Professional Documents

Culture Documents

Selective

Selective

Uploaded by

CC Ambassa DWS0 ratings0% found this document useful (0 votes)

7 views9 pagesgood

Original Title

selective

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentgood

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

7 views9 pagesSelective

Selective

Uploaded by

CC Ambassa DWSgood

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 9

MANUAL ON WATER SUPPLY

AND TREATMENT

THIRD EDITION - REVISED AND UPDATED

Prepared by

THE EXPERT COMMITTEE

Constituted by

THE GOVERNMENT OF INDIA

CENTRAL PUBLIC HEALTH

AND ENVIRONMENTAL ENGINEERING ORGANISATION

MINISTRY OF URBAN DEVELOPMENT, NEW DELHI

MAY, 1999

CHAPTER 10

DISTRIBUTION SYSTEM

10.1 GENERAL

"The puspose of the distsibution system is to convey wholesome water to the consumer at

adequate residual pressure in sufficient quantity at convenient points. Water distribution

usually accounts for 40 to 70% of the capital cost of the water supply project. As such,

proper design and layout of the system is of great importance. Metering is recommended for

all cities as indicated in section 17.4.2.

10.2 BASIC REQUIREMENTS

‘The requirements for the distribution system may be classified as functional and hycteautc.

‘The geometrical configuration of pipes, ceservoirs and boosters, selection and proper

location of valves, specials, etc., for efficient operation and maintenance and overall

economy in cost constitute some of the functional aspects. Adequate residual pressure at the

maximum demand depends upon the hydeaulic characteristics of the system.

10.2.1 CONTINUOUS VERSUS INTERMITTENT SYSTEM OF SUPPLY

In the continuous system of supply, water is made available to consumer all the

‘twenty-four hours a day, whereas in the intermittent system, the consumer gets supply only

for certain fixed hours (a few hours in the morning and a few hours in the evening).

‘The intermittent system suffers from several disadvantages. ‘The distribution system is

usually designed as a continuous system but ofien operated as an intermittent one. There is

always a constant doubt about the supply in the minds of the consumers. This leads to

limited use of water supplied, which does not promote personal hygiene. ‘The water is stored

during non-supply hours in all sorts of vessels which might contaminate it and once the

supply is resumed, this water is wasted and feesh supply stored. During non-supply hours,

polluted water might each the water mains through leaky joints and thus could pollute the

protected water. There will be difficulty ia finding sufficient water for fire fighting purposes

also during these hours. The taps are always kept open in such system leading to wastage

when supply is resumed. This system docs not promote hygiene and hence, wherever

possible, intermittent supply should be discouraged.

10.2.2 SYSTEM PATTERN

For efficient and ecuitable distribution of water, a grid pattern, where the different mains

are interconnected keeping dead ends to a minimum, is tecommended, ‘The system facilitates

359

any one point being fed at least from two different directions. For small water supplies, the

tree or branch system with smaller mains branching off from a single trunk main may be

adequate

10.23 ZONING

‘Zoning in the distribution system ensures equalization of supply of water throughout the

area. The zoning depends upon (a) density of population (b) type of locality () topography

and (d) facility for isolating for assessment of waste and leak detection. If there is an average

dlevation difference of 15 to 25m between zones, then each zone should be served by a

separate system. ‘The neighboring zones may be interconnected to provide emergency

supplies. The valves between the zones, however, should normally be kept closed and not

partially opened. The layout should be such that the difference in pressure between different

areas of the same zone or same system does not exceed 3 to Sm.

10.2.4 SysTEM OF SUPPLY

Jn selecting a source of water supply for a inwn, the mode of conveyance of water from

the source t© the town is a factor for consideration, Water could be conveyed by geavity

alone, of by pumping, ox by gravity-cum-pumping Ay of these three modes could be

selected based mainly on the clevation of the source of supply with respect to the town

Bfforis should be made to minimize the cost of transmission by considering the various

alternatives and their suitability for the given situation

10.2.5. LOCATION OF SERVICE RESERVOIRS

‘The location of ser

ice reservoirs is of importance for regulation of pressures i the

distribution system as well as for coping, up with uctuating demands. Ina distribution

system fed by a single reservoir, the ideal location és a central place in the distribution system,

which effects maximum economy on pipe sizes. Where the system is fed

as well as through reservoirs, the location

direct pumping

the seservoits may be at the tail end of the

system. If topography permits, ground level reservoirs may be located taking full advantage

Of differences in clevation, Liven when the system is fed by a central reservoir, it may be

Ucsirable to have tail end reservoirs for the more distant districts. These tail end reservoirs

may be fed by direct supply during lean hours or booster facilities may be provided,

10.3 GENERAL DESIGN GUIDE LINES

10.3.1 PEAK FACTOR

The per capita rate of water supply indicates only the average consumption of water per

day per person over a period of one yeas: In the design of water supply distribution system, it

is to be tecognized thar consumption varies with the season, month, day and hous. As far as

the design of distribution system is concemed, itis the hourly variation in consumption that

matters, ‘The fluctuation in consumption is accounted for, by considering the peak rate of

consumption (which is equal to average rate multiplied by a peak factor) as rare of flow in the

design of distribution system,

300

The variation in the demand will be more pronounced in the case of smaller population

and will gradually even out with the increase in population. This is so because in a large

population different habits and customs of several groups tend to minimize the variation in

the demand pattern

The following peak factors ate recommended for various population figures

For population less than $0,000 3.0

Fora population range of 50,000 to 2,00,000 25

For population above 2,00, 20

For Small Water Supply Schemes

(Where supply is effected through

standposts for only 6 hours) 30

10.3.2 Fire DEMAND.

Fiee demand can be assessed as per the norms given in section 22.8.3. Reference ean also

bbe made to 1S 9668-1980

10.3.3 RESIDUAL PRESSURE

Distribution system should be designed for the following minimum cesidual pressures at

ferrule points:

Single storey building => 7m

Two storey building => 12m

‘Three storey building => 17m

Distribution system should not ordinarily be designed for residual pressures exceeding, 22

meters. Multistoreyed buildings needing higher pressuse should be provided with boosters.

10.3.4 MINIMUM PIPE SIZES

Minimum Pipe sizes of 100 mim for towns having population upto 50,000 and 150) mm

for those above 50,000 are recommended. For dead ends, less than ‘100 mm can be

considered. If it i a ged, less than 100 mm can be used in siniations where no. further

‘expansion i contemplated,

10.3.5 Layour

‘The distribution layout should be such as ro facilitate hydtnulie isolation of sections,

metering for assessment and control of leakage and wastage

10.3.6 ELEVATION OF RESERVOIR

The elevation of the service reservoir should be such as to maintain the minimum

residual pressure in the distribution system consistent with its cost effectiveness. ‘The

hydraulic gradient in the pipe should normally be between 1 and 4 per thousand at peak flow.

x61

A suitable combination of pipe sizes and staging height has to be determined for

optimization of the system. The staging height of service reservoits is normally kept as 15.

20m.

10.3.7 BoostiNG

For distant localities, boosters may be provided instead of increasing the size of mains or

height of the reservoir unduly for maintaining the required pressure.

10.3.8 LOCATION OF MAINS

For roads wider than 25 metets, the distribution pipes should be provided on both sides

of the road, by sunning rider mains suitably linked with trunk mains

103.9 VaLves

(@) Sluice Valves

Sluice valves shall be located on at least three sides of every cross-junction and at every

Kilometre on long mains. The size of the sluice valve shall be the same as the size of the main

up to 300 mm diameter and at least two-thieds the size of main for larger diameters.

() Air Valves

“These have been discussed in 6.16.3.

(0) Scour or Blow Off Valves

“The scour or blow off valves have been discussed in 6.16.2

(a) Flow Dividing Vaives

“These specially devised and constructed valves ate used in distribution and other mains at

the branch point to ensure that the assigned flow in a disteibution main is always maintained.

These are based on the principle that the diaphragm or the other arcangement in valves

opens proportionally depending upon the upstream pressure allowing the regulation of flow,

irrespective of the pressure conditions obtained in the distribution main.

(e) Maximuwn Demand Controtiers

“The maximum demand controller permits all flows upto a preset value and automatically

assumes control when the flow just exceeds this predetermined rate, thus preventing excess

withelrawals, ‘This form of controller finds considerable use both in municipal and industrial

installations, where two or more users taking water from a common source, ate (0 be

prevented from consuming more than a set quantity

10.4 SERVICE RESERVOIRS

10.4.4 FUNCTION

The service reservoirs provide » suitable reserve of treated water with minimum

interruptions of supply due to failure of mains, pumps etc. ‘They also enable meeting, the

widely Auctuating demands when the supply is by intermittent pumping. ‘They are also

helpful in reducing the size of the mains which would otheewise be necessary to meet the

362

peak rates of demand. They can serve as an alternative to partial duplication of an existing

feeder main as the load on the main increases.

10.4.2 Caractry

“The capacity of the service reservoir to be provided depends upon the better economic

alternatives amongst various options. system supplied by pumps with 100% standby will

require less storage capacity than that with less standby provision. Similarly a system divided

into interconnected zones will requite less storage capacity for all the zones except for the

ones at higher clevations

However, the minimum service or balancing capacity depends on the hours and rate of

pumping in a day, the probable variation of demand or consumption over a day, the hours of

supply can be calculated from a mass diagram or by a demand and pumping budget. The

variation of demand in @ day for a town which depends on the supply hours may have to be

assumed or known fom similar towns o¢ determined based on household survey.

Typical example on estimation of storage eapacity i given in Appendix 10h

10.4.3 STRUCTURE

The ground level reservoir is generally preferred as storage reservoir which is circular or

square or rectangular in shape. If it is circular, itis usually constructed of RCC and in the

‘case of other shapes it is constructed either of RCC or masoney. ‘The elevated reservoirs are

used principally as distributing reservoiss and can have shapes like ciecular, square,

rectangular and conical or may be of Intze type. ‘They are generally made of REC or

prestressed concrete. Small capacity tanks can be fabsicated with steel or PVC or HDPE,

irculae shapes are generally preferable as the length of the wall for a given capacity is a

minimum and further the wall itself is self-supporting and does not require counteefort.

Reseevoirs of one compariment are generally square and those of two or three compartments

may be rectangular with length equal to one and half tines the breadth. ‘The economical

water depth for reservoirs with flat bottom upto 1000? capacity is between 3 and 5.5m, The

service reservoirs should be covered to avoid contamination and prevent algal growths.

Suitable provision should be made for manholes, mosquito-proof ventilation, access laddees,

scour and overflow arrangements, water level inclicator, and if found necessary, lightning

arresters,

10.4.4 INLETS AND OUTLETS

‘The draw pipe should be placed 15 centimenters above the floor and is usually provided

with a steainer of perforated cast iron. ‘The reservoirs filled by geavity ase provided with ball

valves of the equilibrium or other type which close when water reaches full tank level. The

overflow and scour main should be of sufficient size to take away by gravity the maximum

flow that can be delivered through the reservoir. ‘The outlet of the scour and overflow mains

should be protected against the entry of vermin and from other sources of contamination.

The inlet o outlet of keservoie should be such that no water stagnates. When there are two

for more compartments, each compartment should have separate inlet and outlet

arrangements, while the scour and overflow from each compartment may be connected t0 4

363

202 UAREoT—28m

single line. To avoid waste of enesgy, it is advantageous to form the opening of the outlet

with a configuration identical to the surface. This could be achieved by providing a bell

mouth at the opening of the cuter pipe. ‘The details of the bell month for different sizes of

openings are given in Appendix 10.2

10.5 BALANCING RESERVOIRS

‘The tank is said to be "oating on the line” when connected by a single pipe to the source

and the distribution system. When the rate of supply exceeds the demand, water flows into

the tank, When demand exceeds supply, water flows through the same pipe from the tank.

“The relation between rate of supply, rate of demand and tank capacity is based on a study of

the service requited as in case of service reservoirs

When the balancing tank floating on the line is designed for the full service storage based

on a study of the hydrogeaph of demand, its location and altitude is governed by the same

conditions as are applicable to the service reservoir, Whese the distribution system is

designed for direct pumping into the system, it is advantageous to provide a balancing, tank

at the end of the system with 2 nominal capacity (I o¢ 2 hours) 10 provide pressure echef and

improve the tail end distribution. The balancing reservoie has the advantage of minimum of

pipe work and operational maintenance.

10.6 HYDRAULIC NETWORK ANALYSIS.

10.6.1 PRINCIPLES

Hydraulic analysis of the pipe network is the building block for the design of water

distribution system and essentially involves determination of flow conditions associated with

specified pipe sizes, the location and size of reseevoir and capacity of pumps.

Inrespective of the methods used, the hydraulic analysis of pipe nerwork is based on

fundamental laws, viz, EQ = U at a junction, ZH = 0 around a loop or a circuit and

h = kQS, which is the exponentiat friction flow equation relating the head loss to the flow in

Pipe.

The problem of hydiaulic network balancing is one of finding either the disteibution of

flows in the pipes given a set of nodal inflows and outflows, or the distribution of pipe head

losses given a set of some nodal water elevations, subject to Kischot's laws. From the lasout,

a proper skeletonizing of the network is done and pipe lengths are determined, On the basis.

of pipe sizes chosen by the engineer from experience the network balancing reduces 10

problem of solving a set of non-linear simultaneous equations in the pipe flows and pipe

head losses. Bither of the two methods, viz;

(@ Balancing head losses around loops by costecting assumed flows, of

(©) Balancing flows at junctions by correcting assumed head losses in pipes,

is applicable, Notable among the several methods applicable are those developed by ()

Hardy Cross, (i the electrical analogy method developed by Meltroy Gi) the graph theory

approach and more recently, (iv) iterative procedures such as Newton Raphson method

using digital computers. The second method belongs to analog category and the rest belong

364

to digital category. These methods have virtually replaced other earlier ones largely on

account of theie accuracy and efficiency. ‘The Hardy Cross method is a relaxation technique,

‘hich, through successive iterations, applies a series of linearly approximated correction 10

cither assumed flows of head losses of all che pipes of the network.

10.6.2 METHODS OF BALANCING

(@) Hardy Cross Method

(@) Balancing Heads

In this method, from the knowledge of system inflows anu outflows, the flows in all the

pipes of the network are distributed so as fo meet continuity constraints at all the nodes.

When inflows and outflows are explicitly known, chis will involve assigning as many Haws as

there are primacy loops in the system, The requirement that the sum of head losses around

all primary tops should equal zero gives rise to a system of as many equations, Solution of

the exactly determined system of non hnear equations is effected by a systematic relaxation

in the Hardy-Cross method. In the ! fardy Cross method of balancing heads, which is a mal

aad error process, the correction factor for assumed flows (necessary formulae acc made

algebraically consistent by abitrarily assigning positive signs to clockwise flows and

associated head losses and negative sas 10 anti-clockwise Mows and associated head losses)

AQ in a circuit is calculated by the Formula

ag = 2H

"ET

Where Q = Quantity of flow

IT Head loss

8 = Constant, 1.85 for Hazen Willarn’s formula

"The assumed flows are corrected acconlingly and the procedore repeated until the

requited degree of precision is seached, This is essentially a repetitive procedure. ‘The

seqwential steps are presented below:

(@ Assume suitable values of Now (2 in each pipeline such that the Flows coming into

each junetion of the loop. are equal 10 flows leaving the junction,

(8) Assign positive sign to all clockwise flows and negative sign (© all anti-clockwise

Dow,

ii) Compute the head Joss 11 in each pipe by use of the friction formula with the help

of chart or monogram giving the same sigh as for the flows,

(iv) Compute ZH (Ge. algebraic sum of the head losses) around each loop and if this is

nieadly equal to 2er0 in all loops (within allowable limits of ¢ 0.15 rn), the assumed

flows are cortect,

(©) Otherwise, if EH is no equal to 0 for any lonp, compute the error in flow

365

La

ag=-0saeee

Xo

and the correction factor is of the opposite sign. Add the correction factor to the

assumed flows with due regard to the siga of flows.

(wi) Pipes operating in. more than one circuit draw corrections from each circuit.

However, the second correction is of the opposite sign as applied to the first circuit,

(vi) Repeat the cyele, till EH (round each loop) is nearly equal to zero within the

allowable limits. ‘Then the final values of flows are the actual values in the pipelines,

(iii) 1f during the correction process, the head difference in an element becomes zeto,

the pipe should be omitted from the particular balancing operation in which this

occurs.

A computer program for solution of the head balance problem could be written,

In setting up the program, the following guidelines will be helpful

@ Bach primary loop is first numbered, () serially starting from 1 (= 1,2 N)

Gi) The pipes in each loop ace then numbered, (4j) with the loop number first and pipe

number second, serially starting from (, 1) @=1,2,....N,)y

(ii) Flows in the clockwise direction in the pipe of any loop is considered positive, anti-

clockwise negative. This applies to correction AQ, also. ‘The sign of head loss Hy; is

the same as that of Q,, ‘The ratio H/Q or Q/H is thus always positive,

(is) Successive cortections to flows (AQ) are calculated ftom Equation

a0.)

Here a is the exponent of Q in the simplified pipe flow formula Hy; = K,Q'y. These

covtections are applied to Q, by the computer and the balancing operation repeated unt a

desired tolerance for either AQ, or | EH] is obtained, at which the program terminates.

Specification on this criterion is a nontsivia! problem reflecting the desired accuracy.

(8) Pipes common to nwo loops i and k receive flow corrections from both with duc

regard to signs. When the pipe is being considered in loop i, corrected Q.; = Qu

AQ,- AQ) whereas when being considered under loop k as pipe (&), corrected Quy

= (Qut AQ, - AQ).

In case of smaller networks, the calculations could be made manually as well

366

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

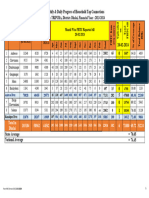

- 06-03-24 FHTC Progress ReportDocument1 page06-03-24 FHTC Progress ReportCC Ambassa DWSNo ratings yet

- 21-02-24 FHTC Progress ReportDocument1 page21-02-24 FHTC Progress ReportCC Ambassa DWSNo ratings yet

- 2021-22 FHTC Progress ReportDocument1 page2021-22 FHTC Progress ReportCC Ambassa DWSNo ratings yet

- 24-01-24 FHTC Progress ReportDocument1 page24-01-24 FHTC Progress ReportCC Ambassa DWSNo ratings yet

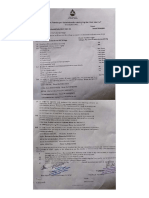

- Certi by DWS Sub DivisionDocument1 pageCerti by DWS Sub DivisionCC Ambassa DWSNo ratings yet

- FORMAT Certificate From GP VCDocument2 pagesFORMAT Certificate From GP VCCC Ambassa DWSNo ratings yet

- GP ResolnDocument1 pageGP ResolnCC Ambassa DWSNo ratings yet

- Certificate From GP VCDocument1 pageCertificate From GP VCCC Ambassa DWSNo ratings yet

- GP Resolution FROMDocument2 pagesGP Resolution FROMCC Ambassa DWSNo ratings yet