Professional Documents

Culture Documents

Ring(s), Piston - Engine Block - 2.7L DOHC Engine - Engine - Dodge Journey Service & Repair Manual - Dodgia

Ring(s), Piston - Engine Block - 2.7L DOHC Engine - Engine - Dodge Journey Service & Repair Manual - Dodgia

Uploaded by

CaballitofelizCopyright:

Available Formats

You might also like

- 061 - Engine Mechanical - 2.4L (LEA LUK) - Repair Instructions - On VehicleDocument334 pages061 - Engine Mechanical - 2.4L (LEA LUK) - Repair Instructions - On VehicleGedas Gvildys100% (1)

- Mutt 125eu501 (Mongrel Twin Shock) Technical Manual - V1 - 0321Document82 pagesMutt 125eu501 (Mongrel Twin Shock) Technical Manual - V1 - 0321Sergio Boni100% (1)

- Motor Ka24de Nissan Frontier 2.4l ManualDocument52 pagesMotor Ka24de Nissan Frontier 2.4l ManualIsaac ArispeNo ratings yet

- Rover 100 TUD5 Overhaul ManualDocument59 pagesRover 100 TUD5 Overhaul ManualAndy Moe63% (8)

- 2000 VW Passat Wiring DiagramsDocument55 pages2000 VW Passat Wiring Diagramsjuan carlos siqueiros ochoaNo ratings yet

- Duratec HE Assembly Manual PDFDocument266 pagesDuratec HE Assembly Manual PDFAlexis100% (2)

- Windstar 2000-2001 3.8 v6Document77 pagesWindstar 2000-2001 3.8 v6Juan RiveraNo ratings yet

- 2az Fse Engine Repair Manual (Rm1083e)Document120 pages2az Fse Engine Repair Manual (Rm1083e)Osvaldo Chimbas100% (2)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- 2RZ 3RZ SC PDFDocument21 pages2RZ 3RZ SC PDFUliAlejandroRodriguezCoriangaNo ratings yet

- Idoc - Pub Blood Bowl Star Player CardsDocument4 pagesIdoc - Pub Blood Bowl Star Player CardsharryposteurNo ratings yet

- Slide Cam Pulley: Instructions ManualDocument5 pagesSlide Cam Pulley: Instructions Manualhenrysaputra168No ratings yet

- General Information: To IndexDocument9 pagesGeneral Information: To IndexandriNo ratings yet

- 1DZ EngineDocument181 pages1DZ EngineGonçalo SousaNo ratings yet

- Vibration Damper - Check: Testing and AdjustingDocument2 pagesVibration Damper - Check: Testing and AdjustingbejoythomasNo ratings yet

- Drive Axle FrontDocument10 pagesDrive Axle FrontAnimemanuel MuñozNo ratings yet

- Adjustment of The Compression BrakeDocument2 pagesAdjustment of The Compression BrakeCarlos Juarez ChungaNo ratings yet

- 4 - 180 Rear Axle Brake Pin ReplacementDocument2 pages4 - 180 Rear Axle Brake Pin ReplacementDonbassNo ratings yet

- C4 4 CalibracionDocument5 pagesC4 4 CalibracionJaya Abadi100% (1)

- Dau Keo EST - Engine ISG (English)Document2,946 pagesDau Keo EST - Engine ISG (English)Vũ Công Minh100% (2)

- Bomba de Aceite MotorDocument8 pagesBomba de Aceite MotorFredy ReyesNo ratings yet

- Power Plant MountDocument12 pagesPower Plant MountMohamed AdelNo ratings yet

- 09Document2 pages09عمر المعاريNo ratings yet

- Sebf 8269 Привод 3408Document16 pagesSebf 8269 Привод 3408mohamed hamedNo ratings yet

- Hyundai Coupe 2.0Document11 pagesHyundai Coupe 2.0BrandonHiDudNo ratings yet

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- Gear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemDocument6 pagesGear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemJose nildo lobato Mendes MendesNo ratings yet

- AXSM0043-Drive Axles Single ReductionDocument34 pagesAXSM0043-Drive Axles Single Reductionwadalla100No ratings yet

- MC99759 8b110brakeDocument18 pagesMC99759 8b110brakeANGELES NIETONo ratings yet

- Driveline System - General Information: Principle of OperationDocument15 pagesDriveline System - General Information: Principle of OperationSergeyNo ratings yet

- Ac Motor Repair: N35ZDR, N45ZR (C264) N30ZDR, N35-40ZR (D470) N30ZDRS, N35-40ZRS (A265)Document14 pagesAc Motor Repair: N35ZDR, N45ZR (C264) N30ZDR, N35-40ZR (D470) N30ZDRS, N35-40ZRS (A265)Linde ForkliftNo ratings yet

- mk2 Golf 90-92front SuspensionDocument5 pagesmk2 Golf 90-92front SuspensionEoin MacEoinNo ratings yet

- John Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)Document16 pagesJohn Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)laopaodunNo ratings yet

- Rear Disc BrakeDocument43 pagesRear Disc BrakeAndreyNo ratings yet

- ANILLOS PentastarDocument1 pageANILLOS PentastarStarsky UrblejoNo ratings yet

- Eaton Fuller Heavy-Duty Transmissions TRSM0996 EN-US: Service ManualDocument56 pagesEaton Fuller Heavy-Duty Transmissions TRSM0996 EN-US: Service Manualr reyesNo ratings yet

- TI 05 010 TurboAxialPlayDocument17 pagesTI 05 010 TurboAxialPlayanggieNo ratings yet

- Workshop MDocument69 pagesWorkshop MmanhNo ratings yet

- Timing Valves 6 CylindersDocument2 pagesTiming Valves 6 Cylindersmorrenita2003No ratings yet

- John Deere 80C Excavator Service Repair Technical Manual (TM1939)Document18 pagesJohn Deere 80C Excavator Service Repair Technical Manual (TM1939)laopaodunNo ratings yet

- JM Engine 20040209Document43 pagesJM Engine 20040209wreckedweasel100% (2)

- Front Drive Halfshafts - : Item SpecificationDocument19 pagesFront Drive Halfshafts - : Item SpecificationJim LiebNo ratings yet

- Ajuste de Tren de EngranesDocument9 pagesAjuste de Tren de Engranessinger50100% (1)

- 017 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - On VehicleDocument98 pages017 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - On VehicleGedas GvildysNo ratings yet

- Service Manual2005 UNIT REPAIRDocument35 pagesService Manual2005 UNIT REPAIRNestor RiverosNo ratings yet

- 205-01 Drive Shaft PICKUP JMCDocument14 pages205-01 Drive Shaft PICKUP JMCRusonegroNo ratings yet

- SECTION 211-03 Steering LinkageDocument5 pagesSECTION 211-03 Steering LinkageTiến Phát Công ty TNHH Đầu Tư Xây DựngNo ratings yet

- 190fe-ManualDocument21 pages190fe-Manualmochamady755No ratings yet

- 10 ACG - Starting ClutchDocument9 pages10 ACG - Starting ClutchLuis Carlos Barrera IdarragaNo ratings yet

- (FORD) Diagrama de Cableado Ford FocusDocument29 pages(FORD) Diagrama de Cableado Ford FocusArturoNoCesaNo ratings yet

- SM - VOLVO L70C WHEEL LOADER Service RepairDocument18 pagesSM - VOLVO L70C WHEEL LOADER Service RepairL. Fernando Ledezma de la FuenteNo ratings yet

- Specifications: 2008 Ford Ranger 2008 Ford RangerDocument15 pagesSpecifications: 2008 Ford Ranger 2008 Ford RangerwawanNo ratings yet

- 1.6l 4 CylDocument29 pages1.6l 4 Cyl25912530100% (1)

- Orbitrol Repairing 2Document25 pagesOrbitrol Repairing 2Islam ShoukryNo ratings yet

- 4JG2 Timing Spec PDFDocument3 pages4JG2 Timing Spec PDF650LNo ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpDocument22 pages303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpCARLOS LIMADANo ratings yet

- Eixo Dif Simples Vel ENGDocument62 pagesEixo Dif Simples Vel ENGAhmedNo ratings yet

- SB1208 - ZF As Tronic - Clutch Component LubricationDocument12 pagesSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNo ratings yet

- Poner A Tiempo ContourDocument4 pagesPoner A Tiempo ContourJuan Carlos Nuñez CastilloNo ratings yet

- 99739-32110-13 - Adjustment and Operation DP50 East AfricaDocument13 pages99739-32110-13 - Adjustment and Operation DP50 East AfricaOli MijanaNo ratings yet

- Mitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Document61 pagesMitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Miroslav TabakovskiNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Motorcycle Dynamics StudyDocument12 pagesMotorcycle Dynamics StudyJuan Lopez100% (2)

- Executive Ckup Full PDFDocument4 pagesExecutive Ckup Full PDFAlgen S. GomezNo ratings yet

- Digital Booklet - The Huntsman - WintDocument12 pagesDigital Booklet - The Huntsman - WintДенис СалаховNo ratings yet

- Shadowrun Combat Cheat Sheet by Adragon202-D71s2y5Document2 pagesShadowrun Combat Cheat Sheet by Adragon202-D71s2y5MasonMcDaniel100% (3)

- A Soldier's StoryDocument3 pagesA Soldier's Storybhargav4700% (1)

- B.Inggris - WPS OfficeDocument9 pagesB.Inggris - WPS OfficeRetno PratiwiNo ratings yet

- Marshall F800RDocument5 pagesMarshall F800RNdubisi AgomoNo ratings yet

- DSC Payment DetailsDocument11 pagesDSC Payment DetailsAbhishek SinghNo ratings yet

- 453-Bank Po 2024 Day-9Document46 pages453-Bank Po 2024 Day-9Amit KishoreNo ratings yet

- Đetić Liga 2011Document25 pagesĐetić Liga 2011FK TuziNo ratings yet

- Availability Etlala 1 - Updated 11.03.2024Document6 pagesAvailability Etlala 1 - Updated 11.03.2024panishaalaNo ratings yet

- PRISAA Regional Sched 2024Document2 pagesPRISAA Regional Sched 2024Ezekiel MarinoNo ratings yet

- Anouk - Nobody's WifeDocument2 pagesAnouk - Nobody's WifeSanto DianoNo ratings yet

- 572004Document1 page572004Dwi Mulyanti DwimulyantishopNo ratings yet

- Department Date Month Year Machine Model WEE KDocument12 pagesDepartment Date Month Year Machine Model WEE KBala Equal BalanceNo ratings yet

- All DistrictDocument1 pageAll DistrictThe Dallas Morning NewsNo ratings yet

- Custom TV Action & EntertainmentDocument6 pagesCustom TV Action & Entertainmentcarpop52No ratings yet

- MDF292 Dorian Pattern Letter A4Document41 pagesMDF292 Dorian Pattern Letter A4SEBASTIAN FLORESNo ratings yet

- Mourinho TacticalDocument101 pagesMourinho TacticalGOKHN AYDİN100% (1)

- Islam and Martial Arts - China's Hui Muslim Tradition - Bahath - Islamic Online MagazineDocument8 pagesIslam and Martial Arts - China's Hui Muslim Tradition - Bahath - Islamic Online MagazineNaoki YamamotoNo ratings yet

- Barney's Colorful World! - Barney Wiki - WikiaDocument3 pagesBarney's Colorful World! - Barney Wiki - WikiachefchadsmithNo ratings yet

- Final Seniority List of SSTs Updated 2021-NewDocument486 pagesFinal Seniority List of SSTs Updated 2021-NewAqib Ahmad100% (1)

- Module 2 P.E. 2Document8 pagesModule 2 P.E. 2alleyausitaNo ratings yet

- Making The Tyvek SailDocument5 pagesMaking The Tyvek Saildanut_docNo ratings yet

- Fh5 Data Cars Partial For WekaDocument5 pagesFh5 Data Cars Partial For WekaRaphaël Cazenave-LévêqueNo ratings yet

- 2021 Spring Concert ProgramDocument10 pages2021 Spring Concert Programapi-307192778No ratings yet

Ring(s), Piston - Engine Block - 2.7L DOHC Engine - Engine - Dodge Journey Service & Repair Manual - Dodgia

Ring(s), Piston - Engine Block - 2.7L DOHC Engine - Engine - Dodge Journey Service & Repair Manual - Dodgia

Uploaded by

CaballitofelizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ring(s), Piston - Engine Block - 2.7L DOHC Engine - Engine - Dodge Journey Service & Repair Manual - Dodgia

Ring(s), Piston - Engine Block - 2.7L DOHC Engine - Engine - Dodge Journey Service & Repair Manual - Dodgia

Uploaded by

CaballitofelizCopyright:

Available Formats

HOME OWNERS SERVICE NEW TOP SITEMAP SEARCH Search

Dodge Journey: Ring(s), piston DODGE JOURNEY OWNERS MANUAL

Dodge Journey Service & Repair Manual / Engine / 2.7L DOHC Engine / Engine block / Ring(s), piston

Things to know before starting your vehicle

Standard Procedure

Understanding the features of your vehicle

PISTON RING FITTING

Understanding your instrument panel

Starting and operating

What to do in emergencies

Maintaining your vehicle

Maintenance schedules

If you need consumer assistance

DODGE JOURNEY SERVICE MANUAL

Accessories and Equipment

Fig. 200: CHECK GAP ON PISTON RINGS

Brakes

1. - FEELER GAUGE

Differential and Driveline

1. Wipe cylinder bore clean. Insert ring and push down with piston to ensure it is square in bore. Electrical

The ring gap measurement must be made with the ring positioning at least 12 mm (0.50 inch.)

from bottom of cylinder bore. Check gap with feeler gauge (1). Refer to Engine - Specifications for Engine

clearance measurements.

Heating & Air Conditioning

Front Suspension

Transmission

Fig. 201: Measuring Piston Ring Side Clearance

1. - FEELER GAUGE

2. Check piston ring to groove clearance (1).

Removal

Fig. 202: PISTON RING - INSTALLATION

1. - SPACER EXPANDER

2. - SIDE RAIL

1. Remove piston and connecting rod.

2. Remove No. 1 and No. 2 piston rings from piston using a ring expander tool.

3. Remove upper oil ring side rail.

4. Remove lower oil ring side rail.

5. Remove oil ring expander.

Installation

Fig. 203: SIDE RAIL - INSTALLATION

1. - SIDE RAIL END

1. Measure clearance of piston rings to the cylinder bore and piston.

CAUTION: Install piston rings in the following order:

Oil ring expander.

Upper oil ring side rail.

Lower oil ring side rail.

No. 2 Intermediate piston ring.

No. 1 Upper piston ring.

2. Install oil ring expander.

Install the side rail (1) by placing one end between the piston ring groove and the oil ring

expander. Hold end firmly and press down the portion to be installed until side rail is in position.

Do not use a piston ring expander during this step.

3. Install upper side rail first and then the lower side rail.

Fig. 204: Upper and Intermediate Rings - Installation

NOTE: The No. 1 and No. 2 piston rings have a different cross section. Ensure No.

2 ring is installed with manufacturers I.D. mark (dot) facing up, towards top of the

piston.

4. Install No. 2 piston ring and then No. 1 piston ring.

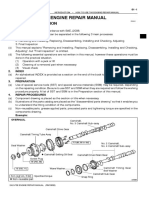

Fig. 205: PISTON RING END GAP POSITION

1. - SIDE RAIL UPPER

2. - NO. 1 RING GAP

3. - PISTON PIN

4. - SIDE RAIL LOWER

5. - NO. 2 RING GAP AND SPACER EXPANDER GAP

Flexplate Rod, piston and connecting

Removal Fig. 198: Flex Plate 1. Remove Description Fig. 206: Piston &

transmission. 2. Remove flex plate attaching Connecting Rod - "F" TOWARD FRONT OF

bolts (2). 3. Remove backing plate (3) and flex ENGINE - RING COMPRESSOR - SPECIAL

plate (1). Installation Fig. 199: FLEX PLATE 1. TOOL 8189 - OIL SQUIRT HOLE The pistons

Posit ... (1) are made of a high stre ...

See also:

Cable, shift

REMOVAL Fig. 306: Identifying Knee Blocker 1. Remove the knee blocker (2). Fig. 307: Identifying

Shift Cable At Shifter NOTE: Ensure the lock tab on the shift cable (2) is depressed before ...

Lines, A/C underbody, extension

Description Fig. 310: Underbody A/C Extension Lines Description Models equipped with the rear

heating-A/C system use metal lines attached to the vehicle underbody to carry refrigerant and

engin ...

Diagnosis and Testing

STRUT ASSEMBLY Fig. 80: Strut Assembly (Exploded) Inspect the strut assembly for the

following conditions: Inspect for a damaged or broken coil spring (7). Inspect for a torn or

damaged dust ...

Copyright © www.dodgia.com

0.0079

You might also like

- 061 - Engine Mechanical - 2.4L (LEA LUK) - Repair Instructions - On VehicleDocument334 pages061 - Engine Mechanical - 2.4L (LEA LUK) - Repair Instructions - On VehicleGedas Gvildys100% (1)

- Mutt 125eu501 (Mongrel Twin Shock) Technical Manual - V1 - 0321Document82 pagesMutt 125eu501 (Mongrel Twin Shock) Technical Manual - V1 - 0321Sergio Boni100% (1)

- Motor Ka24de Nissan Frontier 2.4l ManualDocument52 pagesMotor Ka24de Nissan Frontier 2.4l ManualIsaac ArispeNo ratings yet

- Rover 100 TUD5 Overhaul ManualDocument59 pagesRover 100 TUD5 Overhaul ManualAndy Moe63% (8)

- 2000 VW Passat Wiring DiagramsDocument55 pages2000 VW Passat Wiring Diagramsjuan carlos siqueiros ochoaNo ratings yet

- Duratec HE Assembly Manual PDFDocument266 pagesDuratec HE Assembly Manual PDFAlexis100% (2)

- Windstar 2000-2001 3.8 v6Document77 pagesWindstar 2000-2001 3.8 v6Juan RiveraNo ratings yet

- 2az Fse Engine Repair Manual (Rm1083e)Document120 pages2az Fse Engine Repair Manual (Rm1083e)Osvaldo Chimbas100% (2)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- 2RZ 3RZ SC PDFDocument21 pages2RZ 3RZ SC PDFUliAlejandroRodriguezCoriangaNo ratings yet

- Idoc - Pub Blood Bowl Star Player CardsDocument4 pagesIdoc - Pub Blood Bowl Star Player CardsharryposteurNo ratings yet

- Slide Cam Pulley: Instructions ManualDocument5 pagesSlide Cam Pulley: Instructions Manualhenrysaputra168No ratings yet

- General Information: To IndexDocument9 pagesGeneral Information: To IndexandriNo ratings yet

- 1DZ EngineDocument181 pages1DZ EngineGonçalo SousaNo ratings yet

- Vibration Damper - Check: Testing and AdjustingDocument2 pagesVibration Damper - Check: Testing and AdjustingbejoythomasNo ratings yet

- Drive Axle FrontDocument10 pagesDrive Axle FrontAnimemanuel MuñozNo ratings yet

- Adjustment of The Compression BrakeDocument2 pagesAdjustment of The Compression BrakeCarlos Juarez ChungaNo ratings yet

- 4 - 180 Rear Axle Brake Pin ReplacementDocument2 pages4 - 180 Rear Axle Brake Pin ReplacementDonbassNo ratings yet

- C4 4 CalibracionDocument5 pagesC4 4 CalibracionJaya Abadi100% (1)

- Dau Keo EST - Engine ISG (English)Document2,946 pagesDau Keo EST - Engine ISG (English)Vũ Công Minh100% (2)

- Bomba de Aceite MotorDocument8 pagesBomba de Aceite MotorFredy ReyesNo ratings yet

- Power Plant MountDocument12 pagesPower Plant MountMohamed AdelNo ratings yet

- 09Document2 pages09عمر المعاريNo ratings yet

- Sebf 8269 Привод 3408Document16 pagesSebf 8269 Привод 3408mohamed hamedNo ratings yet

- Hyundai Coupe 2.0Document11 pagesHyundai Coupe 2.0BrandonHiDudNo ratings yet

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- Gear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemDocument6 pagesGear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemJose nildo lobato Mendes MendesNo ratings yet

- AXSM0043-Drive Axles Single ReductionDocument34 pagesAXSM0043-Drive Axles Single Reductionwadalla100No ratings yet

- MC99759 8b110brakeDocument18 pagesMC99759 8b110brakeANGELES NIETONo ratings yet

- Driveline System - General Information: Principle of OperationDocument15 pagesDriveline System - General Information: Principle of OperationSergeyNo ratings yet

- Ac Motor Repair: N35ZDR, N45ZR (C264) N30ZDR, N35-40ZR (D470) N30ZDRS, N35-40ZRS (A265)Document14 pagesAc Motor Repair: N35ZDR, N45ZR (C264) N30ZDR, N35-40ZR (D470) N30ZDRS, N35-40ZRS (A265)Linde ForkliftNo ratings yet

- mk2 Golf 90-92front SuspensionDocument5 pagesmk2 Golf 90-92front SuspensionEoin MacEoinNo ratings yet

- John Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)Document16 pagesJohn Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)laopaodunNo ratings yet

- Rear Disc BrakeDocument43 pagesRear Disc BrakeAndreyNo ratings yet

- ANILLOS PentastarDocument1 pageANILLOS PentastarStarsky UrblejoNo ratings yet

- Eaton Fuller Heavy-Duty Transmissions TRSM0996 EN-US: Service ManualDocument56 pagesEaton Fuller Heavy-Duty Transmissions TRSM0996 EN-US: Service Manualr reyesNo ratings yet

- TI 05 010 TurboAxialPlayDocument17 pagesTI 05 010 TurboAxialPlayanggieNo ratings yet

- Workshop MDocument69 pagesWorkshop MmanhNo ratings yet

- Timing Valves 6 CylindersDocument2 pagesTiming Valves 6 Cylindersmorrenita2003No ratings yet

- John Deere 80C Excavator Service Repair Technical Manual (TM1939)Document18 pagesJohn Deere 80C Excavator Service Repair Technical Manual (TM1939)laopaodunNo ratings yet

- JM Engine 20040209Document43 pagesJM Engine 20040209wreckedweasel100% (2)

- Front Drive Halfshafts - : Item SpecificationDocument19 pagesFront Drive Halfshafts - : Item SpecificationJim LiebNo ratings yet

- Ajuste de Tren de EngranesDocument9 pagesAjuste de Tren de Engranessinger50100% (1)

- 017 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - On VehicleDocument98 pages017 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - On VehicleGedas GvildysNo ratings yet

- Service Manual2005 UNIT REPAIRDocument35 pagesService Manual2005 UNIT REPAIRNestor RiverosNo ratings yet

- 205-01 Drive Shaft PICKUP JMCDocument14 pages205-01 Drive Shaft PICKUP JMCRusonegroNo ratings yet

- SECTION 211-03 Steering LinkageDocument5 pagesSECTION 211-03 Steering LinkageTiến Phát Công ty TNHH Đầu Tư Xây DựngNo ratings yet

- 190fe-ManualDocument21 pages190fe-Manualmochamady755No ratings yet

- 10 ACG - Starting ClutchDocument9 pages10 ACG - Starting ClutchLuis Carlos Barrera IdarragaNo ratings yet

- (FORD) Diagrama de Cableado Ford FocusDocument29 pages(FORD) Diagrama de Cableado Ford FocusArturoNoCesaNo ratings yet

- SM - VOLVO L70C WHEEL LOADER Service RepairDocument18 pagesSM - VOLVO L70C WHEEL LOADER Service RepairL. Fernando Ledezma de la FuenteNo ratings yet

- Specifications: 2008 Ford Ranger 2008 Ford RangerDocument15 pagesSpecifications: 2008 Ford Ranger 2008 Ford RangerwawanNo ratings yet

- 1.6l 4 CylDocument29 pages1.6l 4 Cyl25912530100% (1)

- Orbitrol Repairing 2Document25 pagesOrbitrol Repairing 2Islam ShoukryNo ratings yet

- 4JG2 Timing Spec PDFDocument3 pages4JG2 Timing Spec PDF650LNo ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpDocument22 pages303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpCARLOS LIMADANo ratings yet

- Eixo Dif Simples Vel ENGDocument62 pagesEixo Dif Simples Vel ENGAhmedNo ratings yet

- SB1208 - ZF As Tronic - Clutch Component LubricationDocument12 pagesSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNo ratings yet

- Poner A Tiempo ContourDocument4 pagesPoner A Tiempo ContourJuan Carlos Nuñez CastilloNo ratings yet

- 99739-32110-13 - Adjustment and Operation DP50 East AfricaDocument13 pages99739-32110-13 - Adjustment and Operation DP50 East AfricaOli MijanaNo ratings yet

- Mitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Document61 pagesMitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Miroslav TabakovskiNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Motorcycle Dynamics StudyDocument12 pagesMotorcycle Dynamics StudyJuan Lopez100% (2)

- Executive Ckup Full PDFDocument4 pagesExecutive Ckup Full PDFAlgen S. GomezNo ratings yet

- Digital Booklet - The Huntsman - WintDocument12 pagesDigital Booklet - The Huntsman - WintДенис СалаховNo ratings yet

- Shadowrun Combat Cheat Sheet by Adragon202-D71s2y5Document2 pagesShadowrun Combat Cheat Sheet by Adragon202-D71s2y5MasonMcDaniel100% (3)

- A Soldier's StoryDocument3 pagesA Soldier's Storybhargav4700% (1)

- B.Inggris - WPS OfficeDocument9 pagesB.Inggris - WPS OfficeRetno PratiwiNo ratings yet

- Marshall F800RDocument5 pagesMarshall F800RNdubisi AgomoNo ratings yet

- DSC Payment DetailsDocument11 pagesDSC Payment DetailsAbhishek SinghNo ratings yet

- 453-Bank Po 2024 Day-9Document46 pages453-Bank Po 2024 Day-9Amit KishoreNo ratings yet

- Đetić Liga 2011Document25 pagesĐetić Liga 2011FK TuziNo ratings yet

- Availability Etlala 1 - Updated 11.03.2024Document6 pagesAvailability Etlala 1 - Updated 11.03.2024panishaalaNo ratings yet

- PRISAA Regional Sched 2024Document2 pagesPRISAA Regional Sched 2024Ezekiel MarinoNo ratings yet

- Anouk - Nobody's WifeDocument2 pagesAnouk - Nobody's WifeSanto DianoNo ratings yet

- 572004Document1 page572004Dwi Mulyanti DwimulyantishopNo ratings yet

- Department Date Month Year Machine Model WEE KDocument12 pagesDepartment Date Month Year Machine Model WEE KBala Equal BalanceNo ratings yet

- All DistrictDocument1 pageAll DistrictThe Dallas Morning NewsNo ratings yet

- Custom TV Action & EntertainmentDocument6 pagesCustom TV Action & Entertainmentcarpop52No ratings yet

- MDF292 Dorian Pattern Letter A4Document41 pagesMDF292 Dorian Pattern Letter A4SEBASTIAN FLORESNo ratings yet

- Mourinho TacticalDocument101 pagesMourinho TacticalGOKHN AYDİN100% (1)

- Islam and Martial Arts - China's Hui Muslim Tradition - Bahath - Islamic Online MagazineDocument8 pagesIslam and Martial Arts - China's Hui Muslim Tradition - Bahath - Islamic Online MagazineNaoki YamamotoNo ratings yet

- Barney's Colorful World! - Barney Wiki - WikiaDocument3 pagesBarney's Colorful World! - Barney Wiki - WikiachefchadsmithNo ratings yet

- Final Seniority List of SSTs Updated 2021-NewDocument486 pagesFinal Seniority List of SSTs Updated 2021-NewAqib Ahmad100% (1)

- Module 2 P.E. 2Document8 pagesModule 2 P.E. 2alleyausitaNo ratings yet

- Making The Tyvek SailDocument5 pagesMaking The Tyvek Saildanut_docNo ratings yet

- Fh5 Data Cars Partial For WekaDocument5 pagesFh5 Data Cars Partial For WekaRaphaël Cazenave-LévêqueNo ratings yet

- 2021 Spring Concert ProgramDocument10 pages2021 Spring Concert Programapi-307192778No ratings yet