Professional Documents

Culture Documents

Safe Procedure For Hand Drill

Safe Procedure For Hand Drill

Uploaded by

fatyn farhana0 ratings0% found this document useful (0 votes)

20 views3 pagesThis document provides safety procedures for operating a power hand drill. It outlines potential hazards like moving parts, heat, dust and projectiles. Personal protective equipment like gloves, face masks and protective clothing must be worn. Safe work procedures include checking the drill bit is secure, workpiece is clamped, and drill speed is set before operating. The drill must be held firmly with both hands away from moving parts and ventilation slots. Proper procedures are outlined for starting, using and stopping the drill to avoid overheating and ensure any waste is removed and tools are stored safely after use.

Original Description:

Original Title

Safe Procedure for Hand Drill

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides safety procedures for operating a power hand drill. It outlines potential hazards like moving parts, heat, dust and projectiles. Personal protective equipment like gloves, face masks and protective clothing must be worn. Safe work procedures include checking the drill bit is secure, workpiece is clamped, and drill speed is set before operating. The drill must be held firmly with both hands away from moving parts and ventilation slots. Proper procedures are outlined for starting, using and stopping the drill to avoid overheating and ensure any waste is removed and tools are stored safely after use.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

20 views3 pagesSafe Procedure For Hand Drill

Safe Procedure For Hand Drill

Uploaded by

fatyn farhanaThis document provides safety procedures for operating a power hand drill. It outlines potential hazards like moving parts, heat, dust and projectiles. Personal protective equipment like gloves, face masks and protective clothing must be worn. Safe work procedures include checking the drill bit is secure, workpiece is clamped, and drill speed is set before operating. The drill must be held firmly with both hands away from moving parts and ventilation slots. Proper procedures are outlined for starting, using and stopping the drill to avoid overheating and ensure any waste is removed and tools are stored safely after use.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 3

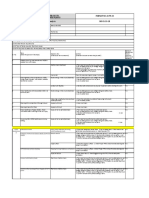

SAFE OPERATING PROCEDURE FOR POWER HAND DRILL

1.0 Purpose

To define the procedure to operate power hand drill

2.0 Scope

This is applicable to all workshop machineries

3.0 Reference

-NIL-

4.0 Safety Precautions

Responsibility Activities Flow Descriptions

Workshop (4.1) - Exposed moving parts and electrical hazard with the

Operator Potential hazards and potential to cause harm through entanglement, impact

risks and cutting, exposure to heat, dust, projectiles and

sharp objects.

(4.2) - Where applicable, PPE must be worn at all times

Personal Protective

Equipment (PPE)

Gloves Face Masks Welding

Eye

Mask

Protection

Appropriate Hearing Protective

Footwear Protection Clothing

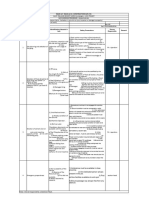

5.0 Safe Work Procedure

Responsibility Activities Flow Descriptions

Workshop (5.1) a) Task (e.g. Drawings, instructions, specifications etc.) is

Operator Pre-Operation Safety clearly understood.

Check b) Ensure drill bit is installed tightly into chuck and chuck

key has been removed (if applicable).

c) Work piece is secured.

d) Correct drill speed has been set.

e) Correct drill bit has been selected for material being

drilled.

f) Identify ON/OFF switch and emergency stop button (if

applicable).

g) Ensure power tool has a suitable safe work area.

h) Examine the power lead and plug for obvious damage.

i) Do not use dull or damaged drill bits.

(5.2) j) Do not connect to power source until all adjustments

Operational Safety have been made.

Check k) Check that the power lead does not create a trip hazard

and that it is well clear of the workpiece.

l) Examine the material to be drilled for splits, loose knots

& nails, etc.

m) Select the correct sized drill bit. Tighten securely in the

chuck.

n) Ensure the workpiece is secure & well supported in a

convenient position for drilling.

o) The power drill must be held firmly with both hands to

control operational accuracy and the rotational torque.

p) Keep hands and fingers well clear of moving parts.

q) Avoid blocking & covering the motor ventilation slots

with your hands.

r) Allow the drill to reach operating speed, then apply

load gradually. Do not apply excessive force.

s) Back the drill bit out to clear away all waste.

t) Avoid prolonged use as this could overheat the motor.

u) Turn off after backing out the drill bit. Do not place the

drill down until the bit has stopped rotating.

v) Exercise caution when removing hot drill bit.

(5.3) a) Switch off drill before removing waste material from

Post-Operation the drill table.

b) Ensure good housekeeping practices are in place to

minimise dust build-up.

c) Return clean drill bit to drill rack and clamps to their

storage area.

d) Leave the work area in a safe, clean, & tidy condition

You might also like

- Product Design SpecificationDocument7 pagesProduct Design Specificationspellbinder50No ratings yet

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (5)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocument5 pagesJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANNo ratings yet

- Kubota V Manual U20!3!25 31Document508 pagesKubota V Manual U20!3!25 31brunosamaeian82% (11)

- Job Safety Analysis Lifting and RiggingDocument17 pagesJob Safety Analysis Lifting and RiggingSam Seed100% (1)

- Lin C.-F. Modern Navigation, Guidance, and Control Processing 1991Document696 pagesLin C.-F. Modern Navigation, Guidance, and Control Processing 1991Neetha Prafa100% (2)

- A Developer's Guide To Protecting Memory: Detect and Eliminate Damaging Memory Leaks With ABAP Memory InspectorDocument6 pagesA Developer's Guide To Protecting Memory: Detect and Eliminate Damaging Memory Leaks With ABAP Memory InspectortaletsaraNo ratings yet

- Design Modeling of Mini Belt Grinder: PROJECT PROPOSAL Template For EGT 417Document4 pagesDesign Modeling of Mini Belt Grinder: PROJECT PROPOSAL Template For EGT 417jamsheed sajid100% (1)

- JSA FabricationDocument3 pagesJSA FabricationSwaroop Cherry100% (1)

- Foundry Sop PDFDocument112 pagesFoundry Sop PDFBorislav VulićNo ratings yet

- (Edit) SWP Bolt TorquingDocument4 pages(Edit) SWP Bolt Torquingainun mardiahNo ratings yet

- Jsa Cable LayingDocument2 pagesJsa Cable LayingAbcd efgh100% (1)

- Jsa For Welding, Grinding, Gas CuttingDocument2 pagesJsa For Welding, Grinding, Gas Cuttingwahyu nugroho67% (3)

- PIPELINE - IF KitsDocument10 pagesPIPELINE - IF KitscamgovaNo ratings yet

- JSA FOR Using The Hand and Power Tools - 2Document2 pagesJSA FOR Using The Hand and Power Tools - 2soubhagya100% (2)

- JSA FOR WELDING, GRINDING, GAS CUTTINGDocument2 pagesJSA FOR WELDING, GRINDING, GAS CUTTINGm.rehanhseNo ratings yet

- JSA 004 Sand Blasting of Exposed RebarDocument1 pageJSA 004 Sand Blasting of Exposed RebarRyanNo ratings yet

- JSA - Sheet FixingDocument5 pagesJSA - Sheet FixingSwaroop CherryNo ratings yet

- Safety Inspection ChecklistDocument3 pagesSafety Inspection Checklistgrc.lehaNo ratings yet

- DLPS JsaDocument23 pagesDLPS JsaDLPS HSENo ratings yet

- Ebpb Method StatementDocument7 pagesEbpb Method StatementMian RubbaniNo ratings yet

- jsa for Arc WeldingDocument3 pagesjsa for Arc Weldingm.rehanhseNo ratings yet

- Arc WeldingDocument2 pagesArc WeldingYoga PradiptaNo ratings yet

- 5.19.3 Job Safety Practices Rev 02-BlankDocument4 pages5.19.3 Job Safety Practices Rev 02-BlankShafie ZubierNo ratings yet

- 71 Arc Welding - Job Procedure - 2Document3 pages71 Arc Welding - Job Procedure - 2Angga EHSKOINNo ratings yet

- New G 2300 Manual 03Document12 pagesNew G 2300 Manual 03Jasmine VaaltynNo ratings yet

- JHA Welding Arc and Cutting (Hotwork)Document2 pagesJHA Welding Arc and Cutting (Hotwork)Popo EaldamaNo ratings yet

- JSA FOR MaxseamDocument20 pagesJSA FOR Maxseamwahyu nugrohoNo ratings yet

- JSA FOR Concerate PlacementDocument1 pageJSA FOR Concerate Placementwahyu nugrohoNo ratings yet

- Safe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety AnalysisDocument2 pagesSafe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety Analysisrazed86No ratings yet

- M013 JSA For Field Coating For Condensate PipelineDocument5 pagesM013 JSA For Field Coating For Condensate PipelineMarvin BerrensteinNo ratings yet

- 71 Arc Welding - JOB PROCEDUREDocument3 pages71 Arc Welding - JOB PROCEDUREAdilMunirNo ratings yet

- Siue Steel Bridge Job Safety AnalysisDocument5 pagesSiue Steel Bridge Job Safety AnalysisArif M PutraNo ratings yet

- JSA - For Trays ErectionDocument1 pageJSA - For Trays ErectionAvinash Rai0% (1)

- Step Description Controls: HazardDocument3 pagesStep Description Controls: HazardMainak KhanraNo ratings yet

- WHR AQC-2 DS (7-10) Column Lift PlanDocument5 pagesWHR AQC-2 DS (7-10) Column Lift Planshahhussain1031No ratings yet

- SOP Working at HeightsDocument5 pagesSOP Working at HeightsPhanankosi DubeNo ratings yet

- JSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadDocument1 pageJSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadRyanNo ratings yet

- Safety Audit During Tunnel ConstructionDocument13 pagesSafety Audit During Tunnel ConstructionIJRASETPublications0% (1)

- Air Winches & Man Riding AwarenesDocument1 pageAir Winches & Man Riding AwarenesMohammed Rashid Al-kalbaniNo ratings yet

- Syllabus Industry Tools, Tower Climbing and Rescue ENER-1020Document11 pagesSyllabus Industry Tools, Tower Climbing and Rescue ENER-1020RasLDKNo ratings yet

- 54 Ffeb 94Document78 pages54 Ffeb 94rafeekhoneyNo ratings yet

- Arcwelding Job (R)Document4 pagesArcwelding Job (R)Sujay Das SonuNo ratings yet

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman NugrahaNo ratings yet

- PCW Pipe Installation JhaDocument2 pagesPCW Pipe Installation Jhafatimah100% (1)

- A-1.JSA-Service Panel & U.P.SDocument1 pageA-1.JSA-Service Panel & U.P.SVivek SinghNo ratings yet

- Bag House ChimmenyDocument2 pagesBag House Chimmenyshahhussain1031No ratings yet

- Triton Dust Bag 1Document27 pagesTriton Dust Bag 1j_abendstern4688No ratings yet

- (Edit) SWP Bolt TensioningDocument4 pages(Edit) SWP Bolt Tensioningainun mardiahNo ratings yet

- Safe Work Procedure in Cold SawDocument1 pageSafe Work Procedure in Cold SawCyril AngkiNo ratings yet

- PIPELINE - Reach System Pin Brazin 2Document8 pagesPIPELINE - Reach System Pin Brazin 2camgovaNo ratings yet

- Woodworking Band Saw - FMDocument2 pagesWoodworking Band Saw - FMumar KhitabNo ratings yet

- Installation ManualDocument5 pagesInstallation Manualbad ProNo ratings yet

- Take Home ExaminationDocument9 pagesTake Home ExaminationEmmanuel SanthanasamyNo ratings yet

- JSA Install Automatic Parking GateDocument6 pagesJSA Install Automatic Parking GateMarhendraNo ratings yet

- KRESS MISSION KR172EKR173EKR174EOwnersmanual-20220902Document152 pagesKRESS MISSION KR172EKR173EKR174EOwnersmanual-20220902dakar3No ratings yet

- Bruc 1 081 001Document6 pagesBruc 1 081 001Adel AhmedNo ratings yet

- Manual: Micromot 50/EDocument10 pagesManual: Micromot 50/Eomega776No ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisDeshbandhu Aman PandeyNo ratings yet

- Jsa Pulsation Dampener Maintenance and N2 Fill UpDocument2 pagesJsa Pulsation Dampener Maintenance and N2 Fill UpAdel AlKhedawyNo ratings yet

- Instruments, Measurement Principles and Communication Technologies for Downhole Drilling EnvironmentsFrom EverandInstruments, Measurement Principles and Communication Technologies for Downhole Drilling EnvironmentsNo ratings yet

- Vector General Presentation 0314Document8 pagesVector General Presentation 0314api-237465088No ratings yet

- Avionics Mag 2011-04Document38 pagesAvionics Mag 2011-04prkushNo ratings yet

- DFCC Report Jan-18Document61 pagesDFCC Report Jan-18shahpinkalNo ratings yet

- Salesforce Creating On Demand AppsDocument380 pagesSalesforce Creating On Demand AppsedelweissNo ratings yet

- Printers' Marketplace 10/20/2009Document32 pagesPrinters' Marketplace 10/20/2009Christopher AllenNo ratings yet

- Original SRSDocument5 pagesOriginal SRSrenzpNo ratings yet

- Final RERA Immensa PDFDocument100 pagesFinal RERA Immensa PDFRani JacobNo ratings yet

- A Specification Is An Explicit Set of Requirements To Be Satisfied by A MaterialDocument12 pagesA Specification Is An Explicit Set of Requirements To Be Satisfied by A MaterialAnb BajwaNo ratings yet

- The Strategic Shift at L&TDocument8 pagesThe Strategic Shift at L&TARUSHINo ratings yet

- ABC For Motors by SiemensDocument168 pagesABC For Motors by Siemensbrome2014No ratings yet

- Prezentare IPC-Master Trainer Augustin StanDocument40 pagesPrezentare IPC-Master Trainer Augustin StanJoao BrandtNo ratings yet

- AWS IoT Lens PDFDocument67 pagesAWS IoT Lens PDFilanNo ratings yet

- Batteries Company, Oil and Gas Company, Manufacturing Company DUBAIDocument28 pagesBatteries Company, Oil and Gas Company, Manufacturing Company DUBAIPacific HRNo ratings yet

- 4388 17565 1 PBpharmDocument10 pages4388 17565 1 PBpharmVinceNo ratings yet

- Enterprise Application Integration Technologies (EAI)Document16 pagesEnterprise Application Integration Technologies (EAI)Peter R. Egli100% (1)

- Stitchmaster ST 100Document18 pagesStitchmaster ST 100Ina MoroşanuNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- CAPM Galway Day 3Document84 pagesCAPM Galway Day 3Anna TrubetskayaNo ratings yet

- Monteferro Product e Service - 08 - 2017Document32 pagesMonteferro Product e Service - 08 - 2017ecrgvpNo ratings yet

- STEELS Planning Loading List of IN12K Container On 2023-10-25 For India INGCODocument58 pagesSTEELS Planning Loading List of IN12K Container On 2023-10-25 For India INGCOravindrapanwar197No ratings yet

- Accsys Group Annual Report 2017Document116 pagesAccsys Group Annual Report 2017sharkl123No ratings yet

- HG Series CatalogDocument22 pagesHG Series CatalogMetin Sinan çelikerNo ratings yet

- Engineering 20abbrevationDocument64 pagesEngineering 20abbrevationsetak100% (2)

- Automation Anywhere User Manual - Tethys SolutionsDocument205 pagesAutomation Anywhere User Manual - Tethys Solutionsnaresh kumar kolla0% (1)

- Evolution of ContainershipsDocument2 pagesEvolution of ContainershipsCarlos GomesNo ratings yet

- 2000 Thomas Flexible Disc Couplings CatalogDocument43 pages2000 Thomas Flexible Disc Couplings CatalogAnonymous 0CnvpxSNo ratings yet

- JAVADocument43 pagesJAVASagarraj WangdareNo ratings yet