Professional Documents

Culture Documents

1-MVCP00116-885PSVr2 20210524100343 852 X

1-MVCP00116-885PSVr2 20210524100343 852 X

Uploaded by

Łukasz BolewskiCopyright:

Available Formats

You might also like

- Datasheet For Pressure TransmitterDocument8 pagesDatasheet For Pressure TransmitterVenkatesan ManikandanNo ratings yet

- A307 Ius DPG DS 2202Document2 pagesA307 Ius DPG DS 2202muddisetty umamaheswarNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- Activity Group 1-8thDocument5 pagesActivity Group 1-8thcharles100% (1)

- Coriolis Mass Flow MeterDocument2 pagesCoriolis Mass Flow MeterSreejesh SundaresanNo ratings yet

- Smoke Control in Atrium Buildings Roger Harrison PDFDocument320 pagesSmoke Control in Atrium Buildings Roger Harrison PDFMustafa OksuzNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Tag No FT-1033: SHEET: 27 OF 102Document1 pageTag No FT-1033: SHEET: 27 OF 102hendra hermawanNo ratings yet

- Specification Sheets For On-Off Manual ValvesDocument5 pagesSpecification Sheets For On-Off Manual ValvesMichell TurbayNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 286Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 286JHONATAN RODRIGUEZ VENTONo ratings yet

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Document2 pagesQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTONo ratings yet

- Data SheetDocument3 pagesData SheetMaribeth AgubaNo ratings yet

- Specification For Pressure TransmitterDocument1 pageSpecification For Pressure TransmitterHarish GundaNo ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- K 61 33 PR DTS 20009 - 0001 - 0Document6 pagesK 61 33 PR DTS 20009 - 0001 - 0santhoshkrishnaNo ratings yet

- 40 NB Globe Tag No (1) - 1309Document1 page40 NB Globe Tag No (1) - 1309SIL PROJECTSNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- FTDocument1 pageFTmanodipNo ratings yet

- 85000FI610Document1 page85000FI610LibyanManNo ratings yet

- 540402diga01015 Na: 0d206-Dma-I-797-La-0001Document16 pages540402diga01015 Na: 0d206-Dma-I-797-La-0001patilrohan4444No ratings yet

- 85000FI608Document1 page85000FI608LibyanManNo ratings yet

- DS DPLTDocument2 pagesDS DPLTYENDRU LALITHAKUMARINo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 186Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 186JHONATAN RODRIGUEZ VENTONo ratings yet

- NSDocument1 pageNSXemtintuc Xem TinNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- A307 Ius Uv DS 1201Document2 pagesA307 Ius Uv DS 1201smartravi222No ratings yet

- 141014.datasheet For PSV-1323Document2 pages141014.datasheet For PSV-1323ocanhthuNo ratings yet

- Drum PDSDocument1 pageDrum PDScavidan20055No ratings yet

- Fi 607Document1 pageFi 607LibyanManNo ratings yet

- 315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevADocument3 pages315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevAanwar sadatNo ratings yet

- KNT-002-TS-IA2-DS-018 - 1 - DATASHEET FOR WATERCUT METER-trang-3-6Document4 pagesKNT-002-TS-IA2-DS-018 - 1 - DATASHEET FOR WATERCUT METER-trang-3-6hoapro537817No ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- Temperature Client Transmitter Project Specification Sheet Unit LocationDocument2 pagesTemperature Client Transmitter Project Specification Sheet Unit LocationFranklin J Talero BNo ratings yet

- General: CRUDE OIL / Liquid 313.9 / 313.9Document1 pageGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirNo ratings yet

- Datasheet of Gas AnalyserDocument1 pageDatasheet of Gas Analyserk singhNo ratings yet

- File 5Document1 pageFile 5VENKATACHALAM SUBBARAJNo ratings yet

- Datasheet For Pressure Transmitter - Process DataDocument4 pagesDatasheet For Pressure Transmitter - Process DataLai HuynhNo ratings yet

- FT 04Document2 pagesFT 04trilok corporationNo ratings yet

- Chiller Data SheetDocument3 pagesChiller Data SheetMoriyasuNguyenNo ratings yet

- Design Notes and AssumptionsDocument19 pagesDesign Notes and AssumptionsDarshan PanchalNo ratings yet

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Document14 pagesFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024No ratings yet

- Process Design Conditions: 842-PA-K17-3"-ES32EKFR-NIDocument2 pagesProcess Design Conditions: 842-PA-K17-3"-ES32EKFR-NITHOMASNo ratings yet

- LCV 01Document4 pagesLCV 01trilok corporationNo ratings yet

- DASDocument39 pagesDASchakrapani vagish chandra pandeyNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-DIT - 188Document2 pagesQ1Co 3000 Q1Co 3620 3620-DIT - 188JHONATAN RODRIGUEZ VENTONo ratings yet

- DS 02995Document2 pagesDS 02995Giovanni ValentinoNo ratings yet

- Tipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For Diverter ValvesDocument5 pagesTipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For Diverter ValvesMichell TurbayNo ratings yet

- Data Sheet For Pressure TransmitterDocument2 pagesData Sheet For Pressure TransmitterDavinder Singh BhattiNo ratings yet

- Technical Specification - LT (DP Based)Document4 pagesTechnical Specification - LT (DP Based)ManodipPatilNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- DS For PG in ISTADocument1 pageDS For PG in ISTAmarlrobles03081992No ratings yet

- Venturi Specification: Client Project Area UnitDocument1 pageVenturi Specification: Client Project Area UnithaisamsarwarNo ratings yet

- Pressure Transmitter Specification Sheet: GeneralDocument1 pagePressure Transmitter Specification Sheet: GeneralFranklin J Talero BNo ratings yet

- En2458 75 Lit60001 - 09Document1 pageEn2458 75 Lit60001 - 09Dela AmandaNo ratings yet

- DS Pressure Transmitter PDFDocument3 pagesDS Pressure Transmitter PDFadrian bargasNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 2012 PTQ q3Document146 pages2012 PTQ q3Osvaldo OmarNo ratings yet

- Gen Chem 2 - Lesson 4. Phase Changes and Phase DiagramDocument39 pagesGen Chem 2 - Lesson 4. Phase Changes and Phase Diagram.....No ratings yet

- DR Engp M II p1 1.1 R.5grifadoDocument176 pagesDR Engp M II p1 1.1 R.5grifadoleo100% (1)

- Review of The Current Technologies and Performances of Hydrogen Compression For Stationary and Automotive ApplicationsDocument21 pagesReview of The Current Technologies and Performances of Hydrogen Compression For Stationary and Automotive ApplicationsamirNo ratings yet

- Introduction To Oil and Gas AllocationDocument33 pagesIntroduction To Oil and Gas AllocationDiego J. PonceNo ratings yet

- Stress Analysis Slug Flow PulsationDocument18 pagesStress Analysis Slug Flow Pulsationbhavesh shuklaNo ratings yet

- A Major Project ON "Well Control Equipment, Principles & Procedures For Surface Installations"Document42 pagesA Major Project ON "Well Control Equipment, Principles & Procedures For Surface Installations"sultanNo ratings yet

- IM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022Document31 pagesIM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022acurvz2005No ratings yet

- (3900LPM - 30M) 150x125 FS4KA 30KWDocument2 pages(3900LPM - 30M) 150x125 FS4KA 30KWĐức Anh NguyễnNo ratings yet

- TM-Editor 25.04.2016 Seite 1 050-Meteorology - LTMDocument308 pagesTM-Editor 25.04.2016 Seite 1 050-Meteorology - LTMIbrahim Med100% (1)

- Line Sizing Philosophy Line Sizing PhilosophyDocument21 pagesLine Sizing Philosophy Line Sizing Philosophyjenish parekhNo ratings yet

- Class Example Pump Sizing-Module 5 - Sep28Document6 pagesClass Example Pump Sizing-Module 5 - Sep28Stefan De Beer0% (1)

- Types of Gas Turbine EngineDocument5 pagesTypes of Gas Turbine EngineLester Ramos0% (1)

- Boe Exam Paper Feb 2012Document9 pagesBoe Exam Paper Feb 2012saurabhshineNo ratings yet

- Ehandbook Strategize Your Steam SystemDocument18 pagesEhandbook Strategize Your Steam SystemMPham100% (1)

- Enhanced NGL Recovery ProcessDocument5 pagesEnhanced NGL Recovery ProcessEdgar HuancaNo ratings yet

- Lecture #12: Distillation Column Design-ContinueDocument7 pagesLecture #12: Distillation Column Design-ContinueAbdul MoeedNo ratings yet

- Vedanta Limited: Cairn Oil & GasDocument52 pagesVedanta Limited: Cairn Oil & GasBALASUBRAMANIAM MEGHANADHNo ratings yet

- Rocket NozzleDocument9 pagesRocket NozzleNainan TrivediNo ratings yet

- Basic Thermodynamics Btech 1 Lecture NotesDocument38 pagesBasic Thermodynamics Btech 1 Lecture Notesrichmondteye2001No ratings yet

- Presentation About CondenserDocument9 pagesPresentation About CondenserVignesh WarNo ratings yet

- CNSM Gas TrainingDocument40 pagesCNSM Gas Trainingstephen burgessNo ratings yet

- Hasil 50839 P1Document2 pagesHasil 50839 P1ARNo ratings yet

- Sheet #7Document4 pagesSheet #7Iam A gnoomNo ratings yet

- Safety Scope MSA CatalogDocument144 pagesSafety Scope MSA Catalogykresna1631No ratings yet

- Pump and Pump Piping System Performance PDFDocument72 pagesPump and Pump Piping System Performance PDFMosaddekNo ratings yet

- Lecture 1 110121 Vacuum SystemDocument46 pagesLecture 1 110121 Vacuum SystemMehreen AkmalNo ratings yet

- Week One Homework Problems: Fundamentals of ! Fluid PowerDocument2 pagesWeek One Homework Problems: Fundamentals of ! Fluid PowerhellfireNo ratings yet

1-MVCP00116-885PSVr2 20210524100343 852 X

1-MVCP00116-885PSVr2 20210524100343 852 X

Uploaded by

Łukasz BolewskiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-MVCP00116-885PSVr2 20210524100343 852 X

1-MVCP00116-885PSVr2 20210524100343 852 X

Uploaded by

Łukasz BolewskiCopyright:

Available Formats

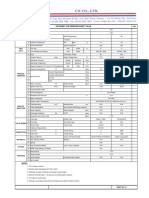

DATA SHEET

Pressure safety valve

Customer:

End User: GRUPA LOTOS

Location : GDANSK, POLAND

JZ Project No. MVCP00116

VRU Model S3-AAD-10-110-115-10 DVP

P.O.Number:

Name Date Document -Nr. Rev.

Drawn Y.COLLARD 12-Jun-20

Checked B.WALHA 12-Jun-20 MVCP00116 - 885-01 2

Approved L.MACHABERT 12-Jun-20

1 Tag Number 4076PSV-101 407- PSV-201

2 Service V1/V2 Protection

3 P&ID No. MVCP00116-150 s1

GENERAL 4 City, Country Gdansk, Poland

6 Area Classification Temperature Class zone 1 T3

8 Ambient Temp. Site Ambient Design Temp. -29°C / +40 °C -29°C / +80 °C

9 Certification API RP 520 last revision

10 Site Altitude 7m

11 Line Number N/A N/A

12 Line Size & Schedule Inlet Outlet 4" sch 40 6" sch 40

LINE 13 Line Material Inlet Outlet A106 Gr B A106 Gr B

14 Insulation Type / Thickness N.A.

15 Piping class JZ STD

16 Fluid Phase AIR + hydrocarbon GAS

17 Molecular Weight Toxic Service 65 N/A

18 Oper. Pressure Set Pressure 0.030 kg/cm² (g) 0.49 kg/cm² (g)

19 Oper. Temperature -29°C / +40 °C

20 Constant atm

PROCESS 21 Back Pressure Variable atm

CONDITIONS 22 Total atm

23 %Allowable Overpressure 21.0%

24 Design Pressure Full Vaccum / 3.5 kg/cm² (g)

25 Exposed surface area of unwetted vessel m² 72.1 m2

26

27 Barometric Pressure Ratio of Specific Heats 1.013 kg/cm² 1.12

28 Design Temperature Min Max -20°C +80°C

29

30 Design Code API RP 520 last revision

31 Sizing Basis Case STANDARD Fire case

BASIS 32 Calculated Area 3.4042 sq in (2196 mm²)

AND 33 Discharge Area selected 3.6 sq in (2323 mm²)

SELECTION 34 Orifice Designation M

35 Wetted / Unwetted Vessel Unwetted

36 Inlet Outlet

37 Type Flange Flange

CONNECTIONS 38 Size 4" 6"

39 Rating 150# 150 #

40 Facing RF (125 Ra) RF (125 Ra)

41 Design SAFETY RELIEF

42 Type Conventional, Bellow, Pilot Operated Conventional

43 Bonnet Type closed

CONSTRUCTION 44 Body & Bonnet Seat & Rings A216-WCB Stainless steel minimum

MATERIALS 45 Guide & Rings Stainless steel minimum

46 Spring Bellows S NA

47 Painting Acc.with site condition RAL9010

48 Cap: Screwed or Bolted Bolted cap or srewed

OPTIONS 49 Lever: Plain or Packed Test Gag No Yes

50 Tag plate Stainless Steel dimension TBA by supplier

51 Tag plate text indication acc. to PED Annex I, Chapter 3.3 (English and polish)

52

53 Vendor TAI MILANO

54 Manufacturer TAI MILANO

PURCHASE 55 Model 300A 3111A 4M6

56

57

Note :

2 Y.C R.T L.M S.T 12-Jun-20 TAG UPDATED

1 Y.C R.T L.M S.T 16-Mar-20 For purchase

0 Y.C R.T L.M S.T 17-Feb-20 First Issue

Rev Engineer Checked Approved Process Project Date Revision Description

Sheet 2 of 4

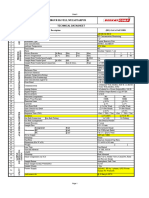

EQUIPMENT DATASHEET

Pressure Safety Relief Valve Number: Rev:.

MVCP00116-A885.01 2

1 Tag Number 407-PSV-301

2 Service V4 protection

3 P&ID No. MVCP00116-150A s3

GENERAL 4 City, Country Gdansk, Poland

6 Area Classification Temperature Class zone T3

8 Ambient Temp. Site Ambient Design Temp. -29°C / +40 °C -29°C / +80 °C

9 Certification API RP 520 last revision

10 Site Altitude 7m

11 Line Number N/A N/A

12 Line Size & Schedule Inlet Outlet 3" sch 40 4" sch 40

LINE 13 Line Material Inlet Outlet A106 Gr B A106 Gr B

14 Insulation Type / Thickness N.A.

15 Piping class JZ STD

16 Fluid Phase Gasoline VAPOR

17 Molecular Weight Toxic Service 65 kg/Kmol N/A

18 Oper. Pressure Set Pressure 0.14 kg/cm² g 0.49 barg

19 Oper. Temperature Relieving Temperature -29°C / +40 °C 176 °C

20 Constant atm

PROCESS 21 Back Pressure Variable atm

CONDITIONS 22 Total atm

23 %Allowable Overpressure 21.0%

24 Compressibility Factor

24b Wet area 8.1 m²

25 Latent Heat of Vaporisation Design Pressure 145.08 BTU/lb (80.6 kcal/kg) 3.5 kg/cm² g

26

27 Barometric Pressure Ratio of Specific Heats 1013 mbar 1.12

28 Design Temperature Min Max -29°C +80°C

29

30 Design Code API RP 520 last revision

31 Sizing Basis Case STANDARD Fire vapor generation

BASIS 32 Calculated Area Area (Fire Case) 2.6566 sq in (1714 mm²) N/A

AND 33 Discharge Area selected 2.853 sq in (1841 mm²)

SELECTION 34 Orifice Designation L

35 Wetted / Unwetted Vessel Wetted

36 Inlet Outlet

37 Type Flange Flange

CONNECTIONS 38 Size 3" 4"

39 Rating 150 # 150 #

40 Facing RF (125 Ra) RF (125 Ra)

41 Design SAFETY RELIEF

42 Type Conventional, Bellow, Pilot Operated Conventional

43 Bonnet Type closed

CONSTRUCTION 44 Body & Bonnet Seat & Rings A216-WCB Stainless steel minimum

MATERIALS 45 Guide & Rings Stainless steel minimum

46 Spring Bellows S NA

47 Painting Acc. to site conditions RAL 9010

48 Cap: Screwed or Bolted Bolted cap or scewed

OPTIONS 49 Lever: Plain or Packed Test Gag No Yes

50 Tag plate Stainless Steel dimension TBA by supplier

51 Tag plate text indication acc. to PED Annex I, Chapter 3.3 (English and polish)

52

53 Vendor TAI MILANO

54 Manufacturer TAI MILANO

PURCHASE 55 Model 300A 3111A 3L4

56

57

Note :

2 Y.C R.T L.M S.T 12-Jun-20 TAG UPDATED

1 Y.C R.T L.M S.T 16-Mar-20 For purchase

0 Y.C R.T L.M S.T 17-Feb-20 First Issue

Rev Engineer Checked Approved Process Project Date Revision Description

Sheet 3 of 4

EQUIPMENT DATASHEET

Pressure Safety Relief Valve Number: Rev:.

MVCP00116-A885.02 2

1 The purpose of this material requisition is to state the user requirements and Sellers scope of works

2 for the supply of Pressure Safety Relief Valve

3 The Seller shall ensure that the supply within his scope will meet all requirements of this material requisition

4 as well as of national statutory regulations and/or official rules, codes and standards applicable to the involved

5 equipment within country of destination and he shall obtain all necessary approvals from statutory authorities.

6

7

GENERAL 8

9

10

11

12

13

14

15

16

17 Documents Delivery

18 WAO = Weeks After Order; AFI = Available at Final Inspection; WD = With Delivery

19 Data Sheet / Product documentation With Quote

20 General Arrangment Drawing With Quote

21 Valve and operator calculations sheet With Quote

22 Installation, operation and maintenance Instructions (IOM) (English and Turkish) WD

23 Pressure test report WD

24 valve test report WD

25 materials certificates WD

26 Atex/PED declaration of conformity WD

27

28

29

30

DOCUMENTS 31

REQUIREMENTS 32

TESTS 33

AND 34

CERTIFICATES 35

36

37

38

39

40

41

42

43

44

45 Specification Number Rev. Description

46

47

APPLICABLE 48

SPECIFICATIONS 49

& 50

REQUIREMENTS 51

52

53

54

55

56

57

58

59

0 Y.C L.M L.M 17-févr-20 FIRST ISSUE

Rev By Checked Approved Date Revision Description

Sheet 4 of 4

MATERIAL REQUISITION

PRESSURE SAFETY RELIF VALVE Spec N° :

TBA

Data sheet N° : Rev

MVCP00116-885.DOC 0

You might also like

- Datasheet For Pressure TransmitterDocument8 pagesDatasheet For Pressure TransmitterVenkatesan ManikandanNo ratings yet

- A307 Ius DPG DS 2202Document2 pagesA307 Ius DPG DS 2202muddisetty umamaheswarNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- Activity Group 1-8thDocument5 pagesActivity Group 1-8thcharles100% (1)

- Coriolis Mass Flow MeterDocument2 pagesCoriolis Mass Flow MeterSreejesh SundaresanNo ratings yet

- Smoke Control in Atrium Buildings Roger Harrison PDFDocument320 pagesSmoke Control in Atrium Buildings Roger Harrison PDFMustafa OksuzNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Tag No FT-1033: SHEET: 27 OF 102Document1 pageTag No FT-1033: SHEET: 27 OF 102hendra hermawanNo ratings yet

- Specification Sheets For On-Off Manual ValvesDocument5 pagesSpecification Sheets For On-Off Manual ValvesMichell TurbayNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 286Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 286JHONATAN RODRIGUEZ VENTONo ratings yet

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Document2 pagesQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTONo ratings yet

- Data SheetDocument3 pagesData SheetMaribeth AgubaNo ratings yet

- Specification For Pressure TransmitterDocument1 pageSpecification For Pressure TransmitterHarish GundaNo ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- K 61 33 PR DTS 20009 - 0001 - 0Document6 pagesK 61 33 PR DTS 20009 - 0001 - 0santhoshkrishnaNo ratings yet

- 40 NB Globe Tag No (1) - 1309Document1 page40 NB Globe Tag No (1) - 1309SIL PROJECTSNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- FTDocument1 pageFTmanodipNo ratings yet

- 85000FI610Document1 page85000FI610LibyanManNo ratings yet

- 540402diga01015 Na: 0d206-Dma-I-797-La-0001Document16 pages540402diga01015 Na: 0d206-Dma-I-797-La-0001patilrohan4444No ratings yet

- 85000FI608Document1 page85000FI608LibyanManNo ratings yet

- DS DPLTDocument2 pagesDS DPLTYENDRU LALITHAKUMARINo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 186Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 186JHONATAN RODRIGUEZ VENTONo ratings yet

- NSDocument1 pageNSXemtintuc Xem TinNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- A307 Ius Uv DS 1201Document2 pagesA307 Ius Uv DS 1201smartravi222No ratings yet

- 141014.datasheet For PSV-1323Document2 pages141014.datasheet For PSV-1323ocanhthuNo ratings yet

- Drum PDSDocument1 pageDrum PDScavidan20055No ratings yet

- Fi 607Document1 pageFi 607LibyanManNo ratings yet

- 315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevADocument3 pages315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevAanwar sadatNo ratings yet

- KNT-002-TS-IA2-DS-018 - 1 - DATASHEET FOR WATERCUT METER-trang-3-6Document4 pagesKNT-002-TS-IA2-DS-018 - 1 - DATASHEET FOR WATERCUT METER-trang-3-6hoapro537817No ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- Temperature Client Transmitter Project Specification Sheet Unit LocationDocument2 pagesTemperature Client Transmitter Project Specification Sheet Unit LocationFranklin J Talero BNo ratings yet

- General: CRUDE OIL / Liquid 313.9 / 313.9Document1 pageGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirNo ratings yet

- Datasheet of Gas AnalyserDocument1 pageDatasheet of Gas Analyserk singhNo ratings yet

- File 5Document1 pageFile 5VENKATACHALAM SUBBARAJNo ratings yet

- Datasheet For Pressure Transmitter - Process DataDocument4 pagesDatasheet For Pressure Transmitter - Process DataLai HuynhNo ratings yet

- FT 04Document2 pagesFT 04trilok corporationNo ratings yet

- Chiller Data SheetDocument3 pagesChiller Data SheetMoriyasuNguyenNo ratings yet

- Design Notes and AssumptionsDocument19 pagesDesign Notes and AssumptionsDarshan PanchalNo ratings yet

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Document14 pagesFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024No ratings yet

- Process Design Conditions: 842-PA-K17-3"-ES32EKFR-NIDocument2 pagesProcess Design Conditions: 842-PA-K17-3"-ES32EKFR-NITHOMASNo ratings yet

- LCV 01Document4 pagesLCV 01trilok corporationNo ratings yet

- DASDocument39 pagesDASchakrapani vagish chandra pandeyNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-DIT - 188Document2 pagesQ1Co 3000 Q1Co 3620 3620-DIT - 188JHONATAN RODRIGUEZ VENTONo ratings yet

- DS 02995Document2 pagesDS 02995Giovanni ValentinoNo ratings yet

- Tipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For Diverter ValvesDocument5 pagesTipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For Diverter ValvesMichell TurbayNo ratings yet

- Data Sheet For Pressure TransmitterDocument2 pagesData Sheet For Pressure TransmitterDavinder Singh BhattiNo ratings yet

- Technical Specification - LT (DP Based)Document4 pagesTechnical Specification - LT (DP Based)ManodipPatilNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- DS For PG in ISTADocument1 pageDS For PG in ISTAmarlrobles03081992No ratings yet

- Venturi Specification: Client Project Area UnitDocument1 pageVenturi Specification: Client Project Area UnithaisamsarwarNo ratings yet

- Pressure Transmitter Specification Sheet: GeneralDocument1 pagePressure Transmitter Specification Sheet: GeneralFranklin J Talero BNo ratings yet

- En2458 75 Lit60001 - 09Document1 pageEn2458 75 Lit60001 - 09Dela AmandaNo ratings yet

- DS Pressure Transmitter PDFDocument3 pagesDS Pressure Transmitter PDFadrian bargasNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 2012 PTQ q3Document146 pages2012 PTQ q3Osvaldo OmarNo ratings yet

- Gen Chem 2 - Lesson 4. Phase Changes and Phase DiagramDocument39 pagesGen Chem 2 - Lesson 4. Phase Changes and Phase Diagram.....No ratings yet

- DR Engp M II p1 1.1 R.5grifadoDocument176 pagesDR Engp M II p1 1.1 R.5grifadoleo100% (1)

- Review of The Current Technologies and Performances of Hydrogen Compression For Stationary and Automotive ApplicationsDocument21 pagesReview of The Current Technologies and Performances of Hydrogen Compression For Stationary and Automotive ApplicationsamirNo ratings yet

- Introduction To Oil and Gas AllocationDocument33 pagesIntroduction To Oil and Gas AllocationDiego J. PonceNo ratings yet

- Stress Analysis Slug Flow PulsationDocument18 pagesStress Analysis Slug Flow Pulsationbhavesh shuklaNo ratings yet

- A Major Project ON "Well Control Equipment, Principles & Procedures For Surface Installations"Document42 pagesA Major Project ON "Well Control Equipment, Principles & Procedures For Surface Installations"sultanNo ratings yet

- IM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022Document31 pagesIM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022acurvz2005No ratings yet

- (3900LPM - 30M) 150x125 FS4KA 30KWDocument2 pages(3900LPM - 30M) 150x125 FS4KA 30KWĐức Anh NguyễnNo ratings yet

- TM-Editor 25.04.2016 Seite 1 050-Meteorology - LTMDocument308 pagesTM-Editor 25.04.2016 Seite 1 050-Meteorology - LTMIbrahim Med100% (1)

- Line Sizing Philosophy Line Sizing PhilosophyDocument21 pagesLine Sizing Philosophy Line Sizing Philosophyjenish parekhNo ratings yet

- Class Example Pump Sizing-Module 5 - Sep28Document6 pagesClass Example Pump Sizing-Module 5 - Sep28Stefan De Beer0% (1)

- Types of Gas Turbine EngineDocument5 pagesTypes of Gas Turbine EngineLester Ramos0% (1)

- Boe Exam Paper Feb 2012Document9 pagesBoe Exam Paper Feb 2012saurabhshineNo ratings yet

- Ehandbook Strategize Your Steam SystemDocument18 pagesEhandbook Strategize Your Steam SystemMPham100% (1)

- Enhanced NGL Recovery ProcessDocument5 pagesEnhanced NGL Recovery ProcessEdgar HuancaNo ratings yet

- Lecture #12: Distillation Column Design-ContinueDocument7 pagesLecture #12: Distillation Column Design-ContinueAbdul MoeedNo ratings yet

- Vedanta Limited: Cairn Oil & GasDocument52 pagesVedanta Limited: Cairn Oil & GasBALASUBRAMANIAM MEGHANADHNo ratings yet

- Rocket NozzleDocument9 pagesRocket NozzleNainan TrivediNo ratings yet

- Basic Thermodynamics Btech 1 Lecture NotesDocument38 pagesBasic Thermodynamics Btech 1 Lecture Notesrichmondteye2001No ratings yet

- Presentation About CondenserDocument9 pagesPresentation About CondenserVignesh WarNo ratings yet

- CNSM Gas TrainingDocument40 pagesCNSM Gas Trainingstephen burgessNo ratings yet

- Hasil 50839 P1Document2 pagesHasil 50839 P1ARNo ratings yet

- Sheet #7Document4 pagesSheet #7Iam A gnoomNo ratings yet

- Safety Scope MSA CatalogDocument144 pagesSafety Scope MSA Catalogykresna1631No ratings yet

- Pump and Pump Piping System Performance PDFDocument72 pagesPump and Pump Piping System Performance PDFMosaddekNo ratings yet

- Lecture 1 110121 Vacuum SystemDocument46 pagesLecture 1 110121 Vacuum SystemMehreen AkmalNo ratings yet

- Week One Homework Problems: Fundamentals of ! Fluid PowerDocument2 pagesWeek One Homework Problems: Fundamentals of ! Fluid PowerhellfireNo ratings yet