Professional Documents

Culture Documents

Opgw - 24g652-Ast-177 (69.8 - 256.7)

Opgw - 24g652-Ast-177 (69.8 - 256.7)

Uploaded by

pedro torresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Opgw - 24g652-Ast-177 (69.8 - 256.7)

Opgw - 24g652-Ast-177 (69.8 - 256.7)

Uploaded by

pedro torresCopyright:

Available Formats

A November 6, 2018 Rocky Lemon Felix

Version Date Prepared Reviewed Approved

1. GENERAL

1.1 SCOPE

This specification covers Optical Ground Wire Cables (OPGW) for the installation on high

voltage overhead power lines. The cable contains optical fibers for data transmission and

telecom purposes and is installed instead of a ground wire.

The specification describes the basic design of an OPGW-cable with its main components: the

fibers, the optical fiber unit and the cable armoring. Furthermore this specification contains

information concerning the quality assurance during manufacturing, the final acceptance tests,

the type tests and the packaging. Any technical data mentioned in this product specification

serve for describing the product only and should not be understood as an assurance of

properties.

1.2 Cable Description

Cable which has the dual performance functions of a conventional ground wire with

telecommunication capabilities.

1.3 Quality

ZTT ensures a continuing level of quality in our cable products through several quality control

programs including ISO 9001.

1.4 Reliability

ZTT ensures product reliability through rigorous qualification testing of each product family. Both

initial and periodic qualification testing are performed to assure the cable's performance and

durability in the field environments.

1.5 Reference

The cable which ZTT offered are designed, manufactured and tested according to international

standards as follows:

IEC 60793-1 Optical fiber Part 1: Generic specifications

IEC 60793-2 Optical fiber Part 2: Product specifications

ITU-T G.652 Characteristics of a single-mode optical fiber cable

Characteristics of a non-zero dispersion-shifted single-mode optical fiber and

ITU-T G.655

cable

EIA/TIA 598 B Color code of fiber optic cables

Aerial optical cables along electrical

IEC 60794-4-10

power lines – Family specification for OPGW

Optical fiber cables-Part 1-2: Generic specification-Basic optical cable test

IEC 60794-1-2

procedures

IEEE Standard for testing and performance for optical ground wire (OPGW) for

IEEE1138-2009

use on electric utility power lines

IEC 61232 Aluminum – clad steel wire for electrical purposes

IEC 60104 Aluminum magnesium-silicon alloy wire for overhead line conductors

IEC 61089 Round wire concentric lay overhead electrical stranded conductors

All Rights Reserved Copyright © 2018 Page 1

2. OPTICAL FIBER

The optical fiber is made of high pure silica and germanium doped silica. UV curable acrylate

material is applied over fiber cladding as optical fiber primary protective coating. The detail data of

optical fiber performance are shown in the following table.

Optical fiber uses special spun device successfully controlled the value of PMD, and makes sure

that it can keep stable in cabling.

G.652D Fiber in cable

Specifications

Category Description

After cabling

Attenuation @1310 nm ≤0.36 dB/km

Attenuation @1550 nm ≤0.22 dB/km

Zero Dispersion Wavelength 1300~1324 nm

Zero Dispersion Slope 0.073~ 0.092 ps/nm2∙km

Optical

PMD Link value ≤0.2 ps/√km

Specifications

Cable Cutoff Wavelength (λcc) ≤1260 nm

Macro bending Loss

(100 turns; Ф50 mm) @1550 nm ≤ 0.05 dB

(100 turns; Ф50 mm) @1625 nm ≤ 0.10 dB

Mode Field Diameter @1310 nm 9.2±0.4μm

Cladding Diameter 125 ±0.7μm

Dimensional

Core/clad concentricity error ≤0.6μm

Specifications

Cladding Non-Circularity ≤1%

Mechanical

Proof stress ≥0.69Gpa

Specifications

All Rights Reserved Copyright © 2018 Page 2

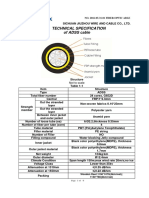

3. CABLE STRUCTURAL DRAWING

Serial No: ZTT18-91938

OPGW Cable Specifications Bid No: OPGW

ZhongTian

Cable Type: OPGW - 24G652-AST-177 [69.8;256.7]

AS wire

Optical fibers and Gel

SUS tube

AL-covered layer

AA wire

Material No Material No. Material Dia.

Fiber G.652 24

OPGW SUS Tube SUS 1

Structure AL-tube 1 Inner-Dia. 3.20 Outer-Dia. 6.80 mm

Layer1 20.3%AS wire 5 AA wire 6 Diameter 2.60 mm

Layer2 AA wire 17 Diameter 2.60 mm

according to IEC60794-4-1, IEEE-1138 standards

Stranding direction of outer layer is right hand(Z-Stranding)

Cable Diameter 17.20 mm

Cable Weight 610 kg/km

Supporting Cross Section 176.9 mm2

Section of AS Wire 26.55 mm2

Section of AA Wire 122.11 mm2

Section of Al Tube 28.28 mm2

Rated Tensile Strength (RTS) 69.8 kN

Technical Data Modulus of Elasticity (E-Modulus) 78.1 kN/mm2

Thermal Elongation Coefficient 19.9 ×10-6/℃

Permissible Maximum Working Stress (40% RTS) 157.8 N/mm2

Everyday Stress(EDS) (16%~25% RTS) 63.1 ~98.6 N/mm2

DC Resistance 0.200 Ω/km

Short Time Current ( 1s ) 16.0 kA

2

Short Time Current Capacity I (50℃~200℃)

t 256.7 kA2S

Minimum Bending Radius: Installation: 344 mm

Operating: 258 mm

Temperature Installation -10℃ ~ +50 ℃

Range: Transportation and Operation -40℃ ~ +80 ℃

Remarks: All Sizes and Values are Nominal Values

Diameter Tolerance: ±1%; Weight Tolerance: ±2%;

Rev. ZECT-TD 20-2008Designer Rocky shen Authorized Lemon lu 2018/11/6

All Rights Reserved Copyright © 2018 Page 3

4. COLOR IDENTIFICATION OF FIBER IN OPGW

4.1 Color code of fiber in OPGW shall be identified referring to the following table:

Typical number of fiber: 24

Remark Fiber No. & Color

1 2 3 4 5 6

Blue Orange Green Brown Gray White

Without Color Ring

7 8 9 10 11 12

Red Nature Yellow Violet Pink Aqua

13 14 15 16 17 18

With S150 Color Blue Orange Green Brown Gray White

Ring 19 20 21 22 23 24

Red Nature Yellow Violet Pink Aqua

Color ring method:

S150:Use single black color ring on the fiber surface with 150mm alternation:

150mm 2.0mm

All Rights Reserved Copyright © 2018 Page 4

5. TEST REQUIREMENTS FOR OPGW

5.1 General

There are different test series to assure the quality of OPGW:

Routine test (in–process testing according to internal quality plan)

Factory acceptance test (FAT, witnessed by customer)

Type test (only in case of a basic new design, repetition in exceptional cases)

OPGW tests shall be in accordance with applicable standards or agreements between purchaser

and manufacturer.

As a general rule the tests will be performed according IEC 60794-4-10.However, if necessary

tests can be done according to IEEE Std1138.

Type test

Type test may be waived by submitting maker’s certificate of the similar product performed in an

internationally acknowledged independent test organization or laboratory. If type test should be

performed, it will be carried out according to an extra type test procedure reached to an

agreement between purchaser and manufacturer.

Routine test

The optical attenuation coefficient on all production cable lengths is measured according to IEC

60793-1-CIC (Back-scattering technique, OTDR). Standard single-mode fibers are measured at

1310nm and at 1550nm. Non-zero dispersion shifted single–mode (NZDS) fibers are measured

at 1550nm.

Factory test

Factory acceptance test is carried out on one sample per order in the presence of the customer

or his representative. The requirements for quality characteristics are determined by relevant

standards and agreed quality plans.

5.2 Test items

The following table shows that the test items will be carried out according to corresponding

references.

All Rights Reserved Copyright © 2018 Page 5

Routine FAT Type Test Test Procedure

Test on fibers

Mode field diameter IEC 60793-1-45

Geometric parameter IEC 60793-1-20

Attenuation (OTDR) ● ● IEC 60793-1-40

Chromatic dispersion IEC 60793-1-42

Cut-off wavelength (cable cut off) IEC 60793-1-44

Test on wires before stranding

Diameter ● ● IEC61232/ IEC60104

Tensile strength ● ● IEC61232/ IEC60104

Stress at 1% extension(Only ACS wire) ● ● IEC61232

Elongation at break ● ● IEC61232/ IEC60104

Wrapping test(Only AA wire) ● ● IEC60104

Conductivity ● ● IEC61232/ IEC60104

Thickness of Al-cladding (Only ACS wire) ● ● IEC61232

Torsion test (Only ACS wire) ● ● IEC61232

Tests on OPGW

Quality of surface ● ● IEC 60794-4-10

Direction of lay outer ● ● IEC 60794-4-10

Lay length ● ● IEC 60794-4-10

Diameter of cable ● ● IEC 60794-4-10

Weight of Cable ● ● IEC 60794-4-10

DC-resistance ● IEC 60794-4-10

Breaking strength test ● ● IEC 60794-4-10

Stress Strain Test ● IEC 60794-4-10

Tensile performance test ● IEC 60794-4-10

Sheave test ● IEC 60794-4-10

Aeolian vibration simulation ● IEC 60794-4-10

Galloping test ● IEC 60794-4-10

Creep test ● IEC 60794-4-10

Temperature cycle test ● IEC 60794-4-10

Water penetration ● IEC 60794-4-10

Short circuit current test ● IEC 60794-4-10

Lightning test ● IEC 60794-4-10

Notes: The mark “●” means different test items which belong to different test series.

All Rights Reserved Copyright © 2018 Page 6

6. PACKING AND DRUM

OPGW shall be wound round a non-returnable wooden drum or iron-wooden drum. Both ends of

OPGW shall be securely fastened to drum and sealed with a shrinkable cap. The required

marking shall be printed with a weatherproof material on the outsides of drum according to

customer’s requirement.

Outside diameter

Inside diameter

Wooden

Wooden strip seal

Iron

Inner tub

Iron

Drum diameter

Arbor hole

Iron

Flange diameter

D

d

b

B A

All Rights Reserved Copyright © 2018 Page 7

Drum Dimensions & Weights

Cable Diameter Drum Length

D b B d A weight

(mm) (m)

cm cm cm cm cm kg

2000 140 90 110 80 10.5±0.5 190

3000 150 90 110 80 10.5±0.5 220

17.0-17.5

4000 180 90 110 90 10.5±0.5 300

5000 180 90 110 90 10.5±0.5 330

All Rights Reserved Copyright © 2018 Page 8

You might also like

- CMXC007 Upgrade Kit ManualDocument97 pagesCMXC007 Upgrade Kit ManualJESUSCALVILLONo ratings yet

- 2.3 Cable de Guardia - OPGW SPEC (15-53931)Document9 pages2.3 Cable de Guardia - OPGW SPEC (15-53931)xcazor morayNo ratings yet

- Alpha HoistsDocument2 pagesAlpha HoistsminakirolosNo ratings yet

- OPGWDocument18 pagesOPGWGuilhermeNo ratings yet

- ZTT OPGW 21-116750 DatasheetDocument9 pagesZTT OPGW 21-116750 DatasheetMalik Shoaib khalidNo ratings yet

- ZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CDocument9 pagesZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CGiancarlos OliveraNo ratings yet

- ZTT Opgw 23-XJ25012Document8 pagesZTT Opgw 23-XJ25012miperNo ratings yet

- ZTT Opgw 19 95588 72FDocument10 pagesZTT Opgw 19 95588 72FmiperNo ratings yet

- Specs ZTT OPGW 24 Fibers PDFDocument9 pagesSpecs ZTT OPGW 24 Fibers PDFVictor DoyoganNo ratings yet

- Spe For Opgw 48F IndiaDocument9 pagesSpe For Opgw 48F IndiaMahesh GKNo ratings yet

- Technical Specification: Optical Ground WireDocument9 pagesTechnical Specification: Optical Ground WireMiftahul KhairNo ratings yet

- Opgw-12b1-48 (62.7 12.7)Document9 pagesOpgw-12b1-48 (62.7 12.7)Palle YulianNo ratings yet

- Norway OPGW DUAL TUBE 96 G.652D-13.9mm 26042018Document5 pagesNorway OPGW DUAL TUBE 96 G.652D-13.9mm 26042018satyam_scribdNo ratings yet

- 24 Fiber OPGW ANDES PDFDocument7 pages24 Fiber OPGW ANDES PDFMAN TNo ratings yet

- OPGW-24B1.3-105 (58 100.0) ITU-TG.652.D Fibers: Characteristics of Cable Cable Construction and ParameterDocument5 pagesOPGW-24B1.3-105 (58 100.0) ITU-TG.652.D Fibers: Characteristics of Cable Cable Construction and ParameterAdanNo ratings yet

- Saixin-72 SMF OPGW Technique Data SheetDocument4 pagesSaixin-72 SMF OPGW Technique Data SheetmiperNo ratings yet

- Saixin-96 SMF OPGW Technique Data sheet0621REV1Document2 pagesSaixin-96 SMF OPGW Technique Data sheet0621REV1miperNo ratings yet

- ZTT AdssDocument9 pagesZTT AdssJose GonzalesNo ratings yet

- OFC 24G.652D SSF S1 Fig.8 HDPE DatasheetDocument8 pagesOFC 24G.652D SSF S1 Fig.8 HDPE Datasheetmahadi_prasetyawanNo ratings yet

- Cable Drop Huawei b.5.11 HW Gjyxfch-1,2b6aDocument6 pagesCable Drop Huawei b.5.11 HW Gjyxfch-1,2b6aEvelyn TorrezNo ratings yet

- Fiche TechniqueDocument4 pagesFiche Techniquew6bdkmng4zNo ratings yet

- YOFC DataSaheet de ADSS Cable-All Dry ADSS Cable - 100m 200m Span Single JacketDocument8 pagesYOFC DataSaheet de ADSS Cable-All Dry ADSS Cable - 100m 200m Span Single JacketEstefany Murga LauraNo ratings yet

- OFC 1G.652D Drop Cable LSZH 400N DatasheetDocument8 pagesOFC 1G.652D Drop Cable LSZH 400N DatasheetAnanggadhipa Sedyanto PutroNo ratings yet

- Multicom Armored Specs - MDocument8 pagesMulticom Armored Specs - Mnaseem AhamdNo ratings yet

- Cable Fo Huawei b.5.10 HW Adss-Pe-24,120 b1.3 (80m)Document7 pagesCable Fo Huawei b.5.10 HW Adss-Pe-24,120 b1.3 (80m)Evelyn TorrezNo ratings yet

- Norway OPGW DAB 48E9 (AA ACS 0 88) DUAL TUBE - 13.8 MMDocument5 pagesNorway OPGW DAB 48E9 (AA ACS 0 88) DUAL TUBE - 13.8 MMAHMED YOUSEFNo ratings yet

- TechnicalSpecification OPGW-24G652DDocument6 pagesTechnicalSpecification OPGW-24G652DMrugesh Samsung.m31sNo ratings yet

- Caract Tecnicas Opgw Lsgs-11-Po0186 24sDocument4 pagesCaract Tecnicas Opgw Lsgs-11-Po0186 24sKamal ArreazaNo ratings yet

- PBT Opgw CableDocument7 pagesPBT Opgw CableChristian CastroNo ratings yet

- Corrigendum2 PDFDocument197 pagesCorrigendum2 PDFBhuvan BajajNo ratings yet

- Lpfig8a22c 2KMDocument5 pagesLpfig8a22c 2KMrgear18No ratings yet

- ZTT ADSS 96-8T Span100 Icon+Document8 pagesZTT ADSS 96-8T Span100 Icon+Frank GonrongNo ratings yet

- Nextramicro 24 48 72 96 144 192 216 288 432 576G652DDocument8 pagesNextramicro 24 48 72 96 144 192 216 288 432 576G652Dgeorgeta.dumitrache50No ratings yet

- Wind GGGGGGGGGGDocument13 pagesWind GGGGGGGGGGKarthikeyan PanchatcharamNo ratings yet

- 72F-Non Metallic Duct HDPE Cable-Technical Offer-18Document6 pages72F-Non Metallic Duct HDPE Cable-Technical Offer-18GUY-FABRE DJILENo ratings yet

- Cust Tp-Duct-48c-1-11762 - 32-006 - 202002-2-CDocument7 pagesCust Tp-Duct-48c-1-11762 - 32-006 - 202002-2-CPEMBINAAN MNM SDN BHDNo ratings yet

- ZTT Adss 20-113931 - BDocument11 pagesZTT Adss 20-113931 - BervanNo ratings yet

- Brosur CcsiDocument38 pagesBrosur CcsiTyrion LannisterNo ratings yet

- YOFC Technical Specification Aerial Cable ADSS SS 100m, 200m nB1.3Document7 pagesYOFC Technical Specification Aerial Cable ADSS SS 100m, 200m nB1.3Diana Cristina Vargas RuizNo ratings yet

- ZTT Riser CableDocument8 pagesZTT Riser CableJuan DonosoNo ratings yet

- Volume IITechnicalspecificationpart IVDocument165 pagesVolume IITechnicalspecificationpart IVronniee287No ratings yet

- Fibra Optica KeezeteckDocument6 pagesFibra Optica KeezeteckAndres Alberto ParraNo ratings yet

- BCC 23120008Document2 pagesBCC 23120008abdulkawi alasharyNo ratings yet

- Spec - AAAC CAIRO DARIEN OPGWDocument4 pagesSpec - AAAC CAIRO DARIEN OPGWErnesto Antonio Astorga FloresNo ratings yet

- Ficha Tecnica Fibra Ducto SM 96F LSZH Antirroedor CHAQ SIMPLE Maintronics GGDocument6 pagesFicha Tecnica Fibra Ducto SM 96F LSZH Antirroedor CHAQ SIMPLE Maintronics GGNestor RondonNo ratings yet

- Optical Fiber Cable - FTTH Drop Cable Outdoor Aerial - G657ADocument5 pagesOptical Fiber Cable - FTTH Drop Cable Outdoor Aerial - G657Airfan.wifi.idNo ratings yet

- ZTT Duct Cable 17-70971 - KAI - 210420 - 195939Document12 pagesZTT Duct Cable 17-70971 - KAI - 210420 - 195939Soebangkit TvNo ratings yet

- NFC Aaac Al4 - 34.4&54.6 Ees CableDocument5 pagesNFC Aaac Al4 - 34.4&54.6 Ees CableazzouzimedNo ratings yet

- FiberHome FHOC-DAL-190-48B1.3Document8 pagesFiberHome FHOC-DAL-190-48B1.3Victor BenavidesNo ratings yet

- Opgw - 36B1-134 (70.0 127.4) (15-51324)Document9 pagesOpgw - 36B1-134 (70.0 127.4) (15-51324)dwas1314No ratings yet

- FastLink 12F (GYXTW) Double ArmouredDocument1 pageFastLink 12F (GYXTW) Double ArmouredHaiderNo ratings yet

- 24 SM Aerial-Duct FibreDocument5 pages24 SM Aerial-Duct FibrePulsmade MalawiNo ratings yet

- FICHA TECNICA - 3X 35+50 SQ - MM AB CableDocument1 pageFICHA TECNICA - 3X 35+50 SQ - MM AB Cablejohana leonNo ratings yet

- Patch Cord2018625Document12 pagesPatch Cord2018625joshsepe-1No ratings yet

- OPGWDocument64 pagesOPGWfNo ratings yet

- Specification ADSS 196FODocument7 pagesSpecification ADSS 196FOJuan Jose PerezNo ratings yet

- YOFC Technical Specification - GYFY (3U) - nB1.3-Span 80mDocument7 pagesYOFC Technical Specification - GYFY (3U) - nB1.3-Span 80mfermac telecomunicacionesNo ratings yet

- UniWay 6F (GYXTW) Double ArmouredDocument1 pageUniWay 6F (GYXTW) Double ArmouredHaiderNo ratings yet

- Aerial Cable ADSS-12FO G.652D Span 120mDocument4 pagesAerial Cable ADSS-12FO G.652D Span 120mWDCNET WORKSNo ratings yet

- Ficha Tecnica Del Cable de Fibra ADSS SJ RP LSZHDocument9 pagesFicha Tecnica Del Cable de Fibra ADSS SJ RP LSZHGersson ColmenaresNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- Data Sheets-T220425-499Document9 pagesData Sheets-T220425-499pedro torresNo ratings yet

- LTP-0029 (Pigging, Pig Launchers and Receivers)Document62 pagesLTP-0029 (Pigging, Pig Launchers and Receivers)pedro torresNo ratings yet

- CS eHORN 092018Document2 pagesCS eHORN 092018pedro torresNo ratings yet

- 889 Gea12945bDocument10 pages889 Gea12945bpedro torresNo ratings yet

- Triconex Tricon ProductSpec 03-10Document35 pagesTriconex Tricon ProductSpec 03-10pedro torresNo ratings yet

- IEC 61058-1 - 2016 - Ed4Document3 pagesIEC 61058-1 - 2016 - Ed4pedro torresNo ratings yet

- Foxboro DCS. Compact FBM239, Digital 16DI - 16DO Module PSS 41H-2C239. Product Specification. AugustDocument27 pagesFoxboro DCS. Compact FBM239, Digital 16DI - 16DO Module PSS 41H-2C239. Product Specification. Augustpedro torresNo ratings yet

- Anwendungsbeispiele SIMOCODE Pro en-US PDFDocument114 pagesAnwendungsbeispiele SIMOCODE Pro en-US PDFpedro torresNo ratings yet

- Crouse Hinds Unf Unl Uny Unions El Elbows Catalog Page PDFDocument4 pagesCrouse Hinds Unf Unl Uny Unions El Elbows Catalog Page PDFpedro torresNo ratings yet

- Rittal Climate Control Quick Reference 5 3082 PDFDocument2 pagesRittal Climate Control Quick Reference 5 3082 PDFpedro torresNo ratings yet

- Rittal Climate Control Quick Reference 5 3082 PDFDocument2 pagesRittal Climate Control Quick Reference 5 3082 PDFpedro torresNo ratings yet

- PSC Ergodyne Range 2021Document45 pagesPSC Ergodyne Range 2021Project Sales CorpNo ratings yet

- Lame and Particle 2D 3DDocument4 pagesLame and Particle 2D 3DSyed ShaulNo ratings yet

- Marine Products: SL-3 Engine ControlsDocument16 pagesMarine Products: SL-3 Engine ControlsPedro GuerraNo ratings yet

- Catalog: Clodfelter Bridge and Structures International, IncDocument28 pagesCatalog: Clodfelter Bridge and Structures International, Incjsyun0831No ratings yet

- Reformulated SoR For The Year 2012-13Document295 pagesReformulated SoR For The Year 2012-13D V BHASKARNo ratings yet

- CordStripper EngDocument18 pagesCordStripper Engcanito73No ratings yet

- Maintenance Practices - IIDocument27 pagesMaintenance Practices - IIrashmiameNo ratings yet

- Tract El Tir ForDocument26 pagesTract El Tir FormapaoloniNo ratings yet

- Burster 8523 Data SheetDocument8 pagesBurster 8523 Data SheetDavid Leonardo Galindo ToapantaNo ratings yet

- Guidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Document6 pagesGuidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Ganiyu100% (1)

- How To Calculate The SWL of Ropes and ChainsDocument10 pagesHow To Calculate The SWL of Ropes and ChainsDeepak GiriNo ratings yet

- Steel Erection ManualDocument18 pagesSteel Erection Manualpradeepyadav1430No ratings yet

- Amarex KRT8041eDocument36 pagesAmarex KRT8041eRui Alves da Silva100% (1)

- Mil DTL 32108Document16 pagesMil DTL 32108syrNo ratings yet

- Groove GaugingDocument3 pagesGroove GauginghshobeyriNo ratings yet

- E&m Works Lmbs RFPDocument84 pagesE&m Works Lmbs RFPSharjeel AkhtarNo ratings yet

- Ladsafe - Protecta - Linha de Vida em EscadaDocument12 pagesLadsafe - Protecta - Linha de Vida em EscadaMamelucoNo ratings yet

- Lifting PlanDocument27 pagesLifting PlanKhuda BukshNo ratings yet

- pdf07 Mufa PDFDocument4 pagespdf07 Mufa PDFEduardo ReyesNo ratings yet

- Model m8 Service ManualDocument34 pagesModel m8 Service ManualMichael TanNo ratings yet

- PulleysDocument13 pagesPulleysHussein AlkafajiNo ratings yet

- Underground Cable Installation: Best Practices FS081Document9 pagesUnderground Cable Installation: Best Practices FS081Tito Adi NugrohoNo ratings yet

- Fältcom Ecii Se: Manual and Installation InstructionsDocument36 pagesFältcom Ecii Se: Manual and Installation InstructionsCarlos BarrosNo ratings yet

- CPS DE 30TL ManualDocument50 pagesCPS DE 30TL ManualAlexander RamirezNo ratings yet

- Installation Instruction ElevatorDocument42 pagesInstallation Instruction ElevatorMárcio Estevam100% (1)

- 7096Document8 pages7096Ema RahamanNo ratings yet

- Linkbelt TCC 750 Telescopic Crawler Cranes BrochureDocument30 pagesLinkbelt TCC 750 Telescopic Crawler Cranes BrochureJansen Fernando TarihoranNo ratings yet

- STL203SDocument6 pagesSTL203SClaudioNo ratings yet