Professional Documents

Culture Documents

Cadem L8

Cadem L8

Uploaded by

mohammed0 ratings0% found this document useful (0 votes)

10 views18 pagesThis document provides an overview of a lecture on computer-aided design of electrical machines. It discusses the need for CAD due to the large number of variables and constraints in electrical machine design. It outlines the input data, constraints, and output data that must be specified and satisfied in a CAD program. The goals of optimization are also discussed, such as maximizing efficiency or minimizing cost or weight. The document provides examples of designing different types of electrical machines using CAD programs.

Original Description:

Original Title

CADEM-L8

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an overview of a lecture on computer-aided design of electrical machines. It discusses the need for CAD due to the large number of variables and constraints in electrical machine design. It outlines the input data, constraints, and output data that must be specified and satisfied in a CAD program. The goals of optimization are also discussed, such as maximizing efficiency or minimizing cost or weight. The document provides examples of designing different types of electrical machines using CAD programs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views18 pagesCadem L8

Cadem L8

Uploaded by

mohammedThis document provides an overview of a lecture on computer-aided design of electrical machines. It discusses the need for CAD due to the large number of variables and constraints in electrical machine design. It outlines the input data, constraints, and output data that must be specified and satisfied in a CAD program. The goals of optimization are also discussed, such as maximizing efficiency or minimizing cost or weight. The document provides examples of designing different types of electrical machines using CAD programs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 18

Computer Aided Design of Electrical Machines

Introduction to Computer-Aided Design (CAD)

Lecture #8

Instructor: Mr. Jaafar Alnoor

jaawish@gmail.com

Electrical & Electronics Engineering Department

Faculty of Engineering & Architecture

National University

Computer-Aided Design

In any practical design the number of variables is so high that hand

calculations are impossible. The number of constraints is also large and for

these to be satisfied by final design, a lengthy iterative approach is required.

This is only possible with the help of computer programs (refer Flowchart 1.1).

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Input Data to be Fed into the Program

(a) Data

1. Rating of the machine (KW/KVA)

2. Rated Voltage

3. Rated Frequency (for AC only)

4. Rated Speed (RPM)

5. Type of Connection of Phases (Star/Delta) for 3 ph AC only

6. Type of Winding (Lap/Wave)

7. Number of Parallel Paths

8. Shunt/Compound in case of DC Machine

9. Squirrel Cage/Slip Ring type for 3-ph Ind.Motor

10. Rated Slip /Rotor speed for Ind.Motor

11. Salient Pole/Round rotor type for 3-ph Alternators

12. Rated power factor for 3-ph Alternators

13. Core/Shell type for Transformers

14. Ratings of HV /L V for Transformers

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Input Data to be Fed into the Program (cont..)

(b) Applicable tables in array format like,

1. Output vs. Specific Electric Loading(q)

2. Output vs. Specific Magnetic Loading(Bav)

3. Output vs. AT/pole

4. No. of poles vs. Pole pitch

5. Depth of Shunt field winding vs. Arm Dia

6. Standard sizes of brushes

7. Power Factor and Efficiency at different ratings of Ind. Motor

8. Frequency vs. Frequency constant of I-ph Ind. Motor

9. No. of poles vs. Di/De ratio for I-ph Ind. Motor

10. Efficiency and PF vs. output for I-ph Ind. Motor

11. Thickness of Stator winding ins vs. Voltage for Rotating machines

12. Window space Factor vs. K V A for transformers.

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Applicable Constraints I Maximum or Minimum Permissible Limits

1. Flux density in core, tooth, yoke

2. Current densities in all windings of the machine

3. Ratio of Pole arc to pole pitch

4. Ratio of Length to pole arc

5. Current Volume per slot of DC armature

6. Peripheral velocity of rotor

7. Frequency of flux reversal in DC armature

8. Current per Brush arm in DC armature

9. Voltage between Commutator segments in DC armature

10. Current per Brush arm in DC armature

11. Pole pitch

12. Temperature Rises

13. Power factor in Ind. Motor

14. No load current in Ind. Motor

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Applicable Constraints I Maximum or Minimum Permissible Limits (cont..)

15. Starting Torque in Ind. Motor

16. Number of Slots in Armature

17. Space motor of the slot in I-ph Ind. Motor

18. Rotor slo.ts in Ind. Motor

19. Eddy current loss factor in AC machine

20. Short Circuit Ratio of Alternator

21. Leakage reactance on AC Machine

22. Regulation

23. Saturation factor.

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Output Data to be Printed after Execution of Program

(a) Applicable Data

1. Main Dimensions and Internal dimensions of the machine

2. No. of slots

3. Turns in all windings

4. Copper sizes in all windings

5. Weights

6. Losses

7. Efficiency

8. Reactances

9. Full load Field current

10. Temperature rise

11. No. of cooling tubes for a transformer

12. Diameter and number of segments in Commutator

13. Full load slip of lnd. Motor.

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Output Data to be Printed after Execution of Program (cont..)

(b) Applicable Curves

1. Open Circuit, Short Circuit and Load magnetization characteristics of

Alternator

2. Slip vs. Torque curves of Ind. Motor.

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Various Objective Parameters for Optimization in an Electrical Machine

(a) Higher Efficiency

(b) Lower weight for given KVA output (Kg/KVA)

(c) Lower Temperature-Rise

(d) Lower Cost

(e) Any other parameter like higher PF for Induction motor, higher Reactance

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Selection of Optimal Design

Depending upon the required objective function, the suitable design variant

from the printed outputs can be picked up. We can also do it by computation

by incorporating a

statement to print only the best suited as per the objective.

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Explanation of Lowest Cost and Significance of "Kg/KVA"

Normally best objective for optimal design is the lowest cost. We will

understand what is the cost?

Total cost = Material Cost + Labour cost + Over head costs

Material cost = Cost of material at manufacturing works + Import

duties + Sales taxes

(For imported materials cost depends on foreign exchange rates

available at that time)

Labour cost = Payment made to Workers

Over head costs = Supervision charges + Depreciation charges on

heavy machinery

We can understand from the above that it is very difficult to get all the

information to arrive at total cost in the bookish design. Hence we look at more

practically feasible objective from class work point of view which is nothing

but minimum Kg/KVA. It means that we are able to get output of rated KVA

with minimum amount of material.

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Core Type Power Transformer

Total design is split into six parts in a proper sequence. Design Calculations are

given for a given Rating of a Transformer, followed by Computer Program

written in "C" language using MA TLAB software for each part. Finally all the

Programs are added together to get the total Program by running which we get

the total design. Computer output of total design is given.

This design may not be the optimum one. Now optimization objective and

design constraints are inserted into this total Program. When this program is

run we will get various alternative feasible designs from which the selected

variant based on the Optimization Criteria can be picked up.

Computer output showing the important design parameters for various feasible

alternatives is given at the end of this chapter along with a logic diagram.

Problem: Design a 800 KVA, 6600/ 440 V, 50 Hz,3 Phase, Delta/Star, Core

Type, ON cooled Power Transformer: (limit temp-rise to 50 deg-C).

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

Sequential Steps for Design of Each Part and Programming Simultaneously

(a) Calculate the dimensions of Magnetic frame consisting of Core, window

and Yoke. Calculate Flux densities in those parts and Iron losses.

(b) Calculate Amp-Turns and No load current.

(c) Calculate No. of turns, size of Copper and final dimensions of LV winding.

(d) Calculate No. of turns, size of Copper and final dimensions of HV winding.

(e) Check weather clearances between Magnetic frame and windings are OK.

(f) Calculate Windings copper Losses, total losses, Efficiency, Reactances and

% Regulation.

(g) Calculate Dimensions of cooling tank, number and size of cooling tubes,

temperature rise, total weight and Kg/KVA.

Note: By adding programs established for each part sequentially we get the

Program for complete design.

Lecture #8 Mr. Jaafar Alnoor, FEA, NU

You might also like

- Making Work Visible - Exposing Time Theft To Optimize Work & FlowDocument209 pagesMaking Work Visible - Exposing Time Theft To Optimize Work & FlowcnwaumyzzsxezjrkbsNo ratings yet

- The Enchanted Map Oracle Cards Free Download PDFDocument5 pagesThe Enchanted Map Oracle Cards Free Download PDFMariere Silva17% (6)

- Over-Flux Protection of The Transformer: Pushpak R. Nimkar T. G. AroraDocument6 pagesOver-Flux Protection of The Transformer: Pushpak R. Nimkar T. G. AroramohammedNo ratings yet

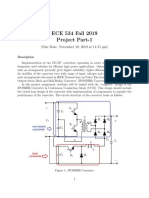

- ECE 534 Project 1 F19Document6 pagesECE 534 Project 1 F19JAY CHHEDANo ratings yet

- Intel Processor Power Delivery DesignDocument13 pagesIntel Processor Power Delivery DesignE.I.OSENo ratings yet

- Speed Control of Three Phase Induction Motor by AurduinoDocument39 pagesSpeed Control of Three Phase Induction Motor by AurduinoVivek Saikorian100% (3)

- 9.2.1.3 Lab - Designing and Implementing A Subnetted IPv4 Addressing SchemeDocument26 pages9.2.1.3 Lab - Designing and Implementing A Subnetted IPv4 Addressing SchemesellysaidiNo ratings yet

- Winding Design of Induction MotorsDocument7 pagesWinding Design of Induction MotorsKarthik MohankumarNo ratings yet

- Tee704 Cad t5 DC Machine and Computer Aided DesignDocument1 pageTee704 Cad t5 DC Machine and Computer Aided DesignKanta PokhriyalNo ratings yet

- Ap4111 Esd - Record (1) (1) 1Document80 pagesAp4111 Esd - Record (1) (1) 1inivetha1998No ratings yet

- Exp 1 Mannual TransformerDocument10 pagesExp 1 Mannual TransformerÅnshùmãn ShùklåNo ratings yet

- Motor Speed Control Using FPGA: July 2014Document5 pagesMotor Speed Control Using FPGA: July 2014Jaime SaenzNo ratings yet

- Ee Cad Lab: Practical ManualDocument10 pagesEe Cad Lab: Practical ManualPavan KhetrapalNo ratings yet

- PDFDocument3 pagesPDFMilan ModhawadiyaNo ratings yet

- 4Document5 pages4Alsmany ArdabNo ratings yet

- Operational Transconductance Amplifier Research PaperDocument6 pagesOperational Transconductance Amplifier Research PaperafeawjjwpNo ratings yet

- Design of Rotation Monitor and Simulation Design To Record The Variation of Frequency Effect On ALFC LoopDocument8 pagesDesign of Rotation Monitor and Simulation Design To Record The Variation of Frequency Effect On ALFC LoopIJRASETPublicationsNo ratings yet

- High-Switching-Frequency SiC Power Converter For High-Speed Switched Reluctance MachineDocument14 pagesHigh-Switching-Frequency SiC Power Converter For High-Speed Switched Reluctance MachineAman joshiNo ratings yet

- Computer Aided Design and FE Analysis of A PM BLDG Hub MotorDocument6 pagesComputer Aided Design and FE Analysis of A PM BLDG Hub MotorDebarati DamNo ratings yet

- Etd820s Lab 3 2018Document3 pagesEtd820s Lab 3 2018TimoNo ratings yet

- Tutorial 1 D Staton & J Goss MDL PDFDocument89 pagesTutorial 1 D Staton & J Goss MDL PDFAndrewNo ratings yet

- Design & Analysis of High Speed Low and Area CMOS Based Comparator With Different ArchitecturesDocument4 pagesDesign & Analysis of High Speed Low and Area CMOS Based Comparator With Different ArchitecturesijeteeditorNo ratings yet

- Design Project: (Due: Friday, December 8, 2006, 5pm PT)Document6 pagesDesign Project: (Due: Friday, December 8, 2006, 5pm PT)Ibrahim MuhammedNo ratings yet

- Design and Construction of 0 500V 3KVA Variac With Digital DisplayDocument9 pagesDesign and Construction of 0 500V 3KVA Variac With Digital DisplayEditor IJTSRDNo ratings yet

- General Model of A Five-Phase Induction Machine Allowing For Harmonics in The Air Gap FieldDocument9 pagesGeneral Model of A Five-Phase Induction Machine Allowing For Harmonics in The Air Gap FieldElayne HolandaNo ratings yet

- EngCalcPPC - User GuideDocument25 pagesEngCalcPPC - User GuideJavorsNo ratings yet

- Design of Three Phase Induction Motors - 240531 - 004654Document42 pagesDesign of Three Phase Induction Motors - 240531 - 004654SubhradeepNo ratings yet

- Ade Record eDocument75 pagesAde Record eSai PrateikNo ratings yet

- Design of Output Filter For Motor Drives: Anirudh Acharya.B Vinod JohnDocument6 pagesDesign of Output Filter For Motor Drives: Anirudh Acharya.B Vinod Johnbharath prabhuNo ratings yet

- Electric Vehicles - Latest EditionsDocument5 pagesElectric Vehicles - Latest EditionsSaeedAhmedKhan100% (1)

- Optimization of Induction Motor With Pole-Changing Winding by Finite Element ModelsDocument7 pagesOptimization of Induction Motor With Pole-Changing Winding by Finite Element ModelsKarthik MohankumarNo ratings yet

- Nasa Technical MemorandumDocument40 pagesNasa Technical MemorandumTurn LewyNo ratings yet

- Carunaiselvane, Jeevananthan - 2012 - Generalized Procedure For BLDC Motor Design and Substantiation in MagNet 7.1.1 SoftwareDocument9 pagesCarunaiselvane, Jeevananthan - 2012 - Generalized Procedure For BLDC Motor Design and Substantiation in MagNet 7.1.1 SoftwaremitulNo ratings yet

- 12 Steps For Designing SMPS TransformersDocument11 pages12 Steps For Designing SMPS TransformersRnDES1 CMLNo ratings yet

- Motor Starting CalculationDocument9 pagesMotor Starting CalculationDewi SihanoNo ratings yet

- Solved Problems in Electric MotorsDocument6 pagesSolved Problems in Electric Motorssumithra93% (15)

- Low Power ThesisDocument6 pagesLow Power Thesistiffanybarbermobile100% (2)

- Generalized Procedure For BLDC Motor Design and SubstantiationDocument9 pagesGeneralized Procedure For BLDC Motor Design and SubstantiationKhandoker Raisul AzadNo ratings yet

- Outcome Based Layer Learning Hardware Lab Task Report: Design and Development of Power Supply of Mobile ChargersDocument17 pagesOutcome Based Layer Learning Hardware Lab Task Report: Design and Development of Power Supply of Mobile ChargersSujith SujithNo ratings yet

- Lesson 3 - ExercisesDocument3 pagesLesson 3 - Exercisesabhilash.dharmishtanNo ratings yet

- Optimal Design of Interior Permanent Magnet - Lee - 2013Document6 pagesOptimal Design of Interior Permanent Magnet - Lee - 2013Maycon MaranNo ratings yet

- Avionics Lightning Protection Design GUIDocument14 pagesAvionics Lightning Protection Design GUIuser123No ratings yet

- Ijet V3i5p16Document13 pagesIjet V3i5p16International Journal of Engineering and TechniquesNo ratings yet

- Machine Design 1Document36 pagesMachine Design 1stanely njogooNo ratings yet

- Jawaharlal Nehru Engineering College: Laboratory ManualDocument36 pagesJawaharlal Nehru Engineering College: Laboratory Manualprathap kumarNo ratings yet

- Reliability Analysis of Aircraft Starter Generator Drive ConverterDocument6 pagesReliability Analysis of Aircraft Starter Generator Drive Convertersezgin bayramNo ratings yet

- TDSDocument2 pagesTDSMahidhar TalapaneniNo ratings yet

- 12V DC To 220V Ac Inverter Using D-MosfetsDocument19 pages12V DC To 220V Ac Inverter Using D-MosfetsNabeel AhmedNo ratings yet

- Eset 211 Lab 08 InverterDocument3 pagesEset 211 Lab 08 InverterPhan HiếuNo ratings yet

- By Robert Prieto, Associate Professor, Universidad: Power Electronics Technology March 2005Document5 pagesBy Robert Prieto, Associate Professor, Universidad: Power Electronics Technology March 2005Constantin DorinelNo ratings yet

- User Guide For Version 2.01c March 2011Document27 pagesUser Guide For Version 2.01c March 2011macpepitoNo ratings yet

- Implementation of PWM Based Firing Scheme For Multilevel Inverter Using MicrocontrollerDocument52 pagesImplementation of PWM Based Firing Scheme For Multilevel Inverter Using MicrocontrollerAbdulaziz MuhammedNo ratings yet

- 06 CSL38 Manual LDDocument68 pages06 CSL38 Manual LDSwathi N SudarshanNo ratings yet

- Mechanical RF Phase - ShifterDocument33 pagesMechanical RF Phase - ShifterutammarryNo ratings yet

- PAPER. (FINETURBO) Investigation of A Steam Turbine With Leaned Blades by Through Flow Analysis and 3D CFD SimulationDocument6 pagesPAPER. (FINETURBO) Investigation of A Steam Turbine With Leaned Blades by Through Flow Analysis and 3D CFD SimulationCJ QuahNo ratings yet

- Project Progress Form Final - 231006 - 121201Document8 pagesProject Progress Form Final - 231006 - 121201rt8nw47hdfNo ratings yet

- Application of GA Took For Design Optimization of Squirrel Cage Induction MotorDocument14 pagesApplication of GA Took For Design Optimization of Squirrel Cage Induction Motordarshil modiNo ratings yet

- Flyback Converter Design ThesisDocument8 pagesFlyback Converter Design Thesisleanneuhlsterlingheights100% (2)

- Multi-Objective Security Constrained Unit CommitmeDocument21 pagesMulti-Objective Security Constrained Unit CommitmeJosé Veríssimo Ribeiro de ToledoNo ratings yet

- Thesis On Pipeline AdcsDocument6 pagesThesis On Pipeline Adcsamyholmesmanchester100% (2)

- Valyou - 2020 - J. - Phys. - Conf. - Ser. - 1452 - 012019Document15 pagesValyou - 2020 - J. - Phys. - Conf. - Ser. - 1452 - 012019umarishaqNo ratings yet

- EPE2013 - FPGA Motor Drive Based SRM PDFDocument8 pagesEPE2013 - FPGA Motor Drive Based SRM PDFKrishnam NaiduNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- Task 1Document1 pageTask 1mohammedNo ratings yet

- Cars and DrivingDocument1 pageCars and DrivingmohammedNo ratings yet

- Introduction LetterDocument1 pageIntroduction LettermohammedNo ratings yet

- Protection: Signalling and Intertripping: Energy AutomationDocument18 pagesProtection: Signalling and Intertripping: Energy AutomationmohammedNo ratings yet

- Cadem-L4 2Document18 pagesCadem-L4 2mohammedNo ratings yet

- Percentage RestraineDocument14 pagesPercentage RestrainemohammedNo ratings yet

- Transformer+Stability SajjadDocument4 pagesTransformer+Stability SajjadMuruganantham Chandrappan100% (1)

- NPAG2012 App2 IndepDocument2 pagesNPAG2012 App2 IndepmohammedNo ratings yet

- Solution A 33.2m2 V Q/a 1.9m/s: Name: Mohammed Karam Saad Aldeen Batch:12 AssignmentDocument2 pagesSolution A 33.2m2 V Q/a 1.9m/s: Name: Mohammed Karam Saad Aldeen Batch:12 AssignmentmohammedNo ratings yet

- Null 5Document96 pagesNull 5mohammedNo ratings yet

- Solution A 33.2m2 V Q/a 1.9m/s: Name: Mohammed Karam Saad Aldeen Batch:12 AssignmentDocument2 pagesSolution A 33.2m2 V Q/a 1.9m/s: Name: Mohammed Karam Saad Aldeen Batch:12 AssignmentmohammedNo ratings yet

- Solution A 33.2m2 V Q/a 1.9m/s: Name: Mohammed Karam Saad Aldeen Batch:12 AssignmentDocument2 pagesSolution A 33.2m2 V Q/a 1.9m/s: Name: Mohammed Karam Saad Aldeen Batch:12 AssignmentmohammedNo ratings yet

- Vdoc - Pub Hadamard-TransformsDocument484 pagesVdoc - Pub Hadamard-Transformsvahidmesic45No ratings yet

- Kenworth Ecat User GuideDocument11 pagesKenworth Ecat User GuideEdwin Alfonso Hernandez MontesNo ratings yet

- Consultant Contractor: Material Inspection RequestDocument1 pageConsultant Contractor: Material Inspection RequestOpal AndpartnersNo ratings yet

- SFT 05 07401Document2 pagesSFT 05 07401danielNo ratings yet

- Improving Grammatical Error Correction Via Pre-Training A Copy-Augmented Architecture With Unlabeled DataDocument10 pagesImproving Grammatical Error Correction Via Pre-Training A Copy-Augmented Architecture With Unlabeled DataLong TrinhNo ratings yet

- The 5Ws of Internet Research Website 1 - Aboud HDocument1 pageThe 5Ws of Internet Research Website 1 - Aboud HAboud HasanNo ratings yet

- Interim Result: National Institute of Technology RaipurDocument1 pageInterim Result: National Institute of Technology RaipurNaman AgrawalNo ratings yet

- G4BM480V12ADTL20 ManualDocument5 pagesG4BM480V12ADTL20 ManualStipe CorakNo ratings yet

- 6.5.2.3 Packet Tracer-ResueltoDocument2 pages6.5.2.3 Packet Tracer-ResueltoKaty Lucero Ccallo ObregonNo ratings yet

- AngularJS TablesDocument3 pagesAngularJS Tablesprr technologiesNo ratings yet

- BANK LOAN MANAGEMENT SYSTEM PROJECT SynopsisDocument5 pagesBANK LOAN MANAGEMENT SYSTEM PROJECT SynopsisVaibhav D Moraskar75% (4)

- SITRAIN Catalog Rev072516Document98 pagesSITRAIN Catalog Rev072516Franklin EgejuruNo ratings yet

- UM HDL Buspro Setup Tool 2 (2020!05!23)Document32 pagesUM HDL Buspro Setup Tool 2 (2020!05!23)crisma tariNo ratings yet

- Microprocessor Chapter 2Document13 pagesMicroprocessor Chapter 2جعفر علي خليل إبراهيمNo ratings yet

- Chapter 7 The Maintenance and Engineering Organization: Facultad de Ingeniería y Ciencias BásicasDocument21 pagesChapter 7 The Maintenance and Engineering Organization: Facultad de Ingeniería y Ciencias BásicasAnonymous OFTUeE6No ratings yet

- Polycom Realpresence Group 500 Data SheetDocument3 pagesPolycom Realpresence Group 500 Data SheetjuanluismegaNo ratings yet

- Cornell University CS 569: Interactive Computer GraphicsDocument4 pagesCornell University CS 569: Interactive Computer GraphicsSoirsee CarlNo ratings yet

- MBA ZC417 Quantitative Methods COURSE HANDOUTDocument8 pagesMBA ZC417 Quantitative Methods COURSE HANDOUTRavi KaviNo ratings yet

- Esquema Final - 98-0022-01 E2c Solution Summary PARTTEAM Kiosk (20.01.23) - 4Document14 pagesEsquema Final - 98-0022-01 E2c Solution Summary PARTTEAM Kiosk (20.01.23) - 4Jorge NetoNo ratings yet

- Enable SSL LabDocument3 pagesEnable SSL Labbenben08No ratings yet

- Perfusor® Compact: Service ManualDocument86 pagesPerfusor® Compact: Service ManualLailly KurniaNo ratings yet

- SCADA-DMS - HIS - Functional Description v05Document101 pagesSCADA-DMS - HIS - Functional Description v05Rinda_RaynaNo ratings yet

- Rangkuman Osce Ukmppd PDFDocument1 pageRangkuman Osce Ukmppd PDFAzizah AlkatiriNo ratings yet

- 21MCI1126 - Nikhil - Raj 2.1Document11 pages21MCI1126 - Nikhil - Raj 2.1nikhilsinghraj11No ratings yet

- Arduino Based Hand Gesture Control of PC / LaptopDocument28 pagesArduino Based Hand Gesture Control of PC / LaptopSRUTHI M SREEKUMARNo ratings yet

- Onboarding FormalitiesDocument2 pagesOnboarding Formalitiestony EugineNo ratings yet

- Assignment Infographic mgt300Document1 pageAssignment Infographic mgt300NUR SYAFIQAH DAYANA MOHD SUFFIANNo ratings yet

- Chapter 5 Slides - Coulouris - SDDocument22 pagesChapter 5 Slides - Coulouris - SDAlencar JuniorNo ratings yet