Professional Documents

Culture Documents

US1960211 (Sudah)

US1960211 (Sudah)

Uploaded by

aris_nurhidayat0 ratings0% found this document useful (0 votes)

12 views3 pagesThis document describes a method for preparing adipic acid and beta-alkyl substituted adipic acids through the oxidation of cyclohexanol with nitric acid. Key points:

- Copper is identified as an effective catalyst for this oxidation reaction, allowing it to proceed smoothly at lower temperatures between 35-70°C.

- The addition of sulfuric acid to the nitric acid/catalyst mixture is found to further increase yields of the desired products and reduce the amount of nitric acid required.

- Examples demonstrate the preparation of adipic acid itself as well as beta-methyl and beta-tertiary-butyl substituted adipic acids using this copper-catalyzed, sulfuric acid-supplemented

Original Description:

Original Title

US1960211 (sudah)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes a method for preparing adipic acid and beta-alkyl substituted adipic acids through the oxidation of cyclohexanol with nitric acid. Key points:

- Copper is identified as an effective catalyst for this oxidation reaction, allowing it to proceed smoothly at lower temperatures between 35-70°C.

- The addition of sulfuric acid to the nitric acid/catalyst mixture is found to further increase yields of the desired products and reduce the amount of nitric acid required.

- Examples demonstrate the preparation of adipic acid itself as well as beta-methyl and beta-tertiary-butyl substituted adipic acids using this copper-catalyzed, sulfuric acid-supplemented

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

12 views3 pagesUS1960211 (Sudah)

US1960211 (Sudah)

Uploaded by

aris_nurhidayatThis document describes a method for preparing adipic acid and beta-alkyl substituted adipic acids through the oxidation of cyclohexanol with nitric acid. Key points:

- Copper is identified as an effective catalyst for this oxidation reaction, allowing it to proceed smoothly at lower temperatures between 35-70°C.

- The addition of sulfuric acid to the nitric acid/catalyst mixture is found to further increase yields of the desired products and reduce the amount of nitric acid required.

- Examples demonstrate the preparation of adipic acid itself as well as beta-methyl and beta-tertiary-butyl substituted adipic acids using this copper-catalyzed, sulfuric acid-supplemented

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Patented May 22, 1934 1960,211

UNITED STATES PATENT OFFICE

,960,21

PREPARATION OF ADIPIC ACIDs

Ralph P. Perkins and Andrew J. Dietzler, Mid

land, Mich, assignors to The Dow Chemical

Company, Midland, Mich., a corporation of

Michigan

No Drawing. Application November 3, 1932,

Serial No. 641,123

2 Claims. (C. 260-2)

This invention relates to methods of preparing in which the principle of the invention may be

adipic acid and beta-alkyl Substituted adipic used.

acids, and also includes a new compound, viz., The general conditions under which we prefer

beta-tertiary-butyl adipic acid, to carry out the Oxidation of the cyclohexanol

The production of adipic acid and the beta or similar starting material are as follows:-The 60

alkyl substituted derivatives thereof is ordinarily cyclohexanol is poured slowly into nitric acid

accomplished by the oxidation with nitric acid having a density between about 32 and about

of cyclohexanol, cyclohexanone, or the 3- and 43 Baumé. The amount of nitric acid used is

4-alkyl substituted derivatives thereof, e. g. 3 preferably to be in the ratio of between about 2

10 and 4-methyl cyclohexanol, 4-tertiary-butyl cy and about 4 moles thereof per mole of cyclo 65

clohexanol, etc. However, in carrying out the ox hexanol oxidized. During the addition of the

idation it has been found that the temperature cyclohexanol to the nitric acid the reaction mix

of the nitric acid should be maintained at or near ture is agitated thoroughly and the temperature

its boiling point, since it is desirable that the thei'eof is maintained by cooling at or near the

15 oxidation of the alcohol or ketone should set in lowest point at which the oxidation will proceed O

as Soon as the first drop thereof is added to the smoothly, usually in the range between about 35°

acid. If any considerable amount of the alcohol and about 70° C. As a catalyst we may incor

is added before the oxidation starts, or should porate With the nitric acid before adding the

accumulate during the reaction, a serious ex cyclohexanol thereto one or more of the metals

20 plosion may result. In view of the foregoing it Cerium, manganese, lead, iron, chromium, cobalt, 75

has been proposed to incorporate into the nitric nickel, tungsten, tellurium, bismuth, calcium,

acid a catalyst capable of Smoothing out the ox magnesium, uranium, barium, silver, molybde

idation, and to permit the oxidation to be car num, Wanadium, mercury, copper, or compounds

ried out at a relatively low temperature, e. g. thereof which are soluble in nitric acid, and in

25 50°-60° C. For instance, British Patent No. particular the oxides, Sulphates, or nitrates there 80

265,959 of 8 December 1927 discloses the use of of. The amount of catalyst which we may em

mercury, molybdenum and vanadium compounds ploy is relatively Small, being between about 0.05

to promote the oxidation in the directions of per cent and about 5.0 per cent, preferably about

increased yield and lowered reaction temperature. 0.3 per cent, by Weight, based on the quantity

30 We have determined that certain other cata of cyclohexanol to be oxidized. 85

lysts can be incorporated with the nitric acid Concentrated Sulphuric acid is employed to

to cause the oxidation to proceed rapidly and improve the product yield and to decrease the

Smoothly, and to lessen the risk of accumulation amount of nitric acid required. The addition

of the alcohol or ketone in the reaction mixture of Such sulphuric acid to the nitric acid may be

35 With Subsequent violent reaction. We have now made before beginning the introduction of the 90

found that Sulphuric acid can be added to the cyclohexanol thereinto. However, we prefer to

nitric acid containing such catalysts, either be add the Sulphuric acid to the reaction mixture

fore or during the reaction, to raise the yield of after about one-half of the cyclohexanol has been

adipic acid in a marked degree, and to permit the introduced into the nitric acid, simultaneously

40 use of less nitric acid. We have also found thatWith, and at about the same rate as the remain 95

the use of Copper as a catalyst exercises a more der of the cyclohexanol. The amount of sul

beneficial effect upon the product yield than any phuric acid to be used is preferably in the ratio

other catalyst which has been previously dis of between about 0.20 and 1.35 moles thereof per

closed, and that the use of copper as a catalyst mole of the cyclohexanol oxidized. Instead of

45

is particularly desirable since when used in suit Sulphuric acid we may use an equivalent amount OO

able amounts it is readily separable from the re of an acid Sulphate, e. g. sodium acid sulphate

(NaHSO4).

action product. . The following examples show in detail the

To the accomplishment of the foregoing and manner of carrying out our improved method

50 related ends, the invention, then, consists of the for the preparation of adipic acid and the beta

method hereinafter fully described and particu alkyl substituted derivatives thereof, and illus

larly pointed out in the claims, the following de trate the results obtained thereby.

Scription setting forth in detail several modes of Eacample 1-Adipic acid

carrying out the invention, Such disclosed modes

55 illustrating, however, but several of various ways A solution of 3 grams of crystallized copper 10

2 1,960,211 .

nitrate in 923 grams of 38° Baumé nitric acid but no sulphuric acid was used during the oxi

was prepared. To this solution was added, over dation. It was found that only 263 grams of ,

a period of 76 minutes, 300 grams of cyclohex cyclohexanone, or 92.5 per cent as much as in

anol. During the addition of the cyclohexanol, the previous run, could be oxidized with the same

5 the nitric acid, solution was cooled to maintain amount of nitric acid as used before. The yield 80

it at a temperature of 60-70° C. and thoroughly of adipic acid was 71 per cent of the theoretical.

agitated. The cooling was then discontinued, Eacample 4-Beta-methyl adipic acid

and the mixture agitated 20 minutes more dur A solution consisting of 268 grams of 43' Baumé

ing which period the temperature rose to 80

() C. The solution was then cooled to 8° C. and nitric acid and 0.6 gram of crystallized copper 85

the crystals thereby precipitated were filtered nitrate Was prepared. To this Soltion was add

from the mother liquor, washed and dried. The ed 114 grams of a mixture of 3- and 4-methyl

yield of Substantially pure adipic acid crystals cyclohexanol. The reaction mixture was agi

thus obtained was 330 grams or 75.4 per cent of tated and cooled to maintain it at a tempera

the theoretical. ture of 60°-70° C. during the addition of the 90

As a basis for judging the activity of the cop alcohol. When 57 grams, i. e. One-half, of the

per catalyst in the foregoing example, a Com alcohol had been added to the reaction mixture,

parable run was made without the use of the the introduction of sulphuric acid was started

copper. This was less Smooth, required a longer and continued at such a rate that 92 grams of

20 time to complete, and the yield of adipic acid concentrated sulphuric acid was introduced into 95

obtained was 68.5 per cent of the theoretical. the reaction mixture simultaneously with the

Eacample 2-Adipic acid latter 57 grams of the alcohol. The period of

addition was 110 minutes, at the conclusion of

A solution consisting of 710 grams of 43 Baumé which the mixture was warmed over a period of

25 nitric acid and 0.6 gram of crystallized, copper 30 minutes to 90° C., maintained at that tem

nitrate was prepared. To this solution 300 grams perature for 30 minutes more, evaporated under

of cyclohexanol was added at a uniform rate reduced pressure to a volume of about 225 milli

over a period of 130 minutes. When 150 grams liters, and then cooled to a temperature of about

of the cyclohexanol had been introduced into 0°C. to precipitate crystals of beta-methyl adipic

30 . the nitric acid the addition of 275 grams of sul acid. ' The crystals were separated from the

phuric acid was started and maintained at a mother liquor and centrifuged, 110 grams, or 68.8

rate such that the introduction into the reac per cent of the theoretical yield, of crude beta

tion mixture of the remaining 150 grams of cy methyl adipic acid being obtained. Carrying out

clohexanol and of the sulphuric acid was com the foregoing reaction under similar conditions

35 pleted simultaneously. During the period of ad except that the catalyst and sulphuric acid were

dition the reaction mixture was agitated and omitted, a yield of 96 grams of product was, ob

cooled to maintain it at a temperature between tained, corresponding to 60.0 per cent of the

39° and 42° C. After the addition of the alcohol theoretical yield.

and sulphuric acid to the nitric acid had been Eacample 5-Beta-tertiary-butyl adipic acid. - a r

40 completed, the temperature of the reaction mix - its

ture was allowed to rise to 60° C., with continued A solution consisting of 335 grams of 38° Baumé

stirring, and after 45 minutes at that tempera nitric acid. and 1.0 gram of crystallized copper

ture the mixture was then cooled to 8 C. The nitrate was prepared. To this solution was add

yield of substantially pure adipic acid, obtained ed in Small portions over a period of 90 minutes

45 by separating the crystals thereof precipitated in 156 grams of 4-teritary-butyl cyclohexanol. The

the foregoing reaction mixture, was 377 grams or reaction mixture was agitated and maintained

86 per cent of the theoretical. at a temperature of 55°-60° C. during the period

As a basis for judging the activity of the sul Of addition. After 89 grams of the alcohol had

phuric acid in the foregoing example, a compa been added, 91 grams of concentrated Sulphuric

50 rable run was made without the use of Sulphuric acid was added to the reaction mixture in One 12,

acid in which the yield of adipic acid obtained charge. Upon completion of the addition of the

was 77.0 per cent of the theoretical. alcohol to the reaction mixture, the temperature

Eacample 3-Adipic acid from cycloheacanone thereat was

thereof raised to about 70° C. and maintained

for about 35 minutes. The mixture was

55 As an example of the results which may be then cooled to 8° C. to precipitate beta-tertiary 13C

obtained in the preparation of adipic acid from butyl adipic acid, the crystals of which were then

cyclohexanone and to illustrate the effect exer separated therefrom by filtration, washed with

cised by the sulphuric acid upon the amount of Water and dried. There was thus obtained 179

cyclohexanone which can be oxidized with a grams of crude tertiary-butyl adipic acid melt

60 given quantity of nitric acid, we dissolved 0.6 ing at 86°-90° C., a yield of 88.5 per cent of 1. 5

gram of crystallized copper nitrate in 533 grams the theoretical. By repeated crystallization from

of 43 Baumé nitric acid, maintained the tem. dilute alcohol and nitric acid, beta-tertiary-butyl

perature of the solution at 65°-70° C. and slo adipic acid melting at 115.2°-115.9° C. was ob

ly added 284 grams of cyclohexanone there tained. The foregoing compound is a white

At this point oxidation practically ceased. Dur-. crystalline substance slightly soluble in cold wa

ing the addition of the latter half of the cyclo ter, soluble in hot water and alcohol, which may

hexanone 200 grams of concentrated Sulphuric be purified by crystallization from water, dilute

acid was added to the reaction mixture Substan alcohol, or nitric acid.

tially in the manner described in Example 1. The present invention, then, as illustrated in

The yield of adipic acid was 311 grams or 73.5 the foregoing examples, comprehends oxidizing

per cent of the theoretical. cyclohexanol, cyclohexanone, and the 3- and 4

A second solution of 0.6 gram of copper ni alkylated derivatives thereof, to form adipic acid

trate in an equivalent amount of 38' Baumé ni and the beta-alkyl substituted adipic acid. The

tric acid was prepared. The slow addition of conditions under which such oxidation is carried

cyclohexanone to the solution was then begun, out comprise the addition of the alcohol or ketone;

1,960,211 3

to nitric acid having incorporated therein a cat salts of copper and between about 0.20 and

alyst capable of smoothing out the foregoing about 1.35 moles of concentrated sulphuric acid

oxidation; and have regard for the employment per one mole of compound to be oxidized.

of sulphuric acid, or its equivalent, in the re 7. The method of preparing adipic acid which

action mixture whereby the yield of the desired comprises oxidizing a compound from the class

product is markedly increased and the amount of consisting of cyclohexanol and cyclohexanone

nitric acid required is reduced. Among the Cat with nitric acid having incorporated therewith a

alysts hereinbefore recited we wish to note par relatively small amount of a catalyst from the

ticularly copper, or the oxides or nitrates thereof, class consisting of copper, copper oxide, and salts

O Since copper compounds exert a more pronounced of copper and between about 0.20 and about 1.35

effect upon the yield of product obtained than moles of concentrated sulphuric acid per one mole

any other catalyst we have employed, and, be of compound to be oxidized, cooling the reaction

cause when used in suitable amounts they re mixture to precipitate adipic acid crystals there

main dissolved in the mother liquor during crys from and separating the crystals from the mother

5 tallization of the product therefrom. This is a liquor.

distinct advantage, resulting in a product un 8. The method of preparing adipic acid which

contaminated by the catalyst, which result can comprises introducing a compound from the class

not be realized when, for example, mercury com consisting of cyclohexanol and cyclohexanone

pounds are employed. into between about 2 and about 4 moles of nitric

20 Other modes of applying the principle of Our acid of a density between about 32 and 43

invention may be employed instead of those ex Baumé per one mole of said compound, said acid

plained, change being made as regards the meth having incorporated therewith between about 0.05

od hereinafter disclosed, provided the step or and about 5.0 per cent by weight based on the

steps stated by any of the following claims or weight of said compound of a catalyst from the

25 the equivalent of Such stated step or steps be class consisting of copper, copper oxide, and salts 100

employed. of copper and between about 0.20 and about 1.35

We therefore particularly point out and dis moles of concentrated sulphuric acid per one mole

tinctly claim as our invention:- of compound from the first named class, and

1. In the preparation of adipic acid and the maintaining the temperature of the reaction mix

30 beta-alkyl substituted derivatives thereof by the ture in the range between about 35 and about 105

oxidation of a compound selected from the group

consisting of cyclohexanol, cyclohexanone, and 70°9.C.The during the reaction.

method of preparing adipic acid and the

the 3- and 4-alkyl substituted derivatives thereof, beta-alkyl substituted derivatives thereof which

with nitric acid, the step which consists in in comprises oxidizing a compound selected from the

35 troducing Sulphuric acid into the reaction mix group consisting of cyclohexanol, cyclohexanone, 110

ture before the oxidation is completed. and the 3- and 4-alkyl Substituted derivatives

2. In the preparation of adipic acid and the thereof with nitric acid having incorporated

beta-alkyl substituted derivatives thereof by the therewith a relatively small amount of a catalyst

oxidation of a compound selected from the group from the class consisting of copper, copper oxide,

40 consisting of cyclohexanol, cyclohexanone, and and Salts of copper. 115

the 3- and 4-alkyl substituted derivatives thereof 10. The preparation of beta-methyl adipic acid

With nitric acid having incorporated therewith a which comprises introducing a compound from

catalytic compound, the step which consists in the class consisting of 3- and 4-methyl cyclo

introducing sulphuric acid into the reaction mix \hexanol and 3- and 4-methyl cyclohexanone into

ture before the oxidation is completed. nitric acid of a density between about 32° and 120

3. The method of preparing adipic acid and about 43 Baumé having incorporated therewith

the beta-alkyl substituted derivatives thereof a relatively small amount of a catalytic con

which comprises oxidizing a compound selected pound, simultaneously introducing into the re

from the group consisting of cyclohexanol, cyclo action mixture between about 0.20 and about 1.35

50 hexanone, and the 3- and 4-alkyl Substituted moles of concentrated sulphuric acid per one mole 25

derivatives thereof with nitric acid having in

corporated therewith a catalyst and a compound of compound from the first named class while

maintaining the reaction mixture at a tempera

from the class consisting of Sulphuric acid and ture between about 35° and 70° C. and with agita

an acid sulphate. tion thereof, cooling the reaction mixture to pre

4. The method of preparing adipic acid and cipitate beta-methyl adipic acid crystals there 30

the beta-alkyl substituted derivatives thereof

which comprises oxidizing a compound selected from, liquor.

and separating the crystals from the mother

from the group consisting of cyclohexanol, cyclo 11. The method for the preparation of beta

hexanone, and the 3- and 4-alkyl substituted tertiary-butyl adipic acid which comprises intro

derivatives thereof with nitric acid having incor ducing 4-tertiary-butyl cyclohexanol into nitric 18

porated therewith a catalyst and sulphuric acid. acid of a density between about 32 and about

5. The method of preparing adipic acid which 43 Baumé having incorporated therewith a rela

comprises oxidizing a compound from the class tively small amount of a catalytic compound,

consisting of cyclohexanol and cyclohexanone simultaneously introducing into the reaction mix

with nitric acid having incorporated therewith ture between about 0.20 and about 1.35 moles of 140

a relatively small amount of a catalyst from the concentrated sulphuric acid per one mole of 4

class consisting of copper, Copper Oxide, and tertiary-butyl cyclohexanol while maintaining

salts of copper, in the presence of concentrated the reaction mixture at a temperature between

Sulphuric acid. about 35° and 70° C. and with agitation thereof,

6. The method of preparing adipic acid which cooling the reaction mixture to precipitate beta- 145

comprises oxidizing a compound from the class tertiary-butyl adipic acid crystals therefrom, and

consisting of cyclohexanol and cyclohexanone separating the crystals from the mother liquor.

With nitric acid having incorporated therewith 12. Beta-tertiary-butyl adipic acid.

a relatively small amount of a catalyst from the RAPH. P. PERKINS.

class consisting of copper, copper oxide, and ANOREW J. OEZER, 1)

You might also like

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- US3093691Document2 pagesUS3093691Ayu GirlsNo ratings yet

- US2343534 (Proses Sulit)Document4 pagesUS2343534 (Proses Sulit)aris_nurhidayatNo ratings yet

- United States Patent 0: '3, l50, l74 ICCDocument2 pagesUnited States Patent 0: '3, l50, l74 ICCMuhammadAmdadulHoqueNo ratings yet

- ' United States Patent Office : Ljatented Nov. 7, 195.0Document2 pages' United States Patent Office : Ljatented Nov. 7, 195.0Agape Ruth BaliloNo ratings yet

- Acetyl Salicylate PDFDocument3 pagesAcetyl Salicylate PDFtechkasambaNo ratings yet

- United States Patent O?ice: 15H: LLQ?ZDocument3 pagesUnited States Patent O?ice: 15H: LLQ?ZadamNo ratings yet

- US4780224Document4 pagesUS4780224Mohamad Reza JahanbakhshNo ratings yet

- ,425,500. Patented Aug. 8, 1922.: H. W., Matheson and G, E, GrattanDocument3 pages,425,500. Patented Aug. 8, 1922.: H. W., Matheson and G, E, GrattanrzgarNo ratings yet

- Design Report 1Document12 pagesDesign Report 123vikenNo ratings yet

- Manufacture: 1. Oxalic Acid From Sodium FormateDocument10 pagesManufacture: 1. Oxalic Acid From Sodium Formate23viken100% (1)

- Filed June l5, 1935Document6 pagesFiled June l5, 1935Yustinus Selis ToronNo ratings yet

- Atent Offitce: Patented July '5, 1927Document2 pagesAtent Offitce: Patented July '5, 1927Yustinus Selis ToronNo ratings yet

- US ButyraldehydeDocument2 pagesUS ButyraldehydeAstriany AnyNo ratings yet

- Benzoic Acid To Benzaldehyde, P-Nitrobenzoic Acid To Nitrobenzene and More.Document3 pagesBenzoic Acid To Benzaldehyde, P-Nitrobenzoic Acid To Nitrobenzene and More.banjo010% (1)

- Glycerol Acetylation 1Document224 pagesGlycerol Acetylation 1Matheus ZimermannNo ratings yet

- United States Patent (191: MercadeDocument4 pagesUnited States Patent (191: MercadeSoufi BadrNo ratings yet

- Con Acido Acrílico US3753968Document4 pagesCon Acido Acrílico US3753968Agustin CantilloNo ratings yet

- United States Patent Office: 1. 2 This Serves Not Only To Free Nitrourea From The Acid SoluDocument3 pagesUnited States Patent Office: 1. 2 This Serves Not Only To Free Nitrourea From The Acid SoluSmokeNo ratings yet

- Production of Sodium DithioniteDocument10 pagesProduction of Sodium DithioniteDhaval PadaliaNo ratings yet

- US3373187Document2 pagesUS3373187Haruo YamashitaNo ratings yet

- W United States Patent Office: Patented Mar. 21, 1961Document3 pagesW United States Patent Office: Patented Mar. 21, 1961tajudinNo ratings yet

- Us 2731492Document3 pagesUs 2731492ayuniNo ratings yet

- US3945843Document3 pagesUS3945843rajesh kothariNo ratings yet

- Thioglycolic Acid ProductionDocument2 pagesThioglycolic Acid Productionfake77No ratings yet

- US3036885Document2 pagesUS3036885pradipNo ratings yet

- Preparation Sulfatel: Lynn ShoemakerDocument3 pagesPreparation Sulfatel: Lynn ShoemakerMilan PetrikNo ratings yet

- United States Patent Office: Patented Nov. 7, 1950Document2 pagesUnited States Patent Office: Patented Nov. 7, 1950bayuminecraftNo ratings yet

- Semon: Waldo I,. and V. Richard DamereliDocument4 pagesSemon: Waldo I,. and V. Richard DamereliUttam PawarNo ratings yet

- US2960514Document4 pagesUS2960514PRASSAN SHAHNo ratings yet

- Indigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnDocument4 pagesIndigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnCillian CreedonNo ratings yet

- United States Patent Office: Patented Jan. I9, 1954Document2 pagesUnited States Patent Office: Patented Jan. I9, 1954JavierNo ratings yet

- Paten Basf Asam AsetatDocument2 pagesPaten Basf Asam Asetatwilliam fathNo ratings yet

- Acrylic 2520acid Methods 2520of 2520 ProductionDocument8 pagesAcrylic 2520acid Methods 2520of 2520 Productionapi-3714811No ratings yet

- United States Patent Office: Patented May 30, 1933Document5 pagesUnited States Patent Office: Patented May 30, 1933DAMIAN RAMOS CRISTHIAN JESUSNo ratings yet

- United States Patent Office: Patented Nov. 6, 1956Document2 pagesUnited States Patent Office: Patented Nov. 6, 1956Syahrul SandreaNo ratings yet

- US2373717Document2 pagesUS2373717Ruchita PoilkarNo ratings yet

- United States Patent Office: Patented Mar. 21, 1950Document2 pagesUnited States Patent Office: Patented Mar. 21, 1950alexNo ratings yet

- A Convenient Preparation of Volatile Acid ChloridesDocument4 pagesA Convenient Preparation of Volatile Acid ChloridesScott SwartzNo ratings yet

- Determination of Gamma No and TSDocument3 pagesDetermination of Gamma No and TSAditya ShrivastavaNo ratings yet

- Process For AADocument15 pagesProcess For AASantiago BorgesNo ratings yet

- This Invention Relates To A Process For Making A Stable CopperDocument3 pagesThis Invention Relates To A Process For Making A Stable CopperAngel BuenoNo ratings yet

- United States: Patent OfficeDocument2 pagesUnited States: Patent OfficeShandy ArmandoNo ratings yet

- Acetylated Castor Oil - Preparation and Thermal DecompositionDocument7 pagesAcetylated Castor Oil - Preparation and Thermal DecompositionPee Hai NingNo ratings yet

- AlkylationDocument9 pagesAlkylationabhishek sharma100% (1)

- 49 2 Philadelphia 10-04 1181Document4 pages49 2 Philadelphia 10-04 1181lumengentiunNo ratings yet

- Process of Acetic Acid From AcetaldehydeDocument3 pagesProcess of Acetic Acid From AcetaldehydeManish PatelNo ratings yet

- Paten Asm Astat Dari Asetaldehid TH1975Document4 pagesPaten Asm Astat Dari Asetaldehid TH1975Agus PurnamaNo ratings yet

- Patent US2446233Document3 pagesPatent US2446233Alan ConnorNo ratings yet

- Chem 101.1 Back Titration Formal ReportDocument5 pagesChem 101.1 Back Titration Formal ReporttoopiarNo ratings yet

- Esterification of Oleic Acid With Glycerol in The PresenceDocument5 pagesEsterification of Oleic Acid With Glycerol in The PresencesapastuchNo ratings yet

- Translate Paten US5976485Document24 pagesTranslate Paten US5976485Lenywulandari AyundaNo ratings yet

- 0304 S1 Abs PDFDocument7 pages0304 S1 Abs PDFFajar RumantoNo ratings yet

- United States Patent (19) : Koch Et A1Document3 pagesUnited States Patent (19) : Koch Et A1Solomon EricksonNo ratings yet

- United States Patent Office: Patented June 29, 1948Document3 pagesUnited States Patent Office: Patented June 29, 1948jhartmann8No ratings yet

- Sheffield High-Temperature Combustion Method (Belcher and Spooner, 1955)Document4 pagesSheffield High-Temperature Combustion Method (Belcher and Spooner, 1955)aaaNo ratings yet

- United States Patent (191: Merk Er AlDocument4 pagesUnited States Patent (191: Merk Er AlPlatiitha Winchester WilliamsNo ratings yet

- US4495107ADocument2 pagesUS4495107AWojciech RedutkoNo ratings yet

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresFrom EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresRating: 5 out of 5 stars5/5 (1)

- A Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidFrom EverandA Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidNo ratings yet

- US2343534 (Proses Sulit)Document4 pagesUS2343534 (Proses Sulit)aris_nurhidayatNo ratings yet

- Carbosulfan 55285-14-8Document7 pagesCarbosulfan 55285-14-8aris_nurhidayatNo ratings yet

- Matsumoto2018 (Gak Jelas)Document6 pagesMatsumoto2018 (Gak Jelas)aris_nurhidayatNo ratings yet

- cv1p0018 (Sudah)Document4 pagescv1p0018 (Sudah)aris_nurhidayatNo ratings yet

- CN102924301ADocument6 pagesCN102924301Aaris_nurhidayatNo ratings yet

- Lefevre1990 (Sudah)Document2 pagesLefevre1990 (Sudah)aris_nurhidayatNo ratings yet

- CN103230724BDocument6 pagesCN103230724Baris_nurhidayatNo ratings yet

- Microalgae PDFDocument20 pagesMicroalgae PDFaris_nurhidayatNo ratings yet

- Chemistry 211 Experiment 7 (Sudah)Document6 pagesChemistry 211 Experiment 7 (Sudah)aris_nurhidayatNo ratings yet

- Atkins-Chapter05 Lect02Document17 pagesAtkins-Chapter05 Lect02aris_nurhidayatNo ratings yet

- US3870756 (Sudah)Document4 pagesUS3870756 (Sudah)aris_nurhidayatNo ratings yet

- Pchem3 ch21Document32 pagesPchem3 ch21aris_nurhidayatNo ratings yet

- Lab Report Flame TestDocument7 pagesLab Report Flame TestRikachuNo ratings yet

- Review of Development The Application Alkaline Surfactant and Polymer in EOR TechnologyDocument15 pagesReview of Development The Application Alkaline Surfactant and Polymer in EOR TechnologyALVE DINO RUMANDANo ratings yet

- 16 Types of 3D Printer Filaments - Comparison & List of 3D MaterialsDocument1 page16 Types of 3D Printer Filaments - Comparison & List of 3D MaterialsCliqueLearn E-LearningNo ratings yet

- Human Activity Impact On EnvironmentDocument29 pagesHuman Activity Impact On EnvironmentHemant KushwahNo ratings yet

- Home 2 Updates Questions Jobs: Add NewDocument18 pagesHome 2 Updates Questions Jobs: Add NewweaamNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument19 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentUmar OmarNo ratings yet

- Experiments NotesDocument53 pagesExperiments NotesJulianne TanNo ratings yet

- The Language of Chemistry - Lesson - 3Document11 pagesThe Language of Chemistry - Lesson - 3samsonNo ratings yet

- IIT-JAM 2005 With Solution PDFDocument22 pagesIIT-JAM 2005 With Solution PDFgaurav100% (3)

- A New Method of Analyzing Thermogravimetric Data (Ozawa)Document6 pagesA New Method of Analyzing Thermogravimetric Data (Ozawa)namsaigon316No ratings yet

- Balfour Class Rings Brochure - School Year 2010Document32 pagesBalfour Class Rings Brochure - School Year 2010timfox80No ratings yet

- Literature Review Air PollutionDocument5 pagesLiterature Review Air Pollutionaflsbegdo100% (2)

- 5107 FL en Profi-Tipp Co2Document8 pages5107 FL en Profi-Tipp Co2Bung Ma'rufNo ratings yet

- Characterization Studies Waste Plastic Oil and Its BlendsDocument12 pagesCharacterization Studies Waste Plastic Oil and Its BlendsPieyah ChomelNo ratings yet

- CH New Horizon Public School: Practice Worksheet (October - 2023)Document4 pagesCH New Horizon Public School: Practice Worksheet (October - 2023)Vasudhara yadavNo ratings yet

- Grade 8 BUDGET OF WORK IN ScienceDocument7 pagesGrade 8 BUDGET OF WORK IN ScienceYanika Baras100% (1)

- RICE SEED TREATMENT AND RECOATING WITH POLYMERS การรักษาเมล็ดและการเคลือบด้วยโพลีเมอร์Document8 pagesRICE SEED TREATMENT AND RECOATING WITH POLYMERS การรักษาเมล็ดและการเคลือบด้วยโพลีเมอร์Phuwanai PalakachenNo ratings yet

- Manual MSA Lineas de VidaDocument92 pagesManual MSA Lineas de VidaHllcNo ratings yet

- Effect of Nitrogen, Phosphorus and Potassium Fertilization On Growth, Yield and Quality of Pomegranate 'Kandhari'Document7 pagesEffect of Nitrogen, Phosphorus and Potassium Fertilization On Growth, Yield and Quality of Pomegranate 'Kandhari'Faten AbdallahNo ratings yet

- Textile WastewaterDocument43 pagesTextile Wastewatersujal jhaNo ratings yet

- 3 9 1 bMSDS-Reagen-LaboratoriumDocument4 pages3 9 1 bMSDS-Reagen-Laboratoriumswahyulisah50% (2)

- Repuestos Zoomlion HBT40Document1 pageRepuestos Zoomlion HBT40Cristian Javier SierraNo ratings yet

- Chapter 5 WSEE-4192Document31 pagesChapter 5 WSEE-4192Esayas DerejeNo ratings yet

- ThermochemistryDocument17 pagesThermochemistryBrian Smith100% (9)

- Hard & Soft Acids and Bases: B.Sc. III YearDocument14 pagesHard & Soft Acids and Bases: B.Sc. III YearGaurav 016No ratings yet

- Certificado de Análisis de Resina Con 97.8% de CannabinoidesDocument2 pagesCertificado de Análisis de Resina Con 97.8% de CannabinoidesSativa Info PerúNo ratings yet

- Read Through Each Section and Answer The Following QuestionsDocument4 pagesRead Through Each Section and Answer The Following QuestionsAngelica Calamba CalicaNo ratings yet

- A Review On Comparative Study Between Emulsion, Microemulsion and NanoemulsionDocument8 pagesA Review On Comparative Study Between Emulsion, Microemulsion and NanoemulsionHoàngNo ratings yet

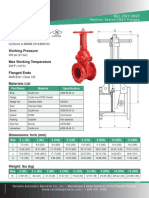

- OS&Y Gate Valve PDFDocument1 pageOS&Y Gate Valve PDFAhmed Mohamed Abd Elhakam100% (1)

- TLE - Hazard Control and PreventionDocument9 pagesTLE - Hazard Control and Preventionmarci.alimb16No ratings yet