Professional Documents

Culture Documents

BMW F 800 R K73 Desmontaje-Montaje Bloque Motor

BMW F 800 R K73 Desmontaje-Montaje Bloque Motor

Uploaded by

Gustavo FajardoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BMW F 800 R K73 Desmontaje-Montaje Bloque Motor

BMW F 800 R K73 Desmontaje-Montaje Bloque Motor

Uploaded by

Gustavo FajardoCopyright:

Available Formats

BMW-Motorrad - 0B54 - F 800 R, K73 12

11 11 514 Replace engine block (engine removed)

NOTICE

Pistons and piton pins have to be renewed if the engine block is

replaced.

Preparatory work

Removing oil filter

Removing starter

Removing flange for heat exchanger with coolant lines

Securing engine to assembly stand

Removing direct ignition coils

Removing spark plugs

Remove the cylinder head cover

Removing crankshaft sensor

Removing right crankcase cover

Setting engine to firing TDC

Checking valve clearance

Locking engine at firing TDC

Removing chain tensioner

Removing camshaft bearing cap unit

Removing both camshafts

Removing timing chain slide rail

Remove the cylinder head

Operating and removing gear lever

Removing pinion

Removing left crankcase cover

Removing selector shaft

Removing clutch pressure plate

Remove the lined plates

Removing clutch hub

Removing clutch cage

Removing oil pan

Remove the swing-arm shaft cover and oil pressure control

valve

Releasing TDC locator

Removing bottom crankcase half

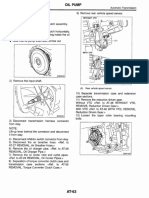

Removing oil-pump drive gear

Removing cover of oil delivery pump

Removing oil delivery pump

Removing cover of oil suction pump

092017 BMW Motorrad, UX-VA-4 1/9

BMW-Motorrad - 0B54 - F 800 R, K73 12

Removing oil suction pump

Removing gearbox potentiometer

Removing oil-pump shaft

Removing shaft sealing ring for gearbox output shaft

Removing transmission output shaft and transmission input

shaft

Removing shift forks for 1st/3rd and 2nd/4th gears

Removing shift fork, 5th/6th gear

Removing locking lever

Removing selector drum with star-shaped locking element

Removing conrod bearing caps

Core activity

(-) Removing piston with conrod

Mark the conrods to ensure that they remain matched with their

original cylinders.

Mark the exhaust side on the crown.

Push both conrods with pistons (1) down, taking care not to damage

the crankpins and the bearing shells.

Check

Check bearing shells for wear (scoring, damage).

Result:

Bearing shells show scoring or other signs of damage.

Measure:

Replace the bearing shells.

(-) Removing piston

Clamp conrod (1) in a vice fitted with protective jaws.

Remove circlip (2).

Remove piston pin (3).

Remove piston (4).

(-) Installing piston (conrod removed)

092017 BMW Motorrad, UX-VA-4 2/9

BMW-Motorrad - 0B54 - F 800 R, K73 12

Lubricate the piston pin with engine oil.

Heat the piston.

Technical data

Mating 50 °C

temperature, piston

pin in piston

Install conrod and piston pin (2), making sure that the installed

position is correct.

The dot on the base of the conrod (arrow) must face toward the

exhaust (note the mark on the piston crown).

ATTENTION

Loose circlips or gudgeon pin

Damage to cylinder barrel

Make sure that the circlips are correctly seated on the gudgeon pin.

Install new circlips (1).

Seat the tab of the circlip in the recess and work round the

circumference, pressing the circlip into the groove; the circlip must

engage with an audible click.

(-) Removing crankshaft main bearing caps

Mark both main bearing caps prior to removal to ensure that they

can be reinstalled in their original positions.

Do not mix up the two main bearing caps.

Remove screws (1) and remove both main bearing caps (2).

(-) Removing crankshaft

Mark the direction of rotation on timing chain (1).

Remove timing chain (1) and crankshaft (2).

092017 BMW Motorrad, UX-VA-4 3/9

BMW-Motorrad - 0B54 - F 800 R, K73 12

(-) Removing layshaft for starter

Remove washer (1).

Remove gears (2) and (3) from axles (4).

(-) Removing timing-chain tensioning rail

Remove screw (1) and remove timing chain tensioning rail (2).

(-) Replacing engine block

Install new main bearing shells.

Clean and check the components after removal; replace defective or

worn components as necessary.

(-) Installing timing-chain tensioner rail

Clean the threads.

Install timing chain tensioning rail (2) and install screw (1).

Tightening torques

Chain tensioner rail to engine block

M6, Replace screw 10 Nm

Thread-locking compound (Micro

-encapsulated)

(-) Installing crankshaft bearing shells

Clean the bearing shells and the bearing-shell seats.

092017 BMW Motorrad, UX-VA-4 4/9

BMW-Motorrad - 0B54 - F 800 R, K73 12

ATTENTION

Incorrect positioning of the bearing shells

Engine damage

Position the lubrication holes in the bearing shells over the oil ducts.

Install all the bearing shells (arrows) in pairs, with the projections

engaged in the bearing-shell seats.

NOTICE

Replace the crankshaft bearing shells if the crankshaft is replaced.

(-) Installing layshaft for starter

ATTENTION

Installation of the gears not in compliance with correct procedure

Component damage

Install double gear on bottom axle.

Lubricate axles (4).

Lubricant

Klüberpaste 46 MR 401 11 00 7 660 831

Install gearwheels (3) and (2).

Install washer (1).

(-) Installing crankshaft

Requirement

Bearing shells are installed in the engine block.

Clean the sealing faces.

Before installing crankshaft (2), lubricate all bearing seats with

engine oil.

Install crankshaft (2), while at the same time looping timing chain (1)

over the bearing stub.

Engage timing chain (1).

Make sure that the timing chain is installed right way round, i.e.in its

original direction of rotation.

092017 BMW Motorrad, UX-VA-4 5/9

BMW-Motorrad - 0B54 - F 800 R, K73 12

(-) Installing crankshaft main bearing caps

Clean the mating faces.

Install main bearing caps (2), making sure that the reamed pins

(arrows) are correctly positioned.

Make sure that the marks indicating the correct installed position

match.

Use an electronic torque wrench/angle-of-rotation tightening tool

when tightening.

Workshop equipment

Electronic torque wrench/angle-of-rotation tightening tool

Tightening sequence for main bearing caps

Tighten screws (1) to (8) in the appropriate tightening sequence.

Tightening torques

Main bearing cap

M8 x 77 - 10.9, Replace screw Tightening

Collar flat of screw lightly oiled sequence: See

repair manual

Tightening torque,

15 Nm

Additional angle of

rotation, 45+5°

−5

(-) Installing piston (conrod removed)

Lubricate the piston pin with engine oil.

Heat the piston.

Technical data

Mating 50 °C

temperature, piston

pin in piston

Install conrod and piston pin (2), making sure that the installed

position is correct.

The dot on the base of the conrod (arrow) must face toward the

exhaust (note the mark on the piston crown).

ATTENTION

Loose circlips or gudgeon pin

Damage to cylinder barrel

Make sure that the circlips are correctly seated on the gudgeon pin.

Install new circlips (1).

092017 BMW Motorrad, UX-VA-4 6/9

BMW-Motorrad - 0B54 - F 800 R, K73 12

Seat the tab of the circlip in the recess and work round the

circumference, pressing the circlip into the groove; the circlip must

engage with an audible click.

(-) Installing piston with conrod

Turn the engine to its normal position.

Make sure that the gaps of the piston rings are not in line with the

piston's axis of tilt.

Position the gaps of oil wiper ring (3) so that they are offset approx.

30° from each other (detail).

Position the other piston rings (2), (1) so that the gaps are each

offset 120° from the top gap of the oil wiper ring.

Lubricate the friction face of the cylinder and the friction face of the

piston skirt with engine oil.

Introduce the conrod and piston into the cylinder bore, making sure

that the assembly is installed right way round (arrows).

Technical data

Piston, installed Arrow on piston

direction crown pointing to

exhaust side

Turn the crankshaft until the crankpins are at the bottom.

Slip piston-ring compressor (No. 11 5 731) around the piston in such

a way that it just encloses all the piston rings.

Tighten piston-ring compressor (No. 11 5 731) and carefully ease

the piston into the cylinder, taking care not to allow the conrods to

contact the crankshaft.

(-) Installing conrod bearing caps

ATTENTION

Cracked conrods mismatched or installed wrong way round.

Component damage

Mark both conrod and conrod cap prior to disassembly and use

these marks to ensure that the components are reinstalled in their

original positions.

092017 BMW Motorrad, UX-VA-4 7/9

BMW-Motorrad - 0B54 - F 800 R, K73 12

Clean the mating faces of the conrod.

Lubricate the friction faces with engine oil.

Set conrod bearing cap (2) on the conrod, making sure that the

marks (arrows) are matched.

ATTENTION

Re-tightening of reduced-shaft bolts

Stretching or failure of the reduced-shaft bolts

Tighten reduced-shaft bolts only once.

Oil the threads and collar seats of new conrod bolts (1).

Engage conrod bolts (1).

Use an electronic torque wrench/angle-of-rotation tightening tool

when tightening.

Workshop equipment

Electronic torque wrench/angle-of-rotation tightening tool

Tighten conrod bolts (1).

Tightening torques

Conrod bolt

M9 x 1 x 49, Replace screws 1st tightening

Thread and seating face of the torque, 10 Nm

screw oiled 2nd tightening

torque, 20 Nm

Additional angle of

rotation, 70°

Follow-up work

Installing selector drum with star-shaped locking element

Installing shaft sealing ring of selector drum

Installing locking lever

Installing shift fork, 5th/6th gear

Installing shift forks for 1st/3rd and 2nd/4th gears

Installing oil-pump shaft

Installing gearbox potentiometer

Installing oil delivery pump

Installing cover of oil delivery pump

Installing oil-pump drive gear

Installing oil suction pump

Installing cover of oil suction pump

Installing transmission output shaft and transmission input shaft

Installing bottom half of crankcase

Locking crankshaft in TDC position

Installing clutch cage

Installing clutch hub

092017 BMW Motorrad, UX-VA-4 8/9

BMW-Motorrad - 0B54 - F 800 R, K73 12

Installing lined plates

Installing clutch pressure plate

Installing selector shaft

Install the cover for swing-arm shaft

Installing oil pan

Installing left crankcase cover

Installing shift lever

Installing shaft sealing ring, gearbox output shaft

Installing pinion

Operating gearshift lever

Installing cylinder head

Installing timing-chain slide rail

Installing both camshafts

Securing camshaft bearing cap unit

Installing camshaft bearing cap unit

Install the chain tensioner

Checking engine timing

Releasing TDC locator

Checking engine timing

Rechecking valve clearance

Installing cylinder head cover

Installing spark plugs

Installing direct ignition coils

Installing right crankcase cover

Installing crankshaft sensor

Removing engine from assembly stand

Installing flange for heat exchanger with coolant lines

Installing starter

Installing screw (in hole for TDC locating screw)

Installing oil filter

092017 BMW Motorrad, UX-VA-4 9/9

You might also like

- Engine Manual Service X-Trail t-30Document230 pagesEngine Manual Service X-Trail t-30Edwin WIlfredo Ttito Angeles73% (15)

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn MartinNo ratings yet

- MG Zs TimingDocument6 pagesMG Zs TimingAhmed Taher100% (1)

- Sincronizacion de Motores Ssangyong d20dt d27dtDocument4 pagesSincronizacion de Motores Ssangyong d20dt d27dtMynor Witt100% (5)

- TMT 55 HT XT Parts ManualDocument328 pagesTMT 55 HT XT Parts ManualOskars Rozefelds0% (1)

- Vauxhall Workshop Manuals Astra H J Engine and Engine Aggregates DOHC Petrol Engine Cylinder Head Repair Instructions Valve Lash - Petrol Engine Check and Adjust PDFDocument26 pagesVauxhall Workshop Manuals Astra H J Engine and Engine Aggregates DOHC Petrol Engine Cylinder Head Repair Instructions Valve Lash - Petrol Engine Check and Adjust PDFSean Osborne0% (1)

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Disassembly: 2Uz-Fe Engine Mechanical - Engine UnitDocument21 pagesDisassembly: 2Uz-Fe Engine Mechanical - Engine UnitMateusz Jaskuła100% (1)

- Toyota 4efe - Correa de Distribucion PDFDocument11 pagesToyota 4efe - Correa de Distribucion PDFRonald Gareca RuedaNo ratings yet

- Kohler Carburetor Reference Manual TP-2377-EDocument60 pagesKohler Carburetor Reference Manual TP-2377-EChevronelle100% (1)

- YD25 Engine MechDocument35 pagesYD25 Engine MechAlex Hernandez100% (3)

- Service Manual: Carbureted Suzuki 970 CC EngineDocument95 pagesService Manual: Carbureted Suzuki 970 CC EngineHallex OliveiraNo ratings yet

- Golf VDocument42 pagesGolf Vภูเก็ต เป็นเกาะ67% (3)

- Components of Fuel Injection System-1Document25 pagesComponents of Fuel Injection System-1yoyotoyo100% (3)

- Reman Catalogus CNHDocument145 pagesReman Catalogus CNHMMM-MMM100% (2)

- BMW F 800 R K73 Desmontaje-Montaje CulataDocument18 pagesBMW F 800 R K73 Desmontaje-Montaje CulataGustavo FajardoNo ratings yet

- BMW F 800 R K73 Bajar-Subir MotorDocument7 pagesBMW F 800 R K73 Bajar-Subir MotorGustavo FajardoNo ratings yet

- Poner A Tiempo ContourDocument4 pagesPoner A Tiempo ContourJuan Carlos Nuñez CastilloNo ratings yet

- Toyota LC HZJ78 02 CL ClutchDocument4 pagesToyota LC HZJ78 02 CL Clutchyannis.spinnerNo ratings yet

- Cylinder Bloc DissasemblyDocument8 pagesCylinder Bloc DissasemblyYannick de WalqueNo ratings yet

- BMW R 1200 GS 2006 Desmontaje - Montaje CilindrosDocument26 pagesBMW R 1200 GS 2006 Desmontaje - Montaje CilindrosPablo Ezequiel GarciaNo ratings yet

- AIR - Repair InstructionDocument8 pagesAIR - Repair InstructionOrestes RamNo ratings yet

- Removal: CH-7 SR-24Document3 pagesRemoval: CH-7 SR-24Boncu BoncuNo ratings yet

- 1gr Fe - Cadena de DistribucionDocument5 pages1gr Fe - Cadena de DistribucionMartin KoopmannNo ratings yet

- Manual de Mecánica Toyota 3ADocument7 pagesManual de Mecánica Toyota 3AElmer Aldair Inoñan VilchezNo ratings yet

- Valve Clearance: InspectionDocument5 pagesValve Clearance: InspectionПежов СитроенNo ratings yet

- w040001 PDFDocument31 pagesw040001 PDFresolution8878No ratings yet

- Matrix 2003 2zz 8Document10 pagesMatrix 2003 2zz 8alan lantiguaNo ratings yet

- Remove Injection Pump c4. 4 SN s1mDocument2 pagesRemove Injection Pump c4. 4 SN s1mBadrus AqmarNo ratings yet

- BMW F 800 R K73 Montaje Arboles de Levas CaladoDocument4 pagesBMW F 800 R K73 Montaje Arboles de Levas CaladoGustavo FajardoNo ratings yet

- BMW C650 GT Belt and Roller Service (v2)Document15 pagesBMW C650 GT Belt and Roller Service (v2)Jorge ArijaNo ratings yet

- Exhaust Valve Actuator: S35MC DataDocument6 pagesExhaust Valve Actuator: S35MC DatalijinNo ratings yet

- I Removal of TurbochargerDocument6 pagesI Removal of TurbochargerDavid QuispeNo ratings yet

- 10 ACG - Starting ClutchDocument9 pages10 ACG - Starting ClutchLuis Carlos Barrera IdarragaNo ratings yet

- Front Crankshaft SealDocument4 pagesFront Crankshaft Sealcristi cristiNo ratings yet

- Oil Pump 55,000: Automatic TransmissionDocument7 pagesOil Pump 55,000: Automatic TransmissionAnton FortovNo ratings yet

- ForkDocument15 pagesForkcalvofernandavidNo ratings yet

- Sincronizacion de Motores Ssangyong d20dt d27dt PDFDocument4 pagesSincronizacion de Motores Ssangyong d20dt d27dt PDFMynor WittNo ratings yet

- Engine RemovalDocument13 pagesEngine RemovalShuraihMehlNo ratings yet

- Partial Engine Assembly2Document34 pagesPartial Engine Assembly2jeremih alhegnNo ratings yet

- BMW-2.5L & 2.7L 6-CylinderDocument2 pagesBMW-2.5L & 2.7L 6-CylinderIsrael CurielNo ratings yet

- Automatic Transaxle's DisassemblyDocument32 pagesAutomatic Transaxle's Disassemblymohamed A.abdeltwabNo ratings yet

- Removal: CO-5 EM-34Document5 pagesRemoval: CO-5 EM-34marran almarranyNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 177Document1 pageNissan Almera n16 2001 Electronic Repair Manual 177netifig352No ratings yet

- Motor 1AZ-FE OverhaulDocument29 pagesMotor 1AZ-FE OverhaulfredhNo ratings yet

- P250-250S Cap 10 (A.C. GENERATOR)Document10 pagesP250-250S Cap 10 (A.C. GENERATOR)Minh ChuNo ratings yet

- B234 Camshaft and TappetsDocument9 pagesB234 Camshaft and TappetsAndri OdeNo ratings yet

- TNT25 Engine Intro (HD)Document90 pagesTNT25 Engine Intro (HD)Miguel LemosNo ratings yet

- Platz 02Document7 pagesPlatz 02dawitmesfin9No ratings yet

- 12 - Cylinder Head - RemovalDocument3 pages12 - Cylinder Head - RemovaljordantNo ratings yet

- Cylinder Head Gasket (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )Document6 pagesCylinder Head Gasket (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )mulertilahuneNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 178Document1 pageNissan Almera n16 2001 Electronic Repair Manual 178netifig352No ratings yet

- HONDA2Document8 pagesHONDA2Taller PNCNo ratings yet

- A86&A88-chapter 7 (CYLINDER HEAD VALVES)Document28 pagesA86&A88-chapter 7 (CYLINDER HEAD VALVES)Stojanov MarjanNo ratings yet

- 14 - Cylinder Head - InspectionDocument9 pages14 - Cylinder Head - InspectionNazmul HassanNo ratings yet

- Overhaul: 1. Remove Valve LifterDocument13 pagesOverhaul: 1. Remove Valve LifterMark Anthony FletcherNo ratings yet

- Overhaul: Partial Engine Assy (1Gr Fe)Document50 pagesOverhaul: Partial Engine Assy (1Gr Fe)Islam AttiaNo ratings yet

- 722.369 Valve BodyDocument7 pages722.369 Valve BodyadinxNo ratings yet

- Timing Belt (5S-Fe) : ComponentsDocument14 pagesTiming Belt (5S-Fe) : ComponentsmutasimNo ratings yet

- Service Manual: DaihatsuDocument77 pagesService Manual: Daihatsujuan carlos delgadoNo ratings yet

- Suspension ZF RCU Manual Final AutosavedDocument57 pagesSuspension ZF RCU Manual Final AutosavedTiago ZeferinoNo ratings yet

- 23gearboxDocument56 pages23gearboxcarzclassixNo ratings yet

- Plataforma Manitou 78SEC Servicio Ingles EjesDocument6 pagesPlataforma Manitou 78SEC Servicio Ingles EjesJose LunaNo ratings yet

- Toyota 4Y Engine Cylinder HeadDocument17 pagesToyota 4Y Engine Cylinder HeadJose Antonio PalumboNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- BMW F 800 R K73 Montaje Arboles de Levas CaladoDocument4 pagesBMW F 800 R K73 Montaje Arboles de Levas CaladoGustavo FajardoNo ratings yet

- BMW F 800 R K73 Discos EmbragueDocument4 pagesBMW F 800 R K73 Discos EmbragueGustavo FajardoNo ratings yet

- BMW F 800 R K73 Desmontaje-Montaje CulataDocument18 pagesBMW F 800 R K73 Desmontaje-Montaje CulataGustavo FajardoNo ratings yet

- BMW F 800 R k73 Montaje Carter CambioDocument4 pagesBMW F 800 R k73 Montaje Carter CambioGustavo FajardoNo ratings yet

- BMW F 800 R K73 Bajar-Subir MotorDocument7 pagesBMW F 800 R K73 Bajar-Subir MotorGustavo FajardoNo ratings yet

- BMW F 800 R K73 CaladoDocument2 pagesBMW F 800 R K73 CaladoGustavo FajardoNo ratings yet

- BMW F 800 R K73 AlternadorDocument6 pagesBMW F 800 R K73 AlternadorGustavo FajardoNo ratings yet

- Despiece EC125 2004Document116 pagesDespiece EC125 2004Gustavo FajardoNo ratings yet

- Manual Definitivo NSF250RDocument203 pagesManual Definitivo NSF250RGustavo FajardoNo ratings yet

- Generator Set Data Sheet: Fuel ConsumptionDocument3 pagesGenerator Set Data Sheet: Fuel Consumptionmohsen_cumminsNo ratings yet

- LPG Diagnosis ManualDocument65 pagesLPG Diagnosis ManualmfernandNo ratings yet

- Generator Spare Parts Budget-2020Document106 pagesGenerator Spare Parts Budget-2020mahbubur rahmanNo ratings yet

- Speeduino Miata / MX5 Manual: This Manual Is Compiled From The Speeduino Documentation Wiki: Thu Sep 20 2018Document44 pagesSpeeduino Miata / MX5 Manual: This Manual Is Compiled From The Speeduino Documentation Wiki: Thu Sep 20 2018Manny MoralesNo ratings yet

- Comparative Study in LTC Combustion Between HP Egr and Variable Lift and DurationDocument10 pagesComparative Study in LTC Combustion Between HP Egr and Variable Lift and DurationSachin ShastriNo ratings yet

- Hydraulic Shoe PartsDocument33 pagesHydraulic Shoe PartsLei Zengrong100% (1)

- A Motronic Engine Management System Is An Electronic System That Combines The Fuel and Ignition System Into A Single Electronic Control UnitDocument2 pagesA Motronic Engine Management System Is An Electronic System That Combines The Fuel and Ignition System Into A Single Electronic Control UnitMarcusNo ratings yet

- 400 Series ManualDocument108 pages400 Series Manualsfe100% (1)

- 2012 450 SXF Factory Replica USA EngineDocument28 pages2012 450 SXF Factory Replica USA EnginecharlesNo ratings yet

- MAN B&W Diesel A/S: Service LetterDocument7 pagesMAN B&W Diesel A/S: Service LetterKaushalKishoreNo ratings yet

- Crankshaft Main Bearing MEDIDASDocument2 pagesCrankshaft Main Bearing MEDIDASRECTIMANSANo ratings yet

- 3126 Air in FuelDocument4 pages3126 Air in FuelArnon Rutsalam50% (2)

- 303-03A Engine Cooling - 1.5L EcoBoostDocument71 pages303-03A Engine Cooling - 1.5L EcoBoostMohamed AdelNo ratings yet

- Perkins ManualDocument51 pagesPerkins Manualtech deptNo ratings yet

- Experiment No. - 3: B.S.A. College of Engg. & Technology MathuraDocument3 pagesExperiment No. - 3: B.S.A. College of Engg. & Technology MathuraROHIT SRIVASTAVNo ratings yet

- SM 9 PDFDocument218 pagesSM 9 PDFVictor CostacheNo ratings yet

- Lifeboat Engine, YanmarDocument80 pagesLifeboat Engine, YanmarDuarte100% (1)

- Lehm4965-01 c9 Ficha TecnicaDocument2 pagesLehm4965-01 c9 Ficha TecnicaDavid.QuijanoNo ratings yet

- Perkin 2806 Mechanical Workshop ManualsDocument123 pagesPerkin 2806 Mechanical Workshop ManualsHarris Rao0% (1)

- PCM Inspection (Skyactiv-G 2.5)Document39 pagesPCM Inspection (Skyactiv-G 2.5)Esteban LefontNo ratings yet

- Chapter 1Document24 pagesChapter 1ahmed jemalNo ratings yet

- 675 Race Manual 2011 PDFDocument62 pages675 Race Manual 2011 PDFManuel Martinez CarranzaNo ratings yet

- Chapter - 1 General Information On The EnginesDocument8 pagesChapter - 1 General Information On The EnginesKenmoe T DonasNo ratings yet

- How To Adjust The Idle Mixture On Holley CarbsDocument4 pagesHow To Adjust The Idle Mixture On Holley CarbsIsaias PrestesNo ratings yet