Professional Documents

Culture Documents

Audit2 20220525 0001

Audit2 20220525 0001

Uploaded by

HoodaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Audit2 20220525 0001

Audit2 20220525 0001

Uploaded by

HoodaCopyright:

Available Formats

I

L7-05-2422 ZF Confid

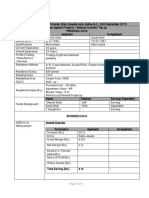

Date (ww'mm'dd): 2022-05-12 Commodity: M106010- Friction - Braking

Supplier name: MA,SU Brakes Pads Pvt Ltd fi$ascn:

Audit Potential supplier audit (P'l)

ZF Supplier lD: 1 685245 Product: Brake Pad- CV&PC

Production site (localionlcity): District: Jhaijar,Bahadurgarh ComparablewithZFpaft: Yes

f1.

Country: lndia Audit scoool Process

n.e. Eresscs-dsssnsliaEi

"1 N4ASU Brake Dads Pvt ltd (Plant il) is a Privote coilpanY of the MASU Brakes group fooilded in 1982;

0 31 0 GREEN & supplyrng PC, CV & 2 wheeler BBke pads world!!ide t0 the Tier T OE(Advik, Knorr Bremse) aftermarket

0 0 0 >>n.e. rated customers.

c 0 0 >>n.e. rated The total turnover ofthis plant is 25 mln. furo ( Expot " 95% and dornestic- 5%),

Masu group is having 2 manufacturing plan$ in NCR, plant I- MASU Brakes Pvt ltd and plant Ii- i!IASU Brake prds

Pvt ltd, IYASU is having 2 R&D centrers, 1 in lndia in mfu.Facility I and other is in lv'iich,gan,UsA.

Monthly manufacturing 3.5 lakh sets of PC brake pads in plant II and 1 Lald sets ofCV brake pads from the plant

N,rt irl)tr\,iri NJrl rr!Jr rs rin Idrslri.: l"otal manpower is 1500 l(os including contract labor.

Main customers are - NAPA-USA, \4/agner-U5A, DFT, DFC, Biakes India for TATA, Advik, Haldex,HJsh4, Knorr

13remse, Autolone.

Mfg. scope in Plant I- CV Brake p6d, brake lining & Broke shoe, pC Brake shoe, Brake pads, snd roll linings for

brefirse, I\4eritor and Brakes india(Cv brake pads), and Tata Motors.

MASU is doing its own aftermarket business under the i\'{qSU brand,

Thls ls a Potential analysis audit ifi plant II from the ZF aftermarket division as per VDA 6.3:2016 requirement$ as

per ZF business requlrements for PC & CV Brake pads.

/ future

Thi6 plant is certified for IATF 16949 & ECE R-90 for Friction pafts,

Audit basis: is:ue Dai.: Conducted by: li.sL lt MASU is having in-house Shot bla$tinE, hot molding, curing. grinding, ,owder eoating, and testing aperatlons.

240368-201 7-AO"lND-IATF 29-07-2021 DNV PASS

[4ASU is having a good testing lab in Plarit il

applications, NVH Dynainorref er conpatible

1 0000 397 6 1 4"1\,4SC"RvA-i ND 2.7-14-2420 DNV PASS salt spray rest \etup.

240373-2111 7-AE-lND-HvA 12-A6'2il2A DNV PASS

During the audit the following dtrengths were identified:

'+ Experienced and Knowledgeable teanr in design and development.

'+ Good manufaduring setup and capacity with required testing equiprnent (Able to meet fF TSA & QD83

requirements)

'J 6ood 55 and process control.

{ Good Qlvls implementa[ion.

Distribution: '+ Automated grinding machine with auto inspection provision.

7r At the suoolier During the audit the following signifieant findings wore ideiltifi€di

'- Supplier audit process has to be improved. Detailed findinss and an actlon plan were missing.

Central Audit NlanagBment Sy$tem Shubneet Sirrgh l(ohll

'- PFMEA has

be reviewed and updated for better control (occurrence 6nd detection numbe6 have tc be ideill,ified as per

PAttiqiQanls: & VDA FNlEA standard).

lt Al the suprrliei '-Conclusion:

capatile supplier. The rESU 0f rating "Green" meanS fully approv€d.

N:tille Nnrr6

is capable p!oduce PC & CV pads by taking imprcvem€nt action 0n the gaps.

a Koh i Director course of action:

hin Sewkar Pl,l lndla kofrll Head need to submit an action plan within 2 \/eeks of receiving the ZF audit report. ZF will review the action

planreceIvedandshallplantheveriflcationactivitYifdeemednecessary.

J Head OualitV

Rafiit sinoh Plant l-lead

ii:lcTt,i ff iitl llnj:riil ui llri in fl)vi:rlLitnf

2A22-05"2* program ( l2weeksaiter 2022-08-06

flflritriir:r il ri (lr!'! )

Lead Gen6$h 5DE lndia Audhor Signed for 0rganization

11 -05-2022 ZF Confidential

Fotential_ analvsis to VDA 6.3 - a-ccordino to ZF evaluation scheme revision level 2017

Oualification timinu plan

0are (yYgi"mm'dd): ztzz-ai-12 Commodity: V1106010 - Frictiorr "Braking

Supplier namel ItilASU Brakes Pads Pvt Ltd Beason:

Audit Pote0tiai supplier airdit (Pl )

'ZF $upplier lD: 1685245 Product: Brake Pad- CV&PC

I Production sito

{location/ciry}: District: Jhajjar,Bahadurgarh ComparablswithZFparr Yes

Country: lndia l,udit scope: Frocess

Timirrg Supplier/Tender

Activities Timing

I ritprcver:-er: I pt'oalrilm rece v6ci 2022-05-1 4

l. Concretion and timing of the improvement program (14 days ) 2422-06-28

ll. Realization of improvement program ( 12 weeks afteraward ) 2022-08-06

lll. Seliassessment according to VDA 6.3 ( only by'GREEN- and "YELLOW', if award is made ) 1 2 cw before SOP

Explanation

The activities must be realized immediately. For large improvement programs the realization can be subdivided in several

realieation pha$es.

f,elfas$sssment: to a$sess sericlrsly the selfassessment, we ask for information about the audit timing (man days) and the

qualification of the auditors used. ln our opinion the audit liming equates a timing of a certification audit. After receivin g

andverifyingtheauditdocuments wewiil,iftheresultisclassifiedas"GREEN",agreeournextauciittiming. lftheresult

ls classified as "YELLOW" we ask for realistic timing you will achieve an "GREEN" classification, We expect then the on

time sending of the audit reporl of the internals follow up audit, wilhout any specific request from us.

Agreement of upgrade qualifieation;

Controlled suppliers / tendors commit themseives, after been awarded, to cooperate rsith an approved consuitrng

company by accepting the upgrade qr-ralification agreenient. Costs will be carried by the sup;:lier.

Bhujbal $DE lndia Sh ub neBt

Lead Auditor Audi'ror [4r. 0anesh Bhujbal Signsd for

You might also like

- Torques Captiva 2.4Document7 pagesTorques Captiva 2.4rectificamos100% (2)

- VW MK5 Jetta Model Introduction SSP 891403Document86 pagesVW MK5 Jetta Model Introduction SSP 891403Alex Stirbu100% (6)

- 64l Power StrokeDocument103 pages64l Power StrokeMathias ChamorroNo ratings yet

- HDFC ReportDocument10 pagesHDFC Reportvishal kharvaNo ratings yet

- CatalogueDocument70 pagesCatalogueGeorge Kwamina Anaman100% (2)

- Water Tank ItpDocument5 pagesWater Tank ItpHgagselim SelimNo ratings yet

- A Multi-Link Suspension System PDFDocument8 pagesA Multi-Link Suspension System PDFmikael bezerra cotias dos santos0% (1)

- SDLG LG958L Wheel LoaderDocument4 pagesSDLG LG958L Wheel LoaderMartin Lee100% (2)

- Honda PgmfiDocument14 pagesHonda Pgmfivivek0630100% (2)

- Introduction To Chemical Process EquipmentDocument24 pagesIntroduction To Chemical Process EquipmentShebnemNo ratings yet

- S646-140-SP-F-001-01 R1 PDFDocument5 pagesS646-140-SP-F-001-01 R1 PDFGoutam GiriNo ratings yet

- EPSOA CalculatorDocument195 pagesEPSOA CalculatorenjoythedocsNo ratings yet

- 140 V 009 PDFDocument4 pages140 V 009 PDFGoutam GiriNo ratings yet

- Piotroski Score - Screener1Document4 pagesPiotroski Score - Screener1visalNo ratings yet

- Forecast - WH5 Cost Report JanDocument7 pagesForecast - WH5 Cost Report JanMarkyNo ratings yet

- Planning SheetDocument2 pagesPlanning Sheetkyi zin ayeNo ratings yet

- Stress TestDocument1 pageStress Testrubyhall bio-medicalNo ratings yet

- SBI Small Cap Fund FactsheetDocument1 pageSBI Small Cap Fund FactsheetPalam PvrNo ratings yet

- BendPak 5260047 HDS 18EA Alignment Lift Exploded View Parts ListDocument38 pagesBendPak 5260047 HDS 18EA Alignment Lift Exploded View Parts ListLuis Fernando BravoNo ratings yet

- Chevrolet-Malibu 2003 en US C554bf8edcDocument354 pagesChevrolet-Malibu 2003 en US C554bf8edcGuillermo Orozco SalasNo ratings yet

- SMS - 67390 8jb0a - K2MCDocument21 pagesSMS - 67390 8jb0a - K2MCmani sNo ratings yet

- Intern Presentation1 DahaitsuDocument19 pagesIntern Presentation1 DahaitsuIqmal HalimNo ratings yet

- Flow CatalogueDocument20 pagesFlow CatalogueMinco100% (1)

- Project:-Jigjiga-Gelelsh-Deghamedo - Segeg Road ProjectDocument10 pagesProject:-Jigjiga-Gelelsh-Deghamedo - Segeg Road ProjecttsegayNo ratings yet

- Toyota: Request For On-Hand (Roh) AdjustmentDocument1 pageToyota: Request For On-Hand (Roh) AdjustmentKarl CruzNo ratings yet

- LPD Comments ClosureDocument33 pagesLPD Comments ClosureChaudhary Wasim MurtazaNo ratings yet

- SS SC003 JO DP 00643 - Rev000Document11 pagesSS SC003 JO DP 00643 - Rev000Wahyu AgustinusNo ratings yet

- DSQ04A11Document1 pageDSQ04A11nafurahmanNo ratings yet

- 2012 TownandcountryDocument652 pages2012 TownandcountryOsama RaghibNo ratings yet

- Memorandum of Understandng Between Mtnistry of Railiilays Ai/D Rites Limited FOR THB YEAR 2016.17Document7 pagesMemorandum of Understandng Between Mtnistry of Railiilays Ai/D Rites Limited FOR THB YEAR 2016.17ANAND V KNo ratings yet

- TA-24 Organogram - CANDocument1 pageTA-24 Organogram - CANUzair AshrafNo ratings yet

- Iso 6403Document34 pagesIso 6403Fabio StuiNo ratings yet

- Stanzen ProfileDocument33 pagesStanzen ProfileAmit SinghNo ratings yet

- PKG 5 Customer List in IndiaDocument5 pagesPKG 5 Customer List in IndiaGiri DharNo ratings yet

- 313 291 17 5 Leave Type: RCRC: Riyadh Sport Boulevard - Wadi Hanifah Zone B (62298)Document13 pages313 291 17 5 Leave Type: RCRC: Riyadh Sport Boulevard - Wadi Hanifah Zone B (62298)AHMAD ABDULLAHNo ratings yet

- SamaroDocument10 pagesSamaroBlack DemonNo ratings yet

- 2.5 Andon Board ExampleDocument2 pages2.5 Andon Board ExampleCarlos HernandezNo ratings yet

- Fenixus (Compatibiliteitsmodus)Document17 pagesFenixus (Compatibiliteitsmodus)William PalozzoNo ratings yet

- SBI Large Midcap Fund Factsheet April 2024Document1 pageSBI Large Midcap Fund Factsheet April 2024Hitesh MiskinNo ratings yet

- Extension of Existing Mou For TITPDocument1 pageExtension of Existing Mou For TITPamanNo ratings yet

- SW37-CODE R (No Comment) -A545-4103-9030-VD-COMM-SW37-R1- LOUVERDocument10 pagesSW37-CODE R (No Comment) -A545-4103-9030-VD-COMM-SW37-R1- LOUVERabdul azizNo ratings yet

- 120025-Hse-001 Company Hse Management PlanDocument19 pages120025-Hse-001 Company Hse Management PlanMoaatazz NouisriNo ratings yet

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- Annex 2Document2 pagesAnnex 2Delwar HossainNo ratings yet

- Assignement Details To Be Uploaded Till August 2023Document57 pagesAssignement Details To Be Uploaded Till August 2023Deoo Milton EximoNo ratings yet

- Bi-bccp-00-Cem-157-Mg-0013 r1 Piping Isometric For Potable Water SystemDocument25 pagesBi-bccp-00-Cem-157-Mg-0013 r1 Piping Isometric For Potable Water SystemmizanNo ratings yet

- PPD Emergency PreparednessDocument4 pagesPPD Emergency Preparednessrustam khanNo ratings yet

- Pakistan Wapda - Power Wing: Payroll RegisterDocument4 pagesPakistan Wapda - Power Wing: Payroll RegisterSana UllahNo ratings yet

- Chrysler Rpa Lujo ×Document706 pagesChrysler Rpa Lujo ×Juan GonzalezNo ratings yet

- Bajaj Supply ChainDocument16 pagesBajaj Supply ChainavadhutgNo ratings yet

- Bajaj Supply ChainDocument16 pagesBajaj Supply ChainavadhutgNo ratings yet

- Application Status TNPDocument4 pagesApplication Status TNPMohit ManchandaNo ratings yet

- Standalone Financial Results, Limited Review Report For December 31, 2016 (Result)Document5 pagesStandalone Financial Results, Limited Review Report For December 31, 2016 (Result)Shyam SunderNo ratings yet

- 10x95 Bolt FlangeDocument83 pages10x95 Bolt FlangeVikas KashyapNo ratings yet

- Poc-851-E-B-Lst-1-006 - Io ListDocument10 pagesPoc-851-E-B-Lst-1-006 - Io ListbennsavyaalrawafNo ratings yet

- Create Scan Old Candlestick P&F Realtime & Alerts WatchlistsDocument5 pagesCreate Scan Old Candlestick P&F Realtime & Alerts WatchlistsSushobhan DasNo ratings yet

- Business Proposal Panna GroupDocument12 pagesBusiness Proposal Panna GroupMazharul HamidNo ratings yet

- VFD Drawings - JSW - PARADIP - CS-4A - Motor-1 - MASTER - R02Document53 pagesVFD Drawings - JSW - PARADIP - CS-4A - Motor-1 - MASTER - R02sudhakarraomNo ratings yet

- Vigilantplant Success Story Collection: TrademarksDocument39 pagesVigilantplant Success Story Collection: TrademarksRaju Gopinathan NairNo ratings yet

- ADB Gallery Synthetic Stone For Gallery Reception Counter Montelli Cloudy CottonDocument8 pagesADB Gallery Synthetic Stone For Gallery Reception Counter Montelli Cloudy Cottonkevin javateNo ratings yet

- Duct Support Data SheetDocument29 pagesDuct Support Data Sheetabdul azizNo ratings yet

- L&H - Score - Report 28 - 07 - 2023Document1 pageL&H - Score - Report 28 - 07 - 2023Koné SékouNo ratings yet

- Trade and Other PayablesDocument14 pagesTrade and Other PayablesMuhammad Zain ShaikhNo ratings yet

- Daily Hydra ChecklistDocument1 pageDaily Hydra ChecklistAbhijit JanaNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNo ratings yet

- Dyno BlairDocument10 pagesDyno BlairAntonino Scordato100% (1)

- Erick PDFDocument94 pagesErick PDFfateless 17100% (1)

- Fuel TrimsDocument6 pagesFuel TrimsahmedNo ratings yet

- B10a8 Air Bag PDFDocument6 pagesB10a8 Air Bag PDFDaniel Garcia100% (1)

- 2.2 Suspension Functionality PDFDocument70 pages2.2 Suspension Functionality PDFDrBalaramakrishna NizampatnamNo ratings yet

- Obd 2 CodesDocument34 pagesObd 2 CodesKatu2010100% (1)

- Ottobock B400Document8 pagesOttobock B400200607807No ratings yet

- Notice: Motor Vehicle Safety Standards: Nonconforming Vehicle Importation Eligibility DeterminationsDocument2 pagesNotice: Motor Vehicle Safety Standards: Nonconforming Vehicle Importation Eligibility DeterminationsJustia.comNo ratings yet

- Blade 600Document306 pagesBlade 600Vedran RimanićNo ratings yet

- DOBDSM1501Document186 pagesDOBDSM1501Sorin CiuculanNo ratings yet

- 920 KVA Data SheetDocument3 pages920 KVA Data SheetPriyanathan ThayalanNo ratings yet

- Clark 19D Planetary Drive Axle PDFDocument104 pagesClark 19D Planetary Drive Axle PDFVladimirEspinozaNo ratings yet

- 02-04-02 Tilt Cylinder (L.HDocument4 pages02-04-02 Tilt Cylinder (L.HricardoNo ratings yet

- Travel Parking BrakeDocument2 pagesTravel Parking BrakeMoncefNo ratings yet

- Tata Indigo Manza 372Document7 pagesTata Indigo Manza 372chaitu3sNo ratings yet

- Craftsman TractorDocument68 pagesCraftsman Tractorbuckeyemarv967No ratings yet

- Product Information: # Toyota #GR86Document7 pagesProduct Information: # Toyota #GR86rodizianoNo ratings yet

- Matic Beat Street D1i02Document21 pagesMatic Beat Street D1i02yoelbagusNo ratings yet

- Ake SystemDocument176 pagesAke Systemghar_dashNo ratings yet

- Hyosung Rapia TE450Document262 pagesHyosung Rapia TE450panpols1No ratings yet

- Calibracion Focus TransmisionDocument1 pageCalibracion Focus TransmisionJeferson SanabriaNo ratings yet

- 1250reozm 0720Document3 pages1250reozm 0720paksongchoiNo ratings yet

- 2020.12.02 - WCX 3A Truck Breakdown and Towing ProcedureDocument6 pages2020.12.02 - WCX 3A Truck Breakdown and Towing ProcedureNaztovenNo ratings yet

- GC/GLC040-065RG/TG/ZG (E187) Service Manual ContentsDocument1 pageGC/GLC040-065RG/TG/ZG (E187) Service Manual ContentsAlexendraNo ratings yet