Professional Documents

Culture Documents

Brochure Rotating Multi Grapple

Brochure Rotating Multi Grapple

Uploaded by

schemy sayCopyright:

Available Formats

You might also like

- Sandvik DL431-7C: Underground Drill RigDocument4 pagesSandvik DL431-7C: Underground Drill RiglidoNo ratings yet

- CorcovadoDocument30 pagesCorcovadoSergarale83% (6)

- CCW rv214w 1s5070 SSWP A4 LeafDocument2 pagesCCW rv214w 1s5070 SSWP A4 LeafHendro SaputroNo ratings yet

- 8L Series Brochure BR0008LDSDocument2 pages8L Series Brochure BR0008LDSManuel GimenezNo ratings yet

- 475 BHP at 1800 R/min - 1850 LB - FT (Cruise) 475 BHP at 1800 R/min 1850 LB FT (Cruise) 475 BHP at 1800 R/min - 1650 LB - FT (Rated)Document2 pages475 BHP at 1800 R/min - 1850 LB - FT (Cruise) 475 BHP at 1800 R/min 1850 LB FT (Cruise) 475 BHP at 1800 R/min - 1650 LB - FT (Rated)Jacinto Garcia Arista100% (1)

- DD 15 Spec SheetDocument2 pagesDD 15 Spec SheetremonrafaatsadekNo ratings yet

- On-Highway Power: Series 60 EXPORT - Truck 14 L 525 BHP at 1800 R/min - 1850 LB FTDocument2 pagesOn-Highway Power: Series 60 EXPORT - Truck 14 L 525 BHP at 1800 R/min - 1850 LB FTRamonNo ratings yet

- Garrett GT1544 454082-2 454083-2Document40 pagesGarrett GT1544 454082-2 454083-2Simo SalonenNo ratings yet

- Design and Fabrication of Stair Climber TrolleyDocument21 pagesDesign and Fabrication of Stair Climber TrolleyAnonymous 1mMOyt9zNo ratings yet

- Wide Operating Speed RangeDocument10 pagesWide Operating Speed Rangezxy320dNo ratings yet

- Construction Eng WEBDocument3 pagesConstruction Eng WEBzliceNo ratings yet

- RCU - Series Upblast Centrifugal Roof Exhaust FanDocument4 pagesRCU - Series Upblast Centrifugal Roof Exhaust FanStephanie GregasNo ratings yet

- Work Boats: SVA/SVAL 630 - 1400 - 3,000 - 20,000 KWDocument8 pagesWork Boats: SVA/SVAL 630 - 1400 - 3,000 - 20,000 KWJulia FalconeNo ratings yet

- Garrett GT1544Document1 pageGarrett GT1544Patricio IvanNo ratings yet

- 8L Series Pump: Three-Screw Pumps Standard Product SpecificationsDocument2 pages8L Series Pump: Three-Screw Pumps Standard Product SpecificationswillNo ratings yet

- Manual ICE 170 Vibratory HammerDocument12 pagesManual ICE 170 Vibratory HammerhaythamNo ratings yet

- Berma - GC - 1666018988 2Document2 pagesBerma - GC - 1666018988 2Elias Morales RosasNo ratings yet

- Screenshot 2023-11-16 at 3.45.42 PMDocument20 pagesScreenshot 2023-11-16 at 3.45.42 PMrajeevbhardwaj20No ratings yet

- Sai Selection GuideDocument8 pagesSai Selection GuideManuel CarvalloNo ratings yet

- MAX SSSeriesActuatorBrochureDocument4 pagesMAX SSSeriesActuatorBrochurealan minayaNo ratings yet

- 85,000 Barrels Every Day!: 8L-912Y Series Standard Product SpecificationsDocument6 pages85,000 Barrels Every Day!: 8L-912Y Series Standard Product SpecificationsManuel GimenezNo ratings yet

- Salient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800Document2 pagesSalient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800patelchiragisNo ratings yet

- Coil Lifters & Upenders: Model 80H - Dixon Coil Hook With Pivoting WedgeDocument1 pageCoil Lifters & Upenders: Model 80H - Dixon Coil Hook With Pivoting WedgeRUD Lifting MexicoNo ratings yet

- 3620 10th Lores 2Document8 pages3620 10th Lores 2Dinh Quang NhamNo ratings yet

- As CC SerieDocument2 pagesAs CC Seriepei chengNo ratings yet

- Salient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800Document2 pagesSalient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800patelchiragisNo ratings yet

- Pump Engineering MSRODocument2 pagesPump Engineering MSROLeonel Rubio100% (1)

- Mov-On Elevating Fifth WheelDocument3 pagesMov-On Elevating Fifth WheelGustavo A CastroNo ratings yet

- Stackers - NewDocument6 pagesStackers - NewsaravananNo ratings yet

- Impactor: Alwasy Step Ahead in TechnologyDocument3 pagesImpactor: Alwasy Step Ahead in TechnologychakmrinalNo ratings yet

- AHPB AHPBDS Product-Brochure 20210119 PDFDocument8 pagesAHPB AHPBDS Product-Brochure 20210119 PDFFelySaezNo ratings yet

- Thermowise Storage Vessels IntDocument12 pagesThermowise Storage Vessels IntIrishadoreStevlandOliphantNo ratings yet

- 1080 TITR618i 1548 G9eDocument2 pages1080 TITR618i 1548 G9emruddey melanixNo ratings yet

- 8frba SeriesDocument2 pages8frba Seriesargo kuncahyoNo ratings yet

- Efficiency & Dependability For A World That'S Always NDocument8 pagesEfficiency & Dependability For A World That'S Always NOscar CampoNo ratings yet

- 2013-07-31 MB-Motorensysteme EuroV Klassik EN Tbu PDFDocument20 pages2013-07-31 MB-Motorensysteme EuroV Klassik EN Tbu PDFmisternyckNo ratings yet

- On-Highway PowerDocument2 pagesOn-Highway PowerRamonNo ratings yet

- 682 v380 ENDocument8 pages682 v380 ENVenk KisaragiNo ratings yet

- Heavy TrucksDocument2 pagesHeavy TrucksAisha KhatibiNo ratings yet

- Manitou CBC Constructiebak - Feyter Forklift ServicesDocument1 pageManitou CBC Constructiebak - Feyter Forklift ServicesJavier Martinez RamirezNo ratings yet

- BifurcatedDocument4 pagesBifurcatedTanveer AzizNo ratings yet

- Productivity For A World That'S Always N.: X12 For Truck ApplicationsDocument6 pagesProductivity For A World That'S Always N.: X12 For Truck ApplicationssalimNo ratings yet

- HP935WCUDocument8 pagesHP935WCUvictoros27No ratings yet

- CC AlignX V5 Leaflet - 250215Document4 pagesCC AlignX V5 Leaflet - 250215jaiganesh011No ratings yet

- Water Jacket Motor PDFDocument8 pagesWater Jacket Motor PDFsultaniusNo ratings yet

- WMS TechnologiesDocument4 pagesWMS Technologiesketan parmarNo ratings yet

- Irbp LDocument2 pagesIrbp LANDRENo ratings yet

- BR CycloneDocument8 pagesBR CycloneRiegos Veracruz100% (1)

- Fiercely Tested.: Jobsite ReadyDocument12 pagesFiercely Tested.: Jobsite Readykismikloshun55No ratings yet

- Dimensions (MM) : Tractor 6x4Document4 pagesDimensions (MM) : Tractor 6x4Sameh MohamedNo ratings yet

- 2020 - 0204 - LT - 6LT Data SheetDocument2 pages2020 - 0204 - LT - 6LT Data SheetEsteban ÑancupelNo ratings yet

- 20150512051926HI Kobelco SK25SR Mini ExcavatorDocument4 pages20150512051926HI Kobelco SK25SR Mini ExcavatorAkhmad SebehNo ratings yet

- DiamondGear Brochure WebDocument4 pagesDiamondGear Brochure WebKunming WangNo ratings yet

- SCA0424R500 560 620SpecSheet SAU2016-8-R500 R560 R620 6x4 WEBDocument4 pagesSCA0424R500 560 620SpecSheet SAU2016-8-R500 R560 R620 6x4 WEBChristopherNo ratings yet

- Stowage Plan On Barge Mitra AbadiDocument1 pageStowage Plan On Barge Mitra AbadifajrikarNo ratings yet

- AP Series Exp 600-700kva 3phDocument6 pagesAP Series Exp 600-700kva 3phsayadul mostafaNo ratings yet

- Lincoln Electric Big Red 600Document4 pagesLincoln Electric Big Red 600eduardoNo ratings yet

- Rotor Specifications Stator Specifications Performance SpecificationsDocument1 pageRotor Specifications Stator Specifications Performance SpecificationsPaul SeatonNo ratings yet

- PressedDocument20 pagesPressedHorea CordunianuNo ratings yet

- Descriptive Pamphlet of the Richmond Mill Furnishing WorksFrom EverandDescriptive Pamphlet of the Richmond Mill Furnishing WorksNo ratings yet

- Abap TablesDocument753 pagesAbap TablesHimanshu SharmaNo ratings yet

- Presentation 1Document15 pagesPresentation 1sruthi_k7776No ratings yet

- Debugging Linux Systems Using GDB and Qemu: Khem RajDocument23 pagesDebugging Linux Systems Using GDB and Qemu: Khem RajMehmet Demir100% (1)

- Partnership Memory Aid AteneoDocument13 pagesPartnership Memory Aid AteneoLucioJr AvergonzadoNo ratings yet

- Bidding Document Lot 16B. Gondanglegi-Sp. Balekambang (B) - 101-201Document101 pagesBidding Document Lot 16B. Gondanglegi-Sp. Balekambang (B) - 101-201Nusantara GroupNo ratings yet

- 637 - 2024 Lab-1 Polyphase PowerDocument14 pages637 - 2024 Lab-1 Polyphase Powereren.alliNo ratings yet

- Tumabini Vs PeopleDocument7 pagesTumabini Vs PeopleAthea Justine YuNo ratings yet

- BP SampleDocument61 pagesBP SampleSean Andrei MntñrNo ratings yet

- Strategic Information Systems ManagementDocument6 pagesStrategic Information Systems ManagementStephen Lundall0% (1)

- Project Management DissertationDocument35 pagesProject Management DissertationDenny KurniawanNo ratings yet

- Sewage Treatment Plant - Operation Manual PDFDocument64 pagesSewage Treatment Plant - Operation Manual PDFDinhQuangDat100% (1)

- Jurnal Syafri AntoniDocument11 pagesJurnal Syafri Antoni170462201014 Syafri AntoniNo ratings yet

- 6020 & 6040 SERIES Environmental Chambers Operations Manual For Models 6020, 6021, 6022, 6023, 6025, 6027 6040, 6041, 6042, 6043, 6045, 6047Document66 pages6020 & 6040 SERIES Environmental Chambers Operations Manual For Models 6020, 6021, 6022, 6023, 6025, 6027 6040, 6041, 6042, 6043, 6045, 6047Walter RomeroNo ratings yet

- Env Policy PosterDocument1 pageEnv Policy Posteralice9No ratings yet

- Operator E-Jets News Rel 040Document12 pagesOperator E-Jets News Rel 040jivomirNo ratings yet

- 3210 HT 21-12-2023 SPLDocument1 page3210 HT 21-12-2023 SPLVishnu Vardhan ANo ratings yet

- Cool Card TricksDocument8 pagesCool Card TricksMarcusNo ratings yet

- PDFDocument6 pagesPDFMiko SeveraNo ratings yet

- Thesis Group 2Document6 pagesThesis Group 2Michael Dimayuga100% (8)

- Publish/Subscribe in A Mobile EnvironmentDocument10 pagesPublish/Subscribe in A Mobile EnvironmentbassbngNo ratings yet

- Aws WHB2 CH25Document30 pagesAws WHB2 CH25Alex SalasNo ratings yet

- Paper 1: Principles and Practice of AccountingDocument2 pagesPaper 1: Principles and Practice of AccountingrajNo ratings yet

- DC Corona Characteristics Derived From Corona Cage Tests and SimulationsDocument9 pagesDC Corona Characteristics Derived From Corona Cage Tests and SimulationsDimension JovenNo ratings yet

- Compiled ProjectDocument74 pagesCompiled ProjectMISHEAL CHIEMELANo ratings yet

- Colector Analizador de Vibraciones Falcon PDF 2 MBDocument6 pagesColector Analizador de Vibraciones Falcon PDF 2 MBGabriel Alexis MartínezNo ratings yet

- TMA 1 BA2 Jan 2015 RevisionDocument4 pagesTMA 1 BA2 Jan 2015 RevisionHamshavathini YohoratnamNo ratings yet

- S16r-Pta (T13-0311-E)Document4 pagesS16r-Pta (T13-0311-E)Dikdik Sidqi100% (1)

- Elo 1717L DS 17121aes00007Document2 pagesElo 1717L DS 17121aes00007Clever BarriosNo ratings yet

- Pitch Deck VolveroDocument19 pagesPitch Deck Volverostart-up.roNo ratings yet

Brochure Rotating Multi Grapple

Brochure Rotating Multi Grapple

Uploaded by

schemy sayOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure Rotating Multi Grapple

Brochure Rotating Multi Grapple

Uploaded by

schemy sayCopyright:

Available Formats

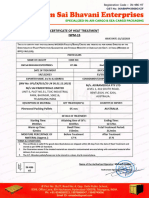

Rotating Multi Grapple 2-50 TON

The DAEHAN Heavy Industry Rotating Multi Grapple is

a uniquely designed and engineered DAEHAN product

that is versatile, durable and powerful. The unique

design manufactured from wear-resistant special solid

steel along with its unlimited 360 degree rotation,

powerful cylinder, and durable swing bearings make this

Rotating Multi Grapple a favourite among contractors in

Demolition, Forestry, Recycling and Landscaping.

K E Y F E AT U R E S Hydraulic Hose

Heat Treated Pins Connection

• Unlimited 360 degree rotation - clockwise Specially Designed

Powerful Motor

- Unlimited

and anti-clockwise Durable Swing

Bearings

360º Rotation

• Specially designed cylinder for more power Powerful Strong

Cylinder AR400 Wear

• Specially designed swing bearing for durability Resistant

Steel

• Manufactured from wear resistant special solid

steel (API 70 & AR 500), no extra reinforcement

is requirement.

• Versatile power rotating grapple for various Cat Tooth

configuration options

A TA

AT T CHMENTS NZ

daehan.co.nz

DHRS

SEE OVERLEAF FOR FULL SPECIFICATIONS

Rotating

Multi

Grapple

2-50 TON

C Z

C Z

B B

A A

MODEL UNIT DHRS 02 DHRS 03 DHRS 04 DHRS 06 DHRS 07 DHRS 08 DHRS 09 DHRS 10 DHRS 12 DHRS 16 DHRS 20

MODEL UNIT DHRS 02 DHRS 03 DHRS 04 DHRS 06 DHRS 07 DHRS 08 DHRS 09 DHRS 10 DHRS 12 DHRS 16 DH

Weight kg 200 370 445 760 850 1235 1260 1685 1830 2400 2670

Weight

Jaw opening m/m

kg1000 2001320 370

1400

445

1800

760

1900 2000

850 2100 12352210 1260

2300

1685

2500

1830

2700

2400 2

Jaw opening

A m/m m/m1000 10001320 1320

1400 1400

1800 1800

1900 20001900 2100 20002210 2100

2300 2210

2500 2300

2700 2500 2

BA m/m m/m100 1000140 1320

170 1400

170 1800

180 1901900 200 2000330 2100

350 2210

370 2300

369 2500 2

CB m/m m/m655 100865 920

140 1130

170 1190

170 1295 180 1375 190 1435 1470

200 1650

330 1770

350 370

Z m² 0.12 0.18 0.22 0.3 0.38 0.43 0.47 0.55 0.58 0.65 0.86

C m/m 655 865 920 1130 1190 1295 1375 1435 1470 1650 1

Operating Pressure Bar 170~250 170~250 190~280 200~350 200~350 220~350 220~350 220~350 220~350 220~350 220~350

Z m² 0.12 0.18 0.22 0.3 0.38 0.43 0.47 0.55 0.58 0.65

Pincer Recommandable Pressure Bar 210 210 210 250 250 250 250 280 280 280 280

Operating

Required OilPressure

Flow Lpm Bar40~60170~250

40~60 170~250

40~60 190~280

90~110 200~350100~180

90~110 200~350 220~350

100~180 120~200220~350

120~200 220~350 220~350 220~350 22

120~200 120~200

Pincer Recommandable Pressure Bar Bar

Operating Pressure 130~150 210 210

130~150 130~150 210

140~160 250 150~170

140~160 250 150~170 250150~170 250 280

150~170 150~170 280

150~170 280

Rotating

Required

Required OilOil

FlowFlow Lpm Lpm

30~50 40~60

30~50 40~60

30~50 40~60

40~60 40~60

90~110 40~60

90~11040~60100~180

40~60 100~180

40~60 120~200

40~60 40~60

120~200 120~200 12

Closing Force Ton 18 22 28 50 50 67 67 79 79 93 93

Operating Pressure Bar 130~150 130~150 130~150 140~160 140~160 150~170 150~170 150~170 150~170 150~170 15

Rotating Load Capacity kg 1000 1000 1000 4000 4000 6000 6000 10000 13500 14000 15000

Required Oil Flow Lpm 30~50 30~50 30~50 40~60 40~60 40~60 40~60 40~60 40~60 40~60 4

Carrier Ton 2~4 4~5 6~10 11~15 15~22 20~24 24~30 26~30 30~33 36~45 40~50

Closing

ୃSpecifications Force to change withoutTon

are subject 18for improvement

prior notice 22 of quality

28 50 50 67 67 79 79 93

Load Capacity kg 1000 1000 1000 4000 4000 6000 6000 10000 13500 14000 1

Carrier Ton 2~4 4~5 6~10 11~15 15~22 20~24 24~30 26~30 30~33 36~45 4

ୃSpecifications are subject to change without prior notice for improvement of quality

A TA

AT T CHMENTS NZ daehan.co.nz

You might also like

- Sandvik DL431-7C: Underground Drill RigDocument4 pagesSandvik DL431-7C: Underground Drill RiglidoNo ratings yet

- CorcovadoDocument30 pagesCorcovadoSergarale83% (6)

- CCW rv214w 1s5070 SSWP A4 LeafDocument2 pagesCCW rv214w 1s5070 SSWP A4 LeafHendro SaputroNo ratings yet

- 8L Series Brochure BR0008LDSDocument2 pages8L Series Brochure BR0008LDSManuel GimenezNo ratings yet

- 475 BHP at 1800 R/min - 1850 LB - FT (Cruise) 475 BHP at 1800 R/min 1850 LB FT (Cruise) 475 BHP at 1800 R/min - 1650 LB - FT (Rated)Document2 pages475 BHP at 1800 R/min - 1850 LB - FT (Cruise) 475 BHP at 1800 R/min 1850 LB FT (Cruise) 475 BHP at 1800 R/min - 1650 LB - FT (Rated)Jacinto Garcia Arista100% (1)

- DD 15 Spec SheetDocument2 pagesDD 15 Spec SheetremonrafaatsadekNo ratings yet

- On-Highway Power: Series 60 EXPORT - Truck 14 L 525 BHP at 1800 R/min - 1850 LB FTDocument2 pagesOn-Highway Power: Series 60 EXPORT - Truck 14 L 525 BHP at 1800 R/min - 1850 LB FTRamonNo ratings yet

- Garrett GT1544 454082-2 454083-2Document40 pagesGarrett GT1544 454082-2 454083-2Simo SalonenNo ratings yet

- Design and Fabrication of Stair Climber TrolleyDocument21 pagesDesign and Fabrication of Stair Climber TrolleyAnonymous 1mMOyt9zNo ratings yet

- Wide Operating Speed RangeDocument10 pagesWide Operating Speed Rangezxy320dNo ratings yet

- Construction Eng WEBDocument3 pagesConstruction Eng WEBzliceNo ratings yet

- RCU - Series Upblast Centrifugal Roof Exhaust FanDocument4 pagesRCU - Series Upblast Centrifugal Roof Exhaust FanStephanie GregasNo ratings yet

- Work Boats: SVA/SVAL 630 - 1400 - 3,000 - 20,000 KWDocument8 pagesWork Boats: SVA/SVAL 630 - 1400 - 3,000 - 20,000 KWJulia FalconeNo ratings yet

- Garrett GT1544Document1 pageGarrett GT1544Patricio IvanNo ratings yet

- 8L Series Pump: Three-Screw Pumps Standard Product SpecificationsDocument2 pages8L Series Pump: Three-Screw Pumps Standard Product SpecificationswillNo ratings yet

- Manual ICE 170 Vibratory HammerDocument12 pagesManual ICE 170 Vibratory HammerhaythamNo ratings yet

- Berma - GC - 1666018988 2Document2 pagesBerma - GC - 1666018988 2Elias Morales RosasNo ratings yet

- Screenshot 2023-11-16 at 3.45.42 PMDocument20 pagesScreenshot 2023-11-16 at 3.45.42 PMrajeevbhardwaj20No ratings yet

- Sai Selection GuideDocument8 pagesSai Selection GuideManuel CarvalloNo ratings yet

- MAX SSSeriesActuatorBrochureDocument4 pagesMAX SSSeriesActuatorBrochurealan minayaNo ratings yet

- 85,000 Barrels Every Day!: 8L-912Y Series Standard Product SpecificationsDocument6 pages85,000 Barrels Every Day!: 8L-912Y Series Standard Product SpecificationsManuel GimenezNo ratings yet

- Salient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800Document2 pagesSalient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800patelchiragisNo ratings yet

- Coil Lifters & Upenders: Model 80H - Dixon Coil Hook With Pivoting WedgeDocument1 pageCoil Lifters & Upenders: Model 80H - Dixon Coil Hook With Pivoting WedgeRUD Lifting MexicoNo ratings yet

- 3620 10th Lores 2Document8 pages3620 10th Lores 2Dinh Quang NhamNo ratings yet

- As CC SerieDocument2 pagesAs CC Seriepei chengNo ratings yet

- Salient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800Document2 pagesSalient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800patelchiragisNo ratings yet

- Pump Engineering MSRODocument2 pagesPump Engineering MSROLeonel Rubio100% (1)

- Mov-On Elevating Fifth WheelDocument3 pagesMov-On Elevating Fifth WheelGustavo A CastroNo ratings yet

- Stackers - NewDocument6 pagesStackers - NewsaravananNo ratings yet

- Impactor: Alwasy Step Ahead in TechnologyDocument3 pagesImpactor: Alwasy Step Ahead in TechnologychakmrinalNo ratings yet

- AHPB AHPBDS Product-Brochure 20210119 PDFDocument8 pagesAHPB AHPBDS Product-Brochure 20210119 PDFFelySaezNo ratings yet

- Thermowise Storage Vessels IntDocument12 pagesThermowise Storage Vessels IntIrishadoreStevlandOliphantNo ratings yet

- 1080 TITR618i 1548 G9eDocument2 pages1080 TITR618i 1548 G9emruddey melanixNo ratings yet

- 8frba SeriesDocument2 pages8frba Seriesargo kuncahyoNo ratings yet

- Efficiency & Dependability For A World That'S Always NDocument8 pagesEfficiency & Dependability For A World That'S Always NOscar CampoNo ratings yet

- 2013-07-31 MB-Motorensysteme EuroV Klassik EN Tbu PDFDocument20 pages2013-07-31 MB-Motorensysteme EuroV Klassik EN Tbu PDFmisternyckNo ratings yet

- On-Highway PowerDocument2 pagesOn-Highway PowerRamonNo ratings yet

- 682 v380 ENDocument8 pages682 v380 ENVenk KisaragiNo ratings yet

- Heavy TrucksDocument2 pagesHeavy TrucksAisha KhatibiNo ratings yet

- Manitou CBC Constructiebak - Feyter Forklift ServicesDocument1 pageManitou CBC Constructiebak - Feyter Forklift ServicesJavier Martinez RamirezNo ratings yet

- BifurcatedDocument4 pagesBifurcatedTanveer AzizNo ratings yet

- Productivity For A World That'S Always N.: X12 For Truck ApplicationsDocument6 pagesProductivity For A World That'S Always N.: X12 For Truck ApplicationssalimNo ratings yet

- HP935WCUDocument8 pagesHP935WCUvictoros27No ratings yet

- CC AlignX V5 Leaflet - 250215Document4 pagesCC AlignX V5 Leaflet - 250215jaiganesh011No ratings yet

- Water Jacket Motor PDFDocument8 pagesWater Jacket Motor PDFsultaniusNo ratings yet

- WMS TechnologiesDocument4 pagesWMS Technologiesketan parmarNo ratings yet

- Irbp LDocument2 pagesIrbp LANDRENo ratings yet

- BR CycloneDocument8 pagesBR CycloneRiegos Veracruz100% (1)

- Fiercely Tested.: Jobsite ReadyDocument12 pagesFiercely Tested.: Jobsite Readykismikloshun55No ratings yet

- Dimensions (MM) : Tractor 6x4Document4 pagesDimensions (MM) : Tractor 6x4Sameh MohamedNo ratings yet

- 2020 - 0204 - LT - 6LT Data SheetDocument2 pages2020 - 0204 - LT - 6LT Data SheetEsteban ÑancupelNo ratings yet

- 20150512051926HI Kobelco SK25SR Mini ExcavatorDocument4 pages20150512051926HI Kobelco SK25SR Mini ExcavatorAkhmad SebehNo ratings yet

- DiamondGear Brochure WebDocument4 pagesDiamondGear Brochure WebKunming WangNo ratings yet

- SCA0424R500 560 620SpecSheet SAU2016-8-R500 R560 R620 6x4 WEBDocument4 pagesSCA0424R500 560 620SpecSheet SAU2016-8-R500 R560 R620 6x4 WEBChristopherNo ratings yet

- Stowage Plan On Barge Mitra AbadiDocument1 pageStowage Plan On Barge Mitra AbadifajrikarNo ratings yet

- AP Series Exp 600-700kva 3phDocument6 pagesAP Series Exp 600-700kva 3phsayadul mostafaNo ratings yet

- Lincoln Electric Big Red 600Document4 pagesLincoln Electric Big Red 600eduardoNo ratings yet

- Rotor Specifications Stator Specifications Performance SpecificationsDocument1 pageRotor Specifications Stator Specifications Performance SpecificationsPaul SeatonNo ratings yet

- PressedDocument20 pagesPressedHorea CordunianuNo ratings yet

- Descriptive Pamphlet of the Richmond Mill Furnishing WorksFrom EverandDescriptive Pamphlet of the Richmond Mill Furnishing WorksNo ratings yet

- Abap TablesDocument753 pagesAbap TablesHimanshu SharmaNo ratings yet

- Presentation 1Document15 pagesPresentation 1sruthi_k7776No ratings yet

- Debugging Linux Systems Using GDB and Qemu: Khem RajDocument23 pagesDebugging Linux Systems Using GDB and Qemu: Khem RajMehmet Demir100% (1)

- Partnership Memory Aid AteneoDocument13 pagesPartnership Memory Aid AteneoLucioJr AvergonzadoNo ratings yet

- Bidding Document Lot 16B. Gondanglegi-Sp. Balekambang (B) - 101-201Document101 pagesBidding Document Lot 16B. Gondanglegi-Sp. Balekambang (B) - 101-201Nusantara GroupNo ratings yet

- 637 - 2024 Lab-1 Polyphase PowerDocument14 pages637 - 2024 Lab-1 Polyphase Powereren.alliNo ratings yet

- Tumabini Vs PeopleDocument7 pagesTumabini Vs PeopleAthea Justine YuNo ratings yet

- BP SampleDocument61 pagesBP SampleSean Andrei MntñrNo ratings yet

- Strategic Information Systems ManagementDocument6 pagesStrategic Information Systems ManagementStephen Lundall0% (1)

- Project Management DissertationDocument35 pagesProject Management DissertationDenny KurniawanNo ratings yet

- Sewage Treatment Plant - Operation Manual PDFDocument64 pagesSewage Treatment Plant - Operation Manual PDFDinhQuangDat100% (1)

- Jurnal Syafri AntoniDocument11 pagesJurnal Syafri Antoni170462201014 Syafri AntoniNo ratings yet

- 6020 & 6040 SERIES Environmental Chambers Operations Manual For Models 6020, 6021, 6022, 6023, 6025, 6027 6040, 6041, 6042, 6043, 6045, 6047Document66 pages6020 & 6040 SERIES Environmental Chambers Operations Manual For Models 6020, 6021, 6022, 6023, 6025, 6027 6040, 6041, 6042, 6043, 6045, 6047Walter RomeroNo ratings yet

- Env Policy PosterDocument1 pageEnv Policy Posteralice9No ratings yet

- Operator E-Jets News Rel 040Document12 pagesOperator E-Jets News Rel 040jivomirNo ratings yet

- 3210 HT 21-12-2023 SPLDocument1 page3210 HT 21-12-2023 SPLVishnu Vardhan ANo ratings yet

- Cool Card TricksDocument8 pagesCool Card TricksMarcusNo ratings yet

- PDFDocument6 pagesPDFMiko SeveraNo ratings yet

- Thesis Group 2Document6 pagesThesis Group 2Michael Dimayuga100% (8)

- Publish/Subscribe in A Mobile EnvironmentDocument10 pagesPublish/Subscribe in A Mobile EnvironmentbassbngNo ratings yet

- Aws WHB2 CH25Document30 pagesAws WHB2 CH25Alex SalasNo ratings yet

- Paper 1: Principles and Practice of AccountingDocument2 pagesPaper 1: Principles and Practice of AccountingrajNo ratings yet

- DC Corona Characteristics Derived From Corona Cage Tests and SimulationsDocument9 pagesDC Corona Characteristics Derived From Corona Cage Tests and SimulationsDimension JovenNo ratings yet

- Compiled ProjectDocument74 pagesCompiled ProjectMISHEAL CHIEMELANo ratings yet

- Colector Analizador de Vibraciones Falcon PDF 2 MBDocument6 pagesColector Analizador de Vibraciones Falcon PDF 2 MBGabriel Alexis MartínezNo ratings yet

- TMA 1 BA2 Jan 2015 RevisionDocument4 pagesTMA 1 BA2 Jan 2015 RevisionHamshavathini YohoratnamNo ratings yet

- S16r-Pta (T13-0311-E)Document4 pagesS16r-Pta (T13-0311-E)Dikdik Sidqi100% (1)

- Elo 1717L DS 17121aes00007Document2 pagesElo 1717L DS 17121aes00007Clever BarriosNo ratings yet

- Pitch Deck VolveroDocument19 pagesPitch Deck Volverostart-up.roNo ratings yet