Professional Documents

Culture Documents

Saic Ut 2010

Saic Ut 2010

Uploaded by

Arjun RawatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic Ut 2010

Saic Ut 2010

Uploaded by

Arjun RawatCopyright:

Available Formats

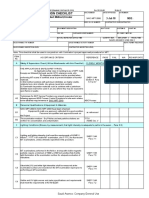

SAUDI ARAMCO ID/PIEU-31-December-2018 - REV.2018.12.00 (Standards Cutoff - December 31,2018) Rev.2018.12.

00 31-Dec-18

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Manual UT Thickness Testing SAIC-UT-2010 04-Mar-19 NDE-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General

UT Thicknes testing procedure incorporates all the requirements of Approved NDT

A1

SAEP-1146 and is approved by Inspection department. Procedure

UT Technecians are certified for UT Thickness Gauging.

Note: Limited Certifications in techniques would require at least half SAEP-1142 Para

A2

of the training hours(40 Hrs) and experience(400 Hrs) required for 7.1

UT Level II certifications. (SAEP-1142 Para 7.1)

Ultrasonic thickness testers used are from the Saudi Aramco

approved equipment list. UTT instrument shall have an A-scan SAEP-1146

A3 display to assist the operator in discrimination of test results. Para

Note: Contact Saudi Aramco NDT Unit Supervisor for the most 5.1

recent Approved Equipment List.

Transducers shall be selected considering the surface temperature,

expected thickness of the specimen and the resolution required. SAEP-1146

A4 Digital thickness meters with A-scan presentation shall use only Para

manufacturer's provided transducers. 5.2

Calibration Blocks shall have a sound velocity within ± 5% of the

SAEP-1146

material to be tested.

A5 Para

Note: Use of SAMMS 4340 material is acceptable for most carbon

5.3

and stainless steel applications.

Couplant shall have chemical compatibility with the surface and the

SAEP-1146

temperature of the specimen and shall not be detrimental to the

A6 Para

material being examined.

5.4

B CALIBRATION

UT equipment shall be calibrated at beginning and end of each shift,

every four hours during the examination, when examination SAEP-1146

B1 personnel are changed, any equipment is changed & any time that Para

malfunctioning is suspected. 6.1

UT equipment shall be calibrated using a two-point calibration range

that overlaps the expected measurement range, i.e., select a SAEP-1146

calibration block or step wedge thickness value greater than the Para

B2 maximum expected measurement value and a calibration block or 6.3

step wedge value less than the expected measurement value. &

All calibration values shall be within ± 0.002 inch of the known Para 6.5

thickness value.

SAEP-1146

Button-type calibration blocks, on the front of some ultrasonic

B3 Para

thickness gauges, shall not be used for calibration.

6.7

Saudi Aramco: Company General Use

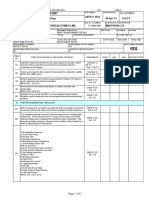

C EXAMINATION/INTERPRETATION

The test area shall be free of corrosion, insulation, weld spatter,

surface irregularities, or foreign matter that might interfere with the SAEP-1146

examination. Where coatings interfere with the examination, the Para

C1 coating shall be removed and recorded. 7.1.1

Note: Many corrosion-monitoring applications require readings to be To

taken in the same condition, i.e., coated, as when originally Para 7.1.3

measured.

The surface temperature below 32°F (0°C) or above 215°F (101°C),

shall be measured and recorded.

Temperature correction shall be performed for metal thickness

greater than 1 inch for temperatures below 32°F and over 215°F.

SAEP-1146

Following formula shall be used:

C2 Para

Ta = Tm x [1.007 – (0.0001 x Temp)] (1)

7.2.2 & 7.2.8

Where:

Ta = the actual thickness of the part

Tm = measured thickness of the part

Temp = surface temperature in °F

The transducer acoustic barrier shall be placed perpendicular to the

center axis when taking measurements on pipe or round objects up

SAEP-1146

to 24 inches in diameter. The acoustic barrier orientation is not

C3 Para

important on pipe and round objects greater than 24 inches in

7.2.4

diameter

SAEP-1146

The transducer shall be held flat on the surface then slowly rocked

Para

tangentially after contact to find the lowest reading.

C4 7.2.5

A valid reading is one that can be maintained on the gauge display

&

for several seconds and the value is steady within ± 0.002 inch.

Para 7.2.6

SAEP-1146

Thickness readings shall be measured and recorded to three

C5 Para

decimal places.

7.2.7

The transducer face shall be cleaned before each measurement at SAEP-1146

C6 temperatures greater than 400°F as evaporated couplant can leave Para

deposits on the transducer face. 7.2.9

UT examinations results shall include the variables specified in SAEP-1146

C7 SAEP-1146 Para 9.1 and it shall be recorded on test report Para

approved in UT procedure. 9.1

REMARKS:

REFERENCE DOCUMENTS:

1. SAEP-1146 -- Manual Ultrasonic Thickness Testing (09 July 2014)

2. SAEP-1142--Qualification of Non-Saudi Aramco NDT Personnel (4 Dec. 2014)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Easy Drive GT20manualV1.1Document102 pagesEasy Drive GT20manualV1.1Musa inverter HouseNo ratings yet

- Saudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand TestingDocument10 pagesSaudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand Testingkarthi51289No ratings yet

- Control Plan AIAGDocument1 pageControl Plan AIAGAhmad Firdaus100% (1)

- Class Annual Survey ChecklistDocument20 pagesClass Annual Survey ChecklistMayank Handa100% (1)

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 ElectDocument7 pagesSaudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 Electkarthi51289No ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Approximate RT Calculation For API 650 TankDocument2 pagesApproximate RT Calculation For API 650 Tankjayaarnav100% (6)

- Yoke Calibration ProcedureDocument1 pageYoke Calibration ProcedureArjun Rawat100% (3)

- Angle Beam Trig Calculations - Ultrasonic TestingDocument3 pagesAngle Beam Trig Calculations - Ultrasonic TestingArjun Rawat100% (3)

- Introduction To Derivatives and Risk Management 10th Edition Chance Test BankDocument8 pagesIntroduction To Derivatives and Risk Management 10th Edition Chance Test BankMavos OdinNo ratings yet

- Practice Questions - Continuous DistributionsDocument19 pagesPractice Questions - Continuous DistributionsSony GuptaNo ratings yet

- Financial Analysis of Fauji Cement LTDDocument27 pagesFinancial Analysis of Fauji Cement LTDMBA...KIDNo ratings yet

- Satr-P-3218 Rev 3Document9 pagesSatr-P-3218 Rev 3Parag WadekarNo ratings yet

- Satr-P-3217 Rev 3Document4 pagesSatr-P-3217 Rev 3Parag WadekarNo ratings yet

- Saudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 Electkarthi51289No ratings yet

- SATR-P-3825 LV Panelboard - Pre-Energized TestingDocument4 pagesSATR-P-3825 LV Panelboard - Pre-Energized TestingheikelNo ratings yet

- Saudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 Electkarthi51289No ratings yet

- Satr-P-3220 Rev 3Document8 pagesSatr-P-3220 Rev 3Parag WadekarNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection 0f Direct Contact Method (Circular Magnetization Technique)Document8 pagesSaudi Aramco Inspection Checklist: In-Process Inspection 0f Direct Contact Method (Circular Magnetization Technique)karthi51289No ratings yet

- Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Electkarthi51289No ratings yet

- SATR-X-3204 Rev 7Document9 pagesSATR-X-3204 Rev 7mustafa abdelshafiNo ratings yet

- Saudi Aramco Test Report: External Tank Bottom Testing 3-Jul-18 CP-SATR-X-3204Document7 pagesSaudi Aramco Test Report: External Tank Bottom Testing 3-Jul-18 CP-SATR-X-3204karthi51289No ratings yet

- Saudi Aramco Test ReportDocument10 pagesSaudi Aramco Test Reportkarthi51289100% (1)

- Saudi Aramco Inspection Checklist: Inspection & Verification of MPT Equipment & Materials SAIC-MPT-2003 3-Jul-18 NdeDocument6 pagesSaudi Aramco Inspection Checklist: Inspection & Verification of MPT Equipment & Materials SAIC-MPT-2003 3-Jul-18 Ndekarthi51289No ratings yet

- Saudi Aramco Test Report: Plant Potential Survey Testing 3-Jul-18 CP-SATR-X-3203Document10 pagesSaudi Aramco Test Report: Plant Potential Survey Testing 3-Jul-18 CP-SATR-X-3203karthi51289No ratings yet

- SATR-X-3205 Rev 7Document8 pagesSATR-X-3205 Rev 7mustafa abdelshafiNo ratings yet

- SAIC-A-2023 Rev 6 Prssure Test Air GasDocument5 pagesSAIC-A-2023 Rev 6 Prssure Test Air Gaspookkoya thangalNo ratings yet

- Saudi Aramco Test Report: Plant Potential Survey Testing 24-Jul-18 CP-SATR-X-3203Document10 pagesSaudi Aramco Test Report: Plant Potential Survey Testing 24-Jul-18 CP-SATR-X-3203nadeem shaikhNo ratings yet

- Satr P 3206Document6 pagesSatr P 3206munnaNo ratings yet

- Satr-P-3216 Rev 3Document4 pagesSatr-P-3216 Rev 3Parag WadekarNo ratings yet

- SAIC A 1005 Compaction TestDocument3 pagesSAIC A 1005 Compaction TestAbdul HannanNo ratings yet

- Saudi Aramco Test Report: DC Cable Holiday Testing 3-Jul-18 CP-SATR-X-3201Document3 pagesSaudi Aramco Test Report: DC Cable Holiday Testing 3-Jul-18 CP-SATR-X-3201karthi51289No ratings yet

- Saic A 1005Document2 pagesSaic A 1005Ansar Ali VemmullyNo ratings yet

- Saic-A-1005 Compaction TestingDocument2 pagesSaic-A-1005 Compaction TestingZia ur Rehman100% (1)

- Saudi Aramco Test Report: Internal Tank Bottom Testing 30-Oct-17 CP-SATR-X-3205Document8 pagesSaudi Aramco Test Report: Internal Tank Bottom Testing 30-Oct-17 CP-SATR-X-3205Tayyab AchakzaiNo ratings yet

- SATR-X-3202 Rev 7Document9 pagesSATR-X-3202 Rev 7mustafa abdelshafiNo ratings yet

- Saudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116karthi51289No ratings yet

- Satr-P-3206 LV Cable TerminationDocument5 pagesSatr-P-3206 LV Cable TerminationSurendren RNo ratings yet

- Saudi Aramco Test Report: DC Cable Holiday Testing 24-Jul-18 CP-SATR-X-3201Document3 pagesSaudi Aramco Test Report: DC Cable Holiday Testing 24-Jul-18 CP-SATR-X-3201nadeem shaikhNo ratings yet

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJagdishNo ratings yet

- SATR-X-3203 Rev 7Document10 pagesSATR-X-3203 Rev 7Rohit BassNo ratings yet

- Saic A 1005Document3 pagesSaic A 1005Naushad AlamNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPnadeem shaikhNo ratings yet

- MRT and Performance Test Visit ReportDocument9 pagesMRT and Performance Test Visit Reportamit kumarNo ratings yet

- QCR W 2004Document6 pagesQCR W 2004Madhan KannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistMuhammadNo ratings yet

- Saudi Aramco Test Report: External Tank Bottom Testing 24-Jul-18 CP-SATR-X-3204Document7 pagesSaudi Aramco Test Report: External Tank Bottom Testing 24-Jul-18 CP-SATR-X-3204nadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 24-Jul-18 CPDocument3 pagesSaudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 24-Jul-18 CPnadeem shaikhNo ratings yet

- SAIC-RT-2004 Verify RT EquipmtDocument3 pagesSAIC-RT-2004 Verify RT EquipmtKirubhakarPooranamNo ratings yet

- Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ElectDocument5 pagesSaudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Document7 pagesSaudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Sreni Excel MacrosNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPkarthi51289No ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPAwais NaeemNo ratings yet

- SB1345Document7 pagesSB1345Yarisa VangeNo ratings yet

- SAIC-L-2095 Rev 7Document6 pagesSAIC-L-2095 Rev 7Jaseel KanhirathingalNo ratings yet

- Saudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116zhangNo ratings yet

- Saudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 15-Jul-18 CPDocument3 pagesSaudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 15-Jul-18 CPSreni Excel MacrosNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Rauf ChaudharyNo ratings yet

- Saudi Aramco Test Report: DC Rectifier Testing 3-Jul-18 CP-SATR-X-3202Document7 pagesSaudi Aramco Test Report: DC Rectifier Testing 3-Jul-18 CP-SATR-X-3202karthi51289No ratings yet

- Hardness Test Procedure: 1 of 8 DE3511.006/EDocument8 pagesHardness Test Procedure: 1 of 8 DE3511.006/Esalman1111aNo ratings yet

- Saudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202Document7 pagesSaudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202nadeem shaikhNo ratings yet

- Saudi Aramco Test Report: High Voltage Power Cable, Termination Torque Testing SATR-P-3213 3-Jul-18 ElectDocument5 pagesSaudi Aramco Test Report: High Voltage Power Cable, Termination Torque Testing SATR-P-3213 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 3-Jul-18 CPDocument3 pagesSaudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 3-Jul-18 CPkarthi51289No ratings yet

- Saic A 1005.Document3 pagesSaic A 1005.Shazab NawazNo ratings yet

- Saudi Aramco Test Report: DC Rectifier Testing CP-SATR-X-3202Document8 pagesSaudi Aramco Test Report: DC Rectifier Testing CP-SATR-X-3202Yehia FelifelNo ratings yet

- Saic Q 1060Document3 pagesSaic Q 1060Arjun RawatNo ratings yet

- Saes-A-207 (2018)Document20 pagesSaes-A-207 (2018)Arjun RawatNo ratings yet

- Comparison Between EN and ASMEDocument6 pagesComparison Between EN and ASMEArjun RawatNo ratings yet

- Saes-A-208 (2018)Document14 pagesSaes-A-208 (2018)Arjun RawatNo ratings yet

- SAEP-1141 Radiation Protection For Industrial Radiography (2018)Document61 pagesSAEP-1141 Radiation Protection For Industrial Radiography (2018)Arjun Rawat100% (1)

- ASME P NumbersDocument2 pagesASME P NumbersArjun RawatNo ratings yet

- ASME BPVC-Section V: Key Changes 2019 EditionDocument7 pagesASME BPVC-Section V: Key Changes 2019 EditionArjun RawatNo ratings yet

- Summary of Changes BPVC-V 2015 Edition ItemsDocument3 pagesSummary of Changes BPVC-V 2015 Edition ItemsArjun RawatNo ratings yet

- TWI CSWIP Study GuideDocument247 pagesTWI CSWIP Study GuideArjun RawatNo ratings yet

- Bangladesh Bank HistoryDocument5 pagesBangladesh Bank HistoryzonayetgaziNo ratings yet

- Platinum Weekly - 03 March 2023 - Rustenburg NewspaperDocument56 pagesPlatinum Weekly - 03 March 2023 - Rustenburg NewspaperSarah LombardNo ratings yet

- Thermocompressor Efficiency & PerformanceDocument4 pagesThermocompressor Efficiency & PerformancerifqizafrilNo ratings yet

- The Verb Have GotDocument2 pagesThe Verb Have GotIsabel Dias100% (1)

- Communication PlanDocument5 pagesCommunication PlanErnani Moveda FlorendoNo ratings yet

- An Investigation Into The Shear Strength of Rock DiscontinuityDocument6 pagesAn Investigation Into The Shear Strength of Rock DiscontinuityAzeNo ratings yet

- Seismic Study of Building With Roof Top Telecommunication TowersDocument4 pagesSeismic Study of Building With Roof Top Telecommunication TowersSyed Ehtesham aliNo ratings yet

- 3 Republic Vs BayaoDocument3 pages3 Republic Vs BayaoWendell Leigh Oasan100% (1)

- Mindray BC-2800 - Service ManualDocument108 pagesMindray BC-2800 - Service ManualAvilianaK.Bintari80% (5)

- Mark Scheme (Results) Summer 2015Document12 pagesMark Scheme (Results) Summer 2015NourNo ratings yet

- CLM TutorialDocument18 pagesCLM Tutorialrico.caballero7No ratings yet

- Final - Road EstimateDocument8 pagesFinal - Road EstimateshakibNo ratings yet

- MM - Assignment Bajaj QuteDocument4 pagesMM - Assignment Bajaj QuteVasudev AcharNo ratings yet

- Overview SRI Shamshiri Et Al May 2018-With-cover-page-V2Document17 pagesOverview SRI Shamshiri Et Al May 2018-With-cover-page-V2micowanNo ratings yet

- H05V-U (Yse) / H05V-K (Ysf)Document21 pagesH05V-U (Yse) / H05V-K (Ysf)Ademir DzanicNo ratings yet

- Eng Cressi Manu 03842Document7 pagesEng Cressi Manu 03842Marin PintarNo ratings yet

- Bafpres Chapter 9Document6 pagesBafpres Chapter 9Jenina Rose SalvadorNo ratings yet

- Gabriel v. PangilinanDocument2 pagesGabriel v. PangilinanMit SkroNo ratings yet

- Phil. Export v. VP EusebioDocument2 pagesPhil. Export v. VP EusebioCZARINA ANN CASTRONo ratings yet

- BH120F - Royal CruiserDocument6 pagesBH120F - Royal CruiserPhilippine Bus Enthusiasts SocietyNo ratings yet

- Legal Ethics Syllabus CompleteDocument4 pagesLegal Ethics Syllabus CompletejessieNo ratings yet

- The Contractor's Liability For Workmanship and Design - Is It A Matter of Competence or Status?Document13 pagesThe Contractor's Liability For Workmanship and Design - Is It A Matter of Competence or Status?Albert NicanorNo ratings yet

- 91397502Document252 pages91397502FyysTé SîMôNo ratings yet

- Data Quality SalesforceDocument190 pagesData Quality SalesforceLariNo ratings yet