Professional Documents

Culture Documents

Data Sheet Docol Tube 780 2016-03-31 57 371857150 en

Data Sheet Docol Tube 780 2016-03-31 57 371857150 en

Uploaded by

Joe TrumpOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet Docol Tube 780 2016-03-31 57 371857150 en

Data Sheet Docol Tube 780 2016-03-31 57 371857150 en

Uploaded by

Joe TrumpCopyright:

Available Formats

DOCOL TUBE 780

E

UT

DOCOL TUBE 780

RIB

General Product Description

Unavailable Product

IST

Dimension Range

TD

Docol Tube 780 is available at circular, square and rectangular shapes.

Circular 15 - 76 mm

Square 12.7x12.7 - 60x60 mm

Rectangular 20x10 - 80x60 mm

NO

Wall thickness 1.0 - 2.0 mm

Mill length 5000 - 8000 mm

Other shapes and sizes are available upon request.

DO

Mechanical Properties

Yield strength Rp0.2 Tensile strength Rm Elongation A

(min MPa) (min MPa) (min %)

600 780 10

T-

AF

DR

Data sheet Docol Tube 780 2016-03-31

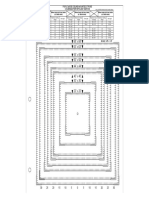

DOCOL TUBE 780

Circular

Diameter 1.0mm 1.25mm 1.5mm 2.0mm

15 mm x x x

16 mm x x x

18 mm x x x

19 mm x x x

20 mm x x x

22 mm x x x x

25 mm x x x x

28 mm x x x x

30 mm x x x x

32 mm x x x x

E

35 mm x x x x

UT

36 mm x x x x

38 mm x x x x

40 mm x x x

RIB x

41 mm x x x

44 mm x x x

48 mm x x x

50 mm x x x

IST

55 mm x x

57 mm x x

60 mm x x

TD

63.5 mm x x

76 mm x x

NO

Square

Height x Width 1.0mm 1.25mm 1.5mm 2.0mm

12.7 x 12.7 mm x x

15 x 15 mm x x

DO

16 x 16 mm x x

19 x 19 mm x x

20 x 20 mm x x

22 x 22 mm x x x

T-

25 x 25 mm x x x x

25.4 x 25.4 mm x x x x

30 x 30 mm x x x x

AF

32 x 32 mm x x x

35 x 35 mm x x x

DR

40 x 40 mm x x x

50 x 50 mm x x

60 x 60 mm x

Data sheet Docol Tube 780 2016-03-31

DOCOL TUBE 780

Rectangular

Height x Width 1.0mm 1.25mm 1.5mm 2.0mm

20 x 10 mm x x x

20 x 15 mm x x x

25 x 15 mm x x

30 x 10 mm x x

30 x 15 mm x x x

30 x 20 mm x x x x

30 x 25 mm x x x x

35 x 15 mm x x x x

35 x 20 mm x x x x

40 x 10 mm x x x

E

40 x 20 mm x x x x

UT

40 x 25 mm x x x x

40 x 30 mm x x x

45 x 15 mm x x RIB x x

50 x 20 mm x x x

50 x 25 mm x x x

50 x 30 mm x x x

50 x 40 mm x x x

IST

50.8 x 25.4 mm x x x

60 x 20 mm x x

60 x 30 mm x x

TD

60 x 40 mm x x

70 x 25 mm x x

70 x 30 mm x x

NO

70 x 50 mm x

80 x 20 mm x

80 x 40 mm x

DO

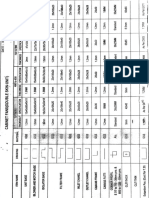

Chemical Composition

C Si Mn P S Cr+Mo Nb+Ti

(max %) (max %) (max %) (max %) (max %) (max %) (max %)

0.18 0.80 2.50 0.025 0.015 1.00 0.15

T-

Tolerances

AF

Circular

DR

Data sheet Docol Tube 780 2016-03-31

DOCOL TUBE 780

Characteristic Circular precision tubes

Tolerances based on the requirements of EN 10305-3

Outside diameter (D) 1)

D< 20 ±0.12 mm

20 ≤ D < 32 ±0.15 mm

32 ≤ D < 44 ±0.20 mm

44 ≤ D < 55 ±0.25 mm

55 ≤ D < 70 ±0.30 mm

70 ≤ D < 80 ±0.35 mm

80 ≤ D < 100 ±0.40 mm

100 ≤ D < 108 ±0.50 mm

108 ≤ D < 127 ±0.60 mm

127 ≤ D ≤ 133 ±0.80 mm

Out-of-roundness The diameter tolerances include the out-of-roundness

E

Thickness (T) T≤ 1.5 mm: ±0.15 mm

UT

T>1.5 mm: ±10% of nominal thickness or ±0.35 mm whichever

is the smaller

Straightness Maximum 0.20% of measured length

Height of internal weld bead, g;

Bead removed

RIB g ≤ 0.3 mm

Bead not removed g < 1.0 mm, when T ≤ 1.5 mm

g < 0.8 x T, when 1.5 mm < T ≤ 4.0 mm

Mill length 0/+50 mm, 5000 ≤ L ≤ 8000 mm (standard length 6000 mm)

IST

Exact length, single cutting

30 ≤ L ≤ 1500 mm ±0.5 mm

1500 < L ≤ 4000 mm ±1.0 mm

TD

Exact length, bundle cutting

1000 ≤ L ≤ 5000 mm ±2 mm

5000 < L ≤ 10000 mm ±3 mm

1) For a maximum distance of 100 mm, the ends may, due to the cutting method, have diameters outside the tolerances

NO

DO

Square

T-

AF

DR

Data sheet Docol Tube 780 2016-03-31

DOCOL TUBE 780

Characteristic Square, rectangular, flat oval and ellipse precision tubes

Tolerances based on the requirements of EN 10305-5

Outside dimensions (H) and (B), longer side 1)

H < 25 mm ±0.20 mm

25 ≤ H < 40 mm ±0.25 mm

40 ≤ H < 60 mm ±0.30 mm

60 ≤ H <70 mm ±0.35 mm

70 ≤ H < 80 mm ±0.40 mm

80 ≤ H < 90 mm ±0.50 mm

90 ≤ H < 100 mm ±0.60 mm

100 ≤ H < 120 mm ±0.65 mm

H ≥ 120 mm ±0.70 mm

Side concavity and convexity Included in outside dimension tolerance

Thickness (T) T≤ 1.5 mm: ±0.15 mm

E

T>1.5 mm: ±10% of nominal thickness or ±0.35 mm whichever

UT

is the smaller

Straightness Maximum 0.15% of measured tube length when shorter side

length > 30 mm

RIB Maximum 0.25% of measured tube length when the shorter

side length ≤ 30 mm

Location of weld seam from the centre line On narrow side for square and rectangular, optionally on wide

side. On wide side for flat oval and ellipse. ± 10% of side length

or ± 3 mm, whichever is greater.

IST

Height of internal weld bead (g)

Bead removed g ≤ 0.3 mm

Bead not removed g < 1.0 mm, when T ≤ 1.5 mm

g < 0.8 x T, when 1.5 mm < T ≤ 4.0 mm

TD

Squareness of sides 90° ± 1°

Corner profile R ≤ 4.0 x T, typically R ≤ 2.5 x T

Twist (V) V ≤ 3 mm for B and H ≤ 30 mm

NO

V ≤ B/10 or ≤ H/10 for B or H > 30 mm

Mill length 0/+50 mm, 5000 ≤ L ≤ 8000 mm (standard length 6000 mm)

Exact length, single cutting

30 ≤ L ≤ 1500 mm ±0.5 mm

DO

1500 < L ≤ 4000 mm ±1.0 mm

Exact length, bundle cutting

1000 ≤ L ≤ 5000 mm ±2 mm

5000 < L ≤ 10000 mm ±3 mm

T-

1) For a maximum distance of 100 mm, the ends may, due to the cutting method, have diameters outside the tolerances

AF

Rectangular

DR

Data sheet Docol Tube 780 2016-03-31

DOCOL TUBE 780

Characteristic Square, rectangular, flat oval and ellipse precision tubes

Tolerances based on the requirements of EN 10305-5

Outside dimensions (H) and (B), longer side 1)

H < 25 mm ±0.20 mm

25 ≤ H < 40 mm ±0.25 mm

40 ≤ H < 60 mm ±0.30 mm

60 ≤ H <70 mm ±0.35 mm

70 ≤ H < 80 mm ±0.40 mm

80 ≤ H < 90 mm ±0.50 mm

90 ≤ H < 100 mm ±0.60 mm

100 ≤ H < 120 mm ±0.65 mm

H ≥ 120 mm ±0.70 mm

Side concavity and convexity Included in outside dimension tolerance

Thickness (T) T≤ 1.5 mm: ±0.15 mm

E

T>1.5 mm: ±10% of nominal thickness or ±0.35 mm whichever

UT

is the smaller

Straightness Maximum 0.15% of measured tube length when shorter side

length > 30 mm

RIB Maximum 0.25% of measured tube length when the shorter

side length ≤ 30 mm

Location of weld seam from the centre line On narrow side for square and rectangular, optionally on wide

side. On wide side for flat oval and ellipse. ± 10% of side length

or ± 3 mm, whichever is greater.

IST

Height of internal weld bead (g)

Bead removed g ≤ 0.3 mm

Bead not removed g < 1.0 mm, when T ≤ 1.5 mm

g < 0.8 x T, when 1.5 mm < T ≤ 4.0 mm

TD

Squareness of sides 90° ± 1°

Corner profile R ≤ 4.0 x T, typically R ≤ 2.5 x T

Twist (V) V ≤ 3 mm for B and H ≤ 30 mm

NO

V ≤ B/10 or ≤ H/10 for B or H > 30 mm

Mill length 0/+50 mm, 5000 ≤ L ≤ 8000 mm (standard length 6000 mm)

Exact length, single cutting

30 ≤ L ≤ 1500 mm ±0.5 mm

DO

1500 < L ≤ 4000 mm ±1.0 mm

Exact length, bundle cutting

1000 ≤ L ≤ 5000 mm ±2 mm

5000 < L ≤ 10000 mm ±3 mm

T-

1) For a maximum distance of 100 mm, the ends may, due to the cutting method, have diameters outside the tolerances

AF

DR

Data sheet Docol Tube 780 2016-03-31

DOCOL TUBE 780

Coatings and Surfaces

Surface designation and general usabil-

ity

C Cold rolled Paintability or chromium plating are

required

GI Zinc coated (zinc 99%) Corrosion resistance is required

ZA Galfan coated (zinc 95%-aluminium 5%) Corrosion resistance and demanding

forming are required

GA Galvannealed coated (zinc 90%-iron 10%) Corrosion resistance and paintability are

required

Surface is slightly oiled to protect it from corrosion during transportation and short-term storaging. By request, tubes can be

delivered dry, however in that case SSAB will not be responsible for any possible rust.

E

Surface roughness, Ra

UT

C < 0,6 µm

Different metal coatings and

minimum coating mass RIB

Coating thickness Zinc (GI) Galfan (ZA) Galvannealed (GA)

µm 2)

g/m2 1)

g/m2 1)

g/m2 1)

7 GI100 GA100

8 GA120

IST

10 GI140 GA140

20 GI275 ZA255

25 GI350

TD

1) Minimum coating mass - g/m2 refers the total weight of coatings on both sides of a 1 m2 plate.

2) Theoretical guidance values for coating thickness per surface.

NO

DO

T-

AF

DR

Data sheet Docol Tube 780 2016-03-31

DOCOL TUBE 780

Indicative specification for

proper coating selection

Coating type Coating mass [g/m2] Coating life - marine [year] Properties

GI 100 10 Good weldability and

formability with tolerable

corrosion resistance.

GI 275 25 Good combination of

corrosion resistance and

usability.

GI 350 30 Excellent corrosion resistance.

ZA 255 80 Superior corrosion resistance

in marine condition

GA 100 15 Superior paint adhesion and

E

corrosion reistance as painted.

Weldability in same level as

UT

cold rolled material under

proper welding conditions.

GA 120 RIB 17 Superior paint adhesion and

corrosion reistance as painted.

Weldability in same level as

cold rolled material under

proper welding conditions.

GA 140 20 Superior paint adhesion and

IST

corrosion reistance as painted.

Weldability in same level as

cold rolled material under

proper welding conditions.

TD

Delivery Conditions

The tubes are not intended to undergo any heat treatment after welding and sizing as that may alter the mechanical properties of

NO

the material (+CR2 delivery condition according to EN10305-3 and -5).

The tubes are oiled with anti-corrosive oil (S4 condition according to EN 10305-3 and -5).

Fabrication and Other Recommendations

Further Fabrication

DO

Pre-heating of the tubes before bending and welding may lower the strength of the material. Docol Tube 800 is not suitable for hot

dip galvanizing. Outside the welded area the surface roughness (Ra) is typically 0.25-0.75 μm.

Bending

The bendability of Docol Tube 800 steels is good and the recommended minimum bending radius is 2.5 x tube diameter. The optimal

radial gap between mandrel and inside wall of the tube should be in the range of 0.10 to 0.15 mm.

T-

Welding

Docol Tube 800 tubes have very low content of alloying elements in relation to the high strength of the steels and the weldability of

Docol Tube 800 is very good. Recommendations in accordance to Eurocode 3 apply for welding.

AF

For information and recommendations for welding Docol Tube 800, see welding brochure for SSAB Docol products and Steelfacts at

www.ssab.com.

For information concerning fabrication, see SSAB´s brochures on www.ssab.com or consult Tech Support. Appropriate health and

safety precautions must be taken when welding, cutting, grinding or otherwise working on the product.

DR

Data sheet Docol Tube 780 2016-03-31

DOCOL TUBE 780

E

UT

RIB

IST

TD

NO

DO

T-

AF

DR

The UK English version of this document shall prevail in case of discrepancy. Download the latest version of this document at www.ssab.com

Hardox, Strenx, Docol, Dogal, Domex, Toolox, Laser, Armox, Ramor, GreenCoat are trademarks of SSAB Technology AB, Sweden

www.ssab.com

Data sheet Docol Tube 780 2016-03-31

You might also like

- Principles of Flight Practice ExamDocument12 pagesPrinciples of Flight Practice ExamthowmasNo ratings yet

- CEILING MOUNT STROBE TEMPLATE Rev B-Model PDFDocument1 pageCEILING MOUNT STROBE TEMPLATE Rev B-Model PDFJohn Philip BuntalesNo ratings yet

- Micro Compound Lever Briquette Press: Parts List, Notes, Drawings & AssemblyDocument12 pagesMicro Compound Lever Briquette Press: Parts List, Notes, Drawings & AssemblyRuth RuizNo ratings yet

- Shape by Shape, Collection 2: Free-Motion Quilting with Angela Walters - 70+ More Designs for Blocks, Backgrounds & BordersFrom EverandShape by Shape, Collection 2: Free-Motion Quilting with Angela Walters - 70+ More Designs for Blocks, Backgrounds & BordersRating: 5 out of 5 stars5/5 (1)

- Fundamental of Heat Exchanger DesignDocument972 pagesFundamental of Heat Exchanger Designabiy12791% (46)

- Besi HDocument5 pagesBesi Hmahendra darmaNo ratings yet

- Section 1 Threaded FastenersDocument1 pageSection 1 Threaded Fastenerssujit5584No ratings yet

- Daftar Tebal Plat Di PasaranDocument1 pageDaftar Tebal Plat Di PasaranLUQMANUL KHAKIMNo ratings yet

- Footing RSB Cutting ListDocument6 pagesFooting RSB Cutting ListZuhair AliNo ratings yet

- Termofusion DesplegableDocument2 pagesTermofusion Desplegableenriquegonzalez3001No ratings yet

- Update Standart Tools Workshop Central All Site Tlse, Gkae, Mjie, Myie, Bmae, Bpae, BPP, Aste, TLSMDocument50 pagesUpdate Standart Tools Workshop Central All Site Tlse, Gkae, Mjie, Myie, Bmae, Bpae, BPP, Aste, TLSMOtong KruwelNo ratings yet

- Lista Shurtape $Document36 pagesLista Shurtape $Edgar Marino Chambi MamaniNo ratings yet

- Ukuran Standar PhotoDocument3 pagesUkuran Standar PhotoArhoel BawellNo ratings yet

- Catálogo Industrial ShurtapeDocument48 pagesCatálogo Industrial ShurtapeMiguel Angel ContrerasNo ratings yet

- Dekopol Duvar Panelleri KatalogDocument74 pagesDekopol Duvar Panelleri KatalogApostol IonNo ratings yet

- Breaker Frame (AF) Breaker Trip (AT) Feeder - XLPE/PVC (MM ) Grounding Conductor (MM ) Conduit Size (Ømm)Document1 pageBreaker Frame (AF) Breaker Trip (AT) Feeder - XLPE/PVC (MM ) Grounding Conductor (MM ) Conduit Size (Ømm)chamitoNo ratings yet

- R2996118 Assembly Instructions A3606581Document34 pagesR2996118 Assembly Instructions A3606581Aneta MihailovaNo ratings yet

- 20 Chevron Packing PDFDocument2 pages20 Chevron Packing PDFZed ZedNo ratings yet

- R4009649-Assembly Instructions-A3600985Document37 pagesR4009649-Assembly Instructions-A3600985Nihada RamovicNo ratings yet

- Cartridge Housings Cartridges: Pt. Cipta Kawan Teknik AbadiDocument1 pageCartridge Housings Cartridges: Pt. Cipta Kawan Teknik Abadisales04 cikasolutionNo ratings yet

- Brosur YamanakaDocument2 pagesBrosur YamanakaFahmi Maladi RohmanNo ratings yet

- DriplineFittings AnilloDocument2 pagesDriplineFittings AnillocamilogueeeeeNo ratings yet

- Gerflor Card Creation Exclusive Edition Creation 70 Intl PDF 348Document12 pagesGerflor Card Creation Exclusive Edition Creation 70 Intl PDF 348corzeaNo ratings yet

- Bulb Flat - LosalDocument3 pagesBulb Flat - LosalKartik DoblekarNo ratings yet

- Ceiling Mount Strobe Template Rev B-ModelDocument1 pageCeiling Mount Strobe Template Rev B-ModelJohn Philip BuntalesNo ratings yet

- Temporary Pool Fencing CatalogDocument2 pagesTemporary Pool Fencing CatalogtempfencingNo ratings yet

- Experience KnowledgeDocument5 pagesExperience KnowledgeHeryy TanujayaNo ratings yet

- Drilled Holes PosterDocument1 pageDrilled Holes PosterRaneesh MohamedNo ratings yet

- Drillingholesfor Quality and Safety: Hot Dip GalvanisingDocument1 pageDrillingholesfor Quality and Safety: Hot Dip Galvanisingmohsen100% (1)

- Pt. Sapta Sumber Lancar: Besi Beton Polos/Reinforcing Bars - Plain SizeDocument19 pagesPt. Sapta Sumber Lancar: Besi Beton Polos/Reinforcing Bars - Plain SizemikelmanikNo ratings yet

- Product Catalog Cielo EnterprisesDocument8 pagesProduct Catalog Cielo EnterprisesSairamVundavilliNo ratings yet

- Infento PartsList Legend2019Document3 pagesInfento PartsList Legend2019brendan.stephensNo ratings yet

- VT 3600 SMDocument104 pagesVT 3600 SMEMILIO LOPEZ ARANGONo ratings yet

- lis material Gondola IDRIB JAKARTADocument7 pageslis material Gondola IDRIB JAKARTATriez zhedhlieNo ratings yet

- Fitinguri PPRDocument2 pagesFitinguri PPRGioni FlorinNo ratings yet

- Specifications/Grades: Key BenefitsDocument2 pagesSpecifications/Grades: Key BenefitsMiguel Martinez GuerreroNo ratings yet

- Unit) : GSS GSSDocument1 pageUnit) : GSS GSSenggNo ratings yet

- Power Take Off Assembly - Input Shaft, Transmission BSN Ajb0356850233Document3 pagesPower Take Off Assembly - Input Shaft, Transmission BSN Ajb0356850233ahmed alaminNo ratings yet

- Copper and GI Earthing Items: Weight/Length Unit Conversion Table (Approx.)Document1 pageCopper and GI Earthing Items: Weight/Length Unit Conversion Table (Approx.)ZIRWA ENTERPRISESNo ratings yet

- Backhoe - Arm and Bucket 590SMDocument3 pagesBackhoe - Arm and Bucket 590SMRicardo OrozcoNo ratings yet

- Decembar 2021 Rukohvati: Barajevo, Bogoljuba Petkovica 1A Tel: +381 11 8302 700 Mob: +381 63 354 000Document41 pagesDecembar 2021 Rukohvati: Barajevo, Bogoljuba Petkovica 1A Tel: +381 11 8302 700 Mob: +381 63 354 000Josif LombauerNo ratings yet

- COMPACT Comfort Ceramic 4 /: Sani SaniDocument36 pagesCOMPACT Comfort Ceramic 4 /: Sani Sanitelefant70No ratings yet

- GRAB - 28junDocument12 pagesGRAB - 28junGustavo ElorzaNo ratings yet

- Additional Websites HDPE ProductDocument21 pagesAdditional Websites HDPE ProductCaturyan PutraNo ratings yet

- R2827201-Assembly Instructions-A3659488Document22 pagesR2827201-Assembly Instructions-A3659488mNo ratings yet

- Models and Sizes: Residential Line Commercial LineDocument2 pagesModels and Sizes: Residential Line Commercial LineClaudio FerrariNo ratings yet

- DSB JAW Crushers 32j - 40j - 53jDocument1 pageDSB JAW Crushers 32j - 40j - 53jАнтон ЛазаровNo ratings yet

- Cupertino: Max 12 KGDocument8 pagesCupertino: Max 12 KGBenedicto BeckerNo ratings yet

- Instalacao SanitopDocument6 pagesInstalacao SanitopFelipe DaroldNo ratings yet

- Wharfdale Pro Brochure 2013Document72 pagesWharfdale Pro Brochure 2013rdbassesNo ratings yet

- Estimate and Cutting ListDocument8 pagesEstimate and Cutting ListJerome AustriaNo ratings yet

- Var - 423000, 442082, 747854 - Radiator & Shroud, Mounting PartsDocument3 pagesVar - 423000, 442082, 747854 - Radiator & Shroud, Mounting PartsBillNo ratings yet

- Data Sheet NITTADocument1 pageData Sheet NITTATMI Optics100% (2)

- MDS CatalogueDocument56 pagesMDS Cataloguedgovender31No ratings yet

- Container Capacity of GranitesDocument3 pagesContainer Capacity of GranitesSHAJU GOPALAKRISHNANNo ratings yet

- X-CR Tabletop Vita Flex en 2015 03Document2 pagesX-CR Tabletop Vita Flex en 2015 03luc1902No ratings yet

- PL Gnetion Desember 2022Document28 pagesPL Gnetion Desember 2022Leona LunetaNo ratings yet

- 621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Document3 pages621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Giovani FariasNo ratings yet

- Material Unit. Qty Usman Ent UnitDocument4 pagesMaterial Unit. Qty Usman Ent Unitasad115222No ratings yet

- Top Hat & Cladding SectionsDocument8 pagesTop Hat & Cladding SectionsDavid ShutteNo ratings yet

- All-in-One Rotary Cutting Magic with Omn: Handy Reference Tool 18 Geometric Shapes Problem Solving GuideFrom EverandAll-in-One Rotary Cutting Magic with Omn: Handy Reference Tool 18 Geometric Shapes Problem Solving GuideNo ratings yet

- Jeans and a T-Shirt: Fun and Fabulous Upcycling Projects for Denim and MoreFrom EverandJeans and a T-Shirt: Fun and Fabulous Upcycling Projects for Denim and MoreNo ratings yet

- Standard Metric Bolt Shank DimensionsDocument4 pagesStandard Metric Bolt Shank DimensionsVIVEK YADAVNo ratings yet

- NOVEMBER 2015 Surplus Record Machinery & Equipment DirectoryDocument748 pagesNOVEMBER 2015 Surplus Record Machinery & Equipment DirectorySurplus RecordNo ratings yet

- Shimmy of Aircraft Main Landing Gears: I.J.M. BesselinkDocument201 pagesShimmy of Aircraft Main Landing Gears: I.J.M. BesselinkSharan RajNo ratings yet

- 317 Training Manual 0704Document219 pages317 Training Manual 0704mliugong100% (4)

- Drager Fabius TechDocument304 pagesDrager Fabius TechCami 10100% (1)

- Fundamentals Machining Material Removal ProcessDocument113 pagesFundamentals Machining Material Removal ProcessDarwisy AhmadNo ratings yet

- Bff3242 Heat Transfer 21516Document9 pagesBff3242 Heat Transfer 21516nadiyaxx0% (1)

- FILE-20210301-195905-QTZ7015 EnglishDocument204 pagesFILE-20210301-195905-QTZ7015 Englishdaclethanh99No ratings yet

- VIAJET 12 ENG EinzelseitenDocument6 pagesVIAJET 12 ENG Einzelseiten77ztfNo ratings yet

- 01 - EN - 3P232550-13C RXL35G3V1B - Installation Manuals - EnglishDocument14 pages01 - EN - 3P232550-13C RXL35G3V1B - Installation Manuals - Englishbuild madeNo ratings yet

- Cummins Power Generator SetDocument3 pagesCummins Power Generator Setstrato1977No ratings yet

- Oscillation (A2) Name Roll No. Class Date 1. Figures1and 2Document4 pagesOscillation (A2) Name Roll No. Class Date 1. Figures1and 2fassekingNo ratings yet

- Datasheet VacuEasylift Stainless Steel LifterDocument2 pagesDatasheet VacuEasylift Stainless Steel LifterNIVAPACKNo ratings yet

- GMCDocument7 pagesGMCErick Quan LunaNo ratings yet

- Double-Jet Ejection of Cooling Air For Improved Film-CoolingDocument11 pagesDouble-Jet Ejection of Cooling Air For Improved Film-CoolingAlexandros DerkNo ratings yet

- Wascomat SU620 Spare Parts CatalogDocument74 pagesWascomat SU620 Spare Parts CatalogIgor GrytsenkoNo ratings yet

- Instructional Manual For Dead Weight Pressure Gauge TesterDocument6 pagesInstructional Manual For Dead Weight Pressure Gauge TesterRAVI BARTIANo ratings yet

- Thermal Arc 161sDocument58 pagesThermal Arc 161srquinchia1No ratings yet

- HS-420 Accelerometer: 4-20ma Velocity Output Via PUR CableDocument1 pageHS-420 Accelerometer: 4-20ma Velocity Output Via PUR CableJeremiah CayondongNo ratings yet

- Automatic Sprinkler System: Total - AED Total - AED With 20% MarginDocument11 pagesAutomatic Sprinkler System: Total - AED Total - AED With 20% Marginmohamed eshaNo ratings yet

- FinalDocument7 pagesFinalMuralee Dharan PillaiNo ratings yet

- The Importance of Compressor Foundation Design Considerations Experience in Algeria by KBR Usa TRAIN ConstructionDocument4 pagesThe Importance of Compressor Foundation Design Considerations Experience in Algeria by KBR Usa TRAIN ConstructionAhmed Ben HmidaNo ratings yet

- SATIP-W-013-01 Welding of Offshore Structures.Document5 pagesSATIP-W-013-01 Welding of Offshore Structures.mathew.genesis.inspNo ratings yet

- Appendix Five Data On Fracture Toughness and Shock Toughness Fatigue Life Characteristics of Thermal Stability Corrosion Resistance and Castability ofDocument3 pagesAppendix Five Data On Fracture Toughness and Shock Toughness Fatigue Life Characteristics of Thermal Stability Corrosion Resistance and Castability ofChin-Min YangNo ratings yet

- Top DriveDocument314 pagesTop Drivesebastian zorroNo ratings yet

- Stability Derivatives For MissileDocument4 pagesStability Derivatives For MissileWaseem SarwarNo ratings yet

- Moment Resistant End Plate-As Per Euro Code PDFDocument23 pagesMoment Resistant End Plate-As Per Euro Code PDFsonofalexanderNo ratings yet

- Threaded Fasteners With Applied Medium or High Strength Threadlockers - Effect of Different Tightening Procedures On The Tribologial ResponseDocument27 pagesThreaded Fasteners With Applied Medium or High Strength Threadlockers - Effect of Different Tightening Procedures On The Tribologial ResponseLucas InacioNo ratings yet