Professional Documents

Culture Documents

Material Table Summary A4 en

Material Table Summary A4 en

Uploaded by

Vladislav ZvyagintsevOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Table Summary A4 en

Material Table Summary A4 en

Uploaded by

Vladislav ZvyagintsevCopyright:

Available Formats

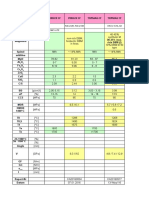

-- -

Printable on Printable on Soluble with Impact

Printing with Dry box Hardened Nozzle Printable on Heat deflection

Material Bed temperature powder coated smooth PEI common resistance Tensile strength Price

enclosure recommended nozzle required temperature satin sheet temperature

sheet sheet solvents (harpy

PLA No No No 185-235 ·c 50-60·c v v v X ■

-- -

PETG No No No 215-270 ·c 70-90 ·c v with glue stick

v X

PETG HT No No No 270 ·c 110 ·c V with glue stick

V X

ASA Yes No No 220-275·c 90-110·c v v

- -

recorrrrended with glue stick with glue stick

ABS

Yes

recorrrrended

No No 230-255·c 95-11o·c

with gl..1e stick with glue stick

v v

Yes

v X

• -

PC (Polycarbonate) No No 270-275 ·c 100-115 ·c

recorrrrended with glJe stick with glue stick

v v X

■

-- •

CPE No Yes No 275·c 90-110·c

with glue stick

PVA/ BVOH No Yes No 195-215 ·c 60 ·c v v v v ■

HIPS No No No 225-255 ·c 100-110 ·c v v v v

- -

PP (Polypropylene) No No 220-245 ·c 0-100 ·c X

not recommended with PP tape

v X

Flex No Yes No 220-260 ·c 40-85 ·c V with glue stick wit!'- glue stick

X ■

nGen No No No 240·c 90·c v I

with glue stick

v X

-

Yes X X

- - -

•

PA (Nylon) Yes No 240-285 ·c 70-115 ·c

recomrrended with glue stick not recommended wit!" glue stick

X

•

Composite materials Yes 225-285 ·c 40-115 ·c

Wood/ metal filled No No 190-220 ·c 60-65·c v v v X ■

PVB No No No 215 ·c 75 ·c X

not recommended

v v v

You might also like

- HJ Arnikar Nuclear ChemistryDocument112 pagesHJ Arnikar Nuclear Chemistrysatyam saxena67% (9)

- Bach - 6 Sonatas e Partitas - GalamianDocument121 pagesBach - 6 Sonatas e Partitas - GalamianMarcela OliveiraNo ratings yet

- 2006-IMR-Processing and Properties of Monolithic TiB2 Based MaterialsDocument23 pages2006-IMR-Processing and Properties of Monolithic TiB2 Based MaterialsAmarNo ratings yet

- Kia Catalogue - 88-154 From Pick PartsDocument67 pagesKia Catalogue - 88-154 From Pick PartsAhmed Ragab100% (1)

- Allied Mineral Refractory Castable - Refractory Cement - Allied MineralDocument2 pagesAllied Mineral Refractory Castable - Refractory Cement - Allied MineralLeo CrisuNo ratings yet

- 2017-06 Refratechnik - Bricks CF SeriesDocument12 pages2017-06 Refratechnik - Bricks CF SeriesSyed Kazam Raza100% (1)

- GeoMetallurgy - TeckDocument21 pagesGeoMetallurgy - Teckrolandoh1No ratings yet

- Purchase: 30 Days 1 Months ForecastDocument3 pagesPurchase: 30 Days 1 Months ForecastLucky ParasharNo ratings yet

- Bbsfor Slab: Along Shorter Span (Main Bar) KitchenDocument12 pagesBbsfor Slab: Along Shorter Span (Main Bar) KitchenAsr FlowerNo ratings yet

- Final VersionsDocument67 pagesFinal Versionsashubablu123No ratings yet

- Hyundai Catalogue - 2-87Document86 pagesHyundai Catalogue - 2-87Ahmed RagabNo ratings yet

- SM 8Document27 pagesSM 8Steven BulckeNo ratings yet

- EBRO HP114-C High Performance Butterfly ValveDocument4 pagesEBRO HP114-C High Performance Butterfly ValveAakash TanwarNo ratings yet

- Wayne 1Document2 pagesWayne 1Константин ОказинNo ratings yet

- Reporte Líneas Lunes 19 Ulio 2021Document6 pagesReporte Líneas Lunes 19 Ulio 2021Juan Gerardo HernandezNo ratings yet

- Crosby® Wide Body Shackles85Document1 pageCrosby® Wide Body Shackles85elias aouadNo ratings yet

- SLD STP ChemindoDocument2 pagesSLD STP ChemindoWildan Abidin100% (1)

- Sampel AcpDocument2 pagesSampel Acphasan albanaNo ratings yet

- Nenutec - NVCB 92065Document4 pagesNenutec - NVCB 92065Oanh NguyenNo ratings yet

- Table UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded JointsDocument1 pageTable UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded Jointsluis armandoNo ratings yet

- DinamicaDocument2 pagesDinamicaAlan FloresNo ratings yet

- Expansion Joint SCP PDFDocument110 pagesExpansion Joint SCP PDFMabel LoNo ratings yet

- Castlegar/Slocan Valley Pennywise May 23, 2017Document40 pagesCastlegar/Slocan Valley Pennywise May 23, 2017Pennywise PublishingNo ratings yet

- Reporte 05 - 07 - 21Document4 pagesReporte 05 - 07 - 21Juan Gerardo HernandezNo ratings yet

- Always There To Help You: EnglishDocument2 pagesAlways There To Help You: EnglishWalter VermehrenNo ratings yet

- Globe Valve - Disk TipleriDocument2 pagesGlobe Valve - Disk TipleriErcan YilmazNo ratings yet

- V-Isaji - mg?-mBE8vi - Ts95t?-Gpeic - : M I0kgDocument40 pagesV-Isaji - mg?-mBE8vi - Ts95t?-Gpeic - : M I0kgBrendha MelloNo ratings yet

- Unknown 14Document20 pagesUnknown 14joseinesoficialNo ratings yet

- Flefbki: / PuttyDocument9 pagesFlefbki: / PuttyDzul FajrinNo ratings yet

- Conveyorcatalogue nz11Document1 pageConveyorcatalogue nz11vankarpNo ratings yet

- Konad CatalogueDocument3 pagesKonad CatalogueChanjin ParkNo ratings yet

- Varibelt V KayışlarDocument17 pagesVaribelt V Kayışlare.korkmazNo ratings yet

- 15 - Cylinder Head, Valve GearDocument41 pages15 - Cylinder Head, Valve GearFocus MarambaNo ratings yet

- MekanikaDocument5 pagesMekanikaSalsabila Putri AndriantiNo ratings yet

- Instalaciones de CloacasDocument1 pageInstalaciones de CloacasYhamil La MadridNo ratings yet

- Fabl - Vor Rwy 20 - Vor-02 DD 11 Dec 2014Document1 pageFabl - Vor Rwy 20 - Vor-02 DD 11 Dec 2014DeanNo ratings yet

- User Manual: Always There To Help YouDocument2 pagesUser Manual: Always There To Help YouDenMarNo ratings yet

- Inspection of Plant and Equipment: Mix DesignDocument20 pagesInspection of Plant and Equipment: Mix DesignDibyalochan ParidaNo ratings yet

- Approximate MethodDocument3 pagesApproximate MethodPooh JrNo ratings yet

- Practica Descriptiva PDFDocument1 pagePractica Descriptiva PDFEVO PARINo ratings yet

- API 650 Tank Design Calculationxls Energy and CompressDocument8 pagesAPI 650 Tank Design Calculationxls Energy and Compressجيلالي نفوسيNo ratings yet

- Reparacion Cremallera Ridgeline 08Document54 pagesReparacion Cremallera Ridgeline 08Jorge Guillermo ManzanoNo ratings yet

- 039 23viDocument4 pages039 23viMarco ZuñigaNo ratings yet

- VW 01103Document9 pagesVW 01103Alexandre GoulartNo ratings yet

- Sites For NospDocument15 pagesSites For NospBalakrishnan KrishnanNo ratings yet

- Alejandra Montero AssessmentDocument6 pagesAlejandra Montero AssessmentAlejandra MonteroNo ratings yet

- Unknown 17Document27 pagesUnknown 17joseinesoficialNo ratings yet

- Rim Seal Area For Floating Roof Tanks Rafp: Detection & Extinguishing SystemDocument3 pagesRim Seal Area For Floating Roof Tanks Rafp: Detection & Extinguishing SystemshijuNo ratings yet

- API 650 Tank Design Calculationxls Energy and CompressDocument8 pagesAPI 650 Tank Design Calculationxls Energy and CompressTech ManagerNo ratings yet

- Api 650 Tank Design Calculationxls Energy andDocument8 pagesApi 650 Tank Design Calculationxls Energy andjalil ahmedNo ratings yet

- Sudha Permission Slip - ETsDocument1 pageSudha Permission Slip - ETschvsuneelNo ratings yet

- DB-43 (Base Oil)Document5 pagesDB-43 (Base Oil)Andreas OktoraNo ratings yet

- Trail/Beaver Valley/Rossland Pennywise June 6, 2017Document40 pagesTrail/Beaver Valley/Rossland Pennywise June 6, 2017Pennywise PublishingNo ratings yet

- EN 022740 4020 Visalys Core 4-Seiter PDFDocument4 pagesEN 022740 4020 Visalys Core 4-Seiter PDFCristian YáñezNo ratings yet

- PT Sumber Maksmur Perkasa: Page 1 of 11Document11 pagesPT Sumber Maksmur Perkasa: Page 1 of 1141122120102No ratings yet

- Hedge Quotes ComparisonDocument42 pagesHedge Quotes ComparisonAnts. LNo ratings yet

- Lecture On Hydropower Development (Design of Civil Components)Document46 pagesLecture On Hydropower Development (Design of Civil Components)RabinNo ratings yet

- Diphthongs Bay Boy by PronunciationDocument1 pageDiphthongs Bay Boy by PronunciationJenny Ruth Golosinda PagtalunanNo ratings yet

- DenverIItest FormeDocument3 pagesDenverIItest FormeNanda UmiyatunNo ratings yet

- Checklist For Equipment Inspection Gas Cutting SetDocument2 pagesChecklist For Equipment Inspection Gas Cutting SetalexNo ratings yet

- 13 - Crankshaft Group: 1 Cylinder Block (Pulley End)Document51 pages13 - Crankshaft Group: 1 Cylinder Block (Pulley End)Roberto Lara MartínezNo ratings yet

- 42.2.2 5 42.2.2 5 42.2.2 5 42.2.2 5 42.2.2 5 /////22222 J X 16 Jx16 Jx16 Jx16 Jx16Document1 page42.2.2 5 42.2.2 5 42.2.2 5 42.2.2 5 42.2.2 5 /////22222 J X 16 Jx16 Jx16 Jx16 Jx16Cristian AsaroffNo ratings yet

- Komatsu Bearing CatalogueDocument3 pagesKomatsu Bearing CatalogueMichael ZhangNo ratings yet

- Unit-I Heat Treatment of SuperalloysDocument15 pagesUnit-I Heat Treatment of SuperalloysJ JhansibaiNo ratings yet

- Tabla de Caracteristicas de Los PlasticosDocument12 pagesTabla de Caracteristicas de Los PlasticosBetty JadueNo ratings yet

- Materials Properties DatabaseDocument34 pagesMaterials Properties DatabaseffontanaNo ratings yet

- Plastics in Medical Devices - 11Document5 pagesPlastics in Medical Devices - 11Emilio HipolaNo ratings yet

- Plastic Material Properties Table - PhysicalDocument3 pagesPlastic Material Properties Table - PhysicalDINAMIKA AVIASI100% (1)

- Deligate ExcelFormatDocument60 pagesDeligate ExcelFormatrashidnyou0% (2)

- Tajuk Eksperimen Ebb 325 0809Document1 pageTajuk Eksperimen Ebb 325 0809fred5181No ratings yet

- Material Science ..Crystal StructureDocument24 pagesMaterial Science ..Crystal StructureSajal MathurNo ratings yet

- So Sanh CableDocument8 pagesSo Sanh CablehungleteNo ratings yet

- Carburization Phenomenon of Enicrfe 7 Nickel Based Alloy Covered ElectrodeDocument8 pagesCarburization Phenomenon of Enicrfe 7 Nickel Based Alloy Covered ElectrodeSudish Jay MishraNo ratings yet

- Lec 25Document32 pagesLec 25Sergio zihadNo ratings yet

- Properties of Minerals How Minerals Form Using Mineral ResourcesDocument28 pagesProperties of Minerals How Minerals Form Using Mineral ResourcesndNo ratings yet

- Applications and Processing of Metal AlloysDocument39 pagesApplications and Processing of Metal Alloysjulito paquitNo ratings yet

- MCP101Document9 pagesMCP101Sushant Cr7No ratings yet

- Extraction of MetalsDocument3 pagesExtraction of MetalsYasmin YehiaNo ratings yet

- Kim HT - 1996 - Article - StudyOnTheSolidificationCracki - PDF - Borland EquationDocument6 pagesKim HT - 1996 - Article - StudyOnTheSolidificationCracki - PDF - Borland Equation이상벽No ratings yet

- BORANG BQ 2019 BP EditDocument5 pagesBORANG BQ 2019 BP EditSyamsul 7511No ratings yet

- Turning TOTIME Miniature Tools PDFDocument14 pagesTurning TOTIME Miniature Tools PDFvedrenne92No ratings yet

- Tabela PeriodicaDocument1 pageTabela PeriodicaEdgarRafaelCardosoNo ratings yet

- Products: NEW Public Prices 1 APRIL 2023Document7 pagesProducts: NEW Public Prices 1 APRIL 2023med b nasrNo ratings yet

- Falcon MetalsDocument37 pagesFalcon Metalschidambaram kasiNo ratings yet

- Adt-03 Engine 3112 Ob1922568Document1 pageAdt-03 Engine 3112 Ob1922568abdul rahmatNo ratings yet

- Orgonite BrochureDocument2 pagesOrgonite BrochureGiannis FakirisNo ratings yet

- Sobat HssDocument29 pagesSobat HssHendra EndhaNo ratings yet

- AzuriteDocument1 pageAzuriteHugoman100% (1)

- 5xxx-Series Extrusions For Automotive Applications With Outstanding Intergranular Corrosion ResistanceDocument12 pages5xxx-Series Extrusions For Automotive Applications With Outstanding Intergranular Corrosion ResistanceFrancesco BernardNo ratings yet