Professional Documents

Culture Documents

MT-Lifting Lug

MT-Lifting Lug

Uploaded by

iksan_adityoCopyright:

Available Formats

You might also like

- Msds Pickling Nikko Steel StaincleanDocument5 pagesMsds Pickling Nikko Steel Staincleaniksan_adityo100% (1)

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- Hex Bushing 0,75 X 0,5Document1 pageHex Bushing 0,75 X 0,5Jovianto PrisilaNo ratings yet

- Padle Blank 16-900 RTJDocument1 pagePadle Blank 16-900 RTJJovianto PrisilaNo ratings yet

- Elbow 2-3000 NPTDocument1 pageElbow 2-3000 NPTJovianto PrisilaNo ratings yet

- Elbow 0,5-3000 NPT - OKDocument1 pageElbow 0,5-3000 NPT - OKJovianto PrisilaNo ratings yet

- A0146908 Matrix Ve Ut Insp Yellow Dehydrator 16oct2012Document15 pagesA0146908 Matrix Ve Ut Insp Yellow Dehydrator 16oct2012Madhan KannanNo ratings yet

- Penetrant Test Report: PT DegremontDocument14 pagesPenetrant Test Report: PT DegremontMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- Form Penetrant TestDocument5 pagesForm Penetrant TestAgung PrasetyooNo ratings yet

- Test Manifold Package No:: Client Saudi Aramco Oil CoDocument7 pagesTest Manifold Package No:: Client Saudi Aramco Oil CosarangpuneNo ratings yet

- Elbow 3 S80 180D SRDocument1 pageElbow 3 S80 180D SRJovianto PrisilaNo ratings yet

- Dye Penetrant Testing: Surface PreparationDocument2 pagesDye Penetrant Testing: Surface PreparationyuwantoniNo ratings yet

- Elbow 2 S40 45D LRDocument1 pageElbow 2 S40 45D LRJovianto PrisilaNo ratings yet

- Elbow 6 s40 90d LR - OkDocument2 pagesElbow 6 s40 90d LR - OkJovianto PrisilaNo ratings yet

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- 02,17,18-12-2021 C1 Turbine Coupling (SKF) Bolts - FMPIDocument5 pages02,17,18-12-2021 C1 Turbine Coupling (SKF) Bolts - FMPIDave CheungNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

- 4373898-a-ZWI-SDR06-Needle Valve With Reverse Flow CheckDocument2 pages4373898-a-ZWI-SDR06-Needle Valve With Reverse Flow CheckGaneshkumar Enkili SundarvasanNo ratings yet

- He Mrut 004Document3 pagesHe Mrut 004Hao TranNo ratings yet

- Summary Daily ReportDocument10 pagesSummary Daily Reportdidi sudiNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument1 pageCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- PT InternalDocument1 pagePT Internalwidnu wirasetiaNo ratings yet

- Elbow 12 XS 90D LR - OkDocument1 pageElbow 12 XS 90D LR - OkJovianto PrisilaNo ratings yet

- CNT230045-6 C3 HRSG Blow Down Vessel - ReportDocument5 pagesCNT230045-6 C3 HRSG Blow Down Vessel - ReportDave CheungNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- Threadolet 0,5 X 3 - 4 3000Document1 pageThreadolet 0,5 X 3 - 4 3000Jovianto PrisilaNo ratings yet

- HE-MRUT-001Document3 pagesHE-MRUT-001Hao TranNo ratings yet

- Elbow 8 STD s40 90d LR - OkDocument1 pageElbow 8 STD s40 90d LR - OkJovianto PrisilaNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- CNT230018-5 C3 HRSG LP Drum - UT ReportDocument6 pagesCNT230018-5 C3 HRSG LP Drum - UT ReportDave CheungNo ratings yet

- He Mrut 003Document3 pagesHe Mrut 003Hao TranNo ratings yet

- 1-UT-Pot Shell 588Document2 pages1-UT-Pot Shell 588Azhar GulzarNo ratings yet

- 08-03-24. Water Injection Pump SambojaDocument1 page08-03-24. Water Injection Pump Sambojawahyudi140417No ratings yet

- PT Request (R&R Team)Document1 pagePT Request (R&R Team)Tuấn PhạmNo ratings yet

- Elbow 3 s80 90d LR - OkDocument1 pageElbow 3 s80 90d LR - OkJovianto PrisilaNo ratings yet

- Float Level Switch Specification - AFC-1 (ALL)Document8 pagesFloat Level Switch Specification - AFC-1 (ALL)Phạm Tấn PhướcNo ratings yet

- Report On-Off Valve - HydrolineDocument3 pagesReport On-Off Valve - HydrolinePeerasut ChaisrimaneepanNo ratings yet

- CNT230018-9 C3 HRSG Deaerator Storage Tank - UTreportDocument6 pagesCNT230018-9 C3 HRSG Deaerator Storage Tank - UTreportDave CheungNo ratings yet

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

- FM Opr-E001 Test Report For Insulation ResistanceDocument2 pagesFM Opr-E001 Test Report For Insulation ResistanceAbdul LatifNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesAmit HasanNo ratings yet

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- Elbow 12 STD 90D LR - OkDocument1 pageElbow 12 STD 90D LR - OkJovianto PrisilaNo ratings yet

- 00000-JDS-015 (ERV Manhole) Rev 0Document10 pages00000-JDS-015 (ERV Manhole) Rev 0sithulibraNo ratings yet

- South Yoloten Gas Field Development Turkmenistan: Daily Welding ReportDocument2 pagesSouth Yoloten Gas Field Development Turkmenistan: Daily Welding ReportOctavian PanteaNo ratings yet

- Elbow 4 s40 90d LR - OkDocument1 pageElbow 4 s40 90d LR - OkJovianto PrisilaNo ratings yet

- Feuille Des Donnees Cables F&G: ProjetDocument6 pagesFeuille Des Donnees Cables F&G: ProjetAshraf Ammar100% (1)

- Pt. Gintam Tehnik: InspeksiDocument4 pagesPt. Gintam Tehnik: Inspeksirizky youlandaNo ratings yet

- Magnetic Examination Report: SketchDocument69 pagesMagnetic Examination Report: SketchSeret BroNo ratings yet

- Non Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairDocument3 pagesNon Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairAkhmad RamdaniNo ratings yet

- He Mrut 005Document3 pagesHe Mrut 005Hao TranNo ratings yet

- 12to15,17 & 20-02-2020 C1 Turbine - Purge Air Line & Pipe Ferrule & Bend - PTDocument5 pages12to15,17 & 20-02-2020 C1 Turbine - Purge Air Line & Pipe Ferrule & Bend - PTDave CheungNo ratings yet

- NDT Report - Dovetail WheelsDocument4 pagesNDT Report - Dovetail WheelsOm Ar TanNo ratings yet

- Daily Lrut Report: Lrut Instrument Lrut Probe TechniqueDocument1 pageDaily Lrut Report: Lrut Instrument Lrut Probe TechniqueSang Nguyen QuangNo ratings yet

- He Mrut 002Document3 pagesHe Mrut 002Hao TranNo ratings yet

- Bao Cao PT Ba Ria-04Document4 pagesBao Cao PT Ba Ria-04Sang Nguyen QuangNo ratings yet

- NDT Report - Old.Turbine BearingsDocument3 pagesNDT Report - Old.Turbine BearingsOm Ar TanNo ratings yet

- He Mrut 006Document3 pagesHe Mrut 006Hao TranNo ratings yet

- SWT V 002Document194 pagesSWT V 002iksan_adityoNo ratings yet

- Eze V 002Document37 pagesEze V 002iksan_adityoNo ratings yet

- JSA (Bejana Tekan, Tangki Timbun Dan Ketel Uap)Document16 pagesJSA (Bejana Tekan, Tangki Timbun Dan Ketel Uap)iksan_adityoNo ratings yet

- Kerja Kurang Me Osbl Kec 10122022Document23 pagesKerja Kurang Me Osbl Kec 10122022iksan_adityoNo ratings yet

- Shortage Material Part 3Document7 pagesShortage Material Part 3iksan_adityoNo ratings yet

- List Material Yang Kurang Di BIO2Document9 pagesList Material Yang Kurang Di BIO2iksan_adityoNo ratings yet

- Cutting ReportDocument1 pageCutting Reportiksan_adityoNo ratings yet

- Osbl OutstandingDocument8 pagesOsbl Outstandingiksan_adityoNo ratings yet

- Osbl DiainchDocument5 pagesOsbl Diainchiksan_adityoNo ratings yet

- SMS-602-RT-001 Rev.7 (2020)Document54 pagesSMS-602-RT-001 Rev.7 (2020)iksan_adityoNo ratings yet

- Kerja Kurang Me Osbl L Kec 10122022Document15 pagesKerja Kurang Me Osbl L Kec 10122022iksan_adityoNo ratings yet

- Pre-Commissioning Check List Form (Blanketing Valve)Document15 pagesPre-Commissioning Check List Form (Blanketing Valve)iksan_adityoNo ratings yet

- WWTP Tank 500 MT (T - 7001)Document8 pagesWWTP Tank 500 MT (T - 7001)iksan_adityoNo ratings yet

- Additional Fitting ISBL PolishingDocument10 pagesAdditional Fitting ISBL Polishingiksan_adityoNo ratings yet

- Dia Inch - OSBL Biodiesel Phase II..Document39 pagesDia Inch - OSBL Biodiesel Phase II..iksan_adityoNo ratings yet

- Outstanding OSBLDocument4 pagesOutstanding OSBLiksan_adityoNo ratings yet

- MRD Glc2 Cs Wp8 DD 0002 - Detail & Section Foundation #1 - Ifc.r1 - 280421Document1 pageMRD Glc2 Cs Wp8 DD 0002 - Detail & Section Foundation #1 - Ifc.r1 - 280421iksan_adityoNo ratings yet

- BA 04 - OSBL Line Header Astom Polishing ProjectDocument4 pagesBA 04 - OSBL Line Header Astom Polishing Projectiksan_adityoNo ratings yet

- Delivery ScheduleDocument1 pageDelivery Scheduleiksan_adityoNo ratings yet

MT-Lifting Lug

MT-Lifting Lug

Uploaded by

iksan_adityoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MT-Lifting Lug

MT-Lifting Lug

Uploaded by

iksan_adityoCopyright:

Available Formats

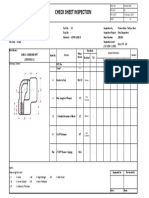

MAGNETIC PARTICLE INSPECTION

Client : PT SMART, Tbk Report No. : 01/MT/PBS-SMART/VII/16

Project : Biodiesel Project Procedure No. : PBS-MT-ASME-01

Location : Marunda

Drawing No. : - Welding Process : GTAW

Material Spec. : SUS-304 Applicable Code : ASME VIII Div.1

Light Meter Type/SN : Lux Meter. SN/: PBS-INV-007 Light Intensity : > 1000 Lux

MT Equipment : √ Yoke Prods Coil Serial No. MPY-1024

Type Current : AC DC HWDC / HWAC √ Others ( Permanent )

Type : Dry √ Wet Fluorescent √ Colour Contrast

Method : √ Continuous Residual

Surface Condition : √ As Welded As Machined As Ground

Time of Examination : √ After Welding After Hydrotest After PWHT Others ( )

Scope of Examination : √ Base Metal Edge Prep. Back Chipping Others ( )

√ Weld part Repair Weld Others

Part / Weld Joint No. Accepted Rejected Type of Discontinuity Remarks

Pressure Vessel Nozzle

S/N: 15T1462

Manway M-01 √ - -

Top Filling Valve N-01 √ - -

Bottom Filling Valve N-02 √ - -

3 Way Divertor Valve N-03 √ - -

Full Trycock Valve N-04 √ - -

Gauge By Pass Valve N-05 √ - - No indication found during

Pressure Gauge N-06 √ - - inspection

Vent Valve N-07 √ - -

Safety Valve N-08 √ - -

Thermal Relief Valve N-09 √ - -

Drain N-10 √ - -

Three Way Valve N-11 √ - -

Sketch

PICTURE

Boompit - 01

PE.03

PE.04

PE.01 PE.02

PE.01 PE.02

PE.03 PE.04

Prepared & Examined by, Witnessed & Approved by,

Client Reps.

IKSAN ADITYO MULYO

Date : July 06, 2016 MT/PT ASNT Lev.II Date : July 06, 2016

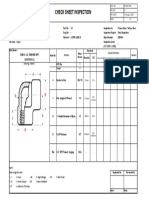

MAGNETIC PARTICLE INSPECTION

Client : PT SMART, Tbk Report No. : 02/MT/PBS-SMART/VII/16

Project : Biodiesel Project Procedure No. : PBS-MT-ASME-01

Location : Marunda

Drawing No. : - Welding Process : GTAW

Material Spec. : SUS-304 Applicable Code : ASME VIII Div.1

Light Meter Type/SN : Lux Meter. SN/: PBS-INV-007 Light Intensity : > 1000 Lux

MT Equipment : √ Yoke Prods Coil Serial No. MPY-1024

Type Current : AC DC HWDC / HWAC √ Others ( Permanent )

Type : Dry √ Wet Fluorescent √ Colour Contrast

Method : √ Continuous Residual

Surface Condition : √ As Welded As Machined As Ground

Time of Examination : √ After Welding After Hydrotest After PWHT Others ( )

Scope of Examination : √ Base Metal Edge Prep. Back Chipping Others ( )

√ Weld part Repair Weld Others

Part / Weld Joint No. Accepted Rejected Type of Discontinuity Remarks

Pressure Vessel Nozzle

S/N: 15T1462

Manway M-01 √ - -

Top Filling Valve N-01 √ - -

Bottom Filling Valve N-02 √ - -

3 Way Divertor Valve N-03 √ - -

Full Trycock Valve N-04 √ - -

Gauge By Pass Valve N-05 √ - - No indication found during

Pressure Gauge N-06 √ - - inspection

Vent Valve N-07 √ - -

Safety Valve N-08 √ - -

Thermal Relief Valve N-09 √ - -

Drain N-10 √ - -

Three Way Valve N-11 √ - -

Sketch

PICTURE

Boompit - 01

PE.03

PE.04

PE.01 PE.02

PE.01 PE.02

PE.03 PE.04

Prepared & Examined by, Witnessed & Approved by,

Client Reps.

IKSAN ADITYO MULYO

Date : July 06, 2016 MT/PT ASNT Lev.II Date : July 06, 2016

Lifting

You might also like

- Msds Pickling Nikko Steel StaincleanDocument5 pagesMsds Pickling Nikko Steel Staincleaniksan_adityo100% (1)

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- Hex Bushing 0,75 X 0,5Document1 pageHex Bushing 0,75 X 0,5Jovianto PrisilaNo ratings yet

- Padle Blank 16-900 RTJDocument1 pagePadle Blank 16-900 RTJJovianto PrisilaNo ratings yet

- Elbow 2-3000 NPTDocument1 pageElbow 2-3000 NPTJovianto PrisilaNo ratings yet

- Elbow 0,5-3000 NPT - OKDocument1 pageElbow 0,5-3000 NPT - OKJovianto PrisilaNo ratings yet

- A0146908 Matrix Ve Ut Insp Yellow Dehydrator 16oct2012Document15 pagesA0146908 Matrix Ve Ut Insp Yellow Dehydrator 16oct2012Madhan KannanNo ratings yet

- Penetrant Test Report: PT DegremontDocument14 pagesPenetrant Test Report: PT DegremontMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- Form Penetrant TestDocument5 pagesForm Penetrant TestAgung PrasetyooNo ratings yet

- Test Manifold Package No:: Client Saudi Aramco Oil CoDocument7 pagesTest Manifold Package No:: Client Saudi Aramco Oil CosarangpuneNo ratings yet

- Elbow 3 S80 180D SRDocument1 pageElbow 3 S80 180D SRJovianto PrisilaNo ratings yet

- Dye Penetrant Testing: Surface PreparationDocument2 pagesDye Penetrant Testing: Surface PreparationyuwantoniNo ratings yet

- Elbow 2 S40 45D LRDocument1 pageElbow 2 S40 45D LRJovianto PrisilaNo ratings yet

- Elbow 6 s40 90d LR - OkDocument2 pagesElbow 6 s40 90d LR - OkJovianto PrisilaNo ratings yet

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- 02,17,18-12-2021 C1 Turbine Coupling (SKF) Bolts - FMPIDocument5 pages02,17,18-12-2021 C1 Turbine Coupling (SKF) Bolts - FMPIDave CheungNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

- 4373898-a-ZWI-SDR06-Needle Valve With Reverse Flow CheckDocument2 pages4373898-a-ZWI-SDR06-Needle Valve With Reverse Flow CheckGaneshkumar Enkili SundarvasanNo ratings yet

- He Mrut 004Document3 pagesHe Mrut 004Hao TranNo ratings yet

- Summary Daily ReportDocument10 pagesSummary Daily Reportdidi sudiNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument1 pageCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- PT InternalDocument1 pagePT Internalwidnu wirasetiaNo ratings yet

- Elbow 12 XS 90D LR - OkDocument1 pageElbow 12 XS 90D LR - OkJovianto PrisilaNo ratings yet

- CNT230045-6 C3 HRSG Blow Down Vessel - ReportDocument5 pagesCNT230045-6 C3 HRSG Blow Down Vessel - ReportDave CheungNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- Threadolet 0,5 X 3 - 4 3000Document1 pageThreadolet 0,5 X 3 - 4 3000Jovianto PrisilaNo ratings yet

- HE-MRUT-001Document3 pagesHE-MRUT-001Hao TranNo ratings yet

- Elbow 8 STD s40 90d LR - OkDocument1 pageElbow 8 STD s40 90d LR - OkJovianto PrisilaNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- CNT230018-5 C3 HRSG LP Drum - UT ReportDocument6 pagesCNT230018-5 C3 HRSG LP Drum - UT ReportDave CheungNo ratings yet

- He Mrut 003Document3 pagesHe Mrut 003Hao TranNo ratings yet

- 1-UT-Pot Shell 588Document2 pages1-UT-Pot Shell 588Azhar GulzarNo ratings yet

- 08-03-24. Water Injection Pump SambojaDocument1 page08-03-24. Water Injection Pump Sambojawahyudi140417No ratings yet

- PT Request (R&R Team)Document1 pagePT Request (R&R Team)Tuấn PhạmNo ratings yet

- Elbow 3 s80 90d LR - OkDocument1 pageElbow 3 s80 90d LR - OkJovianto PrisilaNo ratings yet

- Float Level Switch Specification - AFC-1 (ALL)Document8 pagesFloat Level Switch Specification - AFC-1 (ALL)Phạm Tấn PhướcNo ratings yet

- Report On-Off Valve - HydrolineDocument3 pagesReport On-Off Valve - HydrolinePeerasut ChaisrimaneepanNo ratings yet

- CNT230018-9 C3 HRSG Deaerator Storage Tank - UTreportDocument6 pagesCNT230018-9 C3 HRSG Deaerator Storage Tank - UTreportDave CheungNo ratings yet

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

- FM Opr-E001 Test Report For Insulation ResistanceDocument2 pagesFM Opr-E001 Test Report For Insulation ResistanceAbdul LatifNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesAmit HasanNo ratings yet

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- Elbow 12 STD 90D LR - OkDocument1 pageElbow 12 STD 90D LR - OkJovianto PrisilaNo ratings yet

- 00000-JDS-015 (ERV Manhole) Rev 0Document10 pages00000-JDS-015 (ERV Manhole) Rev 0sithulibraNo ratings yet

- South Yoloten Gas Field Development Turkmenistan: Daily Welding ReportDocument2 pagesSouth Yoloten Gas Field Development Turkmenistan: Daily Welding ReportOctavian PanteaNo ratings yet

- Elbow 4 s40 90d LR - OkDocument1 pageElbow 4 s40 90d LR - OkJovianto PrisilaNo ratings yet

- Feuille Des Donnees Cables F&G: ProjetDocument6 pagesFeuille Des Donnees Cables F&G: ProjetAshraf Ammar100% (1)

- Pt. Gintam Tehnik: InspeksiDocument4 pagesPt. Gintam Tehnik: Inspeksirizky youlandaNo ratings yet

- Magnetic Examination Report: SketchDocument69 pagesMagnetic Examination Report: SketchSeret BroNo ratings yet

- Non Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairDocument3 pagesNon Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairAkhmad RamdaniNo ratings yet

- He Mrut 005Document3 pagesHe Mrut 005Hao TranNo ratings yet

- 12to15,17 & 20-02-2020 C1 Turbine - Purge Air Line & Pipe Ferrule & Bend - PTDocument5 pages12to15,17 & 20-02-2020 C1 Turbine - Purge Air Line & Pipe Ferrule & Bend - PTDave CheungNo ratings yet

- NDT Report - Dovetail WheelsDocument4 pagesNDT Report - Dovetail WheelsOm Ar TanNo ratings yet

- Daily Lrut Report: Lrut Instrument Lrut Probe TechniqueDocument1 pageDaily Lrut Report: Lrut Instrument Lrut Probe TechniqueSang Nguyen QuangNo ratings yet

- He Mrut 002Document3 pagesHe Mrut 002Hao TranNo ratings yet

- Bao Cao PT Ba Ria-04Document4 pagesBao Cao PT Ba Ria-04Sang Nguyen QuangNo ratings yet

- NDT Report - Old.Turbine BearingsDocument3 pagesNDT Report - Old.Turbine BearingsOm Ar TanNo ratings yet

- He Mrut 006Document3 pagesHe Mrut 006Hao TranNo ratings yet

- SWT V 002Document194 pagesSWT V 002iksan_adityoNo ratings yet

- Eze V 002Document37 pagesEze V 002iksan_adityoNo ratings yet

- JSA (Bejana Tekan, Tangki Timbun Dan Ketel Uap)Document16 pagesJSA (Bejana Tekan, Tangki Timbun Dan Ketel Uap)iksan_adityoNo ratings yet

- Kerja Kurang Me Osbl Kec 10122022Document23 pagesKerja Kurang Me Osbl Kec 10122022iksan_adityoNo ratings yet

- Shortage Material Part 3Document7 pagesShortage Material Part 3iksan_adityoNo ratings yet

- List Material Yang Kurang Di BIO2Document9 pagesList Material Yang Kurang Di BIO2iksan_adityoNo ratings yet

- Cutting ReportDocument1 pageCutting Reportiksan_adityoNo ratings yet

- Osbl OutstandingDocument8 pagesOsbl Outstandingiksan_adityoNo ratings yet

- Osbl DiainchDocument5 pagesOsbl Diainchiksan_adityoNo ratings yet

- SMS-602-RT-001 Rev.7 (2020)Document54 pagesSMS-602-RT-001 Rev.7 (2020)iksan_adityoNo ratings yet

- Kerja Kurang Me Osbl L Kec 10122022Document15 pagesKerja Kurang Me Osbl L Kec 10122022iksan_adityoNo ratings yet

- Pre-Commissioning Check List Form (Blanketing Valve)Document15 pagesPre-Commissioning Check List Form (Blanketing Valve)iksan_adityoNo ratings yet

- WWTP Tank 500 MT (T - 7001)Document8 pagesWWTP Tank 500 MT (T - 7001)iksan_adityoNo ratings yet

- Additional Fitting ISBL PolishingDocument10 pagesAdditional Fitting ISBL Polishingiksan_adityoNo ratings yet

- Dia Inch - OSBL Biodiesel Phase II..Document39 pagesDia Inch - OSBL Biodiesel Phase II..iksan_adityoNo ratings yet

- Outstanding OSBLDocument4 pagesOutstanding OSBLiksan_adityoNo ratings yet

- MRD Glc2 Cs Wp8 DD 0002 - Detail & Section Foundation #1 - Ifc.r1 - 280421Document1 pageMRD Glc2 Cs Wp8 DD 0002 - Detail & Section Foundation #1 - Ifc.r1 - 280421iksan_adityoNo ratings yet

- BA 04 - OSBL Line Header Astom Polishing ProjectDocument4 pagesBA 04 - OSBL Line Header Astom Polishing Projectiksan_adityoNo ratings yet

- Delivery ScheduleDocument1 pageDelivery Scheduleiksan_adityoNo ratings yet