Professional Documents

Culture Documents

Specifications 5.1: FLHR/C/S

Specifications 5.1: FLHR/C/S

Uploaded by

Keith ChoiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specifications 5.1: FLHR/C/S

Specifications 5.1: FLHR/C/S

Uploaded by

Keith ChoiCopyright:

Available Formats

HOME

SPECIFICATIONS 5.1

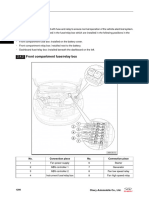

System Fuse Block (Under Left Side Cover)

IGNITION DATA

8

0°-45° BTDC (range) FLHR/C/S

Spark timing advance

12° BTDC@1000 RPM

9

Idle speed 990 ± 50 RPM 10

Spark plug size 12 mm 5

11

0.038-0.043 in

Spark plug gap

0.97-1.09 mm

Harley-Davidson 4

Spark plug type

No. 6R12 (no substitute)

12

Ignition coil primary

0.3-0.5 ohms

resistance 3

f2210x8x

1 2

Ignition coil secondary

2500-3500 ohms

resistance

FLTR, FLHT/C/U 8 7

9 6

Rating 10

Circuit Color

(Amperes)

5

System Fuses 11

Maxi-Fuse 40 Orange

Headlamp 15 Blue

4

Ignition 15 Blue

Lighting 15 Blue

Instruments 15 Blue f2204x8x 1 2 3

Brakes/Cruise 15 Blue 1. Headlamp 7. Radio Power

2. Ignition 8. Accessory

Radio Memory 15 Blue

3. Lighting 9. Battery

Radio Power 10 Red 4. Instruments 10. Brake Light Relay

5. Brakes/Cruise 11. P&A

Accessory 15 Blue 6. Radio Memory 12. Starter Relay

Battery 15 Blue

P&A 15 Blue EFI Fuse Block (Under Right Side Cover)

EFI Fuses

EFI System

Relay

Fuel Pump 15 Blue Spare

ECM Power 15 Blue

Fuel Pump

ECM Power

f2223x9x

Figure 5-1. Fuse Locations

2004 Touring: Engine Management (EFI) 5-1

HOME

NOTES

5-2 2004 Touring: Engine Management (EFI)

HOME

EFI SYSTEM 5.2

GENERAL The bank angle sensor is within the TSM/TSSM. If the vehicle

lean angle exceeds 45 degrees for one second, the fuel

pump is shut off. Once the sensor is tripped, the motorcycle

The engine management system consists of the following must be uprighted, turned off and then on again before the

components: engine can be restarted. This is communicated across the

data bus.

● Electronic control module (ECM).

Front and rear coils fire each spark plug independently (one

● Crank position sensor (CKP).

cylinder at a time - no wasted spark). The coil also has an

● Manifold absolute pressure sensor (MAP). extra terminal to monitor current on the coil secondary circuit.

This is used for knock detection and combustion diagnostics.

● Intake air temperature sensor (IAT).

The ignition system gives a spark near top dead center for

● Engine temperature sensor (ET). starting. At RPM and loads above this, the system gives a

spark advance that varies between 0° and 50°.

● Idle air control (IAC).

The IAT, ET and TP sensors are used to provide information

● Throttle position sensor (TP).

to the ECM to fine tune spark and fuel delivery. The VSS is

● Vehicle speed sensor (VSS). used as an input for idle speed control.

● Turn signal module (TSM) or optional, factory-installed

turn signal security module (TSSM). This includes an TROUBLESHOOTING

integrated bank angle sensor (BAS).

● Ignition coil. See the diagnostic charts that follow for troubleshooting infor-

mation.

The ECM is mounted under the electrical caddie cover (left

side of vehicle). It computes the spark advance for proper

ignition timing based on sensor inputs (from CKP, MAP and

TP sensor) and regulates the low-voltage circuits between

battery and ignition coil.

The ECM contains all of the solid state components used in

the ignition system. The dwell time for the ignition coil is also

calculated in the microprocessor and is dependent upon bat-

tery voltage. The programmed dwell is an added feature to

give adequate spark at all speeds. (The ECM has added pro-

tection against transient voltages, continuous reverse voltage

protection, and damage due to jump starts.) The ECM is fully

enclosed to protect it from vibration, dust, water or oil. This

unit is a non-repairable item. If it fails, it must be replaced.

The crank position sensor (CKP) is located in the front left

side of the crankcase. The CKP generates an AC signal

which is sent to the ECM where it is used to reference engine

position (TDC) and speed. It functions by taking readings off

the 30 teeth on the left side flywheel (two teeth are missing to

establish a reference point).

The MAP sensor is located on top of the intake manifold. The

MAP sensor monitors the intake manifold pressure (vacuum)

and sends the information to the ECM where the module

adjusts the spark and fuel timing advance curve for optimum

performance.

2004 Touring: Engine Management (EFI) 5-3

HOME

[62B]

CKP To Tachometer Y/GN

87

I Q C P R

(FLHR/C/S Optional) System

87A

[78]

relay

BE/GY

30 85 86

[79A] 1 2 GN/O

3 W/BK

[79B] 1 2

R 30 15 Amp

BK 12 fuel pump [13A] [13B]

fuse

System relay 4 GN/O Fuel

O/GY

1

1

1

1

Y/GN pump

2

2

2

2

AB

AB

Inj. F

3

3

3

3

21 W/Y

Y/GN

[141B] [141A]

[84B] [84A] BK

Y/GN All Except

FLHR/C/S

[83B] [83A]

AB

AB

Inj. R 19 GN/GY

A B

A B

[85B] [85A] Coil

Ion sense 27 GY/BE

Coil R Y/BE

C D

C D

11

Coil F 29 BE/O

A A BE/GN 35 40 Amp

B B BN/R 36 Maxi fuse

C C BK/PK 18

+ –

D D BK/O 17 15 Amp Battery

ECM fuse R

[87A] [87B] Constant 31 BE/GY

Intake air power BK

control

Engine

stop 15 Amp

switch IGN fuse

Switch power 13 W/BK GY R/BK

Ignition switch

BK/W

A B C

A B C

TP

R/W sensor

TP sensor 24 GY/V GY/V To right

[90B] [90A] hand controls

[88B] [88A]

ET sensor 6 PK/Y

1 2

1 2

ET sensor GY

3 4 5

BK/W

W/BK

W/BN

IAT sensor 7 LT GN/Y

A B

A B

IAT sensor

5v sensor gnd. 26 BK/W BK/W [22A]

[89B] [89A] [80B] [80A]

BK/W

A B C

A B C

MAP sensor V/W V/W MAP

25 sensor

5v sensor pwr. 14 R/W R/W

Vehicle

A BC

ABC

Vehicle speed sensor 33 W/GN speed

sensor

[65B] [65A]

LT GN/V To speedometer

Serial data 5

and tachometer

[91A]

3

Data link

1 connector

2

Flash pin 1 LT GN/R

4 [30B] 2 3 7 TSM/

Power gnd. 10 BK TSSM

[30A] 2 3 7

Power gnd. 28 BK

f2208g8x

Figure 5-2. EFI System Circuit - Simplified

5-4 2004 Touring: Engine Management (EFI)

HOME

EFI DIAGNOSTIC INTRODUCTION 5.3

SYSTEM PROBLEMS

All system problems fall into at least one of three general cat-

egories. 40

50 60 70 30 50

40 80

No Start 30 90 20

MPH RPM x100

The engine cranks over freely, but will not start. This does not 20 100

10

include situations where the engine will not crank, such as a 10 110

security disabled starter, dead battery, etc. This condition 0 120 0

assumes that all obvious checks (fuel in tank, etc.) have been

made. C

H A E R TIFI E D HA

R L E Y-D A VI D S O N

R L E Y-D A VI D S O N

Poor Performance

The engine starts but there are performance problems. These

problems may include poor fuel economy, rough idle, engine

Check Engine Lamp

misfire, engine hesitation, severe spark knock, etc. f2160x8x

Check Engine Lamp Figure 5-3. Speedometer

See Figure 5-3. The check engine lamp indicates the ECM

has determined a fault condition exists. There may also be

starting or performance problems.

RESOLVING PROBLEMS

To resolve system problems, five basic steps are involved. In

order of occurrence, they are:

1. Check for diagnostic trouble codes by using speedome-

ter self diagnostics. See 5.4 CHECKING FOR DIAG-

NOSTIC TROUBLE CODES: EFI.

2. Retrieve diagnostic trouble codes by using speedometer

self diagnostics. See 5.6 SPEEDOMETER SELF DIAG-

NOSTICS.

3. Diagnose system problems. This involves using special

tools and the diagnostic flow charts in this section.

4. Correct problems through the replacement and/or repair

of the affected components.

5. After repairs are performed, the work must be validated.

This involves clearing the trouble codes and confirming

proper vehicle operation as indicated by the lack of trou-

ble codes.

2004 Touring: Engine Management (EFI) 5-5

HOME

CHECKING FOR DIAGNOSTIC TROUBLE CODES: EFI 5.4

CHECK ENGINE LAMP

To diagnose system problems, start by observing the behav-

ior of the check engine lamp.

NOTES

● See Figure 5-4. “Key ON” means that the ignition key is

turned to IGN and the engine stop switch is set to RUN

(although the engine is not running).

● When the ignition key is turned ON, the check engine

lamp will illuminate for approximately four seconds and

then turn off.

f1240x2x

● If the check engine lamp is not illuminated at Key ON or if

it fails to turn OFF after the initial four second period,

then the speedometer may need to be replaced. See 5.5 Figure 5-4. Ignition Switch (FLTR, FLHT/C/U)

INITIAL DIAGNOSTIC CHECK: EFI.

1. When the lamp turns off after being illuminated for the

first four second period, it will: 2. See CODE TYPES which follows for a complete descrip-

tion of trouble code formats.

a. Remain off if there are no fault conditions or trouble

NOTE

codes currently detected by the ignition control mod-

ule. See A of Figure 5-5. Some trouble codes can only be fully diagnosed during actu-

ation. For example, a problem with the ignition coil will be

b. Come back on for an 8 second period if only historic considered a current fault even after the problem is corrected,

codes exist. See B of Figure 5-5. since the ECM will not know of its resolution until after the coil

is exercised by vehicle start sequence. In this manner, there

c. Come back on, and remain on, if a current trouble may sometimes be a false indication of the current trouble

code exists. See C of Figure 5-5. code.

ON 4 Sec.

A Lamp OFF: No Current or Historic Trouble Codes

OFF

Key On

Lamp ON 8 Seconds:

Only Historic Trouble Codes Exist

ON 4 Sec. 8 Sec.

B Lamp OFF

OFF 4 Sec.

Key On

Lamp Remains ON: Current Trouble Code *

ON 4 Sec.

C

OFF 4 Sec.

Key On * Historic Trouble Codes May Also Exist

Figure 5-5. Check Engine Lamp Operation

5-6 2004 Touring: Engine Management (EFI)

HOME

CODE TYPES RETRIEVING DIAGNOSTIC

There are two types of diagnostic trouble codes (DTCs): cur-

TROUBLE CODES

rent and historic. If a diagnostic trouble code is stored, it can

be read using speedometer self diagnostics. See 5.6 The engine management system provides two levels of diag-

SPEEDOMETER SELF DIAGNOSTICS. nostics.

All diagnostic trouble codes reside in the memory of the ● The most sophisticated mode uses a computer based

ECM/ICM, TSM/TSSM, speedometer or tachometer until the diagnostic package called the DIGITAL TECHNICIAN

code is cleared by use of the speedometer self diagnostics. (Part No. HD-44750).

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

● The second mode requires using the speedometer self

A historic diagnostic trouble code is also cleared after a total

diagnostics. Speedometer, tachometer (if equipped),

of 50 trips has elapsed. A trip consists of a start and run

TSM/TSSM and ECM codes can be accessed and

cycle. After the 50 trip retention period, the diagnostic trouble

cleared. See 5.6 SPEEDOMETER SELF DIAGNOSTICS

code is automatically erased from memory providing that no

for more information.

subsequent faults of the same type are detected in that

period.

Current MULTIPLE DIAGNOSTIC TROUBLE

Current trouble codes are those which occur during the

CODES

present ignition cycle. See the appropriate flow charts for

solutions. While it is possible for more than one fault to occur and set

more than one trouble code, there are several conditions

Historic which may result in one fault setting multiple trouble codes:

If a particular problem happens to resolve itself, the active ● The MAP and TP and vehicle speed sensors are con-

status problem is dropped and it becomes a historic code nected to the same reference line (+5V Vref). If the refer-

rather current code. ence line goes to ground or open, multiple codes will be

Historic codes are stored for a length of time to assist in the set (DTC P0107, P0122 and P0501).

diagnosis of intermittent faults. See Figure 5-5. The check

● Serial data codes (DTC U1300, U1301, U1016, U1064,

engine lamp will come back on for 8 seconds to indicate the

U1097 and U1255) may be accompanied by other

existence of only historic codes.

codes. Always correct the serial data codes before

It is important to note that historic codes may also be present resolving the other codes.

whenever the system indicates the existence of a current

code. See MULTIPLE DIAGNOSTIC TROUBLE CODES if Refer to Table 5-5. This table gives most ECM DTCs a priority

multiple trouble codes are found. ranking.

Diagnostic charts are designed for use with current trouble

codes and as a result they frequently suggest part replace-

ment. When diagnosing a historic code the charts can be

helpful but should not lead to part replacement without verifi-

cation the part is faulty.

2004 Touring: Engine Management (EFI) 5-7

HOME

INITIAL DIAGNOSTIC CHECK: EFI 5.5

GENERAL Diagnostic Tips

● If speedometer reads “No Rsp” (no response) while in

To locate faulty circuits or other system problems, follow the diagnostic mode, check data bus for an open or short to

diagnostic flow charts in this section. For a systematic ground between data connector [91A] Terminal 3 and

approach, always begin with INITIAL DIAGNOSTICS which ECM, TSM/TSSM, tachometer (if equipped) or speedom-

follows. Read the general information and then work your way eter. For more information on speedometer diagnostic

through the flow chart box by box. mode see 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Diagnostic Notes ● Check for an open diagnostic test terminal between data

Terminal 3 and ECM Terminal 5. With ignition key turned

If a numbered circle appears adjacent to a flow chart box, ON, transmit data should be typically 0.6-0.8 volts. The

then more information is offered in the diagnostic notes. Many range of acceptable voltage is greater than 0 and less

diagnostic notes contain supplemental information, descrip- than 7.0 volts.

tions of various diagnostic tools or references to other parts

of the manual where information on the location and removal ● If speedometer reads “BUS er” (serial data bus error),

of components may be obtained. refer to flow charts in 5.12 STARTS, THEN STALLS.

Circuit Diagram/Wire Harness Diagnostic Notes

Connector Table The reference numbers below correlate with the circled num-

bers on the diagnostic check flow charts. See page 5-15.

When working through a flow chart, refer to the illustrations,

the associated circuit diagram and the wire harness connec- 1. Compare engine behavior to symptoms tables.

tor table as necessary. The wire harness connector table for

each circuit diagram identifies the connector number, descrip- a. Starts hard. Refer to Table 5-2.

tion, type and general location.

b. Hesitates, stumbles, surges, misfires and/or slug-

In order to perform most diagnostic routines, a Breakout Box gish performance. Refer to Table 5-3.

and a DVOM are required. See 5.7 BREAKOUT BOX: EFI. c. Engine exhaust emits black smoke or fouls plugs.

To perform the circuit checks with any degree of efficiency, a Refer to Table 5-4.

familiarity with the various wire connectors is also necessary. 2. Connect BREAKOUT BOX (Part No. HD-43682) to

speedometer using HD-46601 adapters.

Reprogramming ECM

All EFI diagnostic codes are listed on page 5-11 in Table 5-5.

Diagnostic charts frequently suggest ECM replacement. In

the event an electronic control module (ECM) needs to be Other Codes

replaced, it must be reprogrammed using a computer based

diagnostic package called DIGITAL TECHNICIAN (Part No. See 3.9 INITIAL DIAGNOSTIC CHECK: TSM/TSSM for any

HD-44750). See your dealer. Password learn procedure must codes related to the turn signal module (TSM) or turn signal

also be performed. See 3.24 PASSWORD LEARN. security module (TSSM).

See 2.2 INITIAL DIAGNOSTIC CHECK: SPEEDOMETER for

any codes related to the speedometer or tachometer.

INITIAL DIAGNOSTICS

General Information

The diagnostic check (see page 5-15) is an organized

approach to identifying a problem caused by an electronic

control system malfunction.

5-8 2004 Touring: Engine Management (EFI)

HOME

Table 5-1. Typical Scan Values for Table 5-2. Engine Starts Hard

Engine Data

SYMPTOM SOLUTION

MIN. MAX. HOT

ITEM See charging system trouble-

VALUE VALUE IDLE Battery discharged

shooting in this section.

10.3-13.3 in. Hg 5.17 MISFIRE AT IDLE OR

10 kPa 104 kPa

MAP sensor 35-45 kPa Spark plugs

UNDER LOAD.

0 volts 5.1 volts

5.17 MISFIRE AT IDLE OR

Spark plug wires

0 100 0% UNDER LOAD.

TP sensor

0.2 volts 4.5 volts 0.2-1.0 volts 5.17 MISFIRE AT IDLE OR

Ignition coil

UNDER LOAD.

IAC pintle 0 155 30-45 steps

See Section 3 in the Touring

RPM 800 5600 990 Valve sticking

Service Manual.

3° F 464° F 230-300° F

(-16° C) (240° C) (110-150° C) Water or dirt in fuel system Drain and refill with fresh fuel.

ET sensor

0.0 volts 5.0 volts 0.5-3.23 volts Loss of battery power to

5.11 NO ECM POWER

ECM terminal 31*

3° F 248° F 104-140° F

IAT sensor (-16° C) (120° C) (40-60° C)

0.0 volts 5.0 volts 2.0-3.5 volts * Codes will not clear (although they appear to).

INJ PW front 0 50 mS 2-4 mSec

INJ PW rear 0 50 mS 2-4 mSec

Advance front 0 45° 10-15°

Advance rear 0 45° 10-15°

VSS 0 120 0 MPH

Battery voltage 10 15 14.5 volts

ENG RUN off Run Run

Idle RPM 800 1250 990

NOTE

Hot idle specifications are with stock exhaust, the engine

operating at 990 RPM and an engine temperature of approxi-

mately 260° F (127° C). Idle settings may be changed with

the idle set procedure. See the Touring Service Manual.

2004 Touring: Engine Management (EFI) 5-9

HOME

Table 5-3. Engine Performance Problems Table 5-4. Engine Exhaust Emits

Black Smoke or Fouls Plugs

SYMPTOM SOLUTION

SYMPTOM SOLUTION

Manifold leak

See 5.9 INTAKE LEAK See AIR CLEANER FILTER

NOTE- When manifold leak TEST. Clogged air filter in the Touring Service Man-

is large enough, IAC will A low IAC count may also ual.

close to 0 and code P0505 indicate an air leak. MAP sensor plugged or not

will set 5.19 DTC P0107, P0108.

operating properly

MAP sensor plugged or not

5.19 DTC P0107, P0108.

operating properly

Drain and refill with fresh

Water or dirt in fuel system

fuel.

5.17 MISFIRE AT IDLE OR

Spark plugs

UNDER LOAD.

See throttle cable adjust-

Throttle plate not opening

ment in the Touring Service

fully

Manual.

5.15 FUEL PRESSURE

Low fuel pressure

TEST.

5-10 2004 Touring: Engine Management (EFI)

HOME

Table 5-5. EFI Diagnostic Trouble Codes (DTC) and Fault Conditions

PRIORITY

DTC NO. FAULT CONDITION SOLUTION

RANKING

1 P0605 ECM flash error 5.27 DTC P0603, P0605

2 P0603 ECM EEPROM error 5.27 DTC P0603, P0605

3 “BUS Er” Serial data bus shorted low/open/high 5.12 STARTS, THEN STALLS

4 U1300 ECM serial data low 5.12 STARTS, THEN STALLS

5 U1301 ECM serial data open/high 5.12 STARTS, THEN STALLS

6 U1300 TSSM serial data low 5.12 STARTS, THEN STALLS

7 U1301 TSSM serial data open/high 5.12 STARTS, THEN STALLS

8 U1300 Speedometer/tachometer serial data low 5.12 STARTS, THEN STALLS

Speedometer/tachometer serial data open/

9 U1301 5.12 STARTS, THEN STALLS

high

10 U1064 Loss of TSM/TSSM serial data at ECM 5.30 DTC U1064, U1255

Loss of TSM/TSSM serial data at speedome-

11 U1064 5.30 DTC U1064, U1255

ter

Loss of all ECM serial data (state of health) at

3.21 DTC U1016, U1255

TSSM

Loss of all ECM serial data (state of health) at

3.21 DTC U1016, U1255

12 U1016 speedometer

Loss of vehicle speed 3.21 DTC U1016, U1255

Loss of vehicle inhibit motion 3.21 DTC U1016, U1255

Loss of powertrain security status 3.21 DTC U1016, U1255

13 U1097 Loss of speedometer serial data at TSSM 5.31 DTC U1097, U1255

14 U1255 Missing response at TSSM 3.21 DTC U1016, U1255

15 U1255 Missing response at speedometer 5.31 DTC U1097, U1255

16 P1003 System relay contacts open 5.14 SYSTEM RELAY CHECK

17 P1002 System relay coil high/shorted 5.14 SYSTEM RELAY CHECK

18 P1001 System relay coil open/low 5.14 SYSTEM RELAY CHECK

19 P1004 System relay contacts closed 5.14 SYSTEM RELAY CHECK

20 P1009 Incorrect password 5.28 DTC P1009, P1010

21 P1010 Missing password (starts then stalls) 5.28 DTC P1009, P1010

22 P0373 CKP sensor intermittent 5.24 DTC P0373, P0374

23 P0374 CKP sensor synch error 5.24 DTC P0373, P0374

24 P0122 TP sensor open/low 5.22 DTC P0122, P0123

25 P0123 TP sensor high 5.22 DTC P0122, P0123

26 P0107 MAP sensor open/low 5.19 DTC P0107, P0108

27 P0108 MAP sensor high 5.19 DTC P0107, P0108

28 P0117 ET sensor voltage low 5.21 DTC P0117, P0118

29 P0118 ET sensor open/high 5.21 DTC P0117, P0118

30 P0112 IAT sensor voltage low 5.20 DTC P0112, P0113

31 P0113 IAT sensor open/high 5.20 DTC P0112, P0113

32 P1351 Front ignition coil open/low 5.29 DTC P1351, P1352, P1354, P1355

33 P1354 Rear ignition coil open/low 5.29 DTC P1351, P1352, P1354, P1355

34 P1352 Front ignition coil high/shorted 5.29 DTC P1351, P1352, P1354, P1355

35 P1355 Rear ignition coil high/shorted 5.29 DTC P1351, P1352, P1354, P1355

36 P1357 Front cylinder combustion intermittent 5.18 COMBUSTION ABSENT/INTERMITTENT

37 P1358 Rear cylinder combustion intermittent 5.18 COMBUSTION ABSENT/INTERMITTENT

38 P0261 Front injector open/low 5.23 DTC P0261, P0262, P0263, P0264

39 P0263 Rear injector open/low 5.23 DTC P0261, P0262, P0263, P0264

40 P0262 Front injector high 5.23 DTC P0261, P0262, P0263, P0264

2004 Touring: Engine Management (EFI) 5-11

HOME

Table 5-5. EFI Diagnostic Trouble Codes (DTC) and Fault Conditions

PRIORITY

DTC NO. FAULT CONDITION SOLUTION

RANKING

41 P0264 Rear injector high 5.23 DTC P0261, P0262, P0263, P0264

42 P0562 Battery voltage low 5.26 DTC P0562, P0563

43 P0563 Battery voltage high 5.26 DTC P0562, P0563

44 P0501 VSS sensor low 5.25 DTC P0501, P0502

45 P0502 VSS sensor high 5.25 DTC P0501, P0502

46 P1356 Rear cylinder no combustion 5.18 COMBUSTION ABSENT/INTERMITTENT

47 P1353 Front cylinder no combustion 5.18 COMBUSTION ABSENT/INTERMITTENT

48 P0505 Loss of idle speed control 5.16 IDLE AIR CONTROL

49 B1135 Accelerometer fault 3.19 DTC B1135

51 B1134 Starter output high 3.18 DTC B1134

52 B1121 Left turn output fault 3.15 TURN SIGNAL ERRORS

53 B1122 Right turn output fault 3.15 TURN SIGNAL ERRORS

54 B0563 Battery voltage high 3.16 DTC B0563

55 B1131 Alarm output low 3.17 DTC B1131, B1132

56 B1132 Alarm output high 3.17 DTC B1131, B1132

57 B1141 Ignition switch open/low 3.15 TURN SIGNAL ERRORS

5-12 2004 Touring: Engine Management (EFI)

HOME

[156B] [156A]

f2208u8x

6 6

Main to Interconnect

5 5 Harness

4 4

BK 3 3 GY

2 2 BK

LtGN/V 1 1 LtGN/V

O

BN/GY 1 2 3 4 5 6 7 8 9 10 11 12 [30B]

1 2 3 4 5 6 7 8 9 10 11 12 [30A]

BN/GY TSM/TSSM

BK

1 2 3 4 5 6 7 8 9 10 11 12 [39B]

GY

1 2 3 4 5 6 7 8 9 10 11 12 [39A]

Speedometer [108B]

1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12 [8B] EFI

1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12 [8A] Harness

[108A]

Tachometer

[1B] [1A]

15A 1

Accessory

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

Fuse 2

Main to Interconnect 3

1 2 3 4 5 6 7 8 9 10 11 12

Harness 4

[2B] Data Link

[2A] 1 2 3 4 5 6 7 8 9 10 11 12 15A

Ignition

Main to Interconnect Fuse [91A]

Harness

LtGN/R

LtGN/V

[78B]

15A 1 5 ECM

Battery [78A]

Fuse

Flash pin

Serial data

Figure 5-6. Diagnostic Check (FLTR, FLHT/C/U)

Table 5-6. Wire Harness Connectors in Figure 5-6.

NO. DESCRIPTION MODEL TYPE LOCATION

Main to Interconnect FLHT/C 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[1]

Harness FLTR 12-Place Deutsch (Black) Inner Fairing - Below Radio (Left Side)

Main to Interconnect FLHT/C 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[2]

Harness FLTR 12-Place Deutsch (Gray) Inner Fairing - Below Radio (Left Side)

[8] Main to EFI Harness All 12-Place Deutsch (Gray) Under Right Side Cover

Turn Signal/Security Cavity in Crossmember at Rear of

[30] All 12-Place Deutsch

Module Battery Box (Under Seat)

FLHT/C 12-Place Packard Inner Fairing (Back of Speedometer)

[39] Speedometer

FLTR 12-Place Packard Under Bezel (Back of Speedometer)

[78] Electronic Control Module All 36-Place Packard Under Right Side Cover

[91] Data Link All 4-Place Deutsch Under Right Side Cover

FLHT/C 12-Place Packard Inner Fairing (Back of Tachometer)

[108] Tachometer

FLTR 12-Place Packard Under Bezel (Back of Tachometer)

Main to Interconnect FLHT/C 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

[156]

Harness FLTR 6-Place Deutsch Inner Fairing - Front of Right Fairing Bracket

2004 Touring: Engine Management (EFI) 5-13

HOME

f2208t8x

BK

GY

LtGN/V LtGN/V BK

BN/GY

O 1 2 3 4 5 6 7 8 9 10 11 12 [30B]

1 2 3 4 5 6 7 8 9 10 11 12 [30A]

BN/GY TSM/TSSM

1 2 3 4 5 6 7 8 9 10 11 12 BK

[39B]

1 2 3 4 5 6 7 8 9 10 11 12 [39A] GY

Speedometer 1 2 3 4 5 6 7 8 9 10 11 12 [8B] EFI

1 2 3 4 5 6 7 8 9 10 11 12 [8A] Harness

15A 15A

Battery Accessory

Fuse Fuse

1

15A 2

Ignition

Fuse 3

4

Data Link

[91A]

LtGN/R

LtGN/V

[78B]

1 5 ECM

[78A]

Flash pin

Serial data

Figure 5-7. Diagnostic Check (FLHR/C/S)

Table 5-7. Wire Harness Connectors in Figure 5-7.

NO. DESCRIPTION TYPE LOCATION

[8] Main to EFI Harness 12-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

[30] Turn Signal/Security Module 12-Place Deutsch

Battery Box (Under Seat)

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[78] Electronic Control Module 36-Place Packard Under Right Side Cover

[91] Data Link 4-Place Deutsch Under Right Side Cover

5-14 2004 Touring: Engine Management (EFI)

HOME

Diagnostic Check (Part 1 of 2)

Does engine

start?

YES. YES. NO. NO.

Starts and Starts, then Cranks, but Engine will not

runs. stalls. will not start. crank.

Check for trouble See 5.12 STARTS, THEN See 5.10 ENGINE CRANKS, See 1.2 STARTING SYSTEM

codes. See 5.6 STALLS. BUT WILL NOT START. DIAGNOSIS.

SPEEDOMETER

SELF DIAGNOSTICS

Codes found?

NO NO

YES 1

Unable to enter diagnostic mode. No codes displayed. For

Refer to applicable trouble code priority chart. With ignition switch OFF, press and symptoms that may not set

All diagnostic codes are listed on page 5-11 release odometer reset switch. diagnostic trouble codes,

in Table 5-5. Codes are listed by priority. Does odometer display appear with refer to table 5-2, Table 5-3

display backlighting? and Table 5-4.

YES

NO

STOP Check for continuity to ground on terminal 7

of speedometer. Wiggle harness during con-

tinuity check. Continuity present?

Go to Diagnostic

Check (Part 2 of 2).

YES NO

Check for battery voltage at

terminal 5 of speedometer Locate and repair open

while wiggling harness. Bat- between terminal 7

tery voltage continuously and ground.

present?

YES NO

Check continuity (with ignition Locate and repair open

switch OFF) between terminals between terminal 5 and

8 and 11 on breakout box. Con- battery fuse.

tinuity present when speedome-

ter reset switch is depressed?

Replace speedometer. Replace speedometer

reset switch.

2004 Touring: Engine Management (EFI) 5-15

HOME

Diagnostic Check (Part 2 of 2)

Continued from Diagnostic Check (Part 1 of 2).

Perform “wow” test. See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

The following features should be functional

1) backlight should illuminate

2) needle should sweep its full range of motion

3) LED’s that should illuminate:

• check engine

• battery

• security (all models)

4) LED’s that may illuminate:

• low fuel (EFI models)

• cruise (even though not cruise equipped)

Are all features functional?

YES

NO

Turn key to ACC. Is

backlight present? Check for battery voltage at

terminal 1 of breakout box.

Battery voltage present?

YES NO

YES NO

Is problem intermittent? Check for battery voltage at Replace speedometer. Is instrument

breakout box terminal 6. fuse blown?

Battery voltage present?

YES YES NO

NO

Replace speedometer. Locate and repair open on O/W Locate and repair Locate and repair

wire between terminal 6 of con- source of fault. open between terminal

nector [39] and accessory fuse. Replace fuse. 1 of connector [39]

and instrument fuse.

YES NO

YES

Intermittent vehicle speed

Repeat Diagnostic indication.

Check while wiggling Tachometer Inoperative

harnesses. Intermittent (no engine speed).

present? Remove and inspect vehi-

cle speed sensor. Debris

present?

See Test 2.4 (Part 1 of 2)

under 2.4 SPEEDOMETER/

YES NO

TACHOMETER.

YES NO

Locate and repair

intermittent. No trouble found.

Remove debris. Reinstall Check for damaged wiring/

vehicle speed sensor. loose connection between

vehicle speed sensor and

ECM. Is wiring damage/loose

connection present?

YES NO

Locate and repair Replace Speedometer.

source of fault.

5-16 2004 Touring: Engine Management (EFI)

HOME

SPEEDOMETER SELF DIAGNOSTICS 5.6

GENERAL d0715x8x

The speedometer is capable of displaying and clearing

speedometer, tachometer, TSM/TSSM, and ICM/ECM trouble

codes (diagnostic mode).

DIAGNOSTICS

Diagnostic Tips

● For a quick check of speedometer function, a “wow” test

can be performed. See Figure 5-8. Press and hold

odometer reset switch then turn ignition switch ON.

Release reset switch. Background lighting should illumi-

nate, speedometer needle should sweep its full range of

motion, and indicator lamps [battery, security, low fuel

(EFI models) check engine and cruise] should illuminate.

Some lamps may illuminate even though they do not 1 5

2 4

apply to the vehicle. For example, the cruise lamp may 3

illuminate even though the motorcycle may not be

equipped with cruise control.

1. Cruise On/Engaged 4. Battery

● If instrument module fails “wow” test, check for battery, 2. Check Engine 5. Security

ground, ignition, speedometer reset switch and acces- 3. Low Fuel

sory to speedometer. If any feature in the speedometer is

non-functional, see 2.2 INITIAL DIAGNOSTIC CHECK:

Figure 5-8. Speedometer (FLHR/C/S)

SPEEDOMETER.

Diagnostic Notes

Use of speedometer self diagnostics assumes that DIGITAL

TECHNICIAN (Part No. HD-44750) is not available.

The reference numbers below correlate with the circled num-

bers in the Speedometer Self Diagnostics (chart)

1. To exit diagnostic mode, turn ignition switch OFF.

2. To clear DTCs for selected module, press speedometer

reset switch for more than 5 seconds when code is dis-

played. This procedure will clear all codes for selected

module.

2004 Touring: Engine Management (EFI) 5-17

HOME

Speedometer Self Diagnostics (chart)

1

While holding odometer reset switch in,

turn ignition switch to IGN. Make sure

Run/Stop switch is in RUN position.

Release reset switch.

Does “diag” appear?

YES NO

See 2.2 INITIAL DIAGNOSTIC

To display DTCs for the CHECK: SPEEDOMETER.

ECM, press and hold

”P” flashing.

reset switch for more

than 5 seconds.

To choose TSM/

TSSM, press and

release reset switch.

To display DTCs for

”S” flashing. TSM/TSSM, press and

hold reset switch for

more than 5 seconds.

To choose Speedometer, Device

press and release reset response?

switch. NO

YES “no rsp” displayed.*

To display DTCs for Tachometer malfunction.

”SP” flashing. speedometer, press and See 2.4 SPEEDOMETER/

hold reset switch for more TACHOMETER.

than 5 seconds.

* Models not equipped

with a tachometer will

display “no rsp” nor-

To choose Tachometer, mally.

“none” displayed.

press and release reset

switch.

DTC

2 displayed.

To display DTCs for

tachometer, press and Press and release Press and release

”T” flashing.

hold reset switch for more reset switch. Part num- reset switch.

than 5 seconds. ber of module will be Are more DTCs

displayed. displayed?

NO

To choose ECM, press

and release reset switch. YES

“end” displayed.

To clear all DTCs for

selected module hold reset

switch for more than 5 sec-

onds. If DTCs are not to be

cleared, Press and release

reset switch. Part number of

module will be displayed.

Press and release reset

switch again to continue to

next module.

Figure 5-9. Speedometer Self Diagnostics

5-18 2004 Touring: Engine Management (EFI)

HOME

BREAKOUT BOX: EFI 5.7

GENERAL

f1917x9x

The BREAKOUT BOX (Part No. HD-43876) splices into the

main harness. Used in conjunction with a DVOM, it allows cir-

cuit diagnosis of wiring harness and connections without hav-

ing to probe with sharp objects.

NOTE

See wiring diagrams for ECM terminal functions.

INSTALLATION

1. Remove right saddlebag and side cover. See Figure 5-

10.

2. Depress latch and remove connector [78B] to release

EFI harness from ECM.

3. Install connectors on Breakout Box to ECM and EFI har- Electronic Control

ness connectors. Module Connector [78]

Figure 5-10. Electrical Bracket (Under Right Side Cover)

REMOVAL

1. Separate connectors to remove Breakout Box between

ECM and EFI harness.

2. Install connector [78B] to connect EFI harness to ECM.

3. Install right side cover and saddlebag.

Figure 5-11. Breakout Box (Part No. HD-43876)

2004 Touring: Engine Management (EFI) 5-19

HOME

WIGGLE TEST 5.8

GENERAL hd39978

The wiggle test indicates the presence of intermittents in a

wiring harness.

PROCEDURE

1. See Figure 5-12. Connect DVOM (Part No. HD-39978) to

wiring harness between the suspect connections. When

diagnosing ECM connections, use a BREAKOUT BOX

(Part No. HD-43876) to simplify the procedure. See 5.7

BREAKOUT BOX: EFI. Figure 5-12. Fluke 78 Multimeter (DVOM)

(Part No. HD-39978)

2. Set DVOM to read voltage changes.

3. Start motorcycle engine and run at idle.

4. Shake or wiggle harness to detect intermittents. If inter-

mittents are present, radical voltage changes will register

on the DVOM.

5-20 2004 Touring: Engine Management (EFI)

HOME

INTAKE LEAK TEST 5.9

GENERAL 9648

1DANGER

Propane is an extremely flammable liquid and vapor.

Vapor may cause flash fire. Keep away from heat, sparks

and flame. Keep container closed. Use only with ade-

quate ventilation.

1WARNING

Read all directions and warnings on propane bottle. Fail-

ure to follow all directions and warnings on bottle could

result in death or serious injury.

Figure 5-13. Nozzle

● To prevent false readings, keep airbox cover installed

when performing test. 9649

● Do not direct propane into air cleaner, false readings will 1 4

result.

3 5

LEAK TESTER

2

Parts List

● Standard 14 oz. propane cylinder. 6

● Snap-on YA7148 Propane Enrichment Kit.

● 12 in. (304 mm) long-1/4 in. (6 mm) diameter copper tub-

ing.

Tester Assembly

1. Nozzle

1. Cut rubber hose from kit to 18 in. (457 mm) in length. 2. Copper tube

3. Hose

2. See Figure 5-13. Flatten one end of copper tube to form

4. Valve

a nozzle.

5. Knob

3. Insert round side of copper tube into end of tubing. 6. Propane bottle

Figure 5-14. Leak Tester

2004 Touring: Engine Management (EFI) 5-21

HOME

INTAKE LEAK TESTING 10054

1. Start engine.

2. Warm engine to operating temperature.

3. See Figure 5-14. Turn knob (5) counterclockwise to open

propane bottle (6).

1DANGER

Propane is an extremely flammable liquid and vapor.

Vapor may cause flash fire. Keep away from heat, sparks

and flame. Keep container closed. Use only with ade-

quate ventilation.

Figure 5-15. Checking for Leaks

NOTE

Do not direct propane stream toward front of engine. If pro-

pane enters air cleaner, a false reading will be obtained.

4. See Figure 5-15. Aim nozzle toward possible sources of

leak such as fuel injectors and intake tract.

5. See Figure 5-14. Push valve (4) to release propane.

Tone of engine will change when propane enters source

of leak.

5-22 2004 Touring: Engine Management (EFI)

HOME

ENGINE CRANKS, BUT WILL NOT START 5.10

GENERAL d0273x8x

If the starter will not crank the engine, the problem is not EFI

related. Refer to SECTION 1-STARTING & CHARGING or

SECTION 3-TSM & TSSM.

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled num-

bers on the Test 5.10 flow charts.

1. Check for trouble codes. See RETRIEVING DIAGNOS- Figure 5-16. Spark Tester

TIC TROUBLE CODES under 5.4 CHECKING FOR

DIAGNOSTIC TROUBLE CODES: EFI. 7863

2. Check the condition of the battery. Perform a voltage test

and recharge if below 12.60V. Check battery connections

and perform load test. Replace the battery if necessary.

See BATTERY in the Touring Service Manual.

3. Connect BREAKOUT BOX (Part No. HD-43876). See 5.7

BREAKOUT BOX: EFI.

4. Remove spark plug cable from spark plug.

a. Visually check condition of plug.

b. See Figure 5-16. Attach cable to SPARK TESTER

(Part No. HD-26792). Clip tester to cylinder head

bolt.

c. While cranking engine, look for spark. Repeat pro-

cedure on other spark plug cables.

Figure 5-17. Ignition Coil Circuit Test

NOTE

Engine will not spark with both spark plugs removed. When

checking for spark, use SPARK TESTER (Part No. HD-

26792) with both plugs installed. Diagnostic Tips

5. Use HARNESS CONNECTOR TEST KIT (Part No. HD- Check TP sensor value with DVOM. If TP sensor is equal to or

41404), gray pin probe and patch cord. greater than 3.8 volts, system is in “clear flood” mode and

engine will not start. While spark is present, fuel is shut off.

6. Typically, when IAC is not functioning, the engine will not Problem can be mechanical, such as throttle cables stuck.

start unless throttle is opened and the engine will stall

when throttle is closed.

7. See Figure 5-17. Plug IGNITION COIL CIRCUIT TEST

ADAPTER (Part No. HD-44687) and FUEL INJECTOR

TEST LAMP (Part No. HD-34730-2C) into Breakout Box

Terminals 13 and 11. Start engine. If lamp flashes, no

problem is found. Repeat for Breakout Box Terminals 13

and 29.

8. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), brown socket probe and patch cord.

2004 Touring: Engine Management (EFI) 5-23

HOME

[62B]

CKP To Tachometer Y/GN

87

I Q C P R

(FLHR/C/S Optional) System

87A

[78]

relay

BE/GY

30 85 86

[79A] 1 2 GN/O

3 W/BK

[79B] 1 2

R 30 15 Amp

BK 12 fuel pump [13A] [13B]

fuse

System relay 4 GN/O Fuel

O/GY

1

1

1

1

Y/GN pump

2

2

2

2

AB

AB

Inj. F

3

3

3

3

21 W/Y

Y/GN

[141B] [141A]

[84B] [84A] BK

Y/GN All Except

FLHR/C/S

[83B] [83A]

AB

AB

Inj. R 19 GN/GY

A B

A B

[85B] [85A] Coil

Ion sense 27 GY/BE

Coil R Y/BE

C D

C D

11

Coil F 29 BE/O

A A BE/GN 35 40 Amp

B B BN/R 36 Maxi fuse

C C BK/PK 18

+ –

D D BK/O 17 15 Amp Battery

ECM fuse R

[87A] [87B] Constant 31 BE/GY

Intake air power BK

control

Engine

stop 15 Amp

switch IGN fuse

Switch power 13 W/BK GY R/BK

Ignition switch

BK/W

A B C

A B C

TP

R/W sensor

TP sensor 24 GY/V GY/V To right

[90B] [90A] hand controls

[88B] [88A]

ET sensor 6 PK/Y

1 2

1 2

ET sensor GY

3 4 5

BK/W

W/BK

W/BN

IAT sensor 7 LT GN/Y

A B

A B

IAT sensor

5v sensor gnd. 26 BK/W BK/W [22A]

[89B] [89A] [80B] [80A]

BK/W

A B C

A B C

MAP sensor V/W V/W MAP

25 sensor

5v sensor pwr. 14 R/W R/W

Vehicle

A BC

ABC

Vehicle speed sensor 33 W/GN speed

sensor

[65B] [65A]

LT GN/V To speedometer

Serial data 5

and tachometer

[91A]

3

Data link

1 connector

2

Flash pin 1 LT GN/R

4 [30B] 2 3 7 TSM/

Power gnd. 10 BK TSSM

[30A] 2 3 7

Power gnd. 28 BK

f2208g8x

Figure 5-18. EFI System Circuit - Simplified

5-24 2004 Touring: Engine Management (EFI)

HOME

Table 5-8. Wire Harness Connectors in Figure 5-18.

NO. DESCRIPTION MODEL TYPE LOCATION

12-Place Deutsch Inner Fairing - Fork Stem Nut Lock Plate

FLHT/C/U

(Black) (Left Side)

Right Handlebar Switch 12-Place Deutsch

[22] FLTR Inner Fairing - Right Side of Radio Bracket

Controls (Black)

Inside Headlamp Nacelle - Fork Stem

FLHR/C/S 6 - Place Deutsch

Nut Lock Plate (Right Side)

Cavity in Crossmember at Rear of

[30] Turn Signal/Security Module All 12 - Place Deutsch

Battery Box (Under Seat)

Under Right Side Cover

[65] Vehicle Speed Sensor All 3 - Place Deutsch

(Behind Electrical Bracket)

[78] Electronic Control Module All 36-Place Packard Under Right Side Cover

[79] Crankshaft Position Sensor All 2 - Place Mini-Deutsch Bottom of Voltage Regulator

Manifold Absolute Pressure

[80] All 3 - Place Packard Top of Induction Module

Sensor

[83] Ignition Coil All 4 - Place Packard Below Fuel Tank (Left Side)

[84] Front Injector All 2 - Place Packard Below Fuel Tank (Left Side)

[85] Rear Injector All 2 - Place Packard Below Fuel Tank (Left Side)

[87] Idle Air Control All 4 - Place Packard Below Fuel Tank (Right Side)

[88] Throttle Position Sensor All 3 - Place Packard Below Fuel Tank (Right Side)

[89] Intake Air Temperature Sensor All 2 - Place Packard Below Fuel Tank (Right Side)

[90] Engine Temperature Sensor All 2 - Place Packard Back of Front Cylinder (Left Side)

[91] Data Link All 4 - Place Deutsch Under Right Side Cover

2004 Touring: Engine Management (EFI) 5-25

HOME

Test 5.10 (Part 1 of 4)

ENGINE CRANKS, BUT WILL NOT START

Fresh fuel in tank?

NOTE

Refer to IGNITION COIL in the Tour-

ing Service Manual for proper coil ter-

minal location.

Spark plug wires firmly

connected to proper coil terminals?

Add fuel /connect

NO

spark plugs.

YES

Check for trouble

1 codes.

Codes found?

NO

Is TSM/TSSM mounted in

proper orientation?

YES

Refer to Table 5-5.

Start with YES

the lowest ranking NO

code. Check battery connections

2 and voltage. Is voltage

Install TSM/TSSM properly.

above 12.60?

YES NO

Does battery pass Was battery allowed to dis-

load test? charge? Was battery drawn

down by starting problem?

Recharge battery.

YES NO

Turn ignition key ON and engine stop Replace battery.

switch to RUN. Did fuel pump run for 2

seconds and check engine lamp illumi-

nate for 4 seconds?

YES NO

No pump, NO

light OK. No light or pump

Connect breakout box to ECM [78]. Measure

3 voltage to breakout box with DVOM at terminal

13 (+) and terminal 4 (-). Crank engine for See

greater than 2 seconds to insure proper system 5.13 FUEL SYSTEM See 5.11 NO ECM POWER.

operation. 6-12 volts present continuously? ELECTRICAL TEST.

YES

NO

Go to bold asterisk in

Go to Test 5.10 Test 5.10 (Part 4 of 4).

STOP (Part 2 of 4).

5-26 2004 Touring: Engine Management (EFI)

HOME

Test 5.10 (Part 2 of 4)

ENGINE CRANKS, BUT WILL NOT START

Continued from Test 5.10 (Part 1 of 4).

Install fuel pressure gauge (Part No. HD-41182).

See 5.15 FUEL PRESSURE TEST. While

cranking engine (for more than 2 seconds to

ensure proper system operation), verify that

fuel pressure rises to 55-62 PSI (380-427 kPa).

Adequate fuel pressure present?

YES NO

Check spark plug condition, replace if fouled. Incorrect pressure. See 5.15

Reinstall spark plugs before checking spark. FUEL PRESSURE TEST.

Check spark at both plugs while cranking.

4 Spark present?

YES NO

Verify connector is securely attached Check battery voltage at

to each injector. If so, disconnect fuel Terminal A (+) of coil connector

injector connector and attach fuel [83B] using DVOM. Battery

injector test lamp (HD-34730-2C). voltage present for 2 seconds

Crank engine. Does lamp flash? 5 after key ON?

YES NO YES NO

Monitor IAC pintle for 10 seconds Correct problems with Open in Y/GN wire

6 after turning ignition OFF. Does pin-

tle extend and then retract during

fuel injectors. See 5.23 STOP between splice for fuel

DTC P0261, P0262, pump wire and ignition

10 second key OFF P0263, P0264. coil. Repair open

reset procedure?

Go to Test 5.10

(Part 3 of 4).

YES NO

Check for plugged fuel See 5.16 IDLE

injectors. Injectors AIR CONTROL.

plugged?

YES NO

Replace plugged Check engine compression.

injector(s).

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Engine Management (EFI) 5-27

HOME

Test 5.10 (Part 3 of 4)

ENGINE CRANKS, BUT WILL NOT START

Continued from Test 5.10 (Part 2 of 4).

7

Perform coil circuit test. Does lamp flash?

YES NO

Check coil connections. Disconnect ECM connector [78]. Inspect

Connections OK? for damaged terminals, terminals backed

out or corroded. Terminal problems

present?

YES NO

Test spark plug cable resis- YES NO

Repair.

tance. See 5.17 MISFIRE AT

IDLE OR UNDER LOAD.

Resistance OK? Repair terminal Reconnect. Problem

damage. still exist?

YES NO

YES NO

Replace spark

Replace plug cables.

coil.

Problem

fixed.

STOP

Go to Test 5.10

(Part 4 of 4).

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

5-28 2004 Touring: Engine Management (EFI)

HOME

Test 5.10 (Part 4 of 4)

ENGINE CRANKS, BUT WILL NOT START

Continued from Test 5.10 (Part 3 of 4).

Check connectors for moisture and cor-

rosion. Check wires for chafing. Con-

nect DVOM to ECM terminals 12 and

30 on Breakout Box and set it for AC

volts. Crank engine. Does DVOM read

1 VAC minimum?

YES NO

Replace ECM.

Reprogram and Disconnect CKP connector

learn password. [79]. Check connectors for

moisture and corrosion. Check

wires for chafing. Is connector

or wire damage present?

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk. YES NO

Disregard the asterisk (but not the

instruction box) if your normal pro-

gression through the chart brings Repair damage.

Connect DVOM to Terminals

you to this location. 8 1 and 2 of [79A]. Crank

engine. Does DVOM read 1

VAC minimum?

YES NO

Check for continuity between

terminal 30 on Breakout Box With meter still connected,

and Terminal 1 of connector check for resistance.

[79B]. Is resistance 600-1200 ohms?

Continuity present?

YES NO YES NO

Locate and repair open on Locate and repair open on Loosen sensor at crankcase. Replace crank position sensor.

BK wire between Terminal 2 of R wire between Terminal 1 of Check for contamination or

connector [79B] and terminal connector [79B] and terminal damage. Tighten sensor.

12 on Breakout Box. 30 on Breakout Box.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Engine Management (EFI) 5-29

HOME

NO ECM POWER 5.11

GENERAL

System Fuse Block (Under Left Side Cover)

8

No Spark/No Check Engine Lamp FLHR/C/S

at Key ON 9

10

Constant power is supplied to the ECM through terminal 31.

The ECM turns on when power is applied to terminal 13 of 5

connector [78]. The ECM goes through an initialization 11

sequence every time power is removed and re-applied to ter-

minal 13. The only visible part of this sequence is the check

engine lamp. Upon starting, the check engine lamp will illumi-

nate for 4 seconds and then (if parameters are normal) go 4

out. 12

If battery power is absent at ECM terminal 31:

● DTCs cannot be cleared. Tool will show them as cleared

f2210x8x

1 2 3

but will be present next time ignition key is cycled.

FLTR, FLHT/C/U 8 7

● ECM cannot be re-flashed.

● Vehicle will start but IAC pintle will not reset at key OFF. 9 6

Eventually pintle will be out of position causing perfor- 10

mance problems. 5

NOTE 11

The key ON sequence also activates the idle air control

motor. If power from terminal 31 is disrupted (blown fuse,

etc.) always turn the key OFF wait 10 seconds then turn the

4

key ON to reset the motor to the default position.

DIAGNOSTICS 3

f2204x8x 1 2

Diagnostic Notes 1. Headlamp 7. Radio Power

2. Ignition 8. Accessory

The reference numbers below correlate with the circled num- 3. Lighting 9. Battery

bers on the Test 5.11 flow charts. 4. Instruments 10. Brake Light Relay

5. Brakes/Cruise 11. P&A

1. Connect BREAKOUT BOX (Part No. HD-43876). See 5.7 6. Radio Memory 12. Starter Relay

BREAKOUT BOX: EFI.

NOTE EFI Fuse Block (Under Right Side Cover)

Adapters are not used on FLTR and FLHT/C/U models.

EFI System

2. Connect BREAKOUT BOX (Part No. HD-42682) Relay

between connectors [22A] and [22B] using Adapters Spare

(HD-42962) on FLHR/C/S models.

Fuel Pump

ECM Power

f2223x9x

Figure 5-19. Fuse Locations

5-30 2004 Touring: Engine Management (EFI)

HOME

[78A] [78B] f2208f8x

BE/GY 40 Amp

31

Maxi Fuse

15 Amp

ECM Fuse + –

Battery

BK

R

13 W/BK

[8A] R/BK

12 11 10 9 8 7 6 5 4 3 2 1 [8B] [33A]

DCBA [33B]

ECM

15 Amp

Ignition Fuse

GY Ignition

Switch

[1A]

12 11 10 9 8 7 6 5 4 3 2 1

[1B]

[22A]

12 11 10 9 8 7 6 5 4 3 2 1

[22B]

10 BK Engine Stop

28 BK Switch

BK

Figure 5-20. ECM Power Circuit (FLTR, FLHT/C/U)

Table 5-9. Wire Harness Connectors in Figure 5-20.

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing (Right Fairing Bracket)

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inner Fairing (Right Fairing Support Brace)

Inner Fairing

[33] Ignition/Light Key Switch 4-Place Packard

(Front of Top Fork Bracket -Below Radio)

[78] ECM 36-Place Packard Under Right Side Cover

2004 Touring: Engine Management (EFI) 5-31

HOME

[78A] [78B] f2208e8x

BE/GY 40 Amp

31

Maxi Fuse

15 Amp

ECM Fuse + –

Battery

BK

R

13 W/BK

[8A] R/BK

12 11 10 9 8 7 6 5 4 3 2 1 [8B] [33A]

I BA [33B]

ECM

15 Amp

Ignition Fuse

GY Ignition

Switch

12-Place on FLHP

[22A]

12 11 10 9 8 7 6 5 4 3 2 1

[22B]

10 BK Engine Stop

28 BK Switch

BK

Figure 5-21. ECM Power Circuit (FLHR/C/S)

Table 5-10. Wire Harness Connectors in Figure 5-21.

NO. DESCRIPTION TYPE LOCATION

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover

[22] Right Handlebar Switches 6-Place Deutsch (Black) Inside Headlamp Nacelle

[33] Ignition/Light Key Switch 3-Place Packard Under Console

[78] ECM 36-Place Packard Under Right Side Cover

5-32 2004 Touring: Engine Management (EFI)

HOME

Test 5.11 (Part 1 of 2)

NO ECM POWER

Check ECM and ignition fuse.

Are fuses OK?

NO

YES

Locate and repair short

Disconnect ECM connector [78]. Inspect to ground. Replace 15

for damaged terminals, terminals backed amp fuse.

out or corrosion. Terminal problems

present?

YES NO

Repair terminal Reconnect. Problem

damage. still exist?

YES NO

With ignition ON, probe ECM Terminal 13 on

1 Breakout Box with a circuit test lamp con-

Problem

fixed.

nected to ground. Does test lamp illuminate?

NO STOP

YES

Go to Test 5.11

(Part 2 of 2).

Probe ECM Terminal 31 on

Breakout Box with test lamp

connected to ground. Does test

lamp illuminate?

YES NO

Probe ECM Terminal 10 and Probe red wire terminal in

28 on Breakout Box with test 15 amp ECM fuse holder

lamp connected to +12V (bat- with test lamp connected

tery positive terminal). Does to ground. Does test lamp

test lamp illuminate? illuminate?

YES NO YES NO

Replace ECM. Repair open in Repair open in BE/GY Repair open in

Reprogram and learn BK wire between wire between fuse red wire between 40

password. connector [78B] and holder and ECM con- amp maxi fuse and 15

ground 1. nector [78]. amp fuse holder.

2004 Touring: Engine Management (EFI) 5-33

HOME

Test 5.11 (Part 2 of 2)

NO ECM POWER

Continued from Test 5.11 (Part 1 of 2).

2 Measure voltage at terminal 3 (BK) of

breakout box. Battery voltage present?

YES NO

Repair open (GY) wire between

connector [22] and fuse.

With ignition ON, Measure

voltage at terminal A (BK).

Battery voltage present?

YES NO

Repair open circuit on W/BK wire Repair/Replace engine stop

between ECM and connector [22A]. switch or wiring.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

5-34 2004 Touring: Engine Management (EFI)

HOME

STARTS, THEN STALLS 5.12

GENERAL

f1917x9x

Diagnostic Trouble Codes U1300, U1301 or

“BUS Er”

See Figure 5-22. The typical serial data voltage range is 0

volts (inactive) to 7 volts (active). Due to the short pulse, volt-

ages will be much lower on a DVOM. In analog mode, a

DVOM reading serial data will show continuous voltage when

active, typically 0.6-0.8 volts. The range for acceptable opera-

tions is greater than 0 and less than 7.0 volts.

NOTE

Problems in the fuel system or idle air control system may

also create this symptom.

Table 5-11. Code Description Data Link

Connector [91]

DTC DESCRIPTION

U1300 Serial data low

Figure 5-22. Electrical Bracket (Under Right Side Cover)

U1301 Serial data open/high

DIAGNOSTICS

Diagnostic Tips

● If serial data is shorted, these codes will automatically

trip the check engine light.

● DTCs P1009 and P1010 may accompany DTCs U1300

and U1301.

Diagnostic Notes

The reference numbers below correlate with the circled num-

bers on the Test 5.12 flow charts.

1. Check for trouble codes. See RETRIEVING DIAGNOS-

TIC TROUBLE CODES under 5.4 CHECKING FOR

DIAGNOSTIC TROUBLE CODES: EFI.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), black socket probes and patch cord.

2004 Touring: Engine Management (EFI) 5-35

HOME

[156B] [156A]

f2208u8x

6 6

Main to Interconnect

5 5 Harness

4 4

BK 3 3 GY

2 2 BK

LtGN/V 1 1 LtGN/V

O

BN/GY 1 2 3 4 5 6 7 8 9 10 11 12 [30B]

1 2 3 4 5 6 7 8 9 10 11 12 [30A]

BN/GY TSM/TSSM

BK

1 2 3 4 5 6 7 8 9 10 11 12 [39B]

GY

1 2 3 4 5 6 7 8 9 10 11 12 [39A]

Speedometer [108B]

1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12 [8B] EFI

1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12 [8A] Harness

[108A]

Tachometer

[1B] [1A]

15A 1

Accessory

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

Fuse 2

Main to Interconnect 3

1 2 3 4 5 6 7 8 9 10 11 12

Harness 4

[2B] Data Link

[2A] 1 2 3 4 5 6 7 8 9 10 11 12 15A

Ignition

Main to Interconnect Fuse [91A]

Harness

LtGN/R

LtGN/V

[78B]

15A 1 5 ECM

Battery [78A]

Fuse

Flash pin

Serial data

Figure 5-23. Serial Data Circuit (FLTR, FLHT/C/U)

Table 5-12. Wire Harness Connectors in Figure 5-23.

NO. DESCRIPTION MODEL TYPE LOCATION

Main to Interconnect FLHT/C 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[1]

Harness FLTR 12-Place Deutsch (Black) Inner Fairing - Below Radio (Left Side)

Main to Interconnect FLHT/C 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[2]

Harness FLTR 12-Place Deutsch (Gray) Inner Fairing - Below Radio (Left Side)

[8] Main to EFI Harness All 12-Place Deutsch Under Right Side Cover

Turn Signal/Security Cavity in Crossmember at Rear of

[30] All 12-Place Deutsch

Module Battery Box (Under Seat)

FLHT/C 12-Place Packard Inner Fairing (Back of Speedometer)

[39] Speedometer

FLTR 12-Place Packard Under Bezel (Back of Speedometer)

[78] Electronic Control Module All 36-Place Packard Under Right Side Cover

[91] Data Link All 4-Place Deutsch Under Right Side Cover

FLHT/C 12-Place Packard Inner Fairing (Back of Tachometer)

[108] Tachometer

FLTR 12-Place Packard Under Bezel (Back of Tachometer)

Main to Interconnect FLHT/C 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

[156]

Harness FLTR 6-Place Deutsch Inner Fairing - Front of Right Fairing Bracket

5-36 2004 Touring: Engine Management (EFI)

HOME

f2208t8x

BK

GY

LtGN/V LtGN/V BK

BN/GY

O 1 2 3 4 5 6 7 8 9 10 11 12 [30B]

1 2 3 4 5 6 7 8 9 10 11 12 [30A]

BN/GY TSM/TSSM

1 2 3 4 5 6 7 8 9 10 11 12 BK

[39B]

1 2 3 4 5 6 7 8 9 10 11 12 [39A] GY

Speedometer 1 2 3 4 5 6 7 8 9 10 11 12 [8B] EFI

1 2 3 4 5 6 7 8 9 10 11 12 [8A] Harness

15A 15A

Battery Accessory

Fuse Fuse

1

15A 2

Ignition

Fuse 3

4

Data Link

[91A]

LtGN/R

LtGN/V

[78B]

1 5 ECM

[78A]

Flash pin

Serial data

Figure 5-24. Serial Data Circuit (FLHR/C/S)

Table 5-13. Wire Harness Connectors in Figure 5-24.

NO. DESCRIPTION TYPE LOCATION

[8] Main to EFI Harness 12-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

[30] Turn Signal/Security Module 12-Place Deutsch

Battery Box (Under Seat)

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[78] Electronic Control Module 36-Place Packard Under Right Side Cover

[91] Data Link 4-Place Deutsch Under Right Side Cover

2004 Touring: Engine Management (EFI) 5-37

HOME

Test 5.12 (Part 1 of 2)

STARTS, THEN STALLS: DTC U1300, U1301 or

“BUS Er”

Fresh gasoline

in tank?

YES NO

Check for trouble codes using.5.6 Add gasoline.

1 SPEEDOMETER SELF DIAG-

NOSTICS. Codes found?

YES.

YES. YES. NO. BUS Er present.

DTC P1009, U1300 or U1301 No codes speedometer will not

P1010 found. See codes found. found. communicate with other

5.28 DTC P1009, modules.

P1010.

Will engine start with throttle

STOP opened partially and stall when STOP Go to Test 5.12

throttle closed? (Part 2 of 2).

Go to Test 5.12

(Part 2 of 2).

YES. NO.

See 5.16 IDLE AIR Check fuel pressure while

CONTROL. cranking engine. See 5.15

FUEL PRESSURE TEST. Is

fuel pressure OK?

YES NO

Tap lightly on fuel injectors. Fuel pressure problem. See

Problem still exist? flow chart under 5.15 FUEL

PRESSURE TEST.

YES NO

Replace fuel injectors. System

Problem still exist? OK.

YES NO

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Replace ECM. System

Confirm proper operation with no check engine

Reprogram and learn OK.

lamp.

password.

5-38 2004 Touring: Engine Management (EFI)

HOME

Test 5.12 (Part 2 of 2)

STARTS, THEN STALLS: DTC U1300, U1301 or

“BUS Er”

Continued from Test 5.12 (Part 1 of 2)

Set run/stop switch to RUN. Turn ignition key ON.

Is BUS Er present?

YES NO

Turn ignition key OFF. Turn ignition key OFF. While wiggling

Disconnect ECM at connector 2 harness, check for continuity to ground at

[78]. Turn ignition key ON. terminal 3 of connector [91A].

Is BUS Er present? Is continuity to ground present at any time?

YES NO

YES NO

Turn ignition key OFF. Replace ECM.

Disconnect TSM/TSSM at connector Reprogram and perform

[30]. Turn ignition key ON. password learn. Locate and repair Turn ignition switch ON.

Is BUS Er present? intermittent short While wiggling harness,

to ground. check for voltage at terminal

3 of connector [91A].

Is voltage present at

any time?

YES NO

Is vehicle equipped Replace TSM/TSSM. Per- YES NO

with a tachometer? form password learn.

Locate and repair No problem

intermittent short found.

NO YES to voltage.

Turn ignition key OFF. Disconnect tachometer

at connector [108]. Turn ignition key ON.

Is BUS Er present?

YES NO

Turn ignition key OFF. Disconnect Replace tachometer.

speedometer at connector [39].

2 Check for continuity to ground at

terminal 3 of connector [91A].

Is continuity to ground present?

YES NO

Locate and repair short Turn ignition switch ON.

to ground. Check for voltage at terminal

3 of connector [91A].

Is voltage present?

YES NO

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine Locate and repair short Replace

lamp. to voltage. speedometer.

2004 Touring: Engine Management (EFI) 5-39

HOME

FUEL SYSTEM ELECTRICAL TEST 5.13

GENERAL

f1924x8x

With ignition switch turned to IGNITION and the engine stop

switch at RUN, the ECM will energize the system relay to

complete the circuit to the in-tank fuel pump. It will remain on

as long as the engine is cranking or running, and the ECM is

receiving ignition reference pulses from the CKP. If there are

no reference pulses, the ECM will de-energize the system

relay within 2 seconds after ignition is ON or engine has

stalled, or immediately after the ignition is shut OFF.

Fuel Tank

The fuel pump delivers fuel to the injectors. The pressure reg-

ulator is where the system pressure is controlled. Excess fuel

flow is bypassed into the fuel tank through the pressure regu-

lator. When the engine is stopped, the pump can be turned on

by applying battery voltage and ground to the fuel pump con-

nector [141A]. The fuel pump connector is located on the can-

opy at the top of the fuel tank. Improper fuel system pressure

may contribute to one or all of the following symptoms. Fuel Tank Harness

Connector [13]

Not Present on FLHR/C/S

● Engine cranks, but won’t run.

● Engine cuts out (may feel like ignition problems). Figure 5-25. Fuel Pump/Fuel Level Sender Connector

(FLTR, FLHT/C/U)

● Hesitation, loss of power and poor fuel economy.

NOTE

EFI System Relay

After turning ignition OFF, you must wait 10 seconds before

Spare

turning the ignition back ON to get the fuel pump to reprime.

This time out period is necessary for the ECM and IAC to

reset.

Fuel

Pump

DIAGNOSTICS

f2223x9x

Diagnostic Notes ECM Power

The reference numbers below correlate with the circled num-

bers on the Test 5.15 flow charts.

1. Turns on fuel pump if wiring is OK. If pump runs, problem Figure 5-26. EFI Fuse Block

is in basic fuel delivery.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), brown pin probe and patch cord.

3. Connect BREAKOUT BOX (Part No. HD-43876). See

Section 5.7 BREAKOUT BOX: EFI.

4. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), purple pin probe and patch cord.

5-40 2004 Touring: Engine Management (EFI)

HOME

[62B]

Y/GN

87

I Q C P R

System

87A

[78]

relay

BE/GY

30 85 86

GN/O

W/BK

[13A] [13B]

Fuel

System relay 4 GN/O pump

O/GY

1

1

1

1

Y/GN 15 Amp

2

2

2

2

fuel pump

AB

AB

Inj. F

Y/GN

W/Y

3

3

fuse

3

3

21

[141B] [141A]

[84B] [84A] BK

Y/GN All Except

FLHR/C/S

AB

AB

Inj. R 19 GN/GY

[85B] [85A]

Idle air

control

[87A] [87B]

A A BE/GN 35

40 Amp

B B BN/R 36 Maxi Fuse

C C BK/PK 18

+ –

D D BK/O 17 15 Amp Battery

ECM fuse R

Constant power 31 BE/GY

BK

Engine

stop 15 Amp

switch IGN fuse

Switch power 13 W/BK GY R/BK

Ignition switch

MAIN FUSE BLOCK COVER

10A

15A P&A IGN RADIO PWR

BRAKE

15A RELAY

BATTERY RADIO MEM

SPARE FUSES

P&A ACCESS. CRUISE/BRK

HEADLAMPS IGN LIGHTS INSTRUMENTS

H F D B

4

10A

BRAKE

RELAY

3

15A 15A

2

15A 15A 15A

1

J 15A G 15A E 15A C 15AA

Power gnd. 10 BK

Power gnd. 28 BK

MAIN FUSE BLOCK

f2208d8x

Figure 5-27. Fuel Pump Circuit

Table 5-14. Wire Harness Connectors in Figure 5-27.

NO. DESCRIPTION TYPE LOCATION

[13] Fuel Tank Harness 3-Place Multilock Behind Fuel Tank (Under Seat)

[78] ECM 36-Place Packard Under Right Side Cover

[141] Fuel Pump/Fuel Level Sender 3-Place Mini-Deutsch Top of Canopy (Under Console)

2004 Touring: Engine Management (EFI) 5-41

HOME

Test 5.13 (Part 1 of 4)

FUEL SYSTEM ELECTRICAL TEST

Is ECM fuse OK?

YES NO

STOP Go to 5.11 NO

Is fuel pump fuse OK? ECM POWER.

NO

YES

Check for 12 volts at terminals 1 (+) and 3 (-) of fuel STOP

1 pump connector [141B] during first 2-3 seconds

Go to Test 5.13

(Part 4 of 4).

after key ON.

2 Voltage present?

YES NO

Check for corroded Check for continuity to

connections or loose ground on [141B] terminal 3.

connectors between fuel pump Continuity present?

and pump connector [141B].

Poor connections?

YES NO

YES NO

Locate and repair open on

BK wire between [141B]

Repair as With key OFF, check for open STOP and ground.

necessary. pump circuit. Connect ohmmeter

between connector Pin 1 of [141A] and

Pin 3 of connector [141A]. Go to Test 5.13

Continuity present? (Part 2 of 4).

YES NO

Check pump Remove fuel pump.

connections and repair Check for continuity

as required. If good, across fuel pump

replace fuel pump. terminals.

Does meter read

continuity?

YES NO

Check for opening Replace

in wiring. fuel pump.

5-42 2004 Touring: Engine Management (EFI)

HOME

Test 5.13 (Part 2 of 4)

FUEL SYSTEM ELECTRICAL TEST

Continued from Test 5.13 (Part 1 of 4).

Is 12 volts present at terminal 87 of system

relay (with relay in place) during first two sec-

onds after key on?

YES

NO

Locate and repair open between

terminal 1 of [141B] and terminal 87 Is 12 volts present at terminal

of system relay. 30 of system relay?

YES

NO

With ignition and Run/Stop

Locate and repair open on BE/GY wire

switch on, is 12 volts present at

between ECM fuse and terminal 30 of

terminal 86 of system relay.

system relay.

YES

NO

Locate and repair open on

STOP W/BK wire to system relay.

Go to Test 5.13

(Part 3 of 4).

2004 Touring: Engine Management (EFI) 5-43

HOME

Test 5.13 (Part 3 of 4)

FUEL SYSTEM ELECTRICAL TEST

Continued from Test 5.13 (Part 2 of 4).

Probe system relay connector Terminal 85 with

a test light to 12 volts. Does test light illuminate

for 2 seconds after key ON?

YES NO

Replace system Probe Breakout Box Terminal 4 with a test light

relay. 3 connected to 12 volts. Does test light illuminate

for 2 seconds after key ON?

YES NO

Locate and repair open Replace ECM. Reprogram

on GN/O wire. and learn password.

Test 5.13 (Part 4 of 4)

FUEL SYSTEM ELECTRICAL TEST

Continued from Test 5.13 (Part 1 of 4) or

Test 5.13 (Part 2 of 4).

Check for intermittent short to ground on

terminal 1 of connector [141B]. Short to

ground present?

YES NO

Reconnect fuel pump connector [141]

Repair short to and Install fuel pressure gauge.

ground on O/GY wire See 5.15 FUEL PRESSURE TEST.

and replace fuse.

With fuel system intact and battery fully charged,

remove fuel pump fuse.

Connect DVOM across fuel pump fuse terminals using probe.

Place male positive probe in H slot. Turn key ON. With pump run-

ning, check current and fuel pressure. Is current draw under 4.5

amps and fuel pressure between 55-62 PSI (380-425 kPA)?

YES

Substitute known good relay for system relay. Test

4 for current draw across fuel pump fuse. terminals.

Replace fuse. Is current draw less than 4.5 amps?

YES NO

Current draw now Replace fuel

in range. Replace pump and replace fuse.

system relay and replace fuse.

5-44 2004 Touring: Engine Management (EFI)

HOME

SYSTEM RELAY CHECK 5.14

GENERAL

EFI System Relay

System Relay Spare

See Figure 5-28. With ignition switch turned to IGNITION and

the engine stop/run switch at RUN, the ECM energizes the

system relay to complete the circuit to the in-tank fuel pump,

ignition coil and fuel injectors. They will remain powered as

Fuel

long as the engine is cranking or running, and the ECM is Pump

receiving ignition reference pulses from the CKP. If there are

no reference pulses, the ECM will de-energize the system

f2223x9x

relay within 2 seconds after ignition is ON or engine has

stalled, or immediately after the ignition is shut OFF.

ECM Power

Table 5-15. Code Description

DTC DESCRIPTION

P1001 System relay coil open/low Figure 5-28. EFI Fuse Block

P1002 System relay coil high/shorted

P1003 System relay contacts open

P1004 System relay contacts closed

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled num-

bers on the Test 5.16 flow charts.

1. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probe and patch cord.

2. Connect BREAKOUT BOX (Part No. HD-43876) to ECM.

See Section 5.7 BREAKOUT BOX: EFI.

2004 Touring: Engine Management (EFI) 5-45

HOME

f2208h8x [62B] System relay

Y/GN

87

I Q C P R

87A

[78A] [78B]

BE/GY

30 85 86

GN/O

W/BK

1 2 3 4 5 6 7

1 2 3 4 5 6 7

[13A] [13B] Fuel pump

O/GY

1

1

1

1

System relay GN/O Y/GN 15 amp

2

2

2

2

fuel pump

AB

AB

W/Y

Y/GN

3

3

3

3

fuse

[141B] [141A]

[84B] [84A] BK

Y/GN

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

AB

AB

Power gnd.

Coil R Y/BE

A B

A B

[85B] [85A]

GY/BE Ignition

Switch power

Y/BE coil

C D

C D

W/BK

BE/O

ECM

W/BK [83B] [83A]

Inj. R GN/GY BE/GY

+ –

15 amp

Inj. F W/Y Battery

ECM fuse

R 40 Amp BK

R

BE/GY

R Maxi Fuse

GY/BE

R/BK

12 12 BK

11 11 DCBA

10 10 [33B]

Ion sense

9 9 [33A]

Power gnd. 8 8 15 amp

BK

Coil F BE/O 7 7 IGN fuse

Ignition

W/BK

6 6

5 5 GY

Constant power

4 4

switch

3 3

2 2 W/BK

1 1

12 11 10 9 8 7 6 5 4 3 2 1 [1B]

[8B] [8A] 12 11 10 9 8 7 6 5 4 3 2 1 [1A]

BK

BK

12 11 10 9 8 7 6 5 4 3 2 1 [22A]

BK 12 11 10 9 8 7 6 5 4 3 2 1 [22B]

Engine stop

switch

Figure 5-29. System Relay Circuit (FLTR, FLHT/C/U)

Table 5-16. Wire Harness Connectors in Figure 5-29.

NO. DESCRIPTION TYPE LOCATION