Professional Documents

Culture Documents

Problematic Wire

Problematic Wire

Uploaded by

Franciscus Manuel0 ratings0% found this document useful (0 votes)

8 views2 pagesThe document discusses problematic wires encountered while running a Gamma 255 machine. Evaluations found that most wires could not be twisted or tinned properly due to bending or off-centered positioning in the machine. It was determined that an extension tube needs to be purchased to guide the wires and prevent bending, to ensure consistent twisting and tinning. The tube will be obtained from Komax and is expected to resolve the issues encountered with the majority of problematic wires.

Original Description:

wire

Original Title

Problematic wire

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses problematic wires encountered while running a Gamma 255 machine. Evaluations found that most wires could not be twisted or tinned properly due to bending or off-centered positioning in the machine. It was determined that an extension tube needs to be purchased to guide the wires and prevent bending, to ensure consistent twisting and tinning. The tube will be obtained from Komax and is expected to resolve the issues encountered with the majority of problematic wires.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

8 views2 pagesProblematic Wire

Problematic Wire

Uploaded by

Franciscus ManuelThe document discusses problematic wires encountered while running a Gamma 255 machine. Evaluations found that most wires could not be twisted or tinned properly due to bending or off-centered positioning in the machine. It was determined that an extension tube needs to be purchased to guide the wires and prevent bending, to ensure consistent twisting and tinning. The tube will be obtained from Komax and is expected to resolve the issues encountered with the majority of problematic wires.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

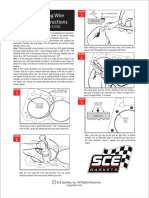

Theme: Problematic wires while running on Gamma 255 Machine.

Department: Cut Cable

Bintan

Prepared: Mohd Zainal

Date: 25 Jan 2017

Introduction:

After we have performed servicing and calibration on Gamma 255 machine, we test out the 9 parts that had

given us a problem during processing. Out of 9 part no, only 3 part no. were able to perform production.

Problem such as:

• Could not twist.

• Could not tin.

We have conducted an evaluation for all these problematic wires to confirm their causes.

Evaluation are as such:

Part No: 113549 Results after tinning

process is that we can see

Picture shows that the tube that the wire is not fully

is centered to the tinning tinned.

pot. But the wire is one

sided, this caused Conclusion:

inconsistent tinning which We need an extension tube

depended on the centrality to prevent the wire from

of the wire to the tinning bending. This extension will

pot. guide the wire while

performing twisting and

tinning

The tube can be purchased

from Komax.

Part No: 903711 Results after tinning

process is that we can see

Picture shows that the tube that the wire is not fully

is centered to the tinning tinned.

pot. But the wire is one

sided, this caused Conclusion:

inconsistent tinning which We need an extension tube

depended on the centrality to prevent the wire from

of the wire to the tinning bending. This extension will

pot. guide the wire while

performing twisting and

tinning.

The tube can be purchased

from Komax.

Part No: 005864 Results after tinning

process is that we can see

Picture shown that the wire that the wire is not fully

is already oxidized causing tinned.

difficulties while tinning.

Conclusion:

We need to create Qsys for

material problem.

Part No: 102395 Results after twist and

tinning process is that we

Picture shows that the tube can see that the wire is not

is centered to the twisting fully twist and tinned.

jaw. But the wire is bend

downward, this caused Conclusion:

inconsistent twist which We need an extension tube

depended on the centrality to prevent the wire from

of the wire to the twisting bending. This extension will

jaw. guide the wire while

performing twisting and

tinning.

The tube can be purchased

from Komax.

Part No: 903255 Results after tinning

process is that we can see

Picture shows that the tube that the wire is not fully

is centered to the tinning tinned.

pot. But the wire is one

sided, this caused Conclusion:

inconsistent tinning which We need an extension tube

depended on the centrality to prevent the wire from

of the wire to the tinning bending. This extension will

pot. guide the wire while

performing twisting and

tinning.

The tube can be purchased

from Komax.

Part No: 811765

Picture shows that the wire

is bent badly. This is

because the wires are too

soft to handle. As a result,

wire could not be twisted

and tinned.

Summarizes and conclusion based on this evaluation:

Based on this evaluation, most of the problematic wire that we have could not be run at Gamma machine, we

need to purchase the extension tube for those wires before processing. This tube will act like a guide while

positioning the wire. We observed that most of the wires have a similar problem.

You might also like

- Sarkisian Employment Agreement - Fully ExecutedDocument21 pagesSarkisian Employment Agreement - Fully ExecutedMatt BrownNo ratings yet

- (Download Ebook) Video-Based LearningDocument101 pages(Download Ebook) Video-Based LearningredwankaaNo ratings yet

- Mobius Coil Winding Tutorial - ToroidalDocument6 pagesMobius Coil Winding Tutorial - Toroidaluragunbaga100% (4)

- Bobina Mobius Succer PunchDocument3 pagesBobina Mobius Succer Punchpedrof33100% (1)

- Official Sat Study Guide CH 23 Sample Math Questions Multiple ChoiceDocument21 pagesOfficial Sat Study Guide CH 23 Sample Math Questions Multiple ChoicePham Thi Thanh ThuyNo ratings yet

- Kenwood TS-440 Repair - OZ1BXMDocument9 pagesKenwood TS-440 Repair - OZ1BXMRui Slva100% (1)

- Popular Mechanics Encyclopedia 04 PDFDocument262 pagesPopular Mechanics Encyclopedia 04 PDFeuqehtbNo ratings yet

- Cable RotationDocument1 pageCable RotationLuisNo ratings yet

- Basic CausesDocument2 pagesBasic CausesvikramporjeNo ratings yet

- Quick Installation and Start-Up Guide: ACS880-M04 DriveDocument2 pagesQuick Installation and Start-Up Guide: ACS880-M04 DriveYacine MesnataNo ratings yet

- Wire WrapDocument16 pagesWire Wrapgretta kopectneNo ratings yet

- The Problems With Tinning Wires U004008ADocument2 pagesThe Problems With Tinning Wires U004008AcrimpsterNo ratings yet

- Stromberg NeedleDocument2 pagesStromberg Needlevanapeer100% (2)

- MANUAL DE COILED TUBING (Schlumberger) PDFDocument10 pagesMANUAL DE COILED TUBING (Schlumberger) PDFJose Sostenes0% (1)

- Sec D BC SeasoningDocument4 pagesSec D BC SeasoningInes delcianeNo ratings yet

- WireWrapTools Eng ManDocument2 pagesWireWrapTools Eng Man1realestabassNo ratings yet

- TeslaDocument9 pagesTeslakrishnaNo ratings yet

- 2VarFormWoundCoil 0701Document2 pages2VarFormWoundCoil 0701andres monederoNo ratings yet

- Scotch® 25 Electrical Grounding Braid: Data SheetDocument3 pagesScotch® 25 Electrical Grounding Braid: Data Sheetprincesa762No ratings yet

- Radio News 1920 02 R OCR Page 0019Document1 pageRadio News 1920 02 R OCR Page 0019giri00767098No ratings yet

- Microwave Plumbing - WadeDocument2 pagesMicrowave Plumbing - WadeUlrich SchmidtNo ratings yet

- Grinder WeldingDocument2 pagesGrinder WeldingbobNo ratings yet

- BWE Brochure After ProofDocument12 pagesBWE Brochure After ProofNut AssanaiNo ratings yet

- MIMSDocument8 pagesMIMShardeep_gNo ratings yet

- BRFACH16GB 11 2017 I GB Klauke Technical ArticleDocument44 pagesBRFACH16GB 11 2017 I GB Klauke Technical ArticlesujaraghupsNo ratings yet

- Antenna Flower Pot 2M 70cm Dual BandDocument5 pagesAntenna Flower Pot 2M 70cm Dual BandSidney GireliNo ratings yet

- Southwire Cable in Conduit Product CatalogDocument65 pagesSouthwire Cable in Conduit Product Catalogjtb12No ratings yet

- Lectrical Ester: How To Diagnose Faulty Cables, Even If You've Tried Everything!Document8 pagesLectrical Ester: How To Diagnose Faulty Cables, Even If You've Tried Everything!AiswaryaUnnikrishnanNo ratings yet

- Electronic Installation Practices Manual - Chapter 9 - Cabling - NAVSHIPS 900171 - PART 5Document7 pagesElectronic Installation Practices Manual - Chapter 9 - Cabling - NAVSHIPS 900171 - PART 5rereNo ratings yet

- Installation Guide For HF/MF Feeder WIREKIT-02 (992001-P) : Package ContentDocument2 pagesInstallation Guide For HF/MF Feeder WIREKIT-02 (992001-P) : Package ContentAntonio ColmenaresNo ratings yet

- Mobius Coil Winding Tutorial - ToroidalDocument10 pagesMobius Coil Winding Tutorial - ToroidalIchbins100% (3)

- Ingolf S Insight Part 2 PDFDocument2 pagesIngolf S Insight Part 2 PDFpushkar rawaleNo ratings yet

- Designing For Flexibility and ReliabilityDocument5 pagesDesigning For Flexibility and Reliabilityluat1983No ratings yet

- عیوب بکسلDocument2 pagesعیوب بکسلjahel2002No ratings yet

- Wire Splices and Soldering JointsDocument17 pagesWire Splices and Soldering JointsKieth Casper MendelebarNo ratings yet

- Electronic Project ProposalDocument35 pagesElectronic Project ProposalmahinayzachlouisNo ratings yet

- O Ring InstructionsDocument1 pageO Ring InstructionsdanielNo ratings yet

- New Main Hoist Wire Rope Installation - Rev0Document1 pageNew Main Hoist Wire Rope Installation - Rev0shakhowiNo ratings yet

- Base Station/Repeater Antenna: CP22E Specifications AssemblyDocument2 pagesBase Station/Repeater Antenna: CP22E Specifications AssemblyChris GuarinNo ratings yet

- Electrical Service Power Station, AC-DC Current, Distribution Board and Wiring SystemDocument16 pagesElectrical Service Power Station, AC-DC Current, Distribution Board and Wiring SystemVala Vraj M.No ratings yet

- Electrical Connector - Inspect: Shutdown SISDocument8 pagesElectrical Connector - Inspect: Shutdown SISEshop ManualNo ratings yet

- HS LeakageDocument1 pageHS LeakageShihab RahmanNo ratings yet

- Cable Installation Guidelines: Business Unit Industrial ProjectsDocument8 pagesCable Installation Guidelines: Business Unit Industrial ProjectsJankoNo ratings yet

- Tesla Coil Project ReportDocument6 pagesTesla Coil Project ReportAnshu Jindal71% (7)

- CABLE GLAND Star Teck ST Series Fittings For Teck and Acwu CableDocument2 pagesCABLE GLAND Star Teck ST Series Fittings For Teck and Acwu CableRobNo ratings yet

- Installation Instructions: Product DescriptionDocument4 pagesInstallation Instructions: Product DescriptionHữu Khánh NguyễnNo ratings yet

- Co Axial CablesDocument4 pagesCo Axial CablesKCTV NEWS PUNGANURNo ratings yet

- Cabac - Pre Insulated TerminalsDocument4 pagesCabac - Pre Insulated TerminalsPaul RyanNo ratings yet

- Local Manufacture of Cast Resin Transformers: Transmission and DistributionDocument2 pagesLocal Manufacture of Cast Resin Transformers: Transmission and DistributionSharafat AliNo ratings yet

- Cable Pulling Method of StatementDocument5 pagesCable Pulling Method of StatementSyed MujahidNo ratings yet

- Crimp VSSolderDocument5 pagesCrimp VSSolderghimpe--No ratings yet

- Learning Module - Joints, Taps and SplicesDocument9 pagesLearning Module - Joints, Taps and SplicesCarlo Cartagenas100% (1)

- 02 Wire Rope StrandDocument36 pages02 Wire Rope StrandBreno Jasser Cordeiro Rodrigues100% (1)

- 02 Wire Rope & Strand - QXD 15 - 2 - 12 5 - 13 PM Page 1 Ope and Wire R & STR PDFDocument39 pages02 Wire Rope & Strand - QXD 15 - 2 - 12 5 - 13 PM Page 1 Ope and Wire R & STR PDFAfzaalUmairNo ratings yet

- Pc-Ar 2007Document12 pagesPc-Ar 2007Augusto OrellanaNo ratings yet

- Slickline and Coiled Tubing ProblemsDocument35 pagesSlickline and Coiled Tubing ProblemsMahmoud Eid0% (1)

- Continuous Vulcanization Cured Rubber - Versus - Mold (Lead) Cured Rubber - for-Extra-Heavy Duty (EHD) Mining Cables JacketsDocument7 pagesContinuous Vulcanization Cured Rubber - Versus - Mold (Lead) Cured Rubber - for-Extra-Heavy Duty (EHD) Mining Cables JacketsShubham BaderiyaNo ratings yet

- How to Install Electric Bells, Annunciators, and AlarmsFrom EverandHow to Install Electric Bells, Annunciators, and AlarmsNo ratings yet

- Mechanics of Optimal Structural Design: Minimum Weight StructuresFrom EverandMechanics of Optimal Structural Design: Minimum Weight StructuresNo ratings yet

- Rope and Harness Work on the Farm - With Information on Rope Construction and Various Knots Used on the FarmFrom EverandRope and Harness Work on the Farm - With Information on Rope Construction and Various Knots Used on the FarmNo ratings yet

- Stanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinFrom EverandStanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinNo ratings yet

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusFrom EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusNo ratings yet

- New Limitation SocketDocument1 pageNew Limitation SocketFranciscus ManuelNo ratings yet

- PN Cable #040258 PDFDocument1 pagePN Cable #040258 PDFFranciscus ManuelNo ratings yet

- Step Picture Task Code and Task Description Twisting: Pilin Awal/putaran/akhir Atau Awal/akhir KakiDocument6 pagesStep Picture Task Code and Task Description Twisting: Pilin Awal/putaran/akhir Atau Awal/akhir KakiFranciscus ManuelNo ratings yet

- Scan B PDFDocument1 pageScan B PDFFranciscus ManuelNo ratings yet

- Reward August 2020Document1 pageReward August 2020Franciscus ManuelNo ratings yet

- Original RequestDocument1 pageOriginal RequestFranciscus ManuelNo ratings yet

- Relflection - Niyati Oceans 5Document2 pagesRelflection - Niyati Oceans 5api-495164088No ratings yet

- ISC2 - CC Preps - CyberprathameshDocument8 pagesISC2 - CC Preps - CyberprathameshR NilNo ratings yet

- Thi online-Giả định cách 3: Ngoaingu24H.Vn 1Document5 pagesThi online-Giả định cách 3: Ngoaingu24H.Vn 1Mon MonNo ratings yet

- Edupreneurship in EducationDocument48 pagesEdupreneurship in EducationAcaciaagns ariesy100% (3)

- Top 5 Alternatives To Articulate Storyline 3 (October 2021) - SaaSworthy - Com3Document3 pagesTop 5 Alternatives To Articulate Storyline 3 (October 2021) - SaaSworthy - Com3شكيب حيمدNo ratings yet

- Shri Sangameshwar Arts, Commerce, Bca, BSC, College, Chadchan - 586 205Document5 pagesShri Sangameshwar Arts, Commerce, Bca, BSC, College, Chadchan - 586 205Md Izaz H DakhaniNo ratings yet

- DMS IIT-D FormDocument2 pagesDMS IIT-D FormPrithvish ShettyNo ratings yet

- October 2 APDocument5 pagesOctober 2 APKim TangoNo ratings yet

- AI in Legal IndustryDocument14 pagesAI in Legal IndustryWarad JaiswalNo ratings yet

- STELLER ProjectDocument6 pagesSTELLER ProjectAnita AnggraeniNo ratings yet

- Seminar Report 2023Document14 pagesSeminar Report 2023Akash TaradaleNo ratings yet

- First Discoveries Scope and SequenceDocument44 pagesFirst Discoveries Scope and SequenceFannyHoyosNo ratings yet

- Lesson Plan PR2 3Document5 pagesLesson Plan PR2 3Jaaziel Ann BaluyutNo ratings yet

- Comprehensive Behavior Management Individualized Classroom and Schoolwide Approaches 2nd Edition Ebook PDF VersionDocument62 pagesComprehensive Behavior Management Individualized Classroom and Schoolwide Approaches 2nd Edition Ebook PDF Versiontommy.villegas301100% (52)

- Reviewer in EntrepreneurshipDocument3 pagesReviewer in EntrepreneurshipJazz Add100% (1)

- Grade 2 Term 1 Week 3 and 4 Exemplary Lesson PlanDocument54 pagesGrade 2 Term 1 Week 3 and 4 Exemplary Lesson Planplaatjiesinazo15No ratings yet

- Laporan Skrip Group Project MandarinDocument9 pagesLaporan Skrip Group Project MandarinFatiha IwaniNo ratings yet

- IntroductionDocument11 pagesIntroductionjainmanya1815No ratings yet

- Irma Resume Teaching eDocument5 pagesIrma Resume Teaching eapi-273353364No ratings yet

- Measuring Language Anxiety in An EFL ContextDocument14 pagesMeasuring Language Anxiety in An EFL ContextChoudhary Zahid Javid100% (1)

- Prepare Test A1Document9 pagesPrepare Test A1Charly Fred100% (1)

- Rubric For Hunting For WordsDocument11 pagesRubric For Hunting For WordsPamela RegidorNo ratings yet

- Harmony in Family and Society 87Document11 pagesHarmony in Family and Society 87Jasleen BoparaiNo ratings yet

- Collective ViolenceDocument3 pagesCollective ViolenceagrawalsushmaNo ratings yet

- A Talk About Motivation: Before ListeningDocument4 pagesA Talk About Motivation: Before ListeningVirginijus KachanovskisNo ratings yet

- Edexcel Primary Paper No 08Document11 pagesEdexcel Primary Paper No 08mathsolutions.etcNo ratings yet

- LP YEAR 10 Addiction - Gentic Influence and TreatmentsDocument13 pagesLP YEAR 10 Addiction - Gentic Influence and TreatmentsoppacokieNo ratings yet