Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

9 views3.2 Viscosity Measurement

3.2 Viscosity Measurement

Uploaded by

Layike AlemayehuCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 3.3 Pressure MeasurementDocument17 pages3.3 Pressure MeasurementLayike AlemayehuNo ratings yet

- CH 04Document42 pagesCH 04Layike AlemayehuNo ratings yet

- 3.1 Density MeasurementDocument16 pages3.1 Density MeasurementLayike AlemayehuNo ratings yet

- Chapter 2 - Compressible FlowDocument58 pagesChapter 2 - Compressible FlowLayike AlemayehuNo ratings yet

- Lecture 4-Pictorial DrawingDocument46 pagesLecture 4-Pictorial DrawingLayike AlemayehuNo ratings yet

- 3.4 Discharge and Velocity MeasurementDocument35 pages3.4 Discharge and Velocity MeasurementLayike AlemayehuNo ratings yet

- HP T N / 63000 T W W F: Transmitted Load, LBDocument35 pagesHP T N / 63000 T W W F: Transmitted Load, LBLayike Alemayehu100% (1)

- External Flow CorrelationsDocument9 pagesExternal Flow CorrelationsLayike AlemayehuNo ratings yet

- Manufacturing Engineering II Chapter 1.1Document23 pagesManufacturing Engineering II Chapter 1.1Layike Alemayehu100% (1)

- AAU-Minda T. CH1Document72 pagesAAU-Minda T. CH1Layike AlemayehuNo ratings yet

- Heat Convection ExerciseDocument2 pagesHeat Convection ExerciseLayike AlemayehuNo ratings yet

- Chapter - 1-1Document18 pagesChapter - 1-1Layike AlemayehuNo ratings yet

- Worksheet 2021Document3 pagesWorksheet 2021Layike AlemayehuNo ratings yet

- Manufacturing Engineering 2 Course OutlineDocument1 pageManufacturing Engineering 2 Course OutlineLayike AlemayehuNo ratings yet

3.2 Viscosity Measurement

3.2 Viscosity Measurement

Uploaded by

Layike Alemayehu0 ratings0% found this document useful (0 votes)

9 views26 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views26 pages3.2 Viscosity Measurement

3.2 Viscosity Measurement

Uploaded by

Layike AlemayehuCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 26

A course on

‘’ Fluid Mechanics-II (MNEG 4361)’’

By : Demise Molawork (PhD Candidates)

School of Mechanical and Industrial Engineering

Addis Ababa Institute of Technology (AAiT)

Addis Ababa University (AAU)

3.2. Viscosity Measurements

OUT LINE:

1.Viscosity definition.

2.Viscosity forms.

3.Viscosity dependent factors.

4.Viscometer types.

a. Rotational viscometers.

b. Tube viscometers.

DEFINITION:

❑ Viscosity is a quantitative measure of a fluid’s resistance

to flow.

❑ The viscosity of a fluid is a measure of its resistance to

gradual deformation by shear stress or tensile stress.

FORMS OF SHEAR VISCOSITY OF A

FLUID

Dynamic (or Absolute) Viscosity (Poises):

The dynamic viscosity(η) of a fluid is a measure of the resistance it

offers to relative motion(force over cross section area).

where τ (Pa) and (1/sec)

Kinematic Viscosity (Stokes):

It is defined as the ratio of absolute viscosity to the density of fluid.

;

ρ= (Kg/m3)density of fluid

VISCOSITY DEPENDENT FACTORS

❑ Viscosity is affected by different factors such as

temperature, shear rate, catalyst, pressure, molecular

weight, concentration and storage age.

❑ Viscosity as a function of temperate:

The temperature dependence of liquid viscosity is the

phenomenon by which liquid viscosity tends to decrease as

its temperature increases.

An exponential model for the temperature-dependence of

shear viscosity (μ) was first proposed by Reynolds in 1886.

µ(T) = µ̥ exp(-bT)

where T is temperature and b and µ̥ are coefficients.

For example:

VISCOSITY DEPENDENT FACTORS

❖ Viscosity as a function of pressure :

viscosity increases, as a rule, with increasing pressure,

provided the liquid is in stable or metastable equilibrium

states.

VISCOMETERS:

❑ All viscometers apply a stress to the fluid and measure

the resistance to flow.

❑ Most viscometers are in 2 major categories :

1. Rotational type viscometer “Dynamic viscosity”.

VISCOMETERS:

2. Tube type viscometer ” kinematic viscosity “

ROTATIONAL VISCOMETERS

❑ These viscometer give the value of the ‘dynamic viscosity’.

❑ It is based on the principle that the fluid whose viscosity is being

measured is sheared between two surfaces.

❑ In these viscometers one of the surfaces is stationary and the other

is rotated by an external drive and the fluid fills the space in

between.

❑ Rotational viscometers use the idea that the torque required to turn

an object in a fluid is a function of the viscosity of that fluid.

❑ They measure the torque required to rotate a disk or bob in a fluid

at a known speed.

ROTATIONAL VISCOMETERS

There are four main types of these viscometers

1.Parallel plate cylinder viscometer.

2. Cone and plate viscometer

3. Rotating cylinder viscometer.

4. Mixer viscometer

1.PARALLEL-PLATE VISCOMETER

❑ It is an instrument consisting of two circular parallel plates,

the lower one stationary, the upper one rotatable, the disk-

shaped specimen being confined between the plates.

2. ROTATING CYLINDER VISCOMETER

❑ A rotating cylinder viscometer is measuring the frequency of a

periodic flow “The terminal angular velocity is measured for a series

of driving torques and of depths of liquid”.

❑ This unit basically consist of two concentric cylinders and a small

intervening annular space contains the test fluids whose viscosity is

to be determined.

❑ The viscous drag due to the liquid between the cylinders produce a

torque on the inner cylinder as the spring torque is proportional to

the angle through which it turns, therefore the angular moment of

the pointer on a fixed disk is used as a measure of viscosity.

❑ Compared with viscometers in common use, the results of this

instrument are influenced to a smaller extent by end effects,

difficulties of adjustment, or the requirement for high precision

parts of special materials.

2. ROTATING CYLINDER VISCOMETER

3. CONE AND PLATE VISCOMETER.

❑ The common feature of a cone-and-plate viscometer is

that the fluid is sheared between a flat plate and a cone

with a low angle.

❑ The cone-and-plate system produces a flow in which the

shear rate is very nearly uniform.

❑ The viscosity is

3𝑇𝜃

𝜇=

2𝜋𝑟 3 𝜔

4. MIXER VISCOMETER

❑ Mixer viscometer technique used to estimate mixer

constants and viscosity using systems of complex

geometry.

TUBE VISCOMETERS

❑ These viscometer give the value of the ‘kinematic viscosity’.

❑ There are fore main types of these viscometers:

1. Glass capillary viscometer.

2. High pressure capillary viscometer .

3. Pipe viscometer.

4. Falling ball viscometer.

1.GLASS CAPILLARY VISCOMETER.

❑ Glass capillary viscometer consists of a U-shaped glass tube held

vertically in a controlled temperature bath.

❑ In one arm of the U is a vertical section of precise narrow bore (the

capillary). Above this is a bulb, with it is another bulb lower down

on the other arm.

❑ In use, liquid is drawn into the upper bulb by suction, then allowed

to flow down through the capillary into the lower bulb. Two marks

(one above and one below the upper bulb) indicate a known

volume. The time taken for the level of the liquid to pass between

these marks is proportional to the kinematic viscosity.

❑ By multiplying the time taken by the factor of the viscometer, the

kinematic viscosity is obtained.

1.GLASS CAPILLARY VISCOMETER.

2.HIGH PRESSURE CAPILLARY VISCOMETER .

❑ The high-pressure capillary viscometer has a measuring liquid

high-pressure which passes through a heat-regulating bath which

can be heated by a built-in heater and whose heat-regulating liquid

is circulated.

❑ A high-pressure device for producing a high pressure in the

measuring liquid comprises a high-pressure pump designed for

continuous delivery and having its suction connection pipe

connected to a measuring liquid stock container and its pressure

connection pipe connected to the measuring liquid high-pressure.

2.HIGH PRESSURE CAPILLARY VISCOMETER

3.PIPE VISCOMETER.

❑ pipe viscometers show better reliability and

accuracy than rotational viscometers.

❑ viscometers are relatively expensive and not

convenient for field applications. As a result, they

are commonly used for research purpose and in-

line viscosity measurement.

❑ A standard pipe viscometer system has flow rate

and pressure loss measuring instrumentations.

❑ To obtain reliable and accurate measurements,

these types of viscometers must have sufficiently

long entrance and exit sections.

3.PIPE VISCOMETER.

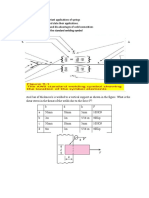

4.FALLING BALL VISCOMETER.

❑ The Falling ball viscometer used to measure the viscosity of

Newtonian liquid by measuring the time required for a ball to

fall under gravity through a sample-filled tube that is inclined at

an angle.

❑ The average time of three tests is taken; the result is converted

into a viscosity value using a simple formula.

4.FALLING BALL VISCOMETER.

wl & ws and are the specific weights of

the liquid and the ball, t is time

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 3.3 Pressure MeasurementDocument17 pages3.3 Pressure MeasurementLayike AlemayehuNo ratings yet

- CH 04Document42 pagesCH 04Layike AlemayehuNo ratings yet

- 3.1 Density MeasurementDocument16 pages3.1 Density MeasurementLayike AlemayehuNo ratings yet

- Chapter 2 - Compressible FlowDocument58 pagesChapter 2 - Compressible FlowLayike AlemayehuNo ratings yet

- Lecture 4-Pictorial DrawingDocument46 pagesLecture 4-Pictorial DrawingLayike AlemayehuNo ratings yet

- 3.4 Discharge and Velocity MeasurementDocument35 pages3.4 Discharge and Velocity MeasurementLayike AlemayehuNo ratings yet

- HP T N / 63000 T W W F: Transmitted Load, LBDocument35 pagesHP T N / 63000 T W W F: Transmitted Load, LBLayike Alemayehu100% (1)

- External Flow CorrelationsDocument9 pagesExternal Flow CorrelationsLayike AlemayehuNo ratings yet

- Manufacturing Engineering II Chapter 1.1Document23 pagesManufacturing Engineering II Chapter 1.1Layike Alemayehu100% (1)

- AAU-Minda T. CH1Document72 pagesAAU-Minda T. CH1Layike AlemayehuNo ratings yet

- Heat Convection ExerciseDocument2 pagesHeat Convection ExerciseLayike AlemayehuNo ratings yet

- Chapter - 1-1Document18 pagesChapter - 1-1Layike AlemayehuNo ratings yet

- Worksheet 2021Document3 pagesWorksheet 2021Layike AlemayehuNo ratings yet

- Manufacturing Engineering 2 Course OutlineDocument1 pageManufacturing Engineering 2 Course OutlineLayike AlemayehuNo ratings yet