pagesE C O - P R I N T I N G - 2 0 2 3 - Compressed - Compressed PDFguru jiNo ratings yet

- Cape Mock Exam 2023Document2 pagesCape Mock Exam 2023Tahj ThomasNo ratings yet

- 3189 PDFDocument5 pages3189 PDFVln SekharNo ratings yet

- Cabinet Thermal Solutions: Web: EmailDocument8 pagesCabinet Thermal Solutions: Web: EmailXiaofeng XuNo ratings yet

- Creativity and Innovation in Building Systems and Construction MethodsDocument6 pagesCreativity and Innovation in Building Systems and Construction MethodsOmoyemi OgunsusiNo ratings yet

- 11 Student Card ApplicationDocument3 pages11 Student Card ApplicationRubenMelchorNo ratings yet

- Review of Economics Rules: The Rights and Wrongs of The Dismal ScienceDocument4 pagesReview of Economics Rules: The Rights and Wrongs of The Dismal ScienceTalhaNo ratings yet

- WORKSHEET Phy lab-IIDocument12 pagesWORKSHEET Phy lab-IIzithNo ratings yet

- Usa Architecture ProjectDocument4 pagesUsa Architecture ProjectnullifyNo ratings yet

- Sampling Distribution and Simulation in RDocument10 pagesSampling Distribution and Simulation in RPremier PublishersNo ratings yet

- Farenheit and Celsius Converions PDFDocument2 pagesFarenheit and Celsius Converions PDFJalinaJoyCanapiPagulayanNo ratings yet

- The Inner Universe Theoryof Dark Energy InterpretationDocument17 pagesThe Inner Universe Theoryof Dark Energy InterpretationCiprian Bitca100% (1)

- Safety Induction Checklist FINALDocument2 pagesSafety Induction Checklist FINALAhmed AbdelradyNo ratings yet

- Coordination Chemistry Reviews: ReviewDocument21 pagesCoordination Chemistry Reviews: ReviewMuhammad RiskiNo ratings yet

- Policy Brief 16 - Internal Migration in China-Integrating Migration With Urbanization Policies and Hukou Reform-Nov 21Document9 pagesPolicy Brief 16 - Internal Migration in China-Integrating Migration With Urbanization Policies and Hukou Reform-Nov 21oreoolepNo ratings yet

- ACON Inst & Aut Alarm 745-890-030 - GDocument37 pagesACON Inst & Aut Alarm 745-890-030 - Gfares ahmedNo ratings yet