Professional Documents

Culture Documents

Shell & Tube Heat Exchanger

Shell & Tube Heat Exchanger

Copyright:

Available Formats

You might also like

- State V Thabo Bester (WCC) 16 Aug 2021 by Cloete AJDocument7 pagesState V Thabo Bester (WCC) 16 Aug 2021 by Cloete AJBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- TEMA Sheet Heat Exchanger Specification SheetDocument3 pagesTEMA Sheet Heat Exchanger Specification SheetSonNguyen100% (1)

- 2019-12-20 Reboiler - Spec. SheetDocument1 page2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaNo ratings yet

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetRizal NajibNo ratings yet

- Blank Tema SheetDocument1 pageBlank Tema SheetYosua ChangNo ratings yet

- En 50216-10Document16 pagesEn 50216-10Mahmoud ShaheenNo ratings yet

- BB 1Document1 pageBB 1SaidFerdjallahNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11anggun 119280087No ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12Document1 pageAspen Exchanger Design and Rating Shell & Tube V12TIPAZONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11anggun 119280087No ratings yet

- Soal A CS Suhu 35 TSDocument1 pageSoal A CS Suhu 35 TSanggun 119280087No ratings yet

- E 106Document1 pageE 106Bith SMGNo ratings yet

- Case 2Document1 pageCase 2nirajkulkarni09No ratings yet

- Tubos y Coraza PDFDocument2 pagesTubos y Coraza PDFsamara navasNo ratings yet

- Tubos y Coraza PDFDocument2 pagesTubos y Coraza PDFsamara navasNo ratings yet

- Case 3Document1 pageCase 3nirajkulkarni09No ratings yet

- Tema SheetDocument1 pageTema SheetMayank AgrawalNo ratings yet

- Case 5Document1 pageCase 5nirajkulkarni09No ratings yet

- Consub TemaDocument1 pageConsub TemaMAYANK AGRAWALNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA Sheetvaratharajan g rNo ratings yet

- Heat Exchanger Rev - 02Document1 pageHeat Exchanger Rev - 02TKT ConsultantNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10MAYANK AGRAWALNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- E-100 TEMA SheetDocument1 pageE-100 TEMA Sheetuse for school google drive storageNo ratings yet

- Case 4Document1 pageCase 4nirajkulkarni09No ratings yet

- Shell&Tube TEMAsheet 1Document1 pageShell&Tube TEMAsheet 1Rikiya FebriyanNo ratings yet

- E-200 TEMA SheetDocument1 pageE-200 TEMA Sheetuse for school google drive storageNo ratings yet

- E-313 DesignDocument1 pageE-313 DesignAamir SultanNo ratings yet

- Case 6Document1 pageCase 6nirajkulkarni09No ratings yet

- 1Document1 page1kkkprotNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Ginna RodriguezNo ratings yet

- E-101, Precalentador de PropanoDocument1 pageE-101, Precalentador de PropanoIsaac RodriguezNo ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- ShellTubeHE Hot PT Konigs E-202 ColdDocument1 pageShellTubeHE Hot PT Konigs E-202 Coldeka prasetiaNo ratings yet

- File: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Document14 pagesFile: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Camila Florencia ScarlatoNo ratings yet

- TEMA Sheed L-R ExchangerDocument1 pageTEMA Sheed L-R ExchangerAlejandra BuenoNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetDocument2 pagesAspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetLandaNo ratings yet

- Output PDFDocument1 pageOutput PDFAlex AgualemaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMAlex AgualemaNo ratings yet

- 1 PDFDocument1 page1 PDFWael BadriNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetWael BadriNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Luis NewballNo ratings yet

- TEMA Sheet CorregidoDocument1 pageTEMA Sheet Corregidosaragineth.saNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- L-R Intercambiador Coraza y Tubos PDFDocument1 pageL-R Intercambiador Coraza y Tubos PDFAlejandro OsorioNo ratings yet

- CCT ShellAndTubeReportDocument2 pagesCCT ShellAndTubeReportLuthfi LegooNo ratings yet

- He 1061Document12 pagesHe 1061vijay88666No ratings yet

- Intercambiador de Calor: Heat Exchanger Data SheetDocument6 pagesIntercambiador de Calor: Heat Exchanger Data SheetBRENDA VIVIANA ARANDA JURADONo ratings yet

- Output - ITEM NO. 113486 - 24 Inch at 10000 KGHRDocument1 pageOutput - ITEM NO. 113486 - 24 Inch at 10000 KGHRyadav yadavNo ratings yet

- Ea 101Document2 pagesEa 101Najmul SaqibNo ratings yet

- Heat Exchanger Sizing E-7010 #1Document2 pagesHeat Exchanger Sizing E-7010 #1Luis Enrique Leyva OvalleNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetWael BadriNo ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- Services EngineerDocument2 pagesServices EngineerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Reliability Engineer VacancyDocument3 pagesReliability Engineer VacancyBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- MSF780 Composite Crack Growth - Right One7Dec20 - JABDocument11 pagesMSF780 Composite Crack Growth - Right One7Dec20 - JABBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- BoilermakerDocument1 pageBoilermakerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Instrumentation MechanicianDocument1 pageInstrumentation MechanicianBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Quick Checklist For Reports and PresentationsDocument1 pageQuick Checklist For Reports and PresentationsBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- MSF Report 20Document2 pagesMSF Report 20Besuidenhout Engineering Solutions and ConsultingNo ratings yet

- Checklist For DivorcesDocument3 pagesChecklist For DivorcesBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Hajali 2006Document18 pagesHajali 2006Besuidenhout Engineering Solutions and ConsultingNo ratings yet

- Npy 416 Study Guide - zp179845Document8 pagesNpy 416 Study Guide - zp179845Besuidenhout Engineering Solutions and ConsultingNo ratings yet

- Dowling Chapter 9 Test 1 MemoDocument6 pagesDowling Chapter 9 Test 1 MemoBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Department of Materials Science and Metallurgical EngineeringDocument10 pagesDepartment of Materials Science and Metallurgical EngineeringBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Subject Conversion - Mechanical EngineeringDocument1 pageSubject Conversion - Mechanical EngineeringBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- MSV 780 Exam 2020 MemoDocument24 pagesMSV 780 Exam 2020 MemoBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Vertical Separator Design Theory & Calculation SheetDocument8 pagesVertical Separator Design Theory & Calculation SheetBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Rotating Machinery AlignmentDocument61 pagesRotating Machinery AlignmentBesuidenhout Engineering Solutions and Consulting100% (1)

- AFRIMATDocument1 pageAFRIMATBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Interns Industrial-EngineeringDocument1 pageInterns Industrial-EngineeringBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Reliability EngineerDocument1 pageReliability EngineerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- PyrovatexDocument12 pagesPyrovatexahsan888No ratings yet

- Casting Defects - Dr. Manjula NanayakkaraDocument22 pagesCasting Defects - Dr. Manjula NanayakkaraDilupa HerathNo ratings yet

- Competence NoDocument5 pagesCompetence NoAjay SinghNo ratings yet

- Sika Resiplot - EGDocument4 pagesSika Resiplot - EGthe pilotNo ratings yet

- Steel InspectionDocument131 pagesSteel InspectionJanatan ChoiNo ratings yet

- Material Selection in Oil and Gas 1684649857Document15 pagesMaterial Selection in Oil and Gas 1684649857Sh MNNo ratings yet

- ECG Interpretation Made Incredibly Easy! (5th Edition)Document29 pagesECG Interpretation Made Incredibly Easy! (5th Edition)Freisan Chen0% (1)

- Construction Project Tasks Status ReportDocument2 pagesConstruction Project Tasks Status ReportAljay Joalson Castillo AlcidNo ratings yet

- Comparison of Batch and Continuous Processes Sergio Pissavini RSC Symposium 2011Document31 pagesComparison of Batch and Continuous Processes Sergio Pissavini RSC Symposium 2011Amro Yulianti SiregarNo ratings yet

- Chapter 11 Prevention, Mitigation, & Monitoring Measures 4 PipelinesDocument17 pagesChapter 11 Prevention, Mitigation, & Monitoring Measures 4 PipelinesMAT-LIONNo ratings yet

- Environmental Test Chamber QuestionnaireDocument4 pagesEnvironmental Test Chamber QuestionnaireTong YeNo ratings yet

- 201208081Document1 page201208081Yng TangNo ratings yet

- Corrosion Tests and StandardsDocument200 pagesCorrosion Tests and Standards이선엽100% (1)

- Method Statement For Site Handling of Concrete Made With GGBSDocument2 pagesMethod Statement For Site Handling of Concrete Made With GGBSabobeedoNo ratings yet

- Physical and Chemical Properties of MatterDocument1 pagePhysical and Chemical Properties of Matterriza amoresNo ratings yet

- Cooling Water TreatmentDocument115 pagesCooling Water TreatmentMuhammad Abdullah100% (1)

- Insulation SpecificationDocument1 pageInsulation SpecificationKittisak SungsanaNo ratings yet

- Baldor NEMA ChartDocument1 pageBaldor NEMA ChartHernan Patarroyo100% (1)

- 411 Ses41 Tillmann 040 FINAL v3Document8 pages411 Ses41 Tillmann 040 FINAL v3Ertugrul CelikNo ratings yet

- E Book - Complete Guide of Polycarbonate Fabrication - ExceliteDocument49 pagesE Book - Complete Guide of Polycarbonate Fabrication - ExcelitecpcdbrNo ratings yet

- Flowable Fill: Versatile Low Strength MixDocument2 pagesFlowable Fill: Versatile Low Strength MixSajjad AnwarNo ratings yet

- Alkali and Alkaline Earth MetalsDocument23 pagesAlkali and Alkaline Earth MetalsInayah Tria PutriNo ratings yet

- Model PMGSY Road Datas 2013-14-SSRDocument91 pagesModel PMGSY Road Datas 2013-14-SSRChManikumarNo ratings yet

- Determine The Maximum Dry DensityDocument4 pagesDetermine The Maximum Dry Densityધર્મેશ મિસ્ત્રીNo ratings yet

- Hydrogen Sulfide (0.0001% - 0.05 %) in Nitrogen: Safety Data Sheet 50248Document9 pagesHydrogen Sulfide (0.0001% - 0.05 %) in Nitrogen: Safety Data Sheet 50248pcatruongNo ratings yet

- Integrated Systems Management: Improving Systems Performance To World Class StatusDocument42 pagesIntegrated Systems Management: Improving Systems Performance To World Class StatusDr. Sandeep KautishNo ratings yet

- TMG PC Strands, Wire & BarDocument10 pagesTMG PC Strands, Wire & BarHenrique Braglia PachecoNo ratings yet

- Masterseal 550Document4 pagesMasterseal 550Haresh BhavnaniNo ratings yet

- Japanese Fridge Manual 2Document8 pagesJapanese Fridge Manual 2scraboNo ratings yet

Shell & Tube Heat Exchanger

Shell & Tube Heat Exchanger

Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell & Tube Heat Exchanger

Shell & Tube Heat Exchanger

Copyright:

Available Formats

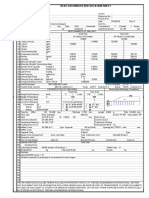

Aspen Exchanger Design and Rating Shell & Tube V11

File: Printed: 17/04/2023 at 21:10:33

TEMA Sheet

Heat Exchanger Specification Sheet

1 Company:XXXX

2 Location: Algiers

3 Service of Unit: Our Reference:

4 Item No.: Your Reference:

5 Date:17-04-2023 Rev No.: 0 Job No.:

6 Size : 300 - 3658 mm Type: AEL Horizontal Connected in: 1 parallel 1 series

7 Surf/unit(eff.) 17,6 m² Shells/unit 1 Surf/shell(eff.) 17,6 m²

8 PERFORMANCE OF ONE UNIT

9 Fluid allocation Shell Side Tube Side

10 Fluid name In PF->Out PF In CW->Out CW

11 Fluid quantity, Total kg/h 3283 17272

12 Vapor (In/Out) kg/h 3283 3283 0 0

13 Liquid kg/h 0 0 17272 17272

14 Noncondensable kg/h 0 0 0 0

15

16 Temperature (In/Out) °C 146,51 36,08 29 38,81

17 Bubble / Dew point °C / / 155,58 / 155,58 154,57 / 154,57

18 Density Vapor/Liquid kg/m³ 21,48 / 32,45 / / 1004,46 / 997

19 Viscosity cp 0,0149 / 0,0115 / / 0,8146 / 0,6671

20 Molecular wt, Vap 27,86 27,86

21 Molecular wt, NC

22 Specific heat kJ/(kg-K) 2,041 / 1,937 / / 4,178 / 4,179

23 Thermal conductivity W/(m-K) 0,0373 / 0,0256 / / 0,6168 / 0,6299

24 Latent heat kcal/kg

25 Pressure (abs) bar 25,47 25,34855 5,51325 5,37074

26 Velocity (Mean/Max) m/s 2,36 / 3,22 1,06 / 1,26

27 Pressure drop, allow./calc. bar 0,1 0,12145 0,1 0,14251

28 Fouling resistance (min) m²-h-C/kcal 0,00041 0,00041 0,00053 Ao based

29 Heat exchanged 169049 kcal/h MTD (corrected) 29,03 °C

30 Transfer rate, Service 331,4 Dirty 282,2 Clean 383,5 kcal/(h-m²-C)

31 CONSTRUCTION OF ONE SHELL Sketch

32 Shell Side Tube Side

33 Design/Vacuum/test pressure bar 29 / / 7 / /

34 Design temperature / MDMT °C 185 / 185 /

S1 T2

35 Number passes per shell 1 3

36 Corrosion allowance mm 3,18 3,18 T1 S2

37 Connections In mm 1 102,26 / - 1 77,93 / -

38 Size/Rating Out 1 77,93 / - 1 77,93 / -

39 ID Intermediate / - / -

40 Tube #: 82 OD: 19,05 Tks. Average 2,11 mm Length: 3658 mm Pitch: 25,4 mm Tube pattern:90

41 Tube type: Plain Insert:None Fin#: #/m Material:Carbon Steel

42 Shell Carbon Steel ID 300 OD 316,76 mm Shell cover -

43 Channel or bonnet Carbon Steel Channel cover Carbon Steel

44 Tubesheet-stationary Carbon Steel - Tubesheet-floating -

45 Floating head cover - Impingement protection None

46 Baffle-cross Carbon Steel Type Single segmental Cut(%d) 25,66 Horizontal

Spacing: c/c 100 mm

47 Baffle-long - Seal Type Inlet 261,48 mm

48 Supports-tube U-bend 0 Type

49 Bypass seal Tube-tubesheet joint Expanded only (2 grooves)(App.A 'i')

50 Expansion joint - Type None

51 RhoV2-Inlet nozzle 574 Bundle entrance 115 Bundle exit 201 kg/(m-s²)

52 Gaskets - Shell side - Tube side Flat Metal Jacket Fibe

53 Floating head -

54 Code requirements ASME Code Sec VIII Div 1 TEMA class R - refinery service

55 Weight/Shell 874,6 Filled with water 1116,4 Bundle 361,2 kg

56 Remarks

57

58

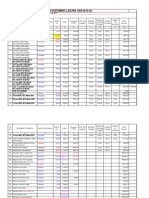

Views on arrow A

A 4306 Overall

3580

203 121 150 3335 353

S1 T2

T1 312

S1

T1 S2

121 732 2194

308

3400

Pulling Length

308

345

S2

75 75

T2

274

274

68

68

312

150 150

2 Bolts 2 Bolts

Fixed Sliding

Nozzle Data Design Data Units Shell Channel Notes: Company:XXXX

Ref OD Wall Standard Notes Design Pressure bar 29 7 Location: Algiers

S1 114 mm 6 mm Slip on Design Temperature °C 185 185 Service of Unit: Our Reference:

S2 89 mm 5,5 mm Slip on Full Vacuum Item No.: Your Reference:

T1 89 mm 5,5 mm Slip on Corrosion Allowance mm 3,175 3,175 Date:17-04-2023 Rev No.: 0 Job No.:

T2 89 mm 5,5 mm Slip on Test Pressure bar

Number of Passes 1 3

Radiography

Company Name

PWHT City, State

Internal Volume m³ 0,1661 0,0958 Scale:

Rev: Date: Description Dwg. Chk. Appd. ASME Section VIII Div. 1

Weight Summary

Setting Plan

TEMA Type: AEL

Empty Flooded Bundle Size: 300 - 3658 Dwg No.: Rev:

875 kg 1116 kg 361 kg TEMA Class: R 1

24

19,05

22 25,3990

36

Shell inside diameter mm 300

111,12 mm

Front head inside diameter mm 307,086

Outer tube limit mm 290,475

Tube number (calcs.) 82

Tube number (layout) 82

Tube length mm 3658

Tube O.D. mm 19,05

Tube pitch mm 25,399

Tube pattern 90

Tube passes 3

Tie rod number 4

Tie rod diameter mm 9,55

111,12 mm

Sealing strips (pairs) 3

Baffle type Single segmental

Centre to outer baffle cut mm 73,0235

Centre to inner baffle cut

Impingement protection None

Shell Side Inlet Nozzle Inside Diameter mm 102,2604

Shell Side Outlet Nozzle Inside Diameter mm 77,9272

Notes: Company:XXXX

Location: Algiers

Service of Unit: Our Reference:

Item No.: Your Reference:

Date:17-04-2023 Rev No.: 0 Job No.:

Company Name

City, State

Scale:

Rev: Date: Description Dwg. Chk. Appd. ASME Code Sec VIII Div 1

TEMA Type: AEL

Tube Layout

Size: 300 - 3658 Dwg No.: Rev:

TEMA Class: R - refinery service 2

You might also like

- State V Thabo Bester (WCC) 16 Aug 2021 by Cloete AJDocument7 pagesState V Thabo Bester (WCC) 16 Aug 2021 by Cloete AJBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- TEMA Sheet Heat Exchanger Specification SheetDocument3 pagesTEMA Sheet Heat Exchanger Specification SheetSonNguyen100% (1)

- 2019-12-20 Reboiler - Spec. SheetDocument1 page2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaNo ratings yet

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetRizal NajibNo ratings yet

- Blank Tema SheetDocument1 pageBlank Tema SheetYosua ChangNo ratings yet

- En 50216-10Document16 pagesEn 50216-10Mahmoud ShaheenNo ratings yet

- BB 1Document1 pageBB 1SaidFerdjallahNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11anggun 119280087No ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12Document1 pageAspen Exchanger Design and Rating Shell & Tube V12TIPAZONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11anggun 119280087No ratings yet

- Soal A CS Suhu 35 TSDocument1 pageSoal A CS Suhu 35 TSanggun 119280087No ratings yet

- E 106Document1 pageE 106Bith SMGNo ratings yet

- Case 2Document1 pageCase 2nirajkulkarni09No ratings yet

- Tubos y Coraza PDFDocument2 pagesTubos y Coraza PDFsamara navasNo ratings yet

- Tubos y Coraza PDFDocument2 pagesTubos y Coraza PDFsamara navasNo ratings yet

- Case 3Document1 pageCase 3nirajkulkarni09No ratings yet

- Tema SheetDocument1 pageTema SheetMayank AgrawalNo ratings yet

- Case 5Document1 pageCase 5nirajkulkarni09No ratings yet

- Consub TemaDocument1 pageConsub TemaMAYANK AGRAWALNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA Sheetvaratharajan g rNo ratings yet

- Heat Exchanger Rev - 02Document1 pageHeat Exchanger Rev - 02TKT ConsultantNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10MAYANK AGRAWALNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- E-100 TEMA SheetDocument1 pageE-100 TEMA Sheetuse for school google drive storageNo ratings yet

- Case 4Document1 pageCase 4nirajkulkarni09No ratings yet

- Shell&Tube TEMAsheet 1Document1 pageShell&Tube TEMAsheet 1Rikiya FebriyanNo ratings yet

- E-200 TEMA SheetDocument1 pageE-200 TEMA Sheetuse for school google drive storageNo ratings yet

- E-313 DesignDocument1 pageE-313 DesignAamir SultanNo ratings yet

- Case 6Document1 pageCase 6nirajkulkarni09No ratings yet

- 1Document1 page1kkkprotNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Ginna RodriguezNo ratings yet

- E-101, Precalentador de PropanoDocument1 pageE-101, Precalentador de PropanoIsaac RodriguezNo ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- ShellTubeHE Hot PT Konigs E-202 ColdDocument1 pageShellTubeHE Hot PT Konigs E-202 Coldeka prasetiaNo ratings yet

- File: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Document14 pagesFile: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Camila Florencia ScarlatoNo ratings yet

- TEMA Sheed L-R ExchangerDocument1 pageTEMA Sheed L-R ExchangerAlejandra BuenoNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetDocument2 pagesAspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetLandaNo ratings yet

- Output PDFDocument1 pageOutput PDFAlex AgualemaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMAlex AgualemaNo ratings yet

- 1 PDFDocument1 page1 PDFWael BadriNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetWael BadriNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Luis NewballNo ratings yet

- TEMA Sheet CorregidoDocument1 pageTEMA Sheet Corregidosaragineth.saNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- L-R Intercambiador Coraza y Tubos PDFDocument1 pageL-R Intercambiador Coraza y Tubos PDFAlejandro OsorioNo ratings yet

- CCT ShellAndTubeReportDocument2 pagesCCT ShellAndTubeReportLuthfi LegooNo ratings yet

- He 1061Document12 pagesHe 1061vijay88666No ratings yet

- Intercambiador de Calor: Heat Exchanger Data SheetDocument6 pagesIntercambiador de Calor: Heat Exchanger Data SheetBRENDA VIVIANA ARANDA JURADONo ratings yet

- Output - ITEM NO. 113486 - 24 Inch at 10000 KGHRDocument1 pageOutput - ITEM NO. 113486 - 24 Inch at 10000 KGHRyadav yadavNo ratings yet

- Ea 101Document2 pagesEa 101Najmul SaqibNo ratings yet

- Heat Exchanger Sizing E-7010 #1Document2 pagesHeat Exchanger Sizing E-7010 #1Luis Enrique Leyva OvalleNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetWael BadriNo ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- Services EngineerDocument2 pagesServices EngineerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Reliability Engineer VacancyDocument3 pagesReliability Engineer VacancyBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- MSF780 Composite Crack Growth - Right One7Dec20 - JABDocument11 pagesMSF780 Composite Crack Growth - Right One7Dec20 - JABBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- BoilermakerDocument1 pageBoilermakerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Instrumentation MechanicianDocument1 pageInstrumentation MechanicianBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Quick Checklist For Reports and PresentationsDocument1 pageQuick Checklist For Reports and PresentationsBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- MSF Report 20Document2 pagesMSF Report 20Besuidenhout Engineering Solutions and ConsultingNo ratings yet

- Checklist For DivorcesDocument3 pagesChecklist For DivorcesBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Hajali 2006Document18 pagesHajali 2006Besuidenhout Engineering Solutions and ConsultingNo ratings yet

- Npy 416 Study Guide - zp179845Document8 pagesNpy 416 Study Guide - zp179845Besuidenhout Engineering Solutions and ConsultingNo ratings yet

- Dowling Chapter 9 Test 1 MemoDocument6 pagesDowling Chapter 9 Test 1 MemoBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Department of Materials Science and Metallurgical EngineeringDocument10 pagesDepartment of Materials Science and Metallurgical EngineeringBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Subject Conversion - Mechanical EngineeringDocument1 pageSubject Conversion - Mechanical EngineeringBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- MSV 780 Exam 2020 MemoDocument24 pagesMSV 780 Exam 2020 MemoBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Vertical Separator Design Theory & Calculation SheetDocument8 pagesVertical Separator Design Theory & Calculation SheetBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Rotating Machinery AlignmentDocument61 pagesRotating Machinery AlignmentBesuidenhout Engineering Solutions and Consulting100% (1)

- AFRIMATDocument1 pageAFRIMATBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Interns Industrial-EngineeringDocument1 pageInterns Industrial-EngineeringBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Reliability EngineerDocument1 pageReliability EngineerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- PyrovatexDocument12 pagesPyrovatexahsan888No ratings yet

- Casting Defects - Dr. Manjula NanayakkaraDocument22 pagesCasting Defects - Dr. Manjula NanayakkaraDilupa HerathNo ratings yet

- Competence NoDocument5 pagesCompetence NoAjay SinghNo ratings yet

- Sika Resiplot - EGDocument4 pagesSika Resiplot - EGthe pilotNo ratings yet

- Steel InspectionDocument131 pagesSteel InspectionJanatan ChoiNo ratings yet

- Material Selection in Oil and Gas 1684649857Document15 pagesMaterial Selection in Oil and Gas 1684649857Sh MNNo ratings yet

- ECG Interpretation Made Incredibly Easy! (5th Edition)Document29 pagesECG Interpretation Made Incredibly Easy! (5th Edition)Freisan Chen0% (1)

- Construction Project Tasks Status ReportDocument2 pagesConstruction Project Tasks Status ReportAljay Joalson Castillo AlcidNo ratings yet

- Comparison of Batch and Continuous Processes Sergio Pissavini RSC Symposium 2011Document31 pagesComparison of Batch and Continuous Processes Sergio Pissavini RSC Symposium 2011Amro Yulianti SiregarNo ratings yet

- Chapter 11 Prevention, Mitigation, & Monitoring Measures 4 PipelinesDocument17 pagesChapter 11 Prevention, Mitigation, & Monitoring Measures 4 PipelinesMAT-LIONNo ratings yet

- Environmental Test Chamber QuestionnaireDocument4 pagesEnvironmental Test Chamber QuestionnaireTong YeNo ratings yet

- 201208081Document1 page201208081Yng TangNo ratings yet

- Corrosion Tests and StandardsDocument200 pagesCorrosion Tests and Standards이선엽100% (1)

- Method Statement For Site Handling of Concrete Made With GGBSDocument2 pagesMethod Statement For Site Handling of Concrete Made With GGBSabobeedoNo ratings yet

- Physical and Chemical Properties of MatterDocument1 pagePhysical and Chemical Properties of Matterriza amoresNo ratings yet

- Cooling Water TreatmentDocument115 pagesCooling Water TreatmentMuhammad Abdullah100% (1)

- Insulation SpecificationDocument1 pageInsulation SpecificationKittisak SungsanaNo ratings yet

- Baldor NEMA ChartDocument1 pageBaldor NEMA ChartHernan Patarroyo100% (1)

- 411 Ses41 Tillmann 040 FINAL v3Document8 pages411 Ses41 Tillmann 040 FINAL v3Ertugrul CelikNo ratings yet

- E Book - Complete Guide of Polycarbonate Fabrication - ExceliteDocument49 pagesE Book - Complete Guide of Polycarbonate Fabrication - ExcelitecpcdbrNo ratings yet

- Flowable Fill: Versatile Low Strength MixDocument2 pagesFlowable Fill: Versatile Low Strength MixSajjad AnwarNo ratings yet

- Alkali and Alkaline Earth MetalsDocument23 pagesAlkali and Alkaline Earth MetalsInayah Tria PutriNo ratings yet

- Model PMGSY Road Datas 2013-14-SSRDocument91 pagesModel PMGSY Road Datas 2013-14-SSRChManikumarNo ratings yet

- Determine The Maximum Dry DensityDocument4 pagesDetermine The Maximum Dry Densityધર્મેશ મિસ્ત્રીNo ratings yet

- Hydrogen Sulfide (0.0001% - 0.05 %) in Nitrogen: Safety Data Sheet 50248Document9 pagesHydrogen Sulfide (0.0001% - 0.05 %) in Nitrogen: Safety Data Sheet 50248pcatruongNo ratings yet

- Integrated Systems Management: Improving Systems Performance To World Class StatusDocument42 pagesIntegrated Systems Management: Improving Systems Performance To World Class StatusDr. Sandeep KautishNo ratings yet

- TMG PC Strands, Wire & BarDocument10 pagesTMG PC Strands, Wire & BarHenrique Braglia PachecoNo ratings yet

- Masterseal 550Document4 pagesMasterseal 550Haresh BhavnaniNo ratings yet

- Japanese Fridge Manual 2Document8 pagesJapanese Fridge Manual 2scraboNo ratings yet