Professional Documents

Culture Documents

Control Narrative: Gas Facilities Projects Department Northern Area Gas Projects Division (Nagpd)

Control Narrative: Gas Facilities Projects Department Northern Area Gas Projects Division (Nagpd)

Uploaded by

Muhammad SalmanCopyright:

Available Formats

You might also like

- 28037.eng - Sta.std - Instrumentation & AutomationDocument49 pages28037.eng - Sta.std - Instrumentation & AutomationMatteoNo ratings yet

- WHCP - Design Calculation Notes For Accumulators, Pumps and Electrical MotorsDocument17 pagesWHCP - Design Calculation Notes For Accumulators, Pumps and Electrical MotorsYasin ElaswadNo ratings yet

- ECA-00-PCS-SPE-0011 - Rev3-INSTRUMENTATION FOR PACKAGED EQUIPMENTDocument19 pagesECA-00-PCS-SPE-0011 - Rev3-INSTRUMENTATION FOR PACKAGED EQUIPMENThcsharma1967No ratings yet

- 5140520-0000-SOW-TE-0204 Rev 01CDocument37 pages5140520-0000-SOW-TE-0204 Rev 01CEngTamerRabahNo ratings yet

- PP-965006 - C Analyzer Shelter & Local PanelsDocument50 pagesPP-965006 - C Analyzer Shelter & Local Panelszizu1234100% (2)

- BIBLE STUDY WORKSHOP USING PHOTOTHEOLOGY BY PASTOR IVOR MYERS For Care GroupDocument2 pagesBIBLE STUDY WORKSHOP USING PHOTOTHEOLOGY BY PASTOR IVOR MYERS For Care GroupMeresa W. MartinNo ratings yet

- Marjan Development Program BI-10-09003: Tanajib Gas Plant (TGP)Document14 pagesMarjan Development Program BI-10-09003: Tanajib Gas Plant (TGP)Maged GalalNo ratings yet

- R789977015 PDFDocument15 pagesR789977015 PDFElie AouadNo ratings yet

- SK-A-YCC-021 Sales Gas Filtration System FSDDocument30 pagesSK-A-YCC-021 Sales Gas Filtration System FSDtouseef88No ratings yet

- Marjan Development Program: Tanajib Gas Plant (TGP)Document7 pagesMarjan Development Program: Tanajib Gas Plant (TGP)Maged GalalNo ratings yet

- 000-SA-E-050026 MR Analyzer Shelter & Process AnalyzersDocument57 pages000-SA-E-050026 MR Analyzer Shelter & Process Analyzerszizu1234No ratings yet

- Cutover Plan at SUBSTATION 10, 77, 79 AND 215 New BuildingsDocument20 pagesCutover Plan at SUBSTATION 10, 77, 79 AND 215 New Buildingsimri ssNo ratings yet

- Model Construction Scope of Work HRDH-1229 (GAS WELL)Document41 pagesModel Construction Scope of Work HRDH-1229 (GAS WELL)rajum465100% (1)

- Sil Study Report: Na Capital Program ManagementDocument20 pagesSil Study Report: Na Capital Program Managementsalman1111aNo ratings yet

- Te 049044Document15 pagesTe 049044salman1111a100% (1)

- TE-419843 - Rev.A - MR For Chemical Injection PackageDocument76 pagesTE-419843 - Rev.A - MR For Chemical Injection Packagerizwan.zamanNo ratings yet

- Be958823113 PDFDocument113 pagesBe958823113 PDFbabadapbadapNo ratings yet

- TE-419895-001 - 863-U-3001 - Gas Corrosion Inhibitor Injection Package - Rev.BDocument16 pagesTE-419895-001 - 863-U-3001 - Gas Corrosion Inhibitor Injection Package - Rev.Brizwan.zamanNo ratings yet

- Calculation: Waste Water Generation and Holding Tank Sizing For Bgcs-5 Sepco & Labor CampDocument5 pagesCalculation: Waste Water Generation and Holding Tank Sizing For Bgcs-5 Sepco & Labor Camp龙琦No ratings yet

- H348837 - FP Sys StudyDocument15 pagesH348837 - FP Sys Studyxxmorph3u5xx0% (1)

- TE-419888-001 - 869-U-1004 - ANTIFOAM INJECTION PACKAGE - Rev.BDocument13 pagesTE-419888-001 - 869-U-1004 - ANTIFOAM INJECTION PACKAGE - Rev.Brizwan.zamanNo ratings yet

- 12 MGDP I 1045 0 (Spec For WHCP)Document26 pages12 MGDP I 1045 0 (Spec For WHCP)Ricardo NapitupuluNo ratings yet

- SamplingDocument20 pagesSamplingShesharam ChouhanNo ratings yet

- P&IDDocument4 pagesP&IDdarshanNo ratings yet

- IVD 21 BQ 195 AGOCO Nafoora Metering SkidsDocument7 pagesIVD 21 BQ 195 AGOCO Nafoora Metering Skidsnader mahfoudhiNo ratings yet

- 769-E-1102 Propane Chiller - P2 PDFDocument8 pages769-E-1102 Propane Chiller - P2 PDFamit8808No ratings yet

- SAES-B-062 Editorial Revision-16 March 2023Document22 pagesSAES-B-062 Editorial Revision-16 March 2023Faheem Khan100% (1)

- HAZOP Study Worksheet 19 Dec 2019 - Remarks1223Document52 pagesHAZOP Study Worksheet 19 Dec 2019 - Remarks1223Mizanul HoqueNo ratings yet

- 000-A-JD-801400-231 - Rev B SOW - Part-3Document6 pages000-A-JD-801400-231 - Rev B SOW - Part-3Senthil KumarNo ratings yet

- Method Statement For Data & Communication Equipments & FOC InstallationDocument13 pagesMethod Statement For Data & Communication Equipments & FOC InstallationziaurrehmanNo ratings yet

- D44 A Re 225498 PDFDocument112 pagesD44 A Re 225498 PDFGN SYSTECHNo ratings yet

- Saes B 058Document15 pagesSaes B 058Rashid ArshadNo ratings yet

- Detail Design: Instrument Air Back Up System by Nitrogen (N2) GasDocument16 pagesDetail Design: Instrument Air Back Up System by Nitrogen (N2) Gasnas_mech8208No ratings yet

- Characteristics Tubulures: + 1 Blind Flange Threaded 1"1/2 NPT For Nozzles N4 & N5Document1 pageCharacteristics Tubulures: + 1 Blind Flange Threaded 1"1/2 NPT For Nozzles N4 & N5MEHDINo ratings yet

- Technical Specification Fire Detection and Alarm System: Saudi Arabian Oil CompanyDocument13 pagesTechnical Specification Fire Detection and Alarm System: Saudi Arabian Oil CompanyJohn Philip BuntalesNo ratings yet

- 5140520-0000-SOW-TE-0204 Rev 01CDocument37 pages5140520-0000-SOW-TE-0204 Rev 01CEngTamerRabahNo ratings yet

- BLDG Piob-001 Lighting Calculation Report Package 1 - Unit A03Document89 pagesBLDG Piob-001 Lighting Calculation Report Package 1 - Unit A03vasuNo ratings yet

- HEI-IMS-CHEM-SOP10 Sodium Hypochlorite Plant OperationDocument8 pagesHEI-IMS-CHEM-SOP10 Sodium Hypochlorite Plant Operationrizwan chNo ratings yet

- H274739001P00 PDFDocument30 pagesH274739001P00 PDFAswin KurupNo ratings yet

- Flare Tip and Ignition PackageDocument8 pagesFlare Tip and Ignition Packageemartinez_bernal5989100% (2)

- Mas-Rtcf-Ms-El-001-Cable TrayDocument10 pagesMas-Rtcf-Ms-El-001-Cable TrayASHIQUE ZAFARNo ratings yet

- Progress Summary CTR 049 - Teras Flare System Improvement DedDocument41 pagesProgress Summary CTR 049 - Teras Flare System Improvement DedRokan PipelineNo ratings yet

- Sample Cause & EffectDocument1 pageSample Cause & EffectNishant AroraNo ratings yet

- Marjan Development Program: Tanajib Gas Plant (TGP)Document11 pagesMarjan Development Program: Tanajib Gas Plant (TGP)Maged GalalNo ratings yet

- 5140520-0000-SPC-TE-0205 Rev 01BDocument21 pages5140520-0000-SPC-TE-0205 Rev 01BEngTamerRabahNo ratings yet

- Design Basis - Package - B224-999-80-43 EDB-1002Document12 pagesDesign Basis - Package - B224-999-80-43 EDB-1002Esakki muthu100% (1)

- Drawings 001Document23 pagesDrawings 001John Philip BuntalesNo ratings yet

- Saudi Aramco: Well LocationsDocument7 pagesSaudi Aramco: Well LocationsMahrouz MadoNo ratings yet

- Temporary ScopeDocument34 pagesTemporary ScopeDheeraj Dheeru100% (1)

- Peq001-03-Dcom-0000-Pl-T601-3001-2 - General Drawing Tlt-La-3170Document1 pagePeq001-03-Dcom-0000-Pl-T601-3001-2 - General Drawing Tlt-La-3170Carlin BabuchasNo ratings yet

- Schedule B - Job SepcificationsDocument129 pagesSchedule B - Job SepcificationsKalpana SrinivasNo ratings yet

- Air Release VacuumDocument7 pagesAir Release VacuumsudjonoNo ratings yet

- 8yetc DWG PR 1010 21 - Rev - B0 PDFDocument10 pages8yetc DWG PR 1010 21 - Rev - B0 PDFmohsin moinNo ratings yet

- Mechanical Data Sheet For Fuel Gas FiltersDocument4 pagesMechanical Data Sheet For Fuel Gas FilterssudjonoNo ratings yet

- Ce Calb02 PDFDocument72 pagesCe Calb02 PDFErin JohnsonNo ratings yet

- DE-119954 - Procedure For Fabrication and Installation of Submarine PipelinesDocument47 pagesDE-119954 - Procedure For Fabrication and Installation of Submarine PipelinesAmr MahmoudNo ratings yet

- 000-A-JD-801400-231 - Rev B SOW - Part-2 PDFDocument6 pages000-A-JD-801400-231 - Rev B SOW - Part-2 PDFSenthil KumarNo ratings yet

- Basics of Wellhead Control Panel (WHCP) Instrumentation ToolsDocument21 pagesBasics of Wellhead Control Panel (WHCP) Instrumentation ToolsJOHNSON SANYANo ratings yet

- Rek 85374012Document12 pagesRek 85374012furqanNo ratings yet

- Lightning Protection Calculations New BuildingsDocument22 pagesLightning Protection Calculations New Buildingsimri ssNo ratings yet

- Pep 20083221Document221 pagesPep 20083221imri ssNo ratings yet

- RecommendationsDocument1 pageRecommendationsMuhammad SalmanNo ratings yet

- Calc Report EMERSONDocument2 pagesCalc Report EMERSONMuhammad SalmanNo ratings yet

- Appendix B - HAZOP WorksheetDocument6 pagesAppendix B - HAZOP WorksheetMuhammad SalmanNo ratings yet

- Rap 46001001Document1 pageRap 46001001Muhammad SalmanNo ratings yet

- Ecr Ins 005 Sa ResponseDocument1 pageEcr Ins 005 Sa ResponseMuhammad SalmanNo ratings yet

- Esd Tbe MR 011Document1 pageEsd Tbe MR 011Muhammad SalmanNo ratings yet

- RDP48052042Document42 pagesRDP48052042Muhammad SalmanNo ratings yet

- Workshop Creativity Input WorksheetDocument9 pagesWorkshop Creativity Input WorksheetMuhammad SalmanNo ratings yet

- TBC-Alderlay - SLFE Response 30th Mar 2020Document24 pagesTBC-Alderlay - SLFE Response 30th Mar 2020Muhammad SalmanNo ratings yet

- Appendix-A: Attendance SheetDocument41 pagesAppendix-A: Attendance SheetMuhammad SalmanNo ratings yet

- TBC - SWTF - SLFE Response - 30th MarchDocument21 pagesTBC - SWTF - SLFE Response - 30th MarchMuhammad SalmanNo ratings yet

- CF.19.D032 - TBC-Petronash - SLFE Response-30th MarchDocument30 pagesCF.19.D032 - TBC-Petronash - SLFE Response-30th MarchMuhammad SalmanNo ratings yet

- Replace Crude Oil Samplers at Yanbu North TerminalDocument4 pagesReplace Crude Oil Samplers at Yanbu North TerminalMuhammad SalmanNo ratings yet

- Componnent Failure ValuesDocument82 pagesComponnent Failure ValuesMuhammad SalmanNo ratings yet

- ID Index File On Class: Saudi Aramco: Company General UseDocument7 pagesID Index File On Class: Saudi Aramco: Company General UseMuhammad SalmanNo ratings yet

- Taking The Control System For Granted - Ensuring The Integrity of Sub-Sil Instrumented FunctionsDocument5 pagesTaking The Control System For Granted - Ensuring The Integrity of Sub-Sil Instrumented FunctionsMuhammad SalmanNo ratings yet

- Replace Crude Oil Samplers at Yanbu North TerminalDocument4 pagesReplace Crude Oil Samplers at Yanbu North TerminalMuhammad SalmanNo ratings yet

- Replace Crude Oil Samplers at Yanbu North TerminalDocument4 pagesReplace Crude Oil Samplers at Yanbu North TerminalMuhammad SalmanNo ratings yet

- 1-POC Termination 2 - FTA Numbers Were Changed and Assignment Was Changed 3 - Iom NUMBER 4 - Poc LAN CABINET ALARM Pib-1Document1 page1-POC Termination 2 - FTA Numbers Were Changed and Assignment Was Changed 3 - Iom NUMBER 4 - Poc LAN CABINET ALARM Pib-1Muhammad SalmanNo ratings yet

- FT 205Document1 pageFT 205Muhammad SalmanNo ratings yet

- Project Title: Replace Crude Oil Samplers - Yanbu North TerminalDocument1 pageProject Title: Replace Crude Oil Samplers - Yanbu North TerminalMuhammad SalmanNo ratings yet

- Jazan: CausesDocument1 pageJazan: CausesMuhammad SalmanNo ratings yet

- Appendix PDFDocument1 pageAppendix PDFMuhammad SalmanNo ratings yet

- Try Jetsign, The Easiest Way To Sign Any Document, AnywhereDocument1 pageTry Jetsign, The Easiest Way To Sign Any Document, AnywhereMuhammad SalmanNo ratings yet

- Saudi Arabian Oil Company: Instrument Specification Sheet - Hydrocarbon Liquid Sampling SystemsDocument1 pageSaudi Arabian Oil Company: Instrument Specification Sheet - Hydrocarbon Liquid Sampling SystemsMuhammad SalmanNo ratings yet

- Replace Crude Oil Samplers at Yanbu North TerminalDocument4 pagesReplace Crude Oil Samplers at Yanbu North TerminalMuhammad SalmanNo ratings yet

- Thursday If Got Out at 9Document2 pagesThursday If Got Out at 9Muhammad SalmanNo ratings yet

- PZV 200a/bDocument1 pagePZV 200a/bMuhammad SalmanNo ratings yet

- P&id: Na-A64714.001Document2 pagesP&id: Na-A64714.001Muhammad SalmanNo ratings yet

- WAMU Servicer GuideDocument136 pagesWAMU Servicer GuideHolly Hill100% (2)

- Lesson 14 - Judicial OrderDocument12 pagesLesson 14 - Judicial Orderdorindodo26maiNo ratings yet

- Jean Jac RousseauDocument19 pagesJean Jac RousseauFroilan TinduganNo ratings yet

- Class and Teachers ProgramDocument2 pagesClass and Teachers ProgramKath BlancoNo ratings yet

- Theoretical Perspectives of Corporate Governance: and Economics, 3 (4), 166-175Document10 pagesTheoretical Perspectives of Corporate Governance: and Economics, 3 (4), 166-175Naod MekonnenNo ratings yet

- Apply For Executive Paramedic Nurse at IndiGo PDFDocument4 pagesApply For Executive Paramedic Nurse at IndiGo PDFPuja SinghNo ratings yet

- ELBIT SYSTEMS - PRESS RELEASE - Flight Training Program of The Hellenic Air ForceDocument2 pagesELBIT SYSTEMS - PRESS RELEASE - Flight Training Program of The Hellenic Air ForceturandotNo ratings yet

- Conflict of Laws - Quita vs. CADocument2 pagesConflict of Laws - Quita vs. CALotus KingNo ratings yet

- Mckinsey Usps Future Bus Model2Document39 pagesMckinsey Usps Future Bus Model2Leo SaitoNo ratings yet

- Pang-Oden v. LeonenDocument2 pagesPang-Oden v. LeonenGillian CalpitoNo ratings yet

- The Netherlands Real Estate Market Outlook 2016Document16 pagesThe Netherlands Real Estate Market Outlook 2016librarian911No ratings yet

- HR Policy Manual 24. Mobile and Telephone PolicyDocument2 pagesHR Policy Manual 24. Mobile and Telephone PolicyFaizan AhmedNo ratings yet

- Audit of Overview: Auditing IsDocument26 pagesAudit of Overview: Auditing IsMaria BeatriceNo ratings yet

- Principal Deputy - Office of The National Coordinator For Health Information TechnologyDocument3 pagesPrincipal Deputy - Office of The National Coordinator For Health Information TechnologyBrian AhierNo ratings yet

- Kashmir Reader 20 Dec 2023Document8 pagesKashmir Reader 20 Dec 2023Shahnawaz Adil ShahNo ratings yet

- Violations of CommandmentsDocument2 pagesViolations of CommandmentsMichael Greenman100% (1)

- Astm D 3172-13 - FCDocument2 pagesAstm D 3172-13 - FCP. K chaturvediNo ratings yet

- PDFDocument1 pagePDFSEKHAR PATELNo ratings yet

- DIN 910 - Screw Plugs With Collar and Outer Hexagon, Cylindrical ThreadDocument6 pagesDIN 910 - Screw Plugs With Collar and Outer Hexagon, Cylindrical ThreadoomoomNo ratings yet

- Cebu Normal University: College Online Applicant Profile SheetDocument1 pageCebu Normal University: College Online Applicant Profile SheetKyllua Theoty Entendez DesolocNo ratings yet

- Pak Affairs Past Paper Analysis 2021Document6 pagesPak Affairs Past Paper Analysis 2021ZuhaibOdho100% (1)

- CA Inter Cost Important Questions For CA Nov'22Document93 pagesCA Inter Cost Important Questions For CA Nov'2202 Tapasvee ShahNo ratings yet

- 3 (Easily) Ignorable Signs You Are With The Wrong Person Darshak Rana in P.S. I Love YouDocument5 pages3 (Easily) Ignorable Signs You Are With The Wrong Person Darshak Rana in P.S. I Love YouthomNo ratings yet

- Place of Supply-GSTDocument7 pagesPlace of Supply-GSTrommelNo ratings yet

- Netflix Code EthicsDocument2 pagesNetflix Code EthicsSofia ChernovaNo ratings yet

- F Nicholas Gruner Crucial Truths To Save Your Soul PDFDocument148 pagesF Nicholas Gruner Crucial Truths To Save Your Soul PDFRiTa SengBuNo ratings yet

- BS 3148Document10 pagesBS 3148muhammad iqbalNo ratings yet

- Disabled Access CreditDocument2 pagesDisabled Access CreditMaro AtakuotorNo ratings yet

- United States of America Before Federal Trade CommissionDocument6 pagesUnited States of America Before Federal Trade CommissionSkip OlivaNo ratings yet

Control Narrative: Gas Facilities Projects Department Northern Area Gas Projects Division (Nagpd)

Control Narrative: Gas Facilities Projects Department Northern Area Gas Projects Division (Nagpd)

Uploaded by

Muhammad SalmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Narrative: Gas Facilities Projects Department Northern Area Gas Projects Division (Nagpd)

Control Narrative: Gas Facilities Projects Department Northern Area Gas Projects Division (Nagpd)

Uploaded by

Muhammad SalmanCopyright:

Available Formats

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

ENGG CERT

MAM

AMHISSUED FO50% REVIEW

DESCRIPTION

GAS FACILITIES PROJECTS DEPARTMENT

NORTHERN AREA GAS PROJECTS DIVISION

(NAGPD)

BI-10-20897

10-20897

JO/EWO

10/13/22

REPLACE FLARE AND BURN PIT-MIDYAN

NO. DATE

REV

DISCIPLINE

ENGINEER

SLFE

DATE:

PROJECT

10/13/22

CONTROL NARRATIVE

ENGINEER

AMH FOR

DATE:

CERTIFIED

10/13/22

PROCESS AND INSTRUMENTATION CONTROL

MAM

10/13/22

DATE:

CONSTRUCTION

AGENCY

AAM

DATE:

10/13/22

Prepared by

OPERATIONS

SET

10/13/22

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

OCTOBER 2022

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

(DCC) NO. _____________________

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 1

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

ENGG CERT

MAM

TABLE OF CONTENTS

AMH

1.0 INTRODUCTION ............................................................................................................ 3

1.1 PURPOSE ...................................................................................................................... 3

1.2 FACILITIES DESCRIPTION ........................................................................................... 3

1.3 ACRONYMS & DEFINITIONS ........................................................................................ 3

1.4 CONFLICTS AND DEVIATIONS..................................................................................... 4

ISSUED FO50% REVIEW

2.0 SCOPE........................................................................................................................... 4

DESCRIPTION

2.1 GENERAL ...................................................................................................................... 4

2.2 NEW EQUIPMENT ......................................................................................................... 5

2.3 DETAILED PROCESS DESCRIPTION ........................................................................... 6

2.4 NEW SOUR WATER CONDENSATE PUMPS .................................................................... 6

2.5 CONTROL AND INSTRUMENT DESCRIPTION ............................................................. 6

3.0 INSTRUMENTATION AND CONTROL SYSTEM CONTROL NARRATIVE. .................. 6

3.1 BLOWDOWN DEGASSING VESSEL CONDENSATE PUMPS (X89-G-0016A/B/ X89-G-

0021A/B). ............................................................................................................................... 7

3.2 BLOWDOWN DEGASSING VESSEL PRODUCED WATER PUMPS (X89-G-XXX3A/B/

10-20897

JO/EWO

X89-G-XXX4A/B). ................................................................................................................ 14

4.0 APPENDIX A: ACRONYMS AND DEFINITIONS.......................................................... 21

5.0 APPENDIX B: APPLICABLE DOCUMENTS ............................................................... 26

10/13/22

NO. DATE

REV

DISCIPLINE

ENGINEER

SLFE

10/13/22

DATE:

PROJECT

ENGINEER

AMH

10/13/22

DATE:

CERTIFIED

MAM

10/13/22

DATE:

CONSTRUCTION

AGENCY

AAM

10/13/22

DATE:

OPERATIONS

SET

10/13/22

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

(DCC) NO. _____________________

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 2

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

1.0 INTRODUCTION

ENGG CERT

MAM

1.1 PURPOSE

AMH

The purpose of this document is to describe the Control Philosophies for the Replace Flare

and Burn Pit- Midyan Gas Plant (MGP), BI-10-200897-001). The Control Philosophies are

developed to provide sufficient details to enable the control engineer to understand the

process intent for the control system and convey the control philosophy to operations

personnel. In this document, only complex control strategies including sequencing loops are

described to obtain safe operation during startup, shutdown and normal operation and to

ISSUED FO50% REVIEW

prevent hazard to environment, personnel and equipment.

DESCRIPTION

This document together with the project specification for Scope of Work and the referenced

Saudi Aramco (SA) standards, material specifications and project specifications shall be

used to define the specific requirements of the Control System required for BI-10-200897-

0001 project, “REPLACE FLARE AND BURN PIT- MIDYAN GAS PLANT (MGP)” PLANT-

X89.

1.2 FACILITIES DESCRIPTION

The main objective of the project is to “REPLACE FLARE AND BURN PIT- MIDYAN GAS

10-20897

JO/EWO

PLANT (MGP)”.

Midyan Gas Processing facility purpose is to support Saudi Aramco’s corporate strategy to

10/13/22

DATE

meet the Kingdom’s energy demands by providing cheap, efficient and environmentally

friendly fuel for power generation in the Kingdom’s West Coast region i.e., Duba Power

NO.

REV

Plant. The facility is planned to be decommissioned in 2030 to avoid conflict with NEOM

A

DISCIPLINE development.

ENGINEER

SLFE

10/13/22

To mitigate/minimize Midyan Gas Plant elevated flare/burn pits flame & smoke visibility

DATE:

issues to NEOM development MGP existing elevated flare(X89-U-0003) will be replaced with

PROJECT

ENGINEER a new Multipoint Ground Flare (MGF) & existing burn pit(X89-U-0002) will be replaced with

AMH new closed hydrocarbon drain system. The associated piping of an existing elevated flare /

DATE:

10/13/22 burn pit will be decommissioned and demolished.

CERTIFIED

MAM

The Project shall expand the existing DCS and ESD Honeywell system located in the Rack

10/13/22

DATE: Room to Monitor and Control the new equipment under this BI-10-20897.

CONSTRUCTION

AGENCY

AAM The proposed process control philosophy can be implemented by utilizing the existing

10/13/22 Operation and Maintenance room control system and operator workstation. All the

DATE:

OPERATIONS associated operations shall be fully integrated with existing operator workstations, plant

SET

network and emergency control center.

10/13/22

DATE:

1.3 ACRONYMS & DEFINITIONS

CONTROL NUMBER

VERIFICATION

When used in this or referenced documents the following words are used in the manner

EDSD

described below:

DATE:

BY:

‘Shall’ and ‘must’ are used in the imperative sense.

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

‘Will’ is used in the preferred sense.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

(DCC) NO. _____________________

‘May’ is used in a permissive sense to state authority or permission to do the act prescribed

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 3

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

or provide the function being defined in the prescribed manner, and the words ‘no person

ENGG CERT

may….’ Or ‘a person may not….’ mean that no person is required, authorized, permitted to

MAM

do the act prescribed, and the words ‘a… may not ….’ mean that the item being described is

not required, authorized, or permitted in the prescribed manner.

AMH

‘Includes’ means ‘includes but not limited to’.

‘COMPANY’ means a SAUDI ARAMCO organization (ARAMCO Services COMPANY,

ARAMCO Overseas COMPANY, SAUDI ARAMCO)

ISSUED FO50% REVIEW

‘CONTRACTOR’ means LSTK contractor or EPC contractor depending on the procurement

DESCRIPTION

method selected for the project. There may be more than one CONTRACTOR involved in

the project. In this case, the term CONTRACTOR refers to all applicable contractors.

‘VENDOR’ means the company providing the PCS to which this specification is applicable.

See Appendix A of this document for acronyms and definition of terms used in this

document.

1.4 CONFLICTS AND DEVIATIONS

10-20897

JO/EWO

If any inconsistency or conflict exists between this specification, and other project or Saudi

Aramco documents, industry standards or drawings, the inconsistency shall be brought to

the attention of the COMPANY / CONTRACTOR(s) for resolution at the time of submitting

10/13/22

DATE

quotation.

2.0 SCOPE

NO.

REV

DISCIPLINE

ENGINEER

SLFE 2.1 GENERAL

10/13/22

DATE:

PROJECT

The new facilities proposed as part of the BI-10-20897: “REPLACE FLARE AND BURN PIT-

ENGINEER MIDYAN GAS PLANT (MGP)” include the following additional equipment:

AMH

•

10/13/22

DATE: The existing Burn Pit is designed to handle the total liquid from the Condensate Surge Drum, and

CERTIFIED

MAM

this is the limiting case for the burn pit overall sizing. The burn pit will be decommissioned and will

10/13/22

be replaced with two Blowdown Degassing Vessels to take care of one day production to provide

DATE: buffer time for the operation to safely shutdown the plant in case of an emergency.

CONSTRUCTION

AGENCY

AAM • Hydrocarbon liquids will be flashed to 15 psig in the new degassing vessels and the flash gases

10/13/22 (approx. 1.5 MMSCFD) will be sent to the existing Flare KO Drum (X89-D-0013). Liquids will be

DATE:

pumped to the Condensate Drum via the new Blowdown Degassing Vessel Pumps. Refer to

OPERATIONS

Figure 1 for a Simplified Block Flow Diagram of Flare and Burn Pit Replacement.

SET

10/13/22 • Two new Degassing vessels will have set off new pumps.

DATE:

•

CONTROL NUMBER

Each vessel will have two pumps all pumps runs at 2X100% capacity.

VERIFICATION

•

EDSD

Temporary flare system will be installed prior to decommissioning the existing elevated flare

system.

DATE:

BY:

• New ground flare will be installed in the location of the existing burn pit. The existing burn pit will

be decommissioned accordingly.

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

• All needed instrumentations filed junction boxes and local control panel of flare will install under

A

(DCC) NO. _____________________

this BI-10-20897.

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 4

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

ENGG CERT

MAM

AMHISSUED FO50% REVIEW

DESCRIPTION

10-20897

JO/EWO

10/13/22

NO. DATE

REV

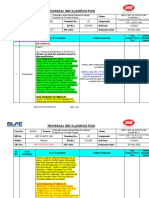

DISCIPLINE Figure 1 - Block Diagram Simplified Block Flow Diagram of Flare and Burn Pit

ENGINEER

SLFE Replacement

10/13/22

DATE:

PROJECT

ENGINEER

AMH The scope required by the project as follows:

10/13/22

DATE:

CERTIFIED 2.2 NEW EQUIPMENT

MAM

10/13/22

DATE: Equipment Tag

Equipment Description Service

CONSTRUCTION Number

AGENCY

AAM X89-D-0039A Blowdown Degassing Vessel Hydrocarbon Liquid

10/13/22 X89-D-0039B Blowdown Degassing Vessel Hydrocarbon Liquid

DATE:

OPERATIONS Blowdown Degassing Vessel Condensate Hydrocarbon Liquid

X89-G-0016A

SET Pump

10/13/22 Blowdown Degassing Vessel Condensate Hydrocarbon Liquid

DATE: X89-G-0016B

Pump

CONTROL NUMBER

VERIFICATION

Blowdown Degassing Vessel Condensate Hydrocarbon Liquid

X89-G-0021A

EDSD

Pump

Blowdown Degassing Vessel Condensate Hydrocarbon Liquid

DATE:

X89-G-0021A

BY:

Pump

X89-G-XXX3A Blowdown Degassing Vessel Produced Pump Hydrocarbon Liquid

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

X89-G-XXX3B Blowdown Degassing Vessel Produced Pump Hydrocarbon Liquid

A

(DCC) NO. _____________________

X89-G-XXX4A Blowdown Degassing Vessel Produced Pump Hydrocarbon Liquid

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 5

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

X89-G-XXX4B Blowdown Degassing Vessel Produced Pump Hydrocarbon Liquid

ENGG CERT

MAM

Temporary Flare System Flash Gases

Multi Point Ground Flare System Flash Gases

AMH

2.3 DETAILED PROCESS DESCRIPTION

2.4 NEW SOUR WATER CONDENSATE PUMPS

ISSUED FO50% REVIEW

Hydrocarbon liquids will be flashed to 15 psig in the new degassing vessels and the flash

DESCRIPTION

gases (approx. 1.5 MMSCFD) will be sent to the existing Flare KO Drum (X89-D-0013).

Liquids will be pumped to the Condensate Drum via the new Sour Water Condensate

Pumps. Each Vessel will have two Pumps all pump runs with 2X100% Capacity. Control

Operation of Pumps runs is Duty/Standby. Blowdown Degassing Vessel X89-D-0016A will

have two pumps (X89-G-0016A/B). Blowdown Degassing Vessel X89-D-0039B will have two

pumps (X89-G-0021A/B).

2.5 CONTROL AND INSTRUMENT DESCRIPTION

The new process equipment will be monitored and controlled from the Existing Process

10-20897

JO/EWO

Control System (PCS) utilizing existing operator consoles for new flare system and

Degassing Vessels.

10/13/22

DATE

Instrumentation installed on the new equipment will be interfaced with the existing DCS, and

ESD systems located in Rack room (Plants X89). Existing spare and space (floor & cabinet)

NO.

REV

will be utilized to accommodate new hardware; existing systems will be expanded by

A

DISCIPLINE providing required components, but not limited to, chassis, I/O cards, FTAs, and new

ENGINEER

SLFE

marshalling cabinets (If needed).

10/13/22

DATE:

PROJECT

Existing DCS, and ESD system manufacturers at Plant-X89 is Honeywell (C300), and

ENGINEER Honeywell (Safety Manager) respectively.

AMH

10/13/22

DATE: DCS field Instrumentation installed by this project will be connected to DCS using

CERTIFIED Foundation Field Bus or 4-20 mA with super imposed HART. ESD field Instrumentation

MAM

installed by this project will be hardwired to ESD system.

10/13/22

DATE:

CONSTRUCTION

AGENCY

All shutdowns’ related actions will be executed through ESD. ESD will be interfaced to DCS

AAM for auxiliary systems monitoring in accordance with Saudi Aramco Standards.

10/13/22

DATE:

OPERATIONS The existing HMI consoles at X89 Operation and Maintenance Building (CCR) will be used

SET for the operator interface with new equipment installed by this project. New Operating

10/13/22 console will be provided for new flare system (Requirement shall be finalized in detailed

DATE:

design stage).

CONTROL NUMBER

VERIFICATION

EDSD

3.0 INSTRUMENTATION AND CONTROL SYSTEM CONTROL NARRATIVE.

DATE:

BY:

The process control philosophy for the new systems is summarized below.

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

(DCC) NO. _____________________

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 6

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

3.1 BLOWDOWN DEGASSING VESSEL CONDENSATE PUMPS (X89-G-0016A/B/ X89-G-

ENGG CERT

0021A/B).

MAM

AMH

a) The BDV (Blowdown Degassing Vessel) Water Condensate pumps take suction from the

BDVs (X89-D-0039A & X89-D-0039B). The BDVs (X89-D-0039A & X89-D-0039B)

receive the hydrocarbon fluid from the Condensate Surge Drum (X89-D-0002). From

BDVs flash gases will be sent to the existing flare KO Drum (X89-D-0013).

b) Level controller (X89-LT-1001/X89-LT-1004) on the BDVs keeps the liquid interface level

in a range between low level and high level.

ISSUED FO50% REVIEW

DESCRIPTION

c) Pressure transmitters are installed on both suction (X89-PIT-1022/X89-PIT-1030/X89-

PIT-1024/X89-PIT-1031)/(X89-PIT-126/X89-PIT-1032/X89-PIT-1033/X89-PIT-1027) and

discharge (X89-PIT-1002/X89-PIT-1023/X89-PIT-1003/X89-PIT-1025) / (X89-PIT-

1012/X89-PIT-1028/X89-PIT-1013/X89-PIT-1029) lines of the new pumps (X89-G-

0016A/B/X89-G-0021A) respectively.

d) Flow transmitters are installed on the common pump discharge (X89-FIT-1001)/(X89-FIT-

1001)/ lines of the new pumps (X89-G-0016A/B/X89-G-0021A) respectively.

e) The Condensate pumps will close on low-low suction pressure (X89-PIT-1030/X89-PIT-

10-20897

JO/EWO

1031)/(X89-PIT-1032/X89-PIT-1033) or high-high discharge pressure (X89-PIT-

1023/X89-PIT-1025)/(/X89-PIT-101028/X89-PIT-1029).

10/13/22

DATE

f) One shutdown valve X89-ZV-1002/X89-ZV-1008 is provided for each vessel on the

blowdown header line. ZV of respective vessels will shut down upon high-level indication

(X89-LIT-1003/X89-LIT-1006).

NO.

REV

DISCIPLINE g) The pressure in the BDVs is maintained by the fuel gas. The pressure control valves

ENGINEER

SLFE (PCV-1001/1002 and PCV-1003/1004) on the Fuel gas line keep the BDV vessel under

10/13/22 constant and stable pressure. In case of HIGH pressure, feedback available from vessel

DATE:

PROJECT PIT-1001 / PIT-1011 respective bypass ZV-1002/1004 will be opened.

ENGINEER

AMH

CONTROL DESCRIPTION:

10/13/22

DATE:

CERTIFIED

MAM a) Two (2) BDV Water Condensate Pumps of respective Degassing vessels Working

10/13/22

Operation Philosophy is an intermittent operation that starts and stops the pumps at the

DATE: predefined level setting, controlled by logic.

CONSTRUCTION

AGENCY

AAM b) The pump selector is provided for the operator to select the desired pump to be operated

10/13/22 together with the permissive and interlocks.

DATE:

OPERATIONS c) ESD reset command is mandatory to restart the pump from DCS after Low-Low trip (X89-

SET LIT-1003) and (LIT-005).

10/13/22

DATE: d) FCV-1001 of Vessel (X89-D-0039A) and FCV-1002 of a vessel (X89-D-0039B) shall be

CONTROL NUMBER

controlled based on the respective flow transmitters FIT-1001A and FIT-1002A flow set

VERIFICATION

point which is updated based on the pumps discharge flow.

EDSD

e) During Start-Up the low-low suction pressure and Low low Discharge flow of the pumps

DATE:

respectively shall be overridden. Startup Low-Low bypass will be configured in the ESD

BY:

and DCS. Startup Bypass can be activated by pressing the momentary push button

provided on the DCS engineering system. Startup Bypass will remain active until the

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

process flow line reaches the normal design operating parameters or when a prescribed

10-20897-0001

A

time duration has elapsed.

(DCC) NO. _____________________

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 7

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

f) The ZV at the suction/discharge of pumps shall be closed when the pump is not running.

ENGG CERT

MAM

BLOWDOWN DEGASSING VESSEL (X89-D-0039A) CONDENSATE PUMPS (X89-G-0016A/B)

AMH

SET POINT:

S. No Control Element (X89-G-0016A) Set Point

1. LT-1001 at X89-D-0039A 0-5000 MM

ISSUED FO50% REVIEW

2. Pump starts at LIT-1001 431 MM

DESCRIPTION

3. Pump stop at LIT-1001 114 MM

4. Suction Pressure (PIT-1030) Low XXX PSI

5. Discharge Pressure (PIT-1023) High XXX PSI

6. Discharge Flow (FIT-1001B) Low XXX GPM

7. Pump Selector (HS-1001A)

X89-G-0016A/B

8. Permissive For Pump Start

ZV-1003 Open Feedback

ZV-1004 Open Feedback

10-20897

JO/EWO

S. No Control Element (X89-G-0016B) Set Point

10/13/22

DATE

1. LT-1001 at X89-D-0039A 0-5000 MM

2. Pump starts at LIT-1001 431 MM

3. Pump stop at LIT-1001 114 MM

NO.

REV

DISCIPLINE 4. Suction Pressure (PIT-1031) Low XXX PSI

ENGINEER

SLFE 5. Discharge Pressure (PIT-1025) High XXX PSI

10/13/22 6. Discharge Flow (FIT-1001B) Low XXX GPM

DATE:

PROJECT 7. Pump Selector (HS-1001A)

ENGINEER

AMH

X89-G-0016A/B

10/13/22

8. Permissive For Pump Start

DATE:

CERTIFIED

ZV-1005 Open Feedback

MAM ZV-1006 Open Feedback

10/13/22

DATE:

CONSTRUCTION

AGENCY

BLOWDOWN DEGASSING VESSEL (X89-D-0039B) CONDENSATE PUMPS (X89-G-0021A/B)

AAM

SET POINT:

10/13/22

DATE:

OPERATIONS

SET S. No Control Element (X89-G-0021A) Set Point

10/13/22

DATE: 1. LT-1004 at X89-D-0039A 0-5000 MM

CONTROL NUMBER

2. Pump starts at LIT-1004 431 MM

VERIFICATION

3. Pump stop at LIT-1004 114 MM

EDSD

4. Suction Pressure (PIT-1032) Low XXX PSI

5. Discharge Pressure (PIT-1028) High XXX PSI

DATE:

BY:

6. Discharge Flow (FIT-1002B) Low XXX GPM

7. Pump Selector (HS-1001A)

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

X89-G-0021A/B

10-20897-0001

A

(DCC) NO. _____________________

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 8

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

8. Permissive For Pump Start

ENGG CERT

ZV-1009 Open Feedback

MAM

ZV-1010 Open Feedback

AMH

S. No Control Element (X89-G-0021B) Set Point

1. LT-1004 at X89-D-0039A 0-5000 MM

2. Pump starts at LIT-1004 431 MM

3. Pump stop at LIT-1004 114 MM

ISSUED FO50% REVIEW

4. Suction Pressure (PIT-1033) Low XXX PSI

DESCRIPTION

5. Discharge Pressure (PIT-1029) High XXX PSI

6. Discharge Flow (FIT-1002B) Low XXX GPM

7. Pump Selector (HS-1001A)

X89-G-0021A/B

8. Permissive For Pump Start

ZV-1011 Open Feedback

ZV-1012 Open Feedback

10-20897

JO/EWO

Pump Alternation:

To implement the control scheme described in the above table, the DCS Supplier shall create all

10/13/22

DATE

necessary DCS logic and operator interface features to designate the order of operation of the pumps.

The DUTY-STANDBY pump selection criteria described below shall apply to each of the groups of two

pumps associated with the degassing vessel. Two options shall be available: fixed start sequence and

NO.

REV

elapsed-time based alternating.

DISCIPLINE

ENGINEER

SLFE

10/13/22 • Under the fixed start sequence the DUTY, STANDBY pump designations assigned by the

DATE:

PROJECT

operator shall determine the order of pump operation.

ENGINEER

AMH • Under the elapsed-time strategy the DCS shall designate the order of pump operation based on

DATE:

10/13/22 each pump’s total running time within the group of three pumps.

CERTIFIED

MAM

Only pumps that are selected for DCS-AUTO mode and available for operation shall be included in either

10/13/22

scheme.

DATE:

CONSTRUCTION

AGENCY Fixed Start Sequence

AAM

10/13/22 The operator shall be prompted at the PCS to designate a role for each available pump as DUTY or

DATE:

STANDBY pump, with the DCS designating the remaining pump as STANDBY if available. The pumps

OPERATIONS

shall be automatically operated in that order by the DCS, as needed, per the Degassing Vessel level

SET

control logic described in the above table. The DCS shall inhibit the selection and sequence assignment

10/13/22

DATE: of any pump that is not in DCS-AUTO mode, is designated OUT-OF-SERVICE, or is otherwise

CONTROL NUMBER

unavailable due to alarms of any type.

VERIFICATION

Elapsed-Time Based Alternating

EDSD

This alternating scheme shall be based on the recorded pump elapsed run time. The elapsed runtime for

DATE:

BY:

each pump shall be tracked by the DCS. Initial elapsed runtime shall be set by the operator based on the

existing hardwired elapsed runtime meters or known use of the pumps prior to the implementation of the

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

DCS elapsed runtime monitoring. For each wet well, the DCS-AUTO available pump with the least

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

running hours shall be selected by the DCS as the DUTY pump, and STANDBY pumps assigned in order

(DCC) NO. _____________________

of increasing total running time and availability for DCS-AUTO service.

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 9

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

Reassignment of Pump Roles for DCS-AUTO Level Control

ENGG CERT

MAM

Reassignment of pump DUTY, and STANDBY roles shall take place without interruption to the process.

AMH

The DCS shall not allow the reassignment of pump roles to occur between a pump that is currently

running and one that is not currently running.

Under Fixed Start Sequence:

a) An operator shall be allowed to switch the roles of any two running pumps or any two stopped

pumps.

ISSUED FO50% REVIEW

b) To switch the role of a running pump with a non-running pump the operator must take manual

DESCRIPTION

control of the two pumps, removing them from the DCS-AUTO scheme and performing any

needed speed changes and the pump starts and stops to balance the system. When the two

pumps to be switched are either both running or both not running, the DCS shall allow the

operator to switch their roles.

Under Time-based Alternation:

The DCS shall only automatically alter or swap the roles of pumps based on the total elapsed running

time when the pumps are stopped. Changes shall only occur between pumps with a difference of greater

than 24 hours of accumulated running time. Any automatic change in roles shall generate an event

message at the PCS and in the event log.

10-20897

JO/EWO

The DCS shall allow an authorized user to reset or correct the elapsed runtime for each pump from the

DCS in the event a pump or its motor is replaced or overhauled.

10/13/22

DATE

MODE OF OPERATION PUMPS (X89-G-0016A)

NO.

REV

DISCIPLINE

PUMP START:

ENGINEER

SLFE The pump can be started either remotely from PCS via DCS or from the Local LCP panel by pressing

DATE:

10/13/22 provided push button on the LCP (HS-0016AA), Pump can be operable either in manual mode or in auto

PROJECT sequence mode, (Auto/Manual) selector switch (HS-0016AB) shall be provided on the local LCP panel.

ENGINEER

AMH

For the pump, remote operation Auto selection feedback signal (XS-0016AB) must be available in the

10/13/22

DCS. The pump can be stopped either from DCS or from the field Local LCP panel by pressing provided

DATE:

push button on the LCP (HS-0016B).

CERTIFIED

MAM

10/13/22 Following permissive required to operate the pump from local LCP (Field) or from DCS (Remotely).

DATE:

CONSTRUCTION

AGENCY a) Pump suction ZV (X89-ZV-1003) open indication must be available to start the pump

AAM

10/13/22 b) Pump discharge ZV (X89-ZV-1004) open indication must be available to start the pump

DATE:

OPERATIONS c) Suction Low-Pressure (PIT-1030) shall be By-Pass. The By-Pass command must be reset

SET automatically for a set delay time and Pump Running feedback available.

10/13/22

DATE: d) No Low level (LIT-1003) from vessel level transmitter.

CONTROL NUMBER

VERIFICATION

e) ESD reset (soft) feedback signal from ESD (X89-HS-0016R) is required after a low-level trip to

EDSD

start the pump from LCP (field) or from DCS.

DATE:

BY:

PUMP STOP/SHUTDOWN:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

The pump can be stopped either from field LCP or remotely from DCS. Based On LIC-1001 low level ;

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

DCS will stop the Pump in automatic mode.

(DCC) NO. _____________________

ESD control system will initiate pump shutdown action upon LALL. The following reference will initiate

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 10

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

pump shutdown action:

ENGG CERT

MAM

a) Pump Suction ZV-1003 Close feedback signal (X89-XLS-1003C) available.

b) Pump Discharge ZV-1004 Close feedback signal (X89-XLS-1004C) available.

AMH

c) Pump Discharge PIT-1023 High High Pressure signal (X89-PSHH-1023) available.

d) Pump Discharge FIT-1001B Low Flow feedback signal available.

ISSUED FO50% REVIEW

MODE OF OPERATION PUMPS (X89-G-0016B)

DESCRIPTION

PUMP START:

The pump can be started either remotely from PCS via DCS or from the Local LCP panel by pressing

provided push button on the LCP (HS-0016BA), Pump can be operable either in manual mode or in auto

sequence mode, (Auto/Manual) selector switch (HS-0016BB) shall be provided on the local LCP panel.

For the pump, remote operation Auto selection feedback signal (XS-0016BB) must be available in the

DCS. The pump can be stopped either from DCS or from the field Local LCP panel by pressing provided

push button on the LCP (HS-0016B).

Following permissive required to operate the pump from local LCP (Field) or from DCS (Remotely).

10-20897

JO/EWO

a) Pump suction ZV (X89-ZV-1005) open indication must be available to start the pump

10/13/22

b) Pump discharge ZV (X89-ZV-1006) open indication must be available to start the pump

DATE

c) Suction Low-Pressure (PIT-1031) shall be By-Pass. The By-Pass command must be reset

automatically for a set delay time and Pump Running feedback available.

NO.

REV

DISCIPLINE d) No Low Level (LIT-1004) from vessel level transmitter.

ENGINEER

SLFE e) ESD reset (soft) feedback signal from ESD (X89-HS-0016R) is required after a low-level trip to

10/13/22

DATE: start the pump from LCP (field) or from DCS.

PROJECT

ENGINEER

AMH

10/13/22 PUMP STOP:

DATE:

CERTIFIED

MAM

a) The pump can be stopped either from field LCP or remotely from DCS. ESD control system will

10/13/22

initiate pump shutdown action upon LALL. The following reference will initiate pump shutdown

DATE: action:

CONSTRUCTION

AGENCY

AAM

b) Pump Suction ZV-1005 Close feedback signal (X89-XLS-1005C) available.

DATE:

10/13/22 c) Pump Discharge ZV-1006 Close feedback signal (X89-XLS-1006C) available.

OPERATIONS

d) Pump Discharge PIT-1025 High High signal (X89-PSHH-1025) available.

SET

10/13/22 e) Pump Discharge FIT-1001B Low Flow feedback signal available.

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

(DCC) NO. _____________________

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 11

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

BLOWDOWN DEGASSING VESSEL (X89-D-0039B) CONDENSATE PUMPS (X89-G-0021A/B)

ENGG CERT

MAM

MODE OF OPERATION PUMPS (X89-G-0021A)

AMH

PUMP START:

The pump can be started either remotely from PCS via DCS or from the Local LCP panel by pressing

provided push button on the LCP (HS-0021AA), Pump can be operable either in manual mode or in auto

sequence mode, (Auto/Manual) selector switch (HS-0021AB) shall be provided on the local LCP panel.

ISSUED FO50% REVIEW

For the pump, remote operation Auto selection feedback signal (XS-0021AB) must be available in the

DCS. The pump can be stopped either from DCS or from the field Local LCP panel by pressing provided

DESCRIPTION

push button on the LCP (HS-0021B).

Following permissive required to operate the pump from local LCP (Field) or from DCS (Remotely).

a) Pump suction ZV (X89-ZV-1009) open indication must be available to start the pump

b) Pump discharge ZV (X89-ZV-1010) open indication must be available to start the pump

c) Suction Low-Pressure (PIT-1032) shall be By-Pass. The By-Pass command must be reset

automatically for a set delay time and Pump Running feedback available.

10-20897

JO/EWO

d) No Low Level (LIT-1006) from vessel level transmitter.

e) ESD reset (soft) feedback signal from ESD (X89-HS-0021R) is required after a low-level trip to

start the pump from LCP (field) or from DCS.

10/13/22

NO. DATE

REV

PUMP STOP/SHUTDOWN:

A

DISCIPLINE

ENGINEER a) The pump can be stopped either from field LCP or remotely from DCS. Based On LIC-1004 low

SLFE level ; DCS will stop the Pump in automatic mode.

10/13/22

DATE:

PROJECT

b) Pump Suction ZV-1009 Close feedback signal (X89-XLS-1003C) available.

ENGINEER

AMH c) Pump Discharge ZV-1010 Close feedback signal (X89-XLS-1004C) available.

10/13/22

DATE: d) Pump Discharge PIT-1028 High High signal (X89-PSHH-1028) available.

CERTIFIED

MAM e) Pump Discharge FIT-1002B Low Flow feedback signal available.

10/13/22

DATE:

CONSTRUCTION

AGENCY

AAM

10/13/22

DATE:

OPERATIONS MODE OF OPERATION PUMPS (X89-G-0021B)

SET

10/13/22 PUMP START:

DATE:

CONTROL NUMBER

The pump can be started either remotely from PCS via DCS or from the Local LCP panel by pressing

VERIFICATION

provided push button on the LCP (HS-0021BA), Pump can be operable either in manual mode or in auto

EDSD

sequence mode, (Auto/Manual) selector switch (HS-0021BB) shall be provided on the local LCP panel.

For the pump, remote operation Auto selection feedback signal (XS-0021BB) must be available in the

DATE:

BY:

DCS. The pump can be stopped either from DCS or from the field Local LCP panel by pressing provided

push button on the LCP (HS-0021B).

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

Following permissive required to operate the pump from local LCP (Field) or from DCS (Remotely).

A

(DCC) NO. _____________________

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 12

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

a) Pump suction ZV (X89-ZV-1011) open indication must be available to start the pump

ENGG CERT

MAM

b) Pump discharge ZV (X89-ZV-1012) open indication must be available to start the pump

c) Suction Low-Pressure (PIT-1033) shall be By-Pass. The By-Pass command must be reset

AMH

automatically for a set delay time and Pump Running feedback available.

d) No Low Level (LIT-1006) from vessel level transmitter.

e) ESD reset (soft) feedback signal from ESD (X89-HS-0021R) is required after a low-level trip to

start the pump from LCP (field) or from DCS.

ISSUED FO50% REVIEW

DESCRIPTION

PUMP STOP/SHUTDOWN:

The pump can be stopped either from field LCP or remotely from DCS. Based On LIC-1004 low level ;

DCS will stop the Pump in automatic mode.

The following reference will initiate pump shutdown action:

a) Pump Suction ZV-011 1Close feedback signal (X89-XLS-1011C) available.

b) Pump Discharge ZV-1012 Close feedback signal (X89-XLS-1012C) available.

c) Pump Discharge PIT-1029 High High signal (X89-PSHH-1025) available.

10-20897

JO/EWO

Pump Discharge FIT-1002B Low Flow feedback signal available

10/13/22

DATE

BLANKET GAS CONTROL (PCV) (X89-D-0039A)

NO.

REV

The pressure in Tanks and Vessels is maintained by the blanketing gas. The pressure control valves

A

DISCIPLINE (marked as PCV-1001A and PCV-1001B in the respected equipment) on the blanketing gas line keep the

ENGINEER

SLFE Tanks and Vessels under constant and stable pressure.

10/13/22

DATE:

PROJECT

Excess pressure buildup in the drum will be released through the respective pressure control valve (PCV-

ENGINEER 1001B) to flare system at high pressure while High-High pressure (PSHH-1010) in the vessel shall open

AMH

the By-Pass ZV (ZV-1001) of excess pressure control valve

10/13/22

DATE:

CERTIFIED PIC-1001 controls PCV-1001A and PCV-100B using split range control to maintain setpoint blanketing

MAM

gas pressure in the Blow down vessel

10/13/22

DATE:

CONSTRUCTION

AGENCY

BLOWDOWN HEADER INLET LINE

AAM

DATE:

10/13/22 High-High Level, (LAHH-1003) will closed inlet ZV (ZV-1002) ZV .

OPERATIONS High level LAH-1001 will close inlet Motor operated Valve (MOV-1005) located on the vessel inlet line

SET

from Blowdown Header.

10/13/22

DATE:

BLANKET GAS CONTROL (PCV) (X89-D-0039B)

CONTROL NUMBER

VERIFICATION

The pressure in Tanks and Vessels is maintained by the blanketing gas. The pressure control valves

EDSD

(marked as PCV-1011A and PCV-1011B in the respected equipment) on the blanketing gas line keep the

Tanks and Vessels under constant and stable pressure.

DATE:

BY:

Excess pressure buildup in the drum will be released through the respective pressure control valve (PCV-

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

1011B) to flare system at high pressure while High-High pressure (PSHH-1020) in the vessel shall open

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

the By-Pass ZV (ZV-1007) of excess pressure control valve

(DCC) NO. _____________________

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 13

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

PIC-1011 controls PCV-1011A and PCV-1011B using split range control to maintain setpoint blanketing

ENGG CERT

gas pressure in the Blow down vessel

MAM

BLOWDOWN HEADER INLET LINE

AMH

High-High Level, (LAHH-1006) will close inlet ZV (ZV-1008) ZV and High level LAH-0104 will close inlet

MOV (MOV-1010) located on the vessel inlet line from Blowdown Header.

3.2 BLOWDOWN DEGASSING VESSEL PRODUCED WATER PUMPS (X89-G-XXX3A/B/ X89-G-

ISSUED FO50% REVIEW

XXX4A/B).

DESCRIPTION

a) The BDV (Blowdown Degassing Vessel) Produced water pumps take suction from the

boot of the BDVs (X89-D-0039A & X89-D-0039B). The BDVs (X89-D-0039A & X89-D-

0039B) receive the hydrocarbon fluid from the Condensate Surge Drum (X89-D-0002).

From BDVs flash gases will be sent to the existing flare KO Drum (X89-D-0013) this

operation will be done via new Produce Water pumps.

b) Level controller (X89-LT-1007/X89-LT-1010) on the BDVs keeps the liquid interface level

in a range between low level and high level.

10-20897

JO/EWO

c) Pressure transmitters are installed on both suction (X89-PIT-1034/X89-PI-1036/X89-PIT-

1039/X89-PIT-1041)/(X89-PIT-1044/X89-PIT-1046/X89-PIT-1049/X89-PIT-1051) and

discharge (X89-PIT-1030/X89-PIT-1038) \ (X89-PIT-1048/X89-PIT-1053) lines of the new

10/13/22

DATE

pumps (X89-G-XX3A/B/X89-G-XXX4A/B) respectively.

d) Flow transmitters are installed on the pump discharge (X89-FIT-1003)/(X89-FIT-1004)

NO.

REV

lines of the new pumps (X89-G-XX3A/B/X89-G-XXX4A/B) respectively.

DISCIPLINE

ENGINEER

SLFE e) The produce water pumps will close on low-low suction pressure (X89-PIT-1036/X89-

10/13/22

DATE: PIT-1041)/(X89-PIT-1046/X89-PIT-1051) or high-high discharge pressure (X89-PIT-

PROJECT

ENGINEER

1038/X89-PIT-1030)/(/X89-PIT-1048/X89-PIT-1053).

AMH

DATE:

10/13/22 f) The Deposal pumps will close on low-low commond dischrge flow (X89-FIT-1003B)/(X89-

CERTIFIED FIT-1004B).

MAM

DATE:

10/13/22 CONTROL DESCRIPTION:

CONSTRUCTION

AGENCY

AAM a) Two (2) BDV Water Condensate

10/13/22 b) Pumps of respective Degassing vessels Working Operation Philosophy is an intermittent

DATE:

OPERATIONS operation that starts and stops the pumps at the predefined level setting, controlled by

SET logic.

10/13/22

DATE: c) The pump selector is provided for the operator to select the desired pump to be operated

CONTROL NUMBER

together with the permissive and interlocks.

VERIFICATION

d) ESD reset command is mandatory to restart the pump from DCS after Low-Low trip (X89-

EDSD

LIT-1009) and (LIT-1012).

DATE:

BY:

e) FCV-1003 of Vessel (X89-D-0039A) and FCV-1004 of a vessel (X89-D-0039B) shall be

controlled based on the respective flow transmitters FIT-1003A and FIT-1004A flow set

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

point which is updated based on the pumps discharge flow.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

f) During Start-Up the low-low suction pressure and Discharge flow of the pumps

(DCC) NO. _____________________

respectively shall be overridden. Startup Low-Low bypass will be configured in the ESD

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 14

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

and DCS. Startup Bypass can be activated by pressing the momentary push button

ENGG CERT

provided on the DCS engineering system. Startup Bypass will remain active until the

MAM

process flow line reaches the normal design operating parameters or when a prescribed

time duration has elapsed.

AMH

BLOWDOWN DEGASSING VESSEL (X89-D-0039A) PRODUCED WATER PUMPS (X89-G-XXX3A/B)

SET POINT:

ISSUED FO50% REVIEW

DESCRIPTION

S. No Control Element (X89-G-XXX3A) Set Point

1. LT-1007 at X89-D-0039A 0-XXX MM

2. Pump starts at LIT-1007 XXX MM

3. Pump stop at LIT-1007 XXX MM

4. Suction Pressure (PIT-1036) Low Level XXX PSI

5. Discharge Pressure (PIT-1038) High Level XXX PSI

6. Discharge Flow (FIT-1003B) Low Flow XXX GPM

7. Pump Selector (HS-XXX3A)

10-20897

X89-G-XXX3A/B

JO/EWO

8. Permissive For Pump Start

No Low Low Level LALL-

10/13/22

DATE

1009

NO.

REV

DISCIPLINE S. No Control Element (X89-G-XXX3B) Set Point

ENGINEER

SLFE 1. LT-1007 at X89-D-0039A 0-XXX MM

DATE:

10/13/22 2. Pump starts at LIT-1007 XXX MM

PROJECT 3. Pump stop at LIT-1007 XXX MM

ENGINEER

AMH 4. Suction Pressure (PIT-1039) Low XXX PSI

10/13/22 5. Discharge Pressure (PIT-1043) High XXX PSI

DATE:

CERTIFIED 6. Discharge Flow (FIT-1003B) Low XXX GPM

MAM 7. Pump Selector (HS-XXX3A)

DATE:

10/13/22 X89-G-XXX3A/B

CONSTRUCTION 8. Permissive For Pump Start

AGENCY

AAM No Low Low Level LALL-

10/13/22 1009

DATE:

OPERATIONS

SET

10/13/22

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

(DCC) NO. _____________________

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 15

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

BLOWDOWN DEGASSING VESSEL (X89-D-0039B) PRODUCED WATER PUMPS (X89-G-XXX4A/B)

ENGG CERT

MAM

SET POINT:

AMH

S. No Control Element (X89-G-XXX4A) Set Point

1. LT-1010 at X89-D-0039B 0-XXX MM

2. Pump starts at LIT-1010 XXX MM

3. Pump stop at LIT-1010 XXX MM

ISSUED FO50% REVIEW

4. Suction Pressure (PIT-1046) Low XXX PSI

DESCRIPTION

5. Discharge Pressure (PIT-1048) High XXX PSI

6. Discharge Flow (FIT-1004B) Low XXX GPM

7. Pump Selector (HS-XXX4A)

X89-G-XXX4A/B

8. Permissive For Pump Start

No Low Low Level LALL-

1012

10-20897

JO/EWO

S. No Control Element (X89-G-XXX4B) Set Point

1. LT-1010 at X89-D-0039B 0-XXX MM

10/13/22

2. Pump starts at LIT-1010 XXX MM

DATE

3. Pump stop at LIT-1010 XXX MM

4. Suction Pressure (PIT-1049) Low XXX PSI

NO.

REV

5. Discharge Pressure (PIT-1053) High XXX PSI

DISCIPLINE

ENGINEER 6. Discharge Flow (FIT-1004B) Low XXX GPM

SLFE

7. Pump Selector (HS-XXX4A)

10/13/22

DATE: X89-G-XXX4A/B

PROJECT

ENGINEER 8. Permissive For Pump Start

AMH No Low Low Level LALL-

DATE:

10/13/22 1012

CERTIFIED

MAM

10/13/22

DATE: Pump Alternation:

CONSTRUCTION

AGENCY

AAM

To implement the control scheme described in the above table, the DCS Supplier shall create all

10/13/22

DATE: necessary distributed control unit (DCU) logic and operator interface features to designate the order of

OPERATIONS operation of the pumps. The DUTY-STANDBY pump selection criteria described below shall apply to

SET each of the groups of two pumps associated with the degassing vessel. Two options shall be available:

10/13/22 fixed start sequence and elapsed-time based alternating.

DATE:

CONTROL NUMBER

VERIFICATION

• Under the fixed start sequence the DUTY, STANDBY pump designations assigned by the

EDSD

operator shall determine the order of pump operation.

DATE:

• Under the elapsed-time strategy the DCS shall designate the order of pump operation based on

BY:

each pump’s total running time within the group of three pumps.

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

Only pumps that are selected for DCS-AUTO mode and available for operation shall be included in either

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

scheme.

(DCC) NO. _____________________

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 16

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

Fixed Start Sequence

ENGG CERT

MAM

The operator shall be prompted at the PCS to designate a role for each available pump as DUTY or

STANDBY pump, with the Distributed Control Unit (DCU) designating the remaining pump as STANDBY

AMH

if available. The pumps shall be automatically operated in that order by the DCS, as needed, per the

Degassing Vessel level control logic described in the above table. The DCS shall inhibit the selection and

sequence assignment of any pump that is not in DCS-AUTO mode, is designated OUT-OF-SERVICE, or

is otherwise unavailable due to alarms of any type.

Elapsed-Time Based Alternating

ISSUED FO50% REVIEW

This alternating scheme shall be based on the recorded pump elapsed run time. The elapsed runtime for

DESCRIPTION

each pump shall be tracked by the DCS. Initial elapsed runtime shall be set by the operator based on the

existing hardwired elapsed runtime meters or known use of the pumps prior to the implementation of the

DCS elapsed runtime monitoring. For each wet well, the DCS-AUTO available pump with the least

running hours shall be selected by the DCS as the DUTY pump, and STANDBY pumps assigned in order

of increasing total running time and availability for DCS-AUTO service.

Reassignment of Pump Roles for DCS-AUTO Level Control

Reassignment of pump DUTY, and STANDBY roles shall take place without interruption to the process.

The DCS shall not allow the reassignment of pump roles to occur between a pump that is currently

running and one that is not currently running.

10-20897

JO/EWO

Under Fixed Start Sequence:

c) An operator shall be allowed to switch the roles of any two running pumps or any two stopped

10/13/22

DATE

pumps.

d) To switch the role of a running pump with a non-running pump the operator must take manual

NO.

REV

control of the two pumps, removing them from the DCS-AUTO scheme and performing any

DISCIPLINE

ENGINEER

needed speed changes and the pump starts and stops to balance the system. When the two

SLFE pumps to be switched are either both running or both not running, the DCS shall allow the

DATE:

10/13/22 operator to switch their roles.

PROJECT

ENGINEER Under Time-based Alternation:

AMH

10/13/22 The DCS shall only automatically alter or swap the roles of pumps based on the total elapsed running

DATE:

CERTIFIED

time when the pumps are stopped. Changes shall only occur between pumps with a difference of greater

MAM than 24 hours of accumulated running time. Any automatic change in roles shall generate an event

10/13/22 message at the PCS and in the event log.

DATE:

CONSTRUCTION

AGENCY

The DCS shall allow an authorized user to reset or correct the elapsed runtime for each pump from the

AAM DCS in the event a pump or its motor is replaced or overhauled.

10/13/22

DATE:

OPERATIONS

SET

MODE OF OPERATION PUMPS (X89-G-XXX3A)

10/13/22

DATE:

PUMP START:

CONTROL NUMBER

VERIFICATION

The pump can be started either remotely from PCS via DCS or from the Local LCP panel by pressing

EDSD

provided push button on the LCP (HS-XXX3AA), Pump can be operable either in manual mode or in auto

sequence mode, (Auto/Manual) selector switch (HS- XXX3AB) shall be provided on the local LCP panel.

DATE:

For the pump, remote operation Auto selection feedback signal (XS- XXX3AB) must be available in the

BY:

DCS. The pump can be stopped either from DCS or from the field Local LCP panel by pressing provided

APPROVAL/CERTIFICATION REQUIREMENTS,

push button on the LCP (HS- XXX3B).

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

10-20897-0001

A

(DCC) NO. _____________________

Following permissive required to operate the pump from local LCP (Field) or from DCS (Remotely).

PROCESS CONTROL NARRATIVE DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REPLACE FLARE AND BURN PIT DOC

MIDYAN GAS PLANT (MGP) X89 J VE-P48021 17

OF 00

MIDYAN SAUDI ARABIA JO / EWO: BI-10-20897-0001 27

Copyright©Saudi Aramco 2009. All rights reserved.

PMT OPRNS

SET SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

AAM

a) Suction Low-Pressure (PIT-1036) shall be By-Pass. The By-Pass command must be reset

ENGG CERT

automatically for a set delay time and Pump Running feedback available.

MAM

b) No Low (LIT-1009) from vessel level transmitter.

AMH

c) ESD reset (soft) feedback signal from ESD (X89-HS-XXX3R) is required after a low-level trip to

start the pump from LCP (field) or from DCS.

PUMP STOP:

ISSUED FO50% REVIEW

a) The pump can be stopped either from field LCP or remotely from DCS. LAH-1009 will stop the

pump in Automatic mode.

DESCRIPTION

ESD control system will initiate pump shutdown action upon LALL. The following reference will

initiate pump shutdown action: