Professional Documents

Culture Documents

Isw-16b (50SS Finian RD)

Isw-16b (50SS Finian RD)

Uploaded by

Am EOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Isw-16b (50SS Finian RD)

Isw-16b (50SS Finian RD)

Uploaded by

Am ECopyright:

Available Formats

WPS No.

:

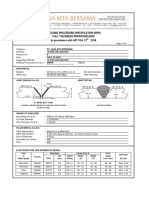

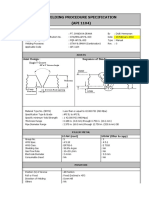

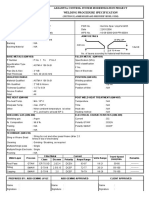

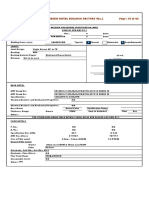

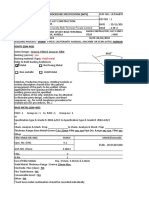

WELDING PROCEDURE SPECIFICATION ISW-16B

PROJECT: Field& In-Service Welding Procedures CLIENT: APA Group Network Operations Rev: 2.2

WORK LOCATION: PQR No.:

SECTION: TP Pressure – Class 150 DYSON & FINIAN RD., PORT NOARLUNGA, SA ISW-16,

ISW-16B

WELDING STANDARD: AS 2885.2 DESCRIPTION: In Service Welding of Thread-O-Ring to Pipe

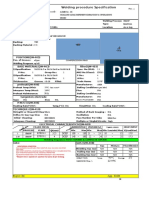

SMYS ALLOWABLE MATERIAL

MATERIAL SPECIFICATION MATERIAL CE DIAMETER GROUP WALL THICKNESS

(MPa) YS (MPa) MANUFACTURER

NOT

1. PIPE: API 5L X42 289 < 483 ≤ 0.37 DN80 5.7mm – 5.9mm

APPLICABLE

NOT

2. FITTING: ASTM A333 Gr. 6 241 < 483 ≤ 0.37 DN50 4.6mm – 11mm

APPLICABLE

WELDING PROCESS: MMAW (SMAW) JOINT DETAIL

EDGE PREPARATION: Refer to Joint Detail

FITTING

JOINT TYPE: Refer to Sketch

50

ROOT FACE (F): 2.5 ± 0.8 mm R

ROOT GAP (R): 3 ± 0.8 mm

BACKING: NOT REQUIRED

WELD RUNS: REFER WELD PASS SEQUENCE SKETCH

RUN PIPE

JOINT POSITION: 2B

SHIELDING GAS AND FLUX: NOT REQUIRED

NO. OF WELDERS: ONE

F

WELD PASS SEQUENCE

TYPE OF LINE UP CLAMP: NOT REQUIRED

% ROOT RUN COMPLETE BEFORE REMOVAL OF CLAMP: N/A

NO. OF TACK WELDS: 2

FITTING

LENGTH OF EACH TACK WELD: 25mm SPACED EQUALLY

TACK WELDS REMOVED (Y/N): No, Feathered into Root

3+

PREHEAT: 50°C - 120°C 1 2

PREHEATING METHOD: OXY-LPG OR PROPANE HAND HELD TORCH

WIDTH OF HEATING: MIN. 75mm EITHER SIDE OF THE WELD

RUN PIPE

PWHT: NOT REQUIRED

CLEANING EQUIPMENT: POWER GRINDER / WIRE BUFF

CLEANING METHOD: GRIND SLAG FROM ROOT RUN, WIRE BUFF FROM

ALL OTHER RUNS

WELD DETAILS ELECTRODE DETAILS ELECTRICAL CHARACTERISTICS MAX. TIME

SPEED HEAT INPUT BETWEEN INTER PASS

SIZE CURRENT (mm/min) (KJ/mm) PASSES TEMP (°C)

PASS NO. DIRECTION TYPE VOLTS POLARITY

(mm) (AMPS) (mins)

1. ROOT Kobe

H–V 2.6 90 – 100 24 – 25 DC + 124 0.6 – 1.1 120

PASS LB52U

15

2. HOT Kobe

H–V 2.6 90 – 100 24 – 25 DC + 102 0.6 – 1.1 120

PASS LB52U

12

Kobe

3. 3+ H–V 3.2 100 – 110 24 – 25 DC + 140 0.6 – 1.1 120

LB52U

NOTES:

Higher heat input on hot pass is due to a weave technique.

Heat input range to be maintained by welders and controlled by welding supervisor.

PREPARED BY: Aaron Castle SIGNATURE: Original Signed DATE: 24/01/2011

APPROVED BY: Stephen Slobodian SIGNATURE: Original Signed DATE: 24/01/2011

Amir Emam

MODIFIED BY:

2023.05.11 10:21:27 +10'00'

You might also like

- The Creative Self Workbook PDFDocument23 pagesThe Creative Self Workbook PDFApril Lee100% (8)

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- BR1 Power Door Strut System With Standalone ECUDocument4 pagesBR1 Power Door Strut System With Standalone ECUkaganNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- 1.6 PNP Spiritual and Values Formation Program PresentationDocument46 pages1.6 PNP Spiritual and Values Formation Program PresentationNathaniel Recto100% (4)

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Zizek Slavoj Living in The End TimesDocument433 pagesZizek Slavoj Living in The End Timesshivant67% (3)

- Ec Declaration of Conformity: QAS60 PDS 400 V 50 HZDocument6 pagesEc Declaration of Conformity: QAS60 PDS 400 V 50 HZFernando Morales PachonNo ratings yet

- Facilitating Learning ReviewerDocument4 pagesFacilitating Learning ReviewerRicson Drew100% (12)

- Q3 Reading and Writing 11 Module 1Document26 pagesQ3 Reading and Writing 11 Module 1Bella Lauron100% (8)

- 7.5.5.2asme Sec Viii Div 2 2017Document3 pages7.5.5.2asme Sec Viii Div 2 2017James100% (2)

- Isw-16b (Goldsmith DR - DN50SS)Document1 pageIsw-16b (Goldsmith DR - DN50SS)Am ENo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Welding Procedure For Plate - WPSDocument1 pageWelding Procedure For Plate - WPSCristian ZidarescuNo ratings yet

- HRP Ii WPS STR 225Document4 pagesHRP Ii WPS STR 225RohiNo ratings yet

- HRP Ii WPS STR 209aDocument4 pagesHRP Ii WPS STR 209aRohiNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Full Thickness Repair Welding Welding Procedure Specification (WPS) in Accordance With API 1104 21: 2016Document6 pagesFull Thickness Repair Welding Welding Procedure Specification (WPS) in Accordance With API 1104 21: 2016Juni KurniyantoNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Draft WPS Welder R0Document51 pagesDraft WPS Welder R0R Bernanda Argandhi SaputraNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- FSIWPSREV0Document2 pagesFSIWPSREV0sooomilNo ratings yet

- HRP Ii WPS LGP 50aDocument2 pagesHRP Ii WPS LGP 50aRohiNo ratings yet

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification SampleBrown's P LikoNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PQR Babbit SCDocument34 pagesPQR Babbit SCagustinusNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- Old WPSDocument1 pageOld WPSDHANEESH VELLILAPULLINo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- Asirusa WPS-P-002 1FDocument5 pagesAsirusa WPS-P-002 1FWalter RuedaNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- WPS (Gtaw)Document2 pagesWPS (Gtaw)Ramadhan AdityaNo ratings yet

- Final Year Project MME: CEET University of The Punjab, Lahore PakistanDocument9 pagesFinal Year Project MME: CEET University of The Punjab, Lahore PakistanAhmad HasanNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- WPS Updated PDFDocument2 pagesWPS Updated PDFRaja Muaz Ahmad KhanNo ratings yet

- Weld Data SheetDocument1 pageWeld Data Sheetsidrui00No ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- WG-WPS-0099 Rev 2Document1 pageWG-WPS-0099 Rev 2mb.pipingNo ratings yet

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- WPS 01-111-2023 enDocument2 pagesWPS 01-111-2023 endiogodemoura95No ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- Isw-16b (Goldsmith DR - DN50SS)Document1 pageIsw-16b (Goldsmith DR - DN50SS)Am ENo ratings yet

- Ned-1501 Finian C01 PDFDocument3 pagesNed-1501 Finian C01 PDFAm ENo ratings yet

- Ned-1501 Finian C02Document3 pagesNed-1501 Finian C02Am ENo ratings yet

- Ned-1501 Finian C01 (BT) PDFDocument3 pagesNed-1501 Finian C01 (BT) PDFAm ENo ratings yet

- TS2607P2Document2 pagesTS2607P2Am ENo ratings yet

- TS2607P1Document2 pagesTS2607P1Am ENo ratings yet

- Project Management Principles PDFDocument727 pagesProject Management Principles PDFAm ENo ratings yet

- Pressure Drop Evaluation Along PipelinesDocument11 pagesPressure Drop Evaluation Along PipelinesAm ENo ratings yet

- Methods of Development Paragraph: Name: Khoirur Reza Nim: 19630034 Class: Chemistry CDocument11 pagesMethods of Development Paragraph: Name: Khoirur Reza Nim: 19630034 Class: Chemistry CKhoirur RezaNo ratings yet

- 2024 Grade 11 Stepahead Learner BookDocument60 pages2024 Grade 11 Stepahead Learner Bookjuliaswarts18No ratings yet

- Unwto's EthicsDocument4 pagesUnwto's EthicsBARIBOR SHADRACHNo ratings yet

- Ans. σ = 70 psi; τ = 40.4 psi: ExercisesDocument2 pagesAns. σ = 70 psi; τ = 40.4 psi: ExercisesJasleneDimarananNo ratings yet

- Unit 1 Argumentative EssayDocument5 pagesUnit 1 Argumentative Essayapi-461399602No ratings yet

- Ielts Reading Neuroscientist Reveals How To Think DifferentlyDocument2 pagesIelts Reading Neuroscientist Reveals How To Think DifferentlyYa LiNo ratings yet

- AnalysisDocument8 pagesAnalysisPSGNo ratings yet

- Icp 201 GDocument6 pagesIcp 201 Gwilly wilantaraNo ratings yet

- Insulin Glargine Injection: Active IngredientDocument31 pagesInsulin Glargine Injection: Active Ingredient44abcNo ratings yet

- Mental Hospital Architecture ThesisDocument8 pagesMental Hospital Architecture Thesissabrinahendrickssalem100% (2)

- Pka Determination APIs PDFDocument19 pagesPka Determination APIs PDFPaolo PiccoliniNo ratings yet

- NCERT Solutions For Class 8 English It So Happened The Comet - IIDocument4 pagesNCERT Solutions For Class 8 English It So Happened The Comet - IIsreekumar raghavanNo ratings yet

- Ee101 19BP002 PKG3 e SH SD 001 002 PDFDocument1 pageEe101 19BP002 PKG3 e SH SD 001 002 PDFTalha AltafNo ratings yet

- CS Course List OnlineDocument29 pagesCS Course List OnlineArXlan XahirNo ratings yet

- Estrategias Cognoscitivas y Afectivas de Aprendizaje. Parte (A)Document24 pagesEstrategias Cognoscitivas y Afectivas de Aprendizaje. Parte (A)Stiven Antony Quispe SanchezNo ratings yet

- 12-Physical Science - Module I - LessonDocument6 pages12-Physical Science - Module I - LessonBhea bianca ReyesNo ratings yet

- Section 3-9: Chain Rule: For Problems 1 - 51 Differentiate The Given Function. 1. 2. 3. 4. 5. 6Document5 pagesSection 3-9: Chain Rule: For Problems 1 - 51 Differentiate The Given Function. 1. 2. 3. 4. 5. 6Alglen GeronaNo ratings yet

- Measuring The Knowledge Economy: A National and Organizational PerspectiveDocument23 pagesMeasuring The Knowledge Economy: A National and Organizational Perspectivesarah alanaNo ratings yet

- American Anthropological Association, Wiley American EthnologistDocument4 pagesAmerican Anthropological Association, Wiley American Ethnologistbolontiku9No ratings yet

- Geometry-Unit 1-Lesson 02Document13 pagesGeometry-Unit 1-Lesson 02Jhems ElisNo ratings yet

- ?CCS Template Guide Attachment 3 V2?Document32 pages?CCS Template Guide Attachment 3 V2?Umair HussainNo ratings yet

- A Standardized Approach To Extra-Oral and Intra-Oral Digital PhotographyDocument17 pagesA Standardized Approach To Extra-Oral and Intra-Oral Digital PhotographyCarolina AssisNo ratings yet