Professional Documents

Culture Documents

Spray Water - Rev 00

Spray Water - Rev 00

Uploaded by

Jacky KaruppaiahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spray Water - Rev 00

Spray Water - Rev 00

Uploaded by

Jacky KaruppaiahCopyright:

Available Formats

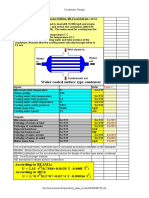

SPRAY WATER

QUANTITY CALCULATION - Rev 00

Project: M/s. Aditya Birla Chemicals Ltd

Date : 26.11.2012

S.No. Description Units

PRDS-I Steam to PRDS-II Steam On load Process Process Deaerator

holding ejector to hoggng Dump Steam Steam PRDS- Steam PRDS- start up

& gland sealing ejector PRDS Guarantee Maximum PRDS

1 Steam flow at D.S.H. outlet kg/h W1 2200 5000 75960 20000 20000 13400

2 Steam pressure at D.S.H. inlet kg/cm^2(g) P1 109 109 109 18 104 104

3 Steam temperature at D.S.H. inlet °C T1 540 540 540 317.5 535 535

Steam enthalpy at D.S.H. inlet

4 kcal/kg h1 Err:511 Err:511 Err:511 Err:511 Err:511 Err:511

(from steam table at P1, T1)

5 Steam pressure at D.S.H.outlet kg/cm^2(g) P2 10.00 10.00 5.00 15.00 15.00 10.00

6 Steam temperature at D.S.H. outlet °C T2 350 350 200 300 300 350

Steam enthalpy at D.S.H. outlet

7 kcal/kg h2 Err:511 Err:511 Err:511 Err:511 Err:511 Err:511

(from steam table at P2, T2)

8 Spray water pressure kg/cm^2(g) P3 30.00 30.00 30.00 30.00 30.00 30.00

9 Spray water temperature °C T3 150 150 128 157 128 128

Spray water enthalpy

10 kcal/kg h3 Err:511 Err:511 Err:511 Err:511 Err:511 Err:511

(from steam table at P3, T3)

Spray water quantity,

11 kg/hr W2 Err:511 Err:511 Err:511 Err:511 Err:511 Err:511

W2 = W1 * (h1 - h2) / (h1 - h3)

Percentage of Spray,

12 % P4 Err:511 Err:511 Err:511 Err:511 Err:511 Err:511

P4 = W2 * 100 / W1

250+270 Err:511 Err:511

550+1390 Err:511 Err:511

250+16000+2900+1390 Err:511 Err:511

Prepared By: Approved BY:

Shiva JRK

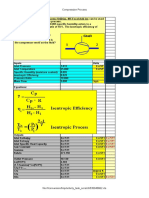

Project: M/s.Siddhi Vinayak Cement Pvt. Ltd. (JB0844)

Flow and head requirement for Pump interstage bleed

Case-1 - On Case-2 - Start Case-3 - Off

load dump up load dump

Flow (m3/hr) Flow (m3/hr) Flow (m3/hr)

Pump Inlet 171.35 160.11 126

Interstage Bleed 14.05 2.81 31

Pump Outlet 157.3 157.3 95

*Head required for interstage bleed is 328mwc

You might also like

- HFO Bulk Storage Tank Steam Coil SizingDocument1 pageHFO Bulk Storage Tank Steam Coil SizingSaeed Rehman100% (1)

- WA0003.encDocument16 pagesWA0003.encNoman Abdul RazzaqNo ratings yet

- 31/41 Tk-1 Efficiency Calculation: S.No. Operating Parameter Unit 31TK-1 41TK-1Document9 pages31/41 Tk-1 Efficiency Calculation: S.No. Operating Parameter Unit 31TK-1 41TK-1Srinath ChowdaryNo ratings yet

- Total Feed Water Through BFW PumpsDocument7 pagesTotal Feed Water Through BFW PumpslightsonsNo ratings yet

- Kristherm - Residential Split Heat PumpDocument4 pagesKristherm - Residential Split Heat PumpAbhishek PNo ratings yet

- Bombas de Calor Sanitarias HAIER (1200 X 4000 PX)Document1 pageBombas de Calor Sanitarias HAIER (1200 X 4000 PX)Davo MoenaNo ratings yet

- Attachment 04 - Milan Conference 2005Document29 pagesAttachment 04 - Milan Conference 2005ElMacheteDelHuesoNo ratings yet

- Suntec Heat Pump Water HeaterDocument18 pagesSuntec Heat Pump Water Heaterajeet ranaNo ratings yet

- Line Size 2010 VerBBDocument12 pagesLine Size 2010 VerBBchemkumar16No ratings yet

- Design Practices of Solid Fuel BoilersDocument16 pagesDesign Practices of Solid Fuel BoilersKaza ShanthiNo ratings yet

- Design Practices of Solid Fuel BoilersDocument16 pagesDesign Practices of Solid Fuel BoilersKaza ShanthiNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ChandrawarNo ratings yet

- NETZSCH Steam Jet Mill S-Jet eDocument20 pagesNETZSCH Steam Jet Mill S-Jet ejojibaNo ratings yet

- Heat Transfer Coefficients For Submerged CoilsDocument70 pagesHeat Transfer Coefficients For Submerged CoilsAdam JinNo ratings yet

- Line III Heat BalanceDocument65 pagesLine III Heat Balancehmaza shakeelNo ratings yet

- Compression Process CalculationsDocument2 pagesCompression Process CalculationsRahul ChandrawarNo ratings yet

- Safety Valve Technical DetailsDocument5 pagesSafety Valve Technical DetailsvineethvskkdNo ratings yet

- Chiller Partload Down To 20% PDFDocument2 pagesChiller Partload Down To 20% PDFscribdquyNo ratings yet

- FW Heater PerformanceDocument30 pagesFW Heater Performancessunilsahu352No ratings yet

- Module No 3: Boil Off Gas ManagementDocument30 pagesModule No 3: Boil Off Gas ManagementkhenzyNo ratings yet

- Blast Furnace OverviewDocument26 pagesBlast Furnace OverviewResego PhiriNo ratings yet

- ECO Heat Pump ENG 5Document16 pagesECO Heat Pump ENG 5Nano SalamNo ratings yet

- Steam Trap & InsulationDocument16 pagesSteam Trap & InsulationArindomNo ratings yet

- Standard Operating InstructionDocument8 pagesStandard Operating InstructionSonrat100% (2)

- Blast Furnace OverviewDocument26 pagesBlast Furnace OverviewProfMVSNo ratings yet

- Biomass PowerplantDocument13 pagesBiomass PowerplantZohre AlinejadNo ratings yet

- ATM CDU Distillation in Aspen HYSYS V10Document27 pagesATM CDU Distillation in Aspen HYSYS V10Ahmad Deyab100% (2)

- 0611 - HPS200-250Document2 pages0611 - HPS200-250Rufus D SNo ratings yet

- RajatvermapptDocument54 pagesRajatvermapptVinay MauryaNo ratings yet

- Line Sizing and Material SpecificationDocument66 pagesLine Sizing and Material SpecificationBSL PanipatNo ratings yet

- Heat Exchanger RatingDocument10 pagesHeat Exchanger RatingAnand BhiseNo ratings yet

- Performance GNC 350 HP BarrickDocument2 pagesPerformance GNC 350 HP BarrickEnrique RafaelNo ratings yet

- Startup Steam RequiredDocument4 pagesStartup Steam RequiredlightsonsNo ratings yet

- Che 455 Fall 2009 Major 1 Phthalic Anhydride Production: BackgroundDocument20 pagesChe 455 Fall 2009 Major 1 Phthalic Anhydride Production: Backgroundاحمد الدلالNo ratings yet

- Furnace Proper FinalDocument49 pagesFurnace Proper FinalPrateek SinghNo ratings yet

- Technique, Sector Results To Date (Arash)Document22 pagesTechnique, Sector Results To Date (Arash)Allison Jazmin Castro PionceNo ratings yet

- fouling factor 중량 비체적: ft^2/Btu m^2/Kcal lb/ft kg/m lb/ft^3 kg/m^3 0.3689556791 1.4881889764 16.018732594Document27 pagesfouling factor 중량 비체적: ft^2/Btu m^2/Kcal lb/ft kg/m lb/ft^3 kg/m^3 0.3689556791 1.4881889764 16.018732594김종민No ratings yet

- PSV Data Sheet WettedDocument7 pagesPSV Data Sheet WettedIoana PopescuNo ratings yet

- Steam CalculatorDocument6 pagesSteam Calculatorthermaxteja2016No ratings yet

- Vapor Comprision DistillationDocument5 pagesVapor Comprision DistillationBAKRNo ratings yet

- Emma MangarooDocument17 pagesEmma MangarooCharlotte BNo ratings yet

- Thermodynamic Properties of SteamDocument10 pagesThermodynamic Properties of SteamMohammed AlSalehNo ratings yet

- Sizing PSV-100 R0Document5 pagesSizing PSV-100 R0XxavierNo ratings yet

- Chapter 10 The Factorial Method of Cost EstimationDocument8 pagesChapter 10 The Factorial Method of Cost Estimationภูมิรพี ศรีโวทานัยNo ratings yet

- Specifications: Model E304-Dz Fluid Heater 300 BHPDocument2 pagesSpecifications: Model E304-Dz Fluid Heater 300 BHPAngel LozaNo ratings yet

- Mel725 37Document44 pagesMel725 37V U P RaoNo ratings yet

- Valve Sizing Calculation8Document2 pagesValve Sizing Calculation8PIDNo ratings yet

- Development of AerofoilDocument6 pagesDevelopment of Aerofoilvaisakp777No ratings yet

- Boi PDFDocument7 pagesBoi PDFdoyanNo ratings yet

- Spe 174521 MS PDFDocument17 pagesSpe 174521 MS PDFLuis Roberto Oliveros GómezNo ratings yet

- Boiler FormulasDocument5 pagesBoiler FormulasAnonymous 6Mb7PZjNo ratings yet

- Torrefiel Boiler, SecuredDocument61 pagesTorrefiel Boiler, SecuredKent Louie EyanaNo ratings yet

- Ciler IspravkaDocument18 pagesCiler IspravkaNevena AksićNo ratings yet

- Package Hygienic Air Handling Units: - PHK SeriesDocument6 pagesPackage Hygienic Air Handling Units: - PHK SeriesTanveer AzizNo ratings yet

- Sizing Sheet PSV Air 175PSIG - CommentsDocument6 pagesSizing Sheet PSV Air 175PSIG - CommentshaseebNo ratings yet

- 13 Steam StrippersDocument10 pages13 Steam StrippersMohsin EhsanNo ratings yet

- Steam Condensate in Return LinesDocument13 pagesSteam Condensate in Return LinesAayushi SinhaNo ratings yet

- Supercritical PlantDocument71 pagesSupercritical PlantNitish KumarNo ratings yet

- A9 Pumplift SolutionsDocument11 pagesA9 Pumplift SolutionsVatsal ShahNo ratings yet

- Boiler FormulasDocument3 pagesBoiler FormulasCaliman SabinaNo ratings yet

- 09 04 2023 - DailyDocument70 pages09 04 2023 - DailyJacky KaruppaiahNo ratings yet

- I20 PriceDocument1 pageI20 PriceJacky KaruppaiahNo ratings yet

- Date Power Generation Avg Load Aux % Aux PLF Coal ConDocument16 pagesDate Power Generation Avg Load Aux % Aux PLF Coal ConJacky KaruppaiahNo ratings yet

- Grand Nios PriceDocument1 pageGrand Nios PriceJacky KaruppaiahNo ratings yet

- Daily Power Generation Report: Fuel ReceivedDocument10 pagesDaily Power Generation Report: Fuel ReceivedJacky KaruppaiahNo ratings yet

- RC FormDocument1 pageRC FormJacky KaruppaiahNo ratings yet

- Mis Oct.2021Document18 pagesMis Oct.2021Jacky KaruppaiahNo ratings yet

- CII Energy Award PPT - KCW TPP 2017-2 PDFDocument61 pagesCII Energy Award PPT - KCW TPP 2017-2 PDFJacky Karuppaiah100% (1)

- Shutdown Observation Report - M/s SRHHL: Grid - Air Nozzle Refractory Dismantling and Dents On TubesDocument4 pagesShutdown Observation Report - M/s SRHHL: Grid - Air Nozzle Refractory Dismantling and Dents On TubesJacky KaruppaiahNo ratings yet

- Detecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Document5 pagesDetecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Hernan MartNo ratings yet

- CG Report ADocument8 pagesCG Report AsachinNo ratings yet

- Neonatal JaundiceDocument15 pagesNeonatal JaundiceSharan SekhonNo ratings yet

- Special Education Supervisor - IDEA Coordinator TxVA Job Description Rev 1-25-2012Document2 pagesSpecial Education Supervisor - IDEA Coordinator TxVA Job Description Rev 1-25-2012ResponsiveEdNo ratings yet

- Ree AnneDocument1 pageRee AnneRee Anne DiolesteNo ratings yet

- QB Ch13 EngDocument69 pagesQB Ch13 EngsssNo ratings yet

- Class 10 ElectricityDocument16 pagesClass 10 ElectricityTapas BanerjeeNo ratings yet

- Agitador OrbitalshakerDocument22 pagesAgitador OrbitalshakerÂlexândêr Râmiirêz MôliinâNo ratings yet

- Foreign Debt, Balance of Payments, and The Economic Crisis of The Philippines in 1983-84Document26 pagesForeign Debt, Balance of Payments, and The Economic Crisis of The Philippines in 1983-84Cielo GriñoNo ratings yet

- Shirdi TicketDocument2 pagesShirdi TicketPOORVA GURAVNo ratings yet

- Sample Specification of FansDocument5 pagesSample Specification of Fanscashlover100% (1)

- Book Covers Lesson PlanDocument3 pagesBook Covers Lesson Planapi-545455548No ratings yet

- Power Engineering PM Check ListDocument11 pagesPower Engineering PM Check ListSelvn SubramanianNo ratings yet

- Duties and Tasks of Indonesian PoliceDocument1 pageDuties and Tasks of Indonesian PoliceName ToomNo ratings yet

- How To Upgrade TP-Link Pharos DevicesDocument5 pagesHow To Upgrade TP-Link Pharos DevicesGina LópezNo ratings yet

- IronDocument27 pagesIronAyman LatifNo ratings yet

- Matrix Decomposition Chap1Document9 pagesMatrix Decomposition Chap1Jordan JooNo ratings yet

- Software Testing MCQs SampleDocument18 pagesSoftware Testing MCQs SamplethejashwiniNo ratings yet

- SOP SAP Landed Cost 0.1Document9 pagesSOP SAP Landed Cost 0.1supendra phuyalNo ratings yet

- Ex Rates 19 03 19Document9 pagesEx Rates 19 03 19Anonymous jTY4ExMNo ratings yet

- S.No Acc No Title of The BookDocument12 pagesS.No Acc No Title of The BookmechhodNo ratings yet

- Diagnosa Prolanis (Seluruhnya)Document6 pagesDiagnosa Prolanis (Seluruhnya)Rasjid tabanalNo ratings yet

- C IntroDocument17 pagesC IntroamitavjhaNo ratings yet

- CIVIL ENGINEERING AND ARCHITECTURE 2nd SemDocument28 pagesCIVIL ENGINEERING AND ARCHITECTURE 2nd SemJinu MadhavanNo ratings yet

- The Affluent Society and A Sense of EmptinessDocument31 pagesThe Affluent Society and A Sense of EmptinessMehwish MalikNo ratings yet

- S10060 SCHWEBD-S10174: Follow UsDocument3 pagesS10060 SCHWEBD-S10174: Follow UsandreviolinoNo ratings yet

- Basic C ProgramDocument1 pageBasic C ProgramPallab DattaNo ratings yet

- Doh HFSRB Qop01form 2 Rev2 6172022Document1 pageDoh HFSRB Qop01form 2 Rev2 6172022Araceli TiuNo ratings yet

- Conveyor ChainDocument51 pagesConveyor ChainRiksaNo ratings yet