Professional Documents

Culture Documents

Raw Material Process Flow (SeAH)

Raw Material Process Flow (SeAH)

Uploaded by

Vianjani AldoeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raw Material Process Flow (SeAH)

Raw Material Process Flow (SeAH)

Uploaded by

Vianjani AldoeCopyright:

Available Formats

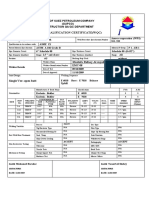

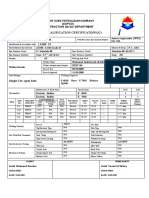

Raw Material Process Flow

● Wire rod process flow (Carbon & Low alloyed Steel, Spring Steel)

Steel making factory Wire rod factory

E.A.F (100M/T) Refining C.C Billet Billet Heating Rolling NTM/RSM

Rough (3Roll Type)

(LF/VD) Grinding Furnace Mill

(5.5~17Φ)[Inspection]

(13~34Φ) UP-set,

Billet Size : 160SQ, 170SQ MT, Grade

Billet serial number

- Cast temperature & speed control

- 2nd cooling zone (ZoneⅠ,Ⅱ,Ⅲ) automatic check

- Mold/Final EMS using MES : Tracking Path

- Billet macro inspection(Surface/Inside)

In-Line Hot ECT (Now preparing Hot Eye)

Billet serial number marking

Rolling measurement check

- Heat No

- Bar Gauge Measurement

- Steel Grade Spring steel (SAE9254)

- Inspector measurement (Micrometer)

- Continuous Casting Machine Strand & - All Grinding of billet surface

Serial No

Surface/Appearance visual

check

Upsetting test

Coil both ends Magnetic

particle inspection

Steel Making

1.Electric furnace (E.A.F) 2. LF (Ladle Furnace) 3.VD (Vacuum Degassing) 4. Continuous Casting

Melt the scrap by using Arc Adjust the alloy element & Adjust ingot steel tiny Give a shape of billet

resistance heating after ingot steel temperature element in vacuum (□160,□170) after putting the

loading into furnace. control by applying Arc to atmosphere, Remove gas ingot steel to water cooling

Ladle. & Inclusion floatation. mold continuously & clotting.

Rolling

5. Billet Grinding 6. Reheating Furnace 7. Wire rod rolling 8. Inspection

Automatic Measurement,

grinder Walking Beam Furnace Appearance,

- Remove the Surface

scratch & scratch,

③ Finishing Mill ④ Pouring Reel Winding Material test

defects on Heat the billet equally ① Roughing Mill ② Intermediate Mill (Precision Sizing Block) - Winding of coil

billet surface - Rolling to Ø70~ - Rolling of middle - ø13~34 shape into

after loading into 85 size by using stage by using - Measurement cylindrical rotary

heated billet. round shape precision control

furnace in required - Total 8 stands material through

reel.

rolling

temperatures. are arranged in roughing mill.

series (Horizontal - Kocks Mill

& vertical roll by (3 Roll Type)

turns)

③ Finishing Mill ④ Laying Head Winding

(NTM-RSM) - Winding of coil

- ø5.5~17 shape on conveyor

- Measurement after passing the

precision control material into pipe.

rolling

You might also like

- Kirchhoff's Law - Online - PHETDocument6 pagesKirchhoff's Law - Online - PHETSebastian Gómez0% (1)

- AXLE Defect Book 05.05.2020 PDFDocument38 pagesAXLE Defect Book 05.05.2020 PDFDevarshi GaurNo ratings yet

- Polycab Cable Selection Chart & Ampere RatingDocument1 pagePolycab Cable Selection Chart & Ampere Ratingshivani77% (26)

- Japanese SectionsDocument27 pagesJapanese SectionsDuy NamNo ratings yet

- ANSYS CFX RadiationDocument14 pagesANSYS CFX RadiationGabriel Nogueira100% (1)

- Hot Rolled Steel SheetDocument40 pagesHot Rolled Steel SheetsyaefulNo ratings yet

- D1e 001Document40 pagesD1e 001Himindra ChaaubeNo ratings yet

- B1e 001Document40 pagesB1e 001Sontosh BhattacharjeeNo ratings yet

- Hot Rolled Steel SheetDocument40 pagesHot Rolled Steel SheetAilynNo ratings yet

- 7 QC Tools Live ExampleDocument12 pages7 QC Tools Live ExampleKamlesh RanaNo ratings yet

- Lecture 2 Continuous CastingDocument41 pagesLecture 2 Continuous Castingnoahshredx13No ratings yet

- Presentation EuroturbineDocument56 pagesPresentation Euroturbinetmz100% (1)

- TMT ProcesesDocument39 pagesTMT ProcesesVikrant HanwatNo ratings yet

- Nscguide2012 - e - 61-Flow Production Nippon SteelDocument2 pagesNscguide2012 - e - 61-Flow Production Nippon SteelAgustine SetiawanNo ratings yet

- Yoshie 1992Document10 pagesYoshie 1992Sesar Bastian MutaqinNo ratings yet

- Pm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationDocument3 pagesPm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationjulianoNo ratings yet

- Etanorm Sya ModelDocument4 pagesEtanorm Sya ModelIna MeranNo ratings yet

- RSP PPs Presentation For CMODocument82 pagesRSP PPs Presentation For CMOVenkatesh NaiduNo ratings yet

- End Milling Technical-GuidanceDocument10 pagesEnd Milling Technical-Guidancelan hoangNo ratings yet

- File KSB Etanorm Syt Thermal Oil Hot Water Pumps 96757Document24 pagesFile KSB Etanorm Syt Thermal Oil Hot Water Pumps 96757Abdullah MunawirNo ratings yet

- Cold Rolling (DG Teori Detil)Document32 pagesCold Rolling (DG Teori Detil)Baginda HamzahNo ratings yet

- Pipeline WeldingDocument61 pagesPipeline Weldingravi00098No ratings yet

- Board Level Power Semiconductor Heat Sinks: 677 Series 680 SeriesDocument1 pageBoard Level Power Semiconductor Heat Sinks: 677 Series 680 SeriesJNarigonNo ratings yet

- Cold Rolling of Steel - Fundamentals and Applications (Tata Steel)Document48 pagesCold Rolling of Steel - Fundamentals and Applications (Tata Steel)Bindesh Lakra75% (4)

- INDUSTRIAL TRAINING PPT Bhel BhopalDocument19 pagesINDUSTRIAL TRAINING PPT Bhel BhopalROHIT YADAV100% (1)

- AJOOFT Fitting CatalogDocument6 pagesAJOOFT Fitting CatalogthoavitNo ratings yet

- Accelerated CoolingDocument7 pagesAccelerated CoolingHarikrishnan N SivaprasadNo ratings yet

- EN - Datasheet Copperhead MonitorDocument3 pagesEN - Datasheet Copperhead MonitorRomina CZNo ratings yet

- WRM Proceses - Copy (Autosaved)Document41 pagesWRM Proceses - Copy (Autosaved)Vikrant HanwatNo ratings yet

- 4G Fcaw WPSDocument3 pages4G Fcaw WPSdjafourNo ratings yet

- Offshore Welding of PipelineDocument1 pageOffshore Welding of PipelinePrabu CholanNo ratings yet

- Overview of Bokaro Steel Plant: Suman SourabhDocument48 pagesOverview of Bokaro Steel Plant: Suman SourabhabhishekNo ratings yet

- Project Report On Casting, Forging, Heat Treatment & MachiningDocument15 pagesProject Report On Casting, Forging, Heat Treatment & MachiningVaibhav BhadouriaNo ratings yet

- Eversendai Offshore RMC Fze: Request For TestingDocument1 pageEversendai Offshore RMC Fze: Request For Testingbharani dharanNo ratings yet

- Bab 4 Pipe Manufacturing & WeldingDocument29 pagesBab 4 Pipe Manufacturing & WeldingrWin doNo ratings yet

- Introduction of CAP1400 IVR ExperimentsDocument40 pagesIntroduction of CAP1400 IVR ExperimentsABNo ratings yet

- DMP PDFDocument39 pagesDMP PDFberkahharianNo ratings yet

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocument1 pageWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNo ratings yet

- Steel Making IntroductionDocument17 pagesSteel Making IntroductionHari sadu100% (2)

- Etm Api 600 Trim Material PDFDocument1 pageEtm Api 600 Trim Material PDFbenabdallah131No ratings yet

- API 600 Trim Materials Disc Wedge Seat RDocument1 pageAPI 600 Trim Materials Disc Wedge Seat RManan DesaiNo ratings yet

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- Norma Saph440 9Document24 pagesNorma Saph440 9Marcos FerreiraNo ratings yet

- RSCT SfeDocument21 pagesRSCT Sfeahmed otmanNo ratings yet

- DMC 2016 Plasma MIG PresentationDocument24 pagesDMC 2016 Plasma MIG PresentationKaushik SenguptaNo ratings yet

- Ball Valves: 3-Way SeriesDocument8 pagesBall Valves: 3-Way SerieslorenzoNo ratings yet

- Rolling Mill DetailsDocument32 pagesRolling Mill DetailsGovind RaoNo ratings yet

- Work Scope - Francis Turbine Refurbishment WorkDocument6 pagesWork Scope - Francis Turbine Refurbishment WorkmanikanthNo ratings yet

- Hot Stamping of Aerospace Aluminium Alloys (MM) FinalDocument20 pagesHot Stamping of Aerospace Aluminium Alloys (MM) FinalMeby MathewNo ratings yet

- 7 Step PfmeaDocument132 pages7 Step PfmeaRajdeep SikdarNo ratings yet

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocument1 pageWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNo ratings yet

- DrillDocument1 pageDrillAhmed SlimNo ratings yet

- Recrystallization 6005Document7 pagesRecrystallization 6005lindberghsoslNo ratings yet

- Turning Handbook: General Turning - Parting and Grooving - ThreadingDocument53 pagesTurning Handbook: General Turning - Parting and Grooving - ThreadingMindrila BogdanNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- Hardfacing Wires: For Steel Mill RollsDocument16 pagesHardfacing Wires: For Steel Mill RollsRaviTeja BhamidiNo ratings yet

- JNF12 Hales 2380 PDFDocument18 pagesJNF12 Hales 2380 PDFagilan89No ratings yet

- AlignmentDocument7 pagesAlignmentmahmouddiaa554No ratings yet

- Slabbrochure Baosteel PDFDocument36 pagesSlabbrochure Baosteel PDFKetnipha SukwannawitNo ratings yet

- Ballscrew Manuf TourDocument5 pagesBallscrew Manuf TourBilal VURALNo ratings yet

- Raw Material Process Flow SUP12 SUP12V (JY)Document3 pagesRaw Material Process Flow SUP12 SUP12V (JY)Vianjani AldoeNo ratings yet

- Raw Material Process Flow (Samwon)Document1 pageRaw Material Process Flow (Samwon)Vianjani AldoeNo ratings yet

- DPL Mis-22-037Document4 pagesDPL Mis-22-037Vianjani AldoeNo ratings yet

- Cadarindo Shipment 1Document1 pageCadarindo Shipment 1Vianjani AldoeNo ratings yet

- Forecast PT. INSASTAMA (Up Mbak Rima Lokal)Document2 pagesForecast PT. INSASTAMA (Up Mbak Rima Lokal)Vianjani AldoeNo ratings yet

- Kathrein 730691Document2 pagesKathrein 730691Roberto EmmeNo ratings yet

- W. G. Tifft - Three-Dimensional Quantized Time in CosmologyDocument11 pagesW. G. Tifft - Three-Dimensional Quantized Time in CosmologyjimNo ratings yet

- Grade8 Science PracticeTestDocument68 pagesGrade8 Science PracticeTestTom JerryNo ratings yet

- Power Supply Unit - QUINT-PS/1AC/24DC/20 - 2866776: Product DescriptionDocument12 pagesPower Supply Unit - QUINT-PS/1AC/24DC/20 - 2866776: Product DescriptionJosé Alberto Gomez JimenezNo ratings yet

- Report On 220kv Grid SubstationDocument79 pagesReport On 220kv Grid SubstationMunish Gaur100% (1)

- Chapter IIIDocument3 pagesChapter IIIMarvin Lucero FiscalNo ratings yet

- Esquema Eléctrico Cargador 966HDocument16 pagesEsquema Eléctrico Cargador 966HLuis Lopez PaucarNo ratings yet

- Electrostatic 1 Notes Class 12Document9 pagesElectrostatic 1 Notes Class 12Ravindra Nath TiwariNo ratings yet

- KadaliDocument21 pagesKadaliArnob SamantaNo ratings yet

- M.SC Thesis PFC - Project - FinalDocument79 pagesM.SC Thesis PFC - Project - FinalRia AlexNo ratings yet

- ECEG-3205 - Chapter 2Document25 pagesECEG-3205 - Chapter 2Yohanes FisehaNo ratings yet

- Quality 1.4021 Chemical Composition: Lucefin GroupDocument2 pagesQuality 1.4021 Chemical Composition: Lucefin Groupmohamedbadawy0% (1)

- 2009 CE Physics Marking SchemeDocument8 pages2009 CE Physics Marking SchemeChoi FungNo ratings yet

- MODERN PHYSICS NumericalsDocument22 pagesMODERN PHYSICS NumericalsTEJ KOHLINo ratings yet

- Photoelectric Sensor: E3S-LSDocument8 pagesPhotoelectric Sensor: E3S-LSAnggi PrasetyoNo ratings yet

- General Physics 2 Module 1 PDF FreeDocument8 pagesGeneral Physics 2 Module 1 PDF FreesacherybebeNo ratings yet

- Boardwork 1Document59 pagesBoardwork 1Tapan BadheiNo ratings yet

- Resonance Theory of ConsciousnessDocument2 pagesResonance Theory of ConsciousnessAltomi AlexNo ratings yet

- Course Plan For Heat and Mass TransferDocument3 pagesCourse Plan For Heat and Mass TransferChinnadurai LakshmananNo ratings yet

- Effects of Faults and Shunt Reactor Parameters On Parallel ResonanceDocument13 pagesEffects of Faults and Shunt Reactor Parameters On Parallel ResonanceCarlos Lino Rojas AgüeroNo ratings yet

- Takex PB-50HF-KH Data SheetDocument2 pagesTakex PB-50HF-KH Data SheetJMAC SupplyNo ratings yet

- 112-118 Fault Localization Using SFRA - SubramanianDocument7 pages112-118 Fault Localization Using SFRA - SubramanianProsenjitroy RoyNo ratings yet

- Design Formulas For Full Wave Ei Core Transformer - NewDocument2 pagesDesign Formulas For Full Wave Ei Core Transformer - NewViet Hoang LeNo ratings yet

- Goldstein Classical Mechanics Notes: 1 Chapter 1: Elementary PrinciplesDocument149 pagesGoldstein Classical Mechanics Notes: 1 Chapter 1: Elementary PrinciplesMarcosNo ratings yet

- Complete - Quarter 3 - Science 7 - Weeks 1 - 8Document42 pagesComplete - Quarter 3 - Science 7 - Weeks 1 - 8alyzamarie deramos100% (1)

- Hall 1996Document11 pagesHall 1996Enrique G Mancheno MendezNo ratings yet

- Static Electricity and Direct Current (DC) Circuit 1.1 Electric Current Voltage, and Resistance (1) Fundamentals of ElectricityDocument60 pagesStatic Electricity and Direct Current (DC) Circuit 1.1 Electric Current Voltage, and Resistance (1) Fundamentals of ElectricityEndraNo ratings yet