Professional Documents

Culture Documents

701 Clavex (Lanko)

701 Clavex (Lanko)

Uploaded by

wwcengCopyright:

Available Formats

You might also like

- A Critical Review of Manufacturing Processes Used in Regenerated Cellulosic Fibers Viscose Cellulose Acetate Cuprammonium EtcDocument28 pagesA Critical Review of Manufacturing Processes Used in Regenerated Cellulosic Fibers Viscose Cellulose Acetate Cuprammonium EtcMoqeet AwanNo ratings yet

- Eccentric FootingDocument8 pagesEccentric Footinghemantkle2uNo ratings yet

- Plants Vs ZombiesDocument11 pagesPlants Vs Zombiesharry_chemNo ratings yet

- Guide Autocad LayersDocument17 pagesGuide Autocad LayersMoe Oo HtunNo ratings yet

- ISO 7005-1-Steel-Flanges PDFDocument88 pagesISO 7005-1-Steel-Flanges PDFwwceng100% (1)

- Epco 1010Document1 pageEpco 1010Bhavik Dhami100% (3)

- Resicrete 218NS - TDSDocument2 pagesResicrete 218NS - TDSPhạm Thanh PhươngNo ratings yet

- MasterEmaco SBR 2Document3 pagesMasterEmaco SBR 2Radja NurNo ratings yet

- Conbextra BPG: Constructive SolutionsDocument4 pagesConbextra BPG: Constructive Solutionsanon_740724146No ratings yet

- Cempatch HM PDFDocument2 pagesCempatch HM PDFharish14586No ratings yet

- Lanko 731 - 1Document2 pagesLanko 731 - 1Mark Angelo CañasNo ratings yet

- Readyplast M Super Ready Mix Plastering MortarDocument2 pagesReadyplast M Super Ready Mix Plastering MortarPritpal SinghNo ratings yet

- Segmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureDocument4 pagesSegmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureAmar Babu ChNo ratings yet

- Cemfair SmoothDocument2 pagesCemfair Smoothosama mohNo ratings yet

- Repcon SDocument2 pagesRepcon SRamu SekarNo ratings yet

- BMC ConcreteDocument3 pagesBMC ConcreteRachelNo ratings yet

- Sika Monotop 615 HB Pds enDocument3 pagesSika Monotop 615 HB Pds enTrialNo ratings yet

- Sikatop - 122: Fibre Reinforce, Polymer Modified Repair MortarDocument2 pagesSikatop - 122: Fibre Reinforce, Polymer Modified Repair MortarJoana Marie Perciano100% (1)

- Conbextra Cable GroutDocument4 pagesConbextra Cable Groutm.elsanee.cubicNo ratings yet

- PDS Pro Struct 618LV October 2017 Replaces January 2014Document2 pagesPDS Pro Struct 618LV October 2017 Replaces January 2014Amar Babu ChNo ratings yet

- TDS Conbextra EP10 India6Document3 pagesTDS Conbextra EP10 India6jasonNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDm.elsanee.cubicNo ratings yet

- DR - Fixit Pidigrout 10 MDocument3 pagesDR - Fixit Pidigrout 10 MBijaya RaulaNo ratings yet

- PDS Pro Struct 617 October 2017 Replaces April 2010Document1 pagePDS Pro Struct 617 October 2017 Replaces April 2010Amar Babu ChNo ratings yet

- NG NP Sikatop Seal 107Document3 pagesNG NP Sikatop Seal 107NourhoudaNo ratings yet

- Abe Construction Chemicals Duraflex DatasheetDocument2 pagesAbe Construction Chemicals Duraflex DatasheetEthanNo ratings yet

- Sikacrete® 114 4Document2 pagesSikacrete® 114 4aslam baigNo ratings yet

- Expangrout GP: General Purpose Non-Shrink Cementitious Grout UsesDocument4 pagesExpangrout GP: General Purpose Non-Shrink Cementitious Grout UsesZaid AhmedNo ratings yet

- Expangrout GP Data SheetDocument6 pagesExpangrout GP Data SheetSuhail BerkeleyNo ratings yet

- Conbextra EP75 PlusDocument4 pagesConbextra EP75 Plusm.elsanee.cubicNo ratings yet

- Cemcoat PuttyDocument2 pagesCemcoat Puttyosama mohNo ratings yet

- Combextra GP ExtraDocument4 pagesCombextra GP ExtrailhamNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds ensahal_akNo ratings yet

- Description Packaging Shelf Life CoverageDocument2 pagesDescription Packaging Shelf Life Coveragejet toledoNo ratings yet

- Conbextra GPXtraDocument4 pagesConbextra GPXtraJoshua EkoNo ratings yet

- Setseal B: DescriptionDocument4 pagesSetseal B: DescriptionRAKESH REDDYNo ratings yet

- RCT-ConGrout EP GPDocument2 pagesRCT-ConGrout EP GPfahadNo ratings yet

- TDS - Conbextra BB72 IN - IndiaDocument2 pagesTDS - Conbextra BB72 IN - IndiaVikas Singh ChandelNo ratings yet

- Conbextra GP: General Purpose Non-Shrink Cementitious GroutDocument4 pagesConbextra GP: General Purpose Non-Shrink Cementitious GroutsizmaruNo ratings yet

- TDS-EN-Congrout AF - Rev 013-Aug 21Document1 pageTDS-EN-Congrout AF - Rev 013-Aug 21LONG LASTNo ratings yet

- Sikadur® 731Document2 pagesSikadur® 731Nguyễn Hoang AnhNo ratings yet

- Cempatch SDocument2 pagesCempatch Sjerry6670100% (1)

- Sikadur - 752: Low Viscosity Epoxy Resin InjectionDocument2 pagesSikadur - 752: Low Viscosity Epoxy Resin Injectionmarc montelibanoNo ratings yet

- SikaTop Seal-107 PDFDocument4 pagesSikaTop Seal-107 PDFDan BermasNo ratings yet

- Sikagrout®-214 KH: Pumpable Shrinkage Compensated Cementitious GroutDocument3 pagesSikagrout®-214 KH: Pumpable Shrinkage Compensated Cementitious GroutReab SimanthNo ratings yet

- Appendix 4 TDS & MSDSDocument8 pagesAppendix 4 TDS & MSDSmohsin.meizaNo ratings yet

- Samtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutDocument3 pagesSamtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutFrancois-No ratings yet

- Sikadur® 752Document2 pagesSikadur® 752ivan rocoNo ratings yet

- Conbextra GP: General Purpose Non-Shrink Cementitious Grout UsesDocument5 pagesConbextra GP: General Purpose Non-Shrink Cementitious Grout UsesTri AryantoNo ratings yet

- Conbextra EP10Document2 pagesConbextra EP10m.elsanee.cubicNo ratings yet

- DR - Fixit Micro ConcreteDocument3 pagesDR - Fixit Micro ConcreteKiran KumarNo ratings yet

- Sika Microcrete-217 PDFDocument3 pagesSika Microcrete-217 PDFGianni MenaNo ratings yet

- Cermiproof FF Plus Tds en 2Document2 pagesCermiproof FF Plus Tds en 2mrcficeNo ratings yet

- 11 Crystalseal enDocument2 pages11 Crystalseal enYoussef ElgendyNo ratings yet

- TDS Consol Grout 600 MFDocument2 pagesTDS Consol Grout 600 MFPEP GUDANGNo ratings yet

- Kem Microconcrete - NDocument2 pagesKem Microconcrete - NIrfan BiradarNo ratings yet

- Duraflex DSDocument2 pagesDuraflex DSFeyiNo ratings yet

- Data - Sheet Qmax Pro 1004 81 PDFDocument2 pagesData - Sheet Qmax Pro 1004 81 PDFGonzalo AlvarezNo ratings yet

- PolycreteDocument2 pagesPolycreteStressDyn ConsultantsNo ratings yet

- Conbextra EP10: High Strength, Epoxy Resin GroutDocument3 pagesConbextra EP10: High Strength, Epoxy Resin GroutR.ThangarajNo ratings yet

- Sikagrout - 214 11hsDocument3 pagesSikagrout - 214 11hsBao PhanNo ratings yet

- ALD AT A Sheet: Conbextra GPDocument4 pagesALD AT A Sheet: Conbextra GPJoan FosterNo ratings yet

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsFrom EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsRating: 5 out of 5 stars5/5 (1)

- กราฟ msiDocument1 pageกราฟ msiwwcengNo ratings yet

- MRP 0067 S BalanceDocument3 pagesMRP 0067 S BalancewwcengNo ratings yet

- Efficiency 81 %Document2 pagesEfficiency 81 %wwcengNo ratings yet

- Clearance of Sleeve BearingDocument1 pageClearance of Sleeve BearingwwcengNo ratings yet

- Vol.2-8 PM-MEDocument3 pagesVol.2-8 PM-MEwwcengNo ratings yet

- Dimension 6 X 8 X 12MDocument1 pageDimension 6 X 8 X 12MwwcengNo ratings yet

- Paitn Procedure - Internal Tank (Touch Up) - 210315Document1 pagePaitn Procedure - Internal Tank (Touch Up) - 210315wwcengNo ratings yet

- Metal Comparation Astm-Jis-Bs (Pcd55)Document1 pageMetal Comparation Astm-Jis-Bs (Pcd55)wwcengNo ratings yet

- Pipe Sch. - Dimensions - ChartDocument1 pagePipe Sch. - Dimensions - ChartwwcengNo ratings yet

- PresentacionKitz ValveDocument1 pagePresentacionKitz ValvewwcengNo ratings yet

- Tora Paint PDFDocument2 pagesTora Paint PDFwwcengNo ratings yet

- DLU - QDC LL100Document1 pageDLU - QDC LL100wwceng0% (1)

- Group 4 ARTISAN ART APPRECIATIONDocument15 pagesGroup 4 ARTISAN ART APPRECIATIONanglsancheztanNo ratings yet

- Crim 1 BDocument1 pageCrim 1 BJose Antonio Peralta Achaval Jr.No ratings yet

- Recruitment Strategies A Power of E Recruiting and Social MediaDocument21 pagesRecruitment Strategies A Power of E Recruiting and Social MediaIjbemrJournalNo ratings yet

- 2018amc J EngDocument7 pages2018amc J EngHero ZhaoNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument16 pagesCambridge International Advanced Subsidiary and Advanced Levelleon1973No ratings yet

- IRS Questions QbankDocument2 pagesIRS Questions Qbanktest1qaz100% (1)

- Autoclave MxmoonfreeDocument5 pagesAutoclave MxmoonfreeVanessa GonzalezNo ratings yet

- Attitudes Towards Artificial IntelligenceDocument3 pagesAttitudes Towards Artificial IntelligencePhạm Quang DuyNo ratings yet

- Centrifugal CastingDocument12 pagesCentrifugal Castingsamurai7_77100% (1)

- Comparative Study Between Conventional MicrolaryngealDocument7 pagesComparative Study Between Conventional MicrolaryngealTeuku Ahmad HasanyNo ratings yet

- 111 F21 Research Paper ProposalDocument2 pages111 F21 Research Paper ProposalKim LaceyNo ratings yet

- GRE Verbal Reasoning Questions and AnswersDocument24 pagesGRE Verbal Reasoning Questions and AnswersTamunotonye Minaye-IlomboNo ratings yet

- Diagnosa Prolanis (Seluruhnya)Document6 pagesDiagnosa Prolanis (Seluruhnya)Rasjid tabanalNo ratings yet

- Cholera Outbreak Guidelines: Preparedness, Prevention and ControlDocument105 pagesCholera Outbreak Guidelines: Preparedness, Prevention and ControlOxfamNo ratings yet

- Table of Contents (OUM)Document5 pagesTable of Contents (OUM)Alvin WongNo ratings yet

- Fantasy Foundry (10032611)Document8 pagesFantasy Foundry (10032611)Oscar Chacon100% (1)

- S10060 SCHWEBD-S10174: Follow UsDocument3 pagesS10060 SCHWEBD-S10174: Follow UsandreviolinoNo ratings yet

- Zodia Taur EnglezaDocument3 pagesZodia Taur EnglezaoantaNo ratings yet

- Luxeon 7070Document22 pagesLuxeon 7070guciNo ratings yet

- Traffic Management and Accident Investigation With DrivingDocument18 pagesTraffic Management and Accident Investigation With DrivingPatrick LeysonNo ratings yet

- Body Paragraph 2Document3 pagesBody Paragraph 2Helen SabuquelNo ratings yet

- Students CircularDocument2 pagesStudents CirculargeraltNo ratings yet

- BSSPAR1: Chapter 5 Measurement Processing: 1 © Nokia Siemens NetworksDocument27 pagesBSSPAR1: Chapter 5 Measurement Processing: 1 © Nokia Siemens NetworksJunaidNo ratings yet

- S.No Acc No Title of The BookDocument12 pagesS.No Acc No Title of The BookmechhodNo ratings yet

- Industrial Training ReportDocument33 pagesIndustrial Training ReportVivek SharmaNo ratings yet

- Detecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Document5 pagesDetecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Hernan MartNo ratings yet

701 Clavex (Lanko)

701 Clavex (Lanko)

Uploaded by

wwcengOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

701 Clavex (Lanko)

701 Clavex (Lanko)

Uploaded by

wwcengCopyright:

Available Formats

B U I L D E R S ’ S O L U T I O N S

NON-SHRINK GROUT

HIGH MECHANICAL STRENGTH

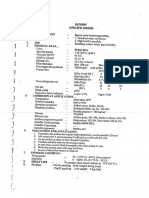

701 CLAVEX

R E P A I R I N G A N D G R O U T I N G

CHARACTERISTICS

High compressive strength.

Non-shrink.

Good workability.

DESCRIPTION WORK INSTRUCTIONS

SHELF LIFE 701 CLAVEX is a premixed cementitious non-shrink,

Up to 12 months in Substrate preparation

unopened original container.

high strength developing grout composed of special ¥ Remove loose and damaged concrete and laitance

cement, sand and admixtures. using a point tool or chisel in order to obtain a clean

STORAGE

Store in a dry place. APPLICATION RANGE surface.

¥ Bedding of industrial equipment, rebars, anchor ¥ The boundaries of the surface must be clearly defined.

PACKAGING

25 kg bag. bolts. ¥ The substrate must be clean, sound, dust-free and

¥ Assembling of precast panels, grip-filling. without any traces of oil, laitance or curing

¥ Bearing casting of heavy machinery, column, crane compound.

rails. ¥ Soak the substrate for several hours prior to

¥ Repairing of concrete structure. application.

Mortar preparation

TECHNICAL DATA ¥ The slurry or mortar is obtained by mixing

¥ Appearance : Grey powder 701 CLAVEX with clean water.

¥ Particle size : 0.1 - 2mm ¥ The quantity of water used depends on the

¥ Bulk density : 1.4 consistency required.

¥ pH : 12.5 ¥ Mixing should be carried out as follows :

Bond strength by slant shear test : ASTM C882* - By high-speed mixer for a fluid consistency.

1 days 6 MPa - By machine or hand-mix for a plastic consistency.

3 days 7 MPa ¥ Mixing time : 3 minutes minimum.

7 days 8.5 MPa ¥ Leave the mixture to stand for several minutes.

28 days 9 MPa Micro-concrete preparation

Flexural strength : ASTM C348* ¥ Micro-concrete is made up by adding 10 litres of clean

1 days 5 MPa 3/8"aggregate for each 25 kg bag of 701 CLAVEX.

3 days 6.8 MPa ¥ Machine mix until a plastic consistency is obtained.

7 days 7.4 MPa Sealing

28 days 7.9 MPa ¥ The diameter of the holes must be equal to at least the

Compressive strength : ASTM C109* (Pouring consistency).

diameter of the anchoring rebar +20 to 30 mm.

1 days 15 MPa ¥ Depth of holes : 10 - 20 times the diameter of the

3 days 43 MPa anchoring rebar, depending on the resistance of the

7 days 54 MPa concrete.

28 days 61 MPa ¥ Above a sealing thickness of 50 mm, a micro-concrete

Compressive strength : ASTM C109* (Plastic consistency). should be used.

1 days 22 MPa ¥ Clean out the area to be sealed, fill with water for

3 days 47 MPa several hours prior to sealing.

7 days 56 MPa ¥ Remove residual water just prior to sealing.

28 days 70 MPa ¥ Position the rebar in the hole and cast the mortar.

*Average laboratory values provided as a general guide

701 CLAVEX

NON-SHRINK GROUT

HIGH MECHANICAL STRENGTH

B U I L D E R S ’ S O L U T I O N S

R E P A I R I N G A N D G R O U T I N G

Grouting

¥ Formworks shall be sufficiently tight-fitting and PRECAUTIONS

sealed against leakages. ¥ Temperature range for use : 5¡C to 45¡C.

¥ On the placement side, the forms should be ¥ Apply only to clean, sound, resistant substrates,

constructed above the bottom of the plate to form a free of loose material.

headbox. The headbox should be positioned at a ¥ Substrate must be soaked for several hours prior

minimum of 50 mm from the plate and slope away to application.

at a 45¡ angle to assist grout placement as well as ¥ Residual water must be removed prior to

prevent air entrapment. application.

¥ The form should be minimum 50 mm away from the

¥ Do not mix with other hydraulic binders.

plate and extend at least 25 mm above the bottom of

¥ Sand and admixtures must not be added.

the plate.

¥ Non-absorbent formwork is preferred, otherwise, it

¥ Foresee the need for intermediate joints and

respect the existing structural jonts.

should be properly oiled to prevent grout adhesion.

¥ Thoroughly wet all surfaces prior placement and

remove any excess water just before introducing the

grout.

¥ The mixed grout should be placed promptly before

it stiffens. Higher temperature will accelerate setting

time.

¥ Pour grout from one side only to avoid air

entrapment.

¥ Adequate grout head must be maintained at all time

to achieve a continuous flow.

¥ Use a rod or strap to assist in large/difficult

placement as well as to facilitate maximum surface

contact. Vibrator should not be used. Excessive

vibration will cause separation of each ingredient.

Curing

¥ As soon as the mortar begins to set, the exposed

surface should be cured for about 3 days.

Dosage / Yield

Plastic consistency

701 CLAVEX 1 bag 25 kg

Water 3 - 3.5 litres

Workable mortar 12 litres

Pouring consistency

701 CLAVEX 1 bag 25 kg

Water 3.5 - 4.4 litres

Workable mortar 12.2 litres

Micro-concrete

701 CLAVEX 1 bag 25 kg

3/8 aggregate 10 litres

Water 3.3 - 4.4 litres

Workable mortar 20 litres

Supplied by

Dubai

P.O. Box 8344,Dubai, U.A.E.

Tel. 04 3245460 Fax 04 3245461

"The information provided in this document results from our knowledge of the products and our experience. On-site results may vary, in particular according to the product application

methods adopted. Where application methods not covered by this document are used, customers must request specific additional information and/or carry out a representative test

Abu Dhabi before using the products. The above-mentioned information in no way constitutes a warranty relative to the use of the products. Our general terms and conditions of sale shall prevail, in

P.O. Box 72642,Abu Dhabi, U.A.E. any event, on the information provided in this document. Prior to application, customers and users are requested to check that they have the latest version of this document."

Tel. 02 6266588 Fax 02 6266577 Technical Documentation English-Version August 2006

Al Ain CCC-PAREX (L.L.C.)

Tel. (Mobile) 050 5515418 PO Box 71544 Dubai, United Arab Emirates T: +971 4 343 1212 F: +971 4 343 0609 www.parex-group.com

Fax 03 7675365

You might also like

- A Critical Review of Manufacturing Processes Used in Regenerated Cellulosic Fibers Viscose Cellulose Acetate Cuprammonium EtcDocument28 pagesA Critical Review of Manufacturing Processes Used in Regenerated Cellulosic Fibers Viscose Cellulose Acetate Cuprammonium EtcMoqeet AwanNo ratings yet

- Eccentric FootingDocument8 pagesEccentric Footinghemantkle2uNo ratings yet

- Plants Vs ZombiesDocument11 pagesPlants Vs Zombiesharry_chemNo ratings yet

- Guide Autocad LayersDocument17 pagesGuide Autocad LayersMoe Oo HtunNo ratings yet

- ISO 7005-1-Steel-Flanges PDFDocument88 pagesISO 7005-1-Steel-Flanges PDFwwceng100% (1)

- Epco 1010Document1 pageEpco 1010Bhavik Dhami100% (3)

- Resicrete 218NS - TDSDocument2 pagesResicrete 218NS - TDSPhạm Thanh PhươngNo ratings yet

- MasterEmaco SBR 2Document3 pagesMasterEmaco SBR 2Radja NurNo ratings yet

- Conbextra BPG: Constructive SolutionsDocument4 pagesConbextra BPG: Constructive Solutionsanon_740724146No ratings yet

- Cempatch HM PDFDocument2 pagesCempatch HM PDFharish14586No ratings yet

- Lanko 731 - 1Document2 pagesLanko 731 - 1Mark Angelo CañasNo ratings yet

- Readyplast M Super Ready Mix Plastering MortarDocument2 pagesReadyplast M Super Ready Mix Plastering MortarPritpal SinghNo ratings yet

- Segmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureDocument4 pagesSegmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureAmar Babu ChNo ratings yet

- Cemfair SmoothDocument2 pagesCemfair Smoothosama mohNo ratings yet

- Repcon SDocument2 pagesRepcon SRamu SekarNo ratings yet

- BMC ConcreteDocument3 pagesBMC ConcreteRachelNo ratings yet

- Sika Monotop 615 HB Pds enDocument3 pagesSika Monotop 615 HB Pds enTrialNo ratings yet

- Sikatop - 122: Fibre Reinforce, Polymer Modified Repair MortarDocument2 pagesSikatop - 122: Fibre Reinforce, Polymer Modified Repair MortarJoana Marie Perciano100% (1)

- Conbextra Cable GroutDocument4 pagesConbextra Cable Groutm.elsanee.cubicNo ratings yet

- PDS Pro Struct 618LV October 2017 Replaces January 2014Document2 pagesPDS Pro Struct 618LV October 2017 Replaces January 2014Amar Babu ChNo ratings yet

- TDS Conbextra EP10 India6Document3 pagesTDS Conbextra EP10 India6jasonNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDm.elsanee.cubicNo ratings yet

- DR - Fixit Pidigrout 10 MDocument3 pagesDR - Fixit Pidigrout 10 MBijaya RaulaNo ratings yet

- PDS Pro Struct 617 October 2017 Replaces April 2010Document1 pagePDS Pro Struct 617 October 2017 Replaces April 2010Amar Babu ChNo ratings yet

- NG NP Sikatop Seal 107Document3 pagesNG NP Sikatop Seal 107NourhoudaNo ratings yet

- Abe Construction Chemicals Duraflex DatasheetDocument2 pagesAbe Construction Chemicals Duraflex DatasheetEthanNo ratings yet

- Sikacrete® 114 4Document2 pagesSikacrete® 114 4aslam baigNo ratings yet

- Expangrout GP: General Purpose Non-Shrink Cementitious Grout UsesDocument4 pagesExpangrout GP: General Purpose Non-Shrink Cementitious Grout UsesZaid AhmedNo ratings yet

- Expangrout GP Data SheetDocument6 pagesExpangrout GP Data SheetSuhail BerkeleyNo ratings yet

- Conbextra EP75 PlusDocument4 pagesConbextra EP75 Plusm.elsanee.cubicNo ratings yet

- Cemcoat PuttyDocument2 pagesCemcoat Puttyosama mohNo ratings yet

- Combextra GP ExtraDocument4 pagesCombextra GP ExtrailhamNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds ensahal_akNo ratings yet

- Description Packaging Shelf Life CoverageDocument2 pagesDescription Packaging Shelf Life Coveragejet toledoNo ratings yet

- Conbextra GPXtraDocument4 pagesConbextra GPXtraJoshua EkoNo ratings yet

- Setseal B: DescriptionDocument4 pagesSetseal B: DescriptionRAKESH REDDYNo ratings yet

- RCT-ConGrout EP GPDocument2 pagesRCT-ConGrout EP GPfahadNo ratings yet

- TDS - Conbextra BB72 IN - IndiaDocument2 pagesTDS - Conbextra BB72 IN - IndiaVikas Singh ChandelNo ratings yet

- Conbextra GP: General Purpose Non-Shrink Cementitious GroutDocument4 pagesConbextra GP: General Purpose Non-Shrink Cementitious GroutsizmaruNo ratings yet

- TDS-EN-Congrout AF - Rev 013-Aug 21Document1 pageTDS-EN-Congrout AF - Rev 013-Aug 21LONG LASTNo ratings yet

- Sikadur® 731Document2 pagesSikadur® 731Nguyễn Hoang AnhNo ratings yet

- Cempatch SDocument2 pagesCempatch Sjerry6670100% (1)

- Sikadur - 752: Low Viscosity Epoxy Resin InjectionDocument2 pagesSikadur - 752: Low Viscosity Epoxy Resin Injectionmarc montelibanoNo ratings yet

- SikaTop Seal-107 PDFDocument4 pagesSikaTop Seal-107 PDFDan BermasNo ratings yet

- Sikagrout®-214 KH: Pumpable Shrinkage Compensated Cementitious GroutDocument3 pagesSikagrout®-214 KH: Pumpable Shrinkage Compensated Cementitious GroutReab SimanthNo ratings yet

- Appendix 4 TDS & MSDSDocument8 pagesAppendix 4 TDS & MSDSmohsin.meizaNo ratings yet

- Samtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutDocument3 pagesSamtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutFrancois-No ratings yet

- Sikadur® 752Document2 pagesSikadur® 752ivan rocoNo ratings yet

- Conbextra GP: General Purpose Non-Shrink Cementitious Grout UsesDocument5 pagesConbextra GP: General Purpose Non-Shrink Cementitious Grout UsesTri AryantoNo ratings yet

- Conbextra EP10Document2 pagesConbextra EP10m.elsanee.cubicNo ratings yet

- DR - Fixit Micro ConcreteDocument3 pagesDR - Fixit Micro ConcreteKiran KumarNo ratings yet

- Sika Microcrete-217 PDFDocument3 pagesSika Microcrete-217 PDFGianni MenaNo ratings yet

- Cermiproof FF Plus Tds en 2Document2 pagesCermiproof FF Plus Tds en 2mrcficeNo ratings yet

- 11 Crystalseal enDocument2 pages11 Crystalseal enYoussef ElgendyNo ratings yet

- TDS Consol Grout 600 MFDocument2 pagesTDS Consol Grout 600 MFPEP GUDANGNo ratings yet

- Kem Microconcrete - NDocument2 pagesKem Microconcrete - NIrfan BiradarNo ratings yet

- Duraflex DSDocument2 pagesDuraflex DSFeyiNo ratings yet

- Data - Sheet Qmax Pro 1004 81 PDFDocument2 pagesData - Sheet Qmax Pro 1004 81 PDFGonzalo AlvarezNo ratings yet

- PolycreteDocument2 pagesPolycreteStressDyn ConsultantsNo ratings yet

- Conbextra EP10: High Strength, Epoxy Resin GroutDocument3 pagesConbextra EP10: High Strength, Epoxy Resin GroutR.ThangarajNo ratings yet

- Sikagrout - 214 11hsDocument3 pagesSikagrout - 214 11hsBao PhanNo ratings yet

- ALD AT A Sheet: Conbextra GPDocument4 pagesALD AT A Sheet: Conbextra GPJoan FosterNo ratings yet

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsFrom EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsRating: 5 out of 5 stars5/5 (1)

- กราฟ msiDocument1 pageกราฟ msiwwcengNo ratings yet

- MRP 0067 S BalanceDocument3 pagesMRP 0067 S BalancewwcengNo ratings yet

- Efficiency 81 %Document2 pagesEfficiency 81 %wwcengNo ratings yet

- Clearance of Sleeve BearingDocument1 pageClearance of Sleeve BearingwwcengNo ratings yet

- Vol.2-8 PM-MEDocument3 pagesVol.2-8 PM-MEwwcengNo ratings yet

- Dimension 6 X 8 X 12MDocument1 pageDimension 6 X 8 X 12MwwcengNo ratings yet

- Paitn Procedure - Internal Tank (Touch Up) - 210315Document1 pagePaitn Procedure - Internal Tank (Touch Up) - 210315wwcengNo ratings yet

- Metal Comparation Astm-Jis-Bs (Pcd55)Document1 pageMetal Comparation Astm-Jis-Bs (Pcd55)wwcengNo ratings yet

- Pipe Sch. - Dimensions - ChartDocument1 pagePipe Sch. - Dimensions - ChartwwcengNo ratings yet

- PresentacionKitz ValveDocument1 pagePresentacionKitz ValvewwcengNo ratings yet

- Tora Paint PDFDocument2 pagesTora Paint PDFwwcengNo ratings yet

- DLU - QDC LL100Document1 pageDLU - QDC LL100wwceng0% (1)

- Group 4 ARTISAN ART APPRECIATIONDocument15 pagesGroup 4 ARTISAN ART APPRECIATIONanglsancheztanNo ratings yet

- Crim 1 BDocument1 pageCrim 1 BJose Antonio Peralta Achaval Jr.No ratings yet

- Recruitment Strategies A Power of E Recruiting and Social MediaDocument21 pagesRecruitment Strategies A Power of E Recruiting and Social MediaIjbemrJournalNo ratings yet

- 2018amc J EngDocument7 pages2018amc J EngHero ZhaoNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument16 pagesCambridge International Advanced Subsidiary and Advanced Levelleon1973No ratings yet

- IRS Questions QbankDocument2 pagesIRS Questions Qbanktest1qaz100% (1)

- Autoclave MxmoonfreeDocument5 pagesAutoclave MxmoonfreeVanessa GonzalezNo ratings yet

- Attitudes Towards Artificial IntelligenceDocument3 pagesAttitudes Towards Artificial IntelligencePhạm Quang DuyNo ratings yet

- Centrifugal CastingDocument12 pagesCentrifugal Castingsamurai7_77100% (1)

- Comparative Study Between Conventional MicrolaryngealDocument7 pagesComparative Study Between Conventional MicrolaryngealTeuku Ahmad HasanyNo ratings yet

- 111 F21 Research Paper ProposalDocument2 pages111 F21 Research Paper ProposalKim LaceyNo ratings yet

- GRE Verbal Reasoning Questions and AnswersDocument24 pagesGRE Verbal Reasoning Questions and AnswersTamunotonye Minaye-IlomboNo ratings yet

- Diagnosa Prolanis (Seluruhnya)Document6 pagesDiagnosa Prolanis (Seluruhnya)Rasjid tabanalNo ratings yet

- Cholera Outbreak Guidelines: Preparedness, Prevention and ControlDocument105 pagesCholera Outbreak Guidelines: Preparedness, Prevention and ControlOxfamNo ratings yet

- Table of Contents (OUM)Document5 pagesTable of Contents (OUM)Alvin WongNo ratings yet

- Fantasy Foundry (10032611)Document8 pagesFantasy Foundry (10032611)Oscar Chacon100% (1)

- S10060 SCHWEBD-S10174: Follow UsDocument3 pagesS10060 SCHWEBD-S10174: Follow UsandreviolinoNo ratings yet

- Zodia Taur EnglezaDocument3 pagesZodia Taur EnglezaoantaNo ratings yet

- Luxeon 7070Document22 pagesLuxeon 7070guciNo ratings yet

- Traffic Management and Accident Investigation With DrivingDocument18 pagesTraffic Management and Accident Investigation With DrivingPatrick LeysonNo ratings yet

- Body Paragraph 2Document3 pagesBody Paragraph 2Helen SabuquelNo ratings yet

- Students CircularDocument2 pagesStudents CirculargeraltNo ratings yet

- BSSPAR1: Chapter 5 Measurement Processing: 1 © Nokia Siemens NetworksDocument27 pagesBSSPAR1: Chapter 5 Measurement Processing: 1 © Nokia Siemens NetworksJunaidNo ratings yet

- S.No Acc No Title of The BookDocument12 pagesS.No Acc No Title of The BookmechhodNo ratings yet

- Industrial Training ReportDocument33 pagesIndustrial Training ReportVivek SharmaNo ratings yet

- Detecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Document5 pagesDetecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Hernan MartNo ratings yet