Professional Documents

Culture Documents

Precambering 5mm: Am/V 71,7 (1/m) Critical Temperature 600 C

Precambering 5mm: Am/V 71,7 (1/m) Critical Temperature 600 C

Uploaded by

Bercea GeorgeDoruOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Precambering 5mm: Am/V 71,7 (1/m) Critical Temperature 600 C

Precambering 5mm: Am/V 71,7 (1/m) Critical Temperature 600 C

Uploaded by

Bercea GeorgeDoruCopyright:

Available Formats

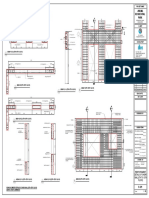

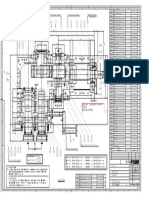

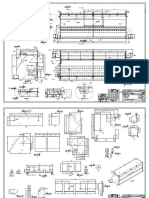

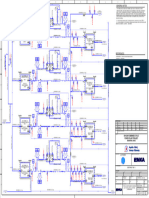

ASSEMBLY LOCATION

08L204-WQ-2 K5.15>/118-124 Top level +47.510

B

A

08L204-WQ-2( 08L204WQP-5) C

PRELIM MARK 08L204WQP-5

220

A 1*D16 C

B

Water drainage hole 2671 2671

4 x SOCKET

1126

2326

3526

4421

5341

0

1300

1750

2200

3141

3591

4041

4491

4941

5341

400

850

Top rebars

0

50

50

180

180

08L204WQL-12

140

140

08L204WQL-12

Hole on bottom flange 80

Hole on Bottom flange 80

r=10mm

r=10mm

1*D10 INTERNAL THREAD1 x M 30 1*D10 08L204WQL-20

INTERNAL THREAD1 x M 30

08L204WQL-1 1*D10

08L204WQL-18 08L204WQL-1

526

596

666

1621

2576

2646

2716

3671

4626

4696

4766

5341

294

0 6

Lifting Parts

1471

3870

5341

0

A-A B-B

242

60 140

6

3

08L204WQL-13 C-C

50

50

6 242 6

3

242

3 08L204WQL-20 08L204WQL-8

20

08L204WQL-8

08L204WQL-18 08L204WQL-12

135

135

6 U>0,5

U>0,5 6 6 5

5

U>0,5

220

3

3 08L204WQM-2

3 6

U>0,5

08L204WQM-5

08L204WQL-12

200

200

3

100

08L204WQM-4

6 6 6

6 3 100(300) 3

189 123 89 89 123 189

Dimensions and welding of WQ-profile Welding of top rebars Critical temperature 600 C Am/V = 71,7 [1/m]

(picture not in scale)

PART LIST FOR ASSEMBLY 08L204-WQ-2, MANUFACTURING AMOUNT 1 PIECES 5 50

Precambering 5mm

5 50

PART PROFILE MATERIAL LENGTH [mm] AREA [m2] WEIGHT [kg] PCS 4.5

4.5 Execution class

08L204WQL-1 CFJ70-320-200-5-10 S355J2 2000 4.6 44.6 2

EXC2

25

08L204WQL-8 PL5X50 S355J2 272 0.3 0.5 10 Technical fabrication requirements:

08L204WQL-12 PL20X283 S355J2 310 0.3 10.1 2 Requirem ents for fabrication, standard Fabrication tolerances

EN1090-2, table A.3 : EXC2 EN 1090-2, Appendix D

08L204WQL-13 PL50X80 S355J2 80 0.1 2.5 2 Execution Specification docum ent nr Special fabrication tolerances PROJECT NAME DRAWING CONTENT

08L204WQL-18 CFJ70-320-200-5-10 S355J2 890 1.0 19.8 1 RA_S_TTXX193 Project specification/ shown on drwg. TRIPLA S ASSEMBLY DRAWING

335

295

Surface preparation grade Weld inspection, requirem ents

08L204WQL-20 CFJ70-320-200-5-10 S355J2 595 0.7 13.3 1 5 50 ISO8501-3, grade P2 EN 1090-2,Table 24, U>0.5 PASILAN ASEMA WQ_PALKKI

08L204WQM-1 D8 B500B 765 0.2 0.3 10 4.5 4.5 5 50 Surface treatm ent

ISO12944-5, EP60/1

Extent of NDT , fillet welds

MT-EN1290,5% of welds 00520 08L204-WQ-2

08L204WQM-2 CFCHS76.1X3 S355J2H 210 0.2 1.1 4

Additional requirem ents on surface treatm ent Extent of NDT , butt welds HELSINKI

Compatible with fire protection coating UT-EN1714,EN1713, 10% of welds DATE ARCHIVING CODE PAGE DESIGN GROUP

Assembly mark location SWECO RAKENNETEKNIIKKA Oy

08L204WQM-4 CFRHS50X50X3 S355J2 242 0.1 1.0 3 Shade Extent of NDT for splices not shown on drawing 26.10.2017 STR

UT-EN1714,EN1713, 100%of welds ILMALANPORTTI 2 DRAWN DESIGNER APPROVED CHECKED

15

08L204WQM-5 CFRHS50X50X3 S355J2 340 0.2 1.4 3 150 200 50 Place assembly mark Welding of built up steel section Requirem ents on holing 00240 HELSINKI

FITAHO B.Sc. V. Tanskanen M.Sc. J. Kihula M.Sc. T. Pekkinen

Appendix 1 / Project spec. EN1090-2 Section 6.6.3 PUH. 020 739 3000

on this end of the beam PROJECT NUMBER SUB NUMBER DWG. NO. REVISION

08L204WQP-5 WQ320X5-25X190-15X400-50 S355J2 5341 7.9 586.0 1

400 a

53805 08L204-WQ-2

Welds, if not specified otherwise Weld class Additional m aterial inspection

a Sustainable engineering and design

TOTAL: 15.5 753.6 C, EN ISO 5817 Shown on drwg.

You might also like

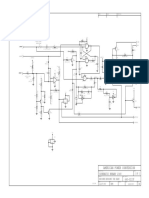

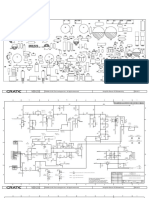

- Rumble 200 V3 Schematics-DiagramsDocument4 pagesRumble 200 V3 Schematics-DiagramsOrlandd Sanchezz100% (1)

- Fender Rumble 40 v3 SCHDocument7 pagesFender Rumble 40 v3 SCHCarlos ZaninNo ratings yet

- Fender Rumble 75Document2 pagesFender Rumble 75GustavoTfLaNo ratings yet

- Fender Rumble 100 V3 TDA8950-88534Document7 pagesFender Rumble 100 V3 TDA8950-88534Claudio Ariel Vera trussy100% (1)

- D2KFBNeo - Fullbridge V.5 Full SchemeDocument1 pageD2KFBNeo - Fullbridge V.5 Full SchemeIbnu Wahyudi100% (1)

- Fender Rumble 350 2010 Schematic Rev BDocument2 pagesFender Rumble 350 2010 Schematic Rev Bqwe123free1231962100% (1)

- Math Workshop, Grade K: A Framework for Guided Math and Independent PracticeFrom EverandMath Workshop, Grade K: A Framework for Guided Math and Independent PracticeRating: 5 out of 5 stars5/5 (1)

- Crate V33H SchematicDocument2 pagesCrate V33H SchematicDanielo ErréNo ratings yet

- APC Back UPS BK300MI, BK500MI - 2 PDFDocument1 pageAPC Back UPS BK300MI, BK500MI - 2 PDFWelington GarciaNo ratings yet

- A10 低速驱动板40 013TDocument1 pageA10 低速驱动板40 013T易行胜No ratings yet

- Half Elevation of P.S.C Girder: Construction DrawingsDocument1 pageHalf Elevation of P.S.C Girder: Construction DrawingsAqib JavidNo ratings yet

- 1233 Pid 03Document11 pages1233 Pid 03Reza AranNo ratings yet

- Jhilmil Residential Park: Reinforcement Details of Shear Wall (5Th To 10Th Floor)Document1 pageJhilmil Residential Park: Reinforcement Details of Shear Wall (5Th To 10Th Floor)Sazzad ChowdhuryNo ratings yet

- Evh® 5150iii LBXDocument3 pagesEvh® 5150iii LBXДмитрийNo ratings yet

- MD 502 3000 Eg CV Dal 00X1 - Rev A02Document1 pageMD 502 3000 Eg CV Dal 00X1 - Rev A02Pro FRGWNo ratings yet

- Crate V33-212Document7 pagesCrate V33-212Danielo ErréNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 05Document1 pageEpcc05 MDR 421 STR DWG 000 0072 05RANJEET PRATAP SINGHNo ratings yet

- FINAL (Door and Window) 2-ModelDocument1 pageFINAL (Door and Window) 2-ModelVanshika DograNo ratings yet

- Akai+AKTV3210+Chassis+TP S506 PB818Document8 pagesAkai+AKTV3210+Chassis+TP S506 PB818bughiudNo ratings yet

- Brownt out线路: 需要快速掉电时装上,否则取消 装上时需将RB104改为120K,芯片用7537: MylarDocument8 pagesBrownt out线路: 需要快速掉电时装上,否则取消 装上时需将RB104改为120K,芯片用7537: MylarAlix M. Zambrano P.No ratings yet

- Rm2 Stand 12Document1 pageRm2 Stand 12Abdullah BawazirNo ratings yet

- Power Supply Analog 28v SchematicsDocument1 pagePower Supply Analog 28v Schematicskhosravimehrdad69No ratings yet

- Power Unit Printed Wiring Board (For 26")Document3 pagesPower Unit Printed Wiring Board (For 26")Jose BenavidesNo ratings yet

- BERAWA CRUISE SHIP - 1ST FLOOR - Rooms Elevations - 1B (2) - 37 - UNIT 1B PLAN-1 BEDROOMDocument1 pageBERAWA CRUISE SHIP - 1ST FLOOR - Rooms Elevations - 1B (2) - 37 - UNIT 1B PLAN-1 BEDROOMKevin KurniawanNo ratings yet

- 6M33 Series CAD English Version Drawing UNLCKD-ModelDocument1 page6M33 Series CAD English Version Drawing UNLCKD-ModelMukulNo ratings yet

- D2KFBNeo - Fullbridge V.4 FINALE Full Scheme-V6Document1 pageD2KFBNeo - Fullbridge V.4 FINALE Full Scheme-V6Ibnu WahyudiNo ratings yet

- IRN90-160k-Of AC-WC Electric SchematicDocument3 pagesIRN90-160k-Of AC-WC Electric Schematicsachin JoshiNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Ed 0900 PRS Pid 000 09041CDocument1 pageEd 0900 PRS Pid 000 09041CMohamed ArafaNo ratings yet

- Lanzar Opts150.4 Car Amplifier SCHDocument1 pageLanzar Opts150.4 Car Amplifier SCHabung teaNo ratings yet

- Car Lift - option 2Document1 pageCar Lift - option 2rqf67yghvhNo ratings yet

- GA55+-90 (2022) AC Pack Metric Dimension Drawing EN Antwerp 9820980032 Ed00Document1 pageGA55+-90 (2022) AC Pack Metric Dimension Drawing EN Antwerp 9820980032 Ed00Luis LabradorNo ratings yet

- Ground Floor Plan: Scale 1:100Document2 pagesGround Floor Plan: Scale 1:100CSEC Uganda Ltd.No ratings yet

- AMPAM321Document1 pageAMPAM321assistenzadavidoffstoreNo ratings yet

- Drawing For Lubrication MillDocument2 pagesDrawing For Lubrication MillDeepakNo ratings yet

- Buje Bronce - 4256364-02-DDocument1 pageBuje Bronce - 4256364-02-Dcesar guerreroNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- V100-2MW T220 95m Tower DrawingDocument1 pageV100-2MW T220 95m Tower DrawingDat TienNo ratings yet

- 426-5051-00 - Turck Breakout & BoxRemote ModuleDocument6 pages426-5051-00 - Turck Breakout & BoxRemote ModulejNo ratings yet

- 22.1 Circuit Diagram Page 1Document1 page22.1 Circuit Diagram Page 1Gelu GeluNo ratings yet

- Original: ControlledDocument1 pageOriginal: Controlledalfan cita nyalaNo ratings yet

- BEKO Chassis 22.1 (100Hz) PDFDocument2 pagesBEKO Chassis 22.1 (100Hz) PDFAouadi AbdellazizNo ratings yet

- Pot Brackets: A PR1045 EC4924 B EC4993 C EC5047 D EC5281 EDocument4 pagesPot Brackets: A PR1045 EC4924 B EC4993 C EC5047 D EC5281 EДмитрийNo ratings yet

- Spreader Beam Drawings & MTODocument3 pagesSpreader Beam Drawings & MTOsales ntscompaniesNo ratings yet

- Rudolf Govic: ApprovedDocument8 pagesRudolf Govic: Approvedkukadiya127_48673372No ratings yet

- Second Floor Plan (Main Building) : Stair Lobby Connecting Walk/PathwayDocument1 pageSecond Floor Plan (Main Building) : Stair Lobby Connecting Walk/PathwayCarl Justin AzucenaNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- Fender Rumble 15 2010 Schematic Rev-ADocument2 pagesFender Rumble 15 2010 Schematic Rev-Abeytullah50% (2)

- Hmc1031ms8e Eval PCB SchematicDocument3 pagesHmc1031ms8e Eval PCB SchematicbaymanNo ratings yet

- General Notes:: Dhi Qar Combined Cycle Power Plant ProjectDocument1 pageGeneral Notes:: Dhi Qar Combined Cycle Power Plant Projectmustafa1989ocNo ratings yet

- Crate V33H Schematic 1Document2 pagesCrate V33H Schematic 1Danielo ErréNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Precambering 0mm: Am/V 70,7 (1/m) Critical Temperature 600 CDocument1 pagePrecambering 0mm: Am/V 70,7 (1/m) Critical Temperature 600 CBercea GeorgeDoruNo ratings yet

- Lista PieseDocument8 pagesLista PieseBercea GeorgeDoruNo ratings yet

- Lista PieseDocument4 pagesLista PieseBercea GeorgeDoruNo ratings yet

- Lista AnsambleDocument1 pageLista AnsambleBercea GeorgeDoruNo ratings yet

- Lista MaterialeDocument4 pagesLista MaterialeBercea GeorgeDoruNo ratings yet