Professional Documents

Culture Documents

Anaerobic System Formulas

Anaerobic System Formulas

Uploaded by

SohailOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anaerobic System Formulas

Anaerobic System Formulas

Uploaded by

SohailCopyright:

Available Formats

Overview

This work aims to develop an anaerobic digestion system, which allows recovering energy from olive

wastes, solving the problem of their disposal. To reach this result, polyphenols, which are contained in

olives inhibiting the digestion process, have to be abated. For this reason a new anaerobic digestion

system able to treat the high concentration of polyphenols has been studied. Particularly, this system,

composed by a storage of olive pomace, a mixing/washing unit, a pomace/water separation unit

(decanter), an ultrafiltration unit and an anaerobic digester, has been numerically investigated to

evaluate the anaerobic digestion key variables as a function of the hydraulic retention time (HRT), as

well as the production of biogas for different values of the biomass yield factor. The results revealed that

by abating polyphenols, the methane potential of the system under investigation rises from 7.5

molCH4/kgTSS to 11.7 molCH4/kgTSS, with an increment of about 56%, for HRT equal to 30 days.

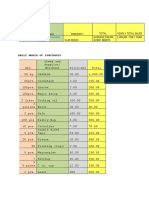

Formulas:

The solids (olive pulp) are hydrolyzed to soluble organic matter, which is further fermented to Volatile

Fatty Acid (VFA), butyrate and propionate. Acetic acid is obtained from the transformation of butyric and

propionic acids and finally methane is produced from acetic acid, hydrogen and carbon dioxide. The

hypothesis of the model are reported next: • first-order kinetics can be assumed for the hydrolysis of

the solids; • simple Monod kinetics for conversion of soluble organic matter to VFA and acetate and

hydrogen to methane; • modified Monod kinetics including hydrogen inhibition for the degradation of

butyric and propionic acids to acetate; • thermodynamical equilibrium between hydrogen in liquid

phase (generated from fermentation of soluble organic matter) and gas-phase; • perfectly mixed

digester; • constant pressure and temperature. The first reaction of the model is represented by

hydrolysis of Total Suspended Solids [TSS]. The [TSS] variation as a function of time () can be written as:

(1) With (2) Where is the kinetic constant of hydrolysis reaction. Marco Milanese et al. / Energy

Procedia 45 ( 2014 ) 141 – 149 145 The kinetics of transformation of Hydrolyzed Solids [HS] is given by

the following equation: (3) With (4) Where and are two kinetic parameters and [VSS]

represents the volatile suspended solids concentration. With regard to butyric acid [BUT], propionic acid

[PROP] and acetic acid [ACET] concentration, we can write: (5) With (6) (7) With

(8) (9) With (10) Where , , , , , , , , are kinetic parameters. Finally, the production of gas-phase

hydrogen () and methane () (as number of moles) can be written as: (11) (12) With (13)

146 Marco Milanese et al. / Energy Procedia 45 ( 2014 ) 141 – 149 In the equations above reported [VSS]

is calculated as: (14) Where represents the biomass yield factor. This parameter, which relates

the amount of bacteria generated with respect to the amount of substrate consumed for its generation,

plays a very important role in the olive waste digestion process because of its strong correlation with the

concentration of polyphenols. In other words, polyphenols, which inhibit reaction kinetics, can be taken

into account by means of biomass yield facto

You might also like

- Fos TacDocument5 pagesFos TacBhavaNo ratings yet

- Fractional Condensation of Multicomponent Vapors From Pyrolysis of Cotton StalkDocument8 pagesFractional Condensation of Multicomponent Vapors From Pyrolysis of Cotton StalkEvansChombaNo ratings yet

- InterSchool Activity ScriptDocument7 pagesInterSchool Activity ScriptJessica Loren Leyco87% (15)

- Anaerobic FormDocument1 pageAnaerobic FormSohailNo ratings yet

- Anaerobic Digestion SystemDocument2 pagesAnaerobic Digestion SystemSohailNo ratings yet

- Olives StudyDocument7 pagesOlives StudySohailNo ratings yet

- Anaerobic Waste SystemDocument2 pagesAnaerobic Waste SystemSohailNo ratings yet

- Thermodynamic Analysis of Bioethanol Production OptimizationDocument9 pagesThermodynamic Analysis of Bioethanol Production Optimizationmurdanetap957No ratings yet

- Influence of Total Solid and Inoculum Contents On Performance of Anaerobic Reactors Treating Food WasteDocument26 pagesInfluence of Total Solid and Inoculum Contents On Performance of Anaerobic Reactors Treating Food Wasterafi mfNo ratings yet

- Anaerobic System Formulas 2Document2 pagesAnaerobic System Formulas 2SohailNo ratings yet

- Olives Analysis 2Document2 pagesOlives Analysis 2SohailNo ratings yet

- Olives ResearchDocument2 pagesOlives ResearchSohailNo ratings yet

- Anaerobic Digestion TheoryDocument4 pagesAnaerobic Digestion TheorytransilvanpopNo ratings yet

- Keq Value¿Document10 pagesKeq Value¿María Camila RolónNo ratings yet

- Reaction Kinetics of Biodiesel Synthesis From Waste Oil Using A Carbon-Based Solid Acid CatalystDocument6 pagesReaction Kinetics of Biodiesel Synthesis From Waste Oil Using A Carbon-Based Solid Acid Catalystsalonso93No ratings yet

- Anaerobic Sys 2Document2 pagesAnaerobic Sys 2SohailNo ratings yet

- Enzymatic Catalysis of Vegetable Oil With Ethanol in The Presence of Co-SolventsDocument6 pagesEnzymatic Catalysis of Vegetable Oil With Ethanol in The Presence of Co-Solventsilidio costaNo ratings yet

- ADM Pada MikroalgaDocument7 pagesADM Pada MikroalgaYahdini QorninNo ratings yet

- 8.3 Fed Batch Reactors 8.3.1 Variable Volume Fermentation (VARVOL and Varvold)Document34 pages8.3 Fed Batch Reactors 8.3.1 Variable Volume Fermentation (VARVOL and Varvold)Hana HamidNo ratings yet

- Boubaker Fezzani, Ridha Ben Cheikh: Bfezzani2007@Document14 pagesBoubaker Fezzani, Ridha Ben Cheikh: Bfezzani2007@GurusangmeshHiremathNo ratings yet

- Process Alternatives For Methyl Acetate Conversion Using Reactive Distillation. 1. HydrolysisDocument15 pagesProcess Alternatives For Methyl Acetate Conversion Using Reactive Distillation. 1. Hydrolysisehsan zeraatkarNo ratings yet

- Ferrer 2010 BITEDocument9 pagesFerrer 2010 BITEoeckhagosNo ratings yet

- Universidad Nacional de Colombia, A.A. 14490, Bogot A D. C., ColombiaDocument1 pageUniversidad Nacional de Colombia, A.A. 14490, Bogot A D. C., ColombiaDanielRicardoDelgadoNo ratings yet

- Biogas Production SystemsDocument22 pagesBiogas Production SystemsEmiliano Rodriguez TellezNo ratings yet

- Souto 2009Document14 pagesSouto 2009labfisicoNo ratings yet

- Belum Di ReviewDocument7 pagesBelum Di ReviewTatang KelanaNo ratings yet

- Oktem Et Al 2006 - Acidification Reactor For Pharma WasteDocument6 pagesOktem Et Al 2006 - Acidification Reactor For Pharma WasteArun EbenezerNo ratings yet

- Research Inventy: International Journal of Engineering and ScienceDocument9 pagesResearch Inventy: International Journal of Engineering and ScienceinventyNo ratings yet

- Synthesis & Mathematical Modeling of PET Via Direct EsterificationDocument10 pagesSynthesis & Mathematical Modeling of PET Via Direct EsterificationMARKASGEORGENo ratings yet

- ANTONOPOULOU - 2015 - Modeling of Anaerobic Digestion of Food Industry WastesDocument7 pagesANTONOPOULOU - 2015 - Modeling of Anaerobic Digestion of Food Industry WastesThobiasNo ratings yet

- SD ArticleDocument16 pagesSD ArticleConsuelo VelandiaNo ratings yet

- M T A T W M B E D IWA A D M: Odelling OF WO Stage Naerobic Reating Astewater From A With The Naerobic Igestion ODEL No.1Document12 pagesM T A T W M B E D IWA A D M: Odelling OF WO Stage Naerobic Reating Astewater From A With The Naerobic Igestion ODEL No.1ngocdungmtNo ratings yet

- Accepted Manuscript: Bioresource TechnologyDocument34 pagesAccepted Manuscript: Bioresource TechnologyMiguel Angel Ramos RuizNo ratings yet

- Bimetanizacion de Residuos Solidos UrbanosDocument8 pagesBimetanizacion de Residuos Solidos UrbanosricardoNo ratings yet

- Ipj 2005 12 547Document9 pagesIpj 2005 12 547Shahin AkhlaghiNo ratings yet

- Methane Generation From Anaerobic Digesters: Considering Different Substrates Rebekkah NelsonDocument11 pagesMethane Generation From Anaerobic Digesters: Considering Different Substrates Rebekkah NelsonTeklit GebregergsNo ratings yet

- Bioreactor Performance in Anaerobic DigeDocument7 pagesBioreactor Performance in Anaerobic DigeĐạt DươngNo ratings yet

- Bouallagui 2005Document7 pagesBouallagui 2005Moto MotoNo ratings yet

- 08 - Improvement of Activated Sludge Stabilisation and Filterability During Anaerobic Digestion by Fruit and Vegetable Waste AdditionDocument6 pages08 - Improvement of Activated Sludge Stabilisation and Filterability During Anaerobic Digestion by Fruit and Vegetable Waste Additionadalcayde2514No ratings yet

- Vol 43 - 3 0004Document112 pagesVol 43 - 3 0004karamniaNo ratings yet

- Rajab 2016Document32 pagesRajab 2016simoesrosadutra6752No ratings yet

- Synthesis of Biomass-Derived Gasoline Fuel Oxygenates by Microwave IrradiationDocument18 pagesSynthesis of Biomass-Derived Gasoline Fuel Oxygenates by Microwave IrradiationDevesh Pratap ChandNo ratings yet

- Impact of Seed Bioaugmentation On Thermophilic Anaerobic Digesters During Startup and Steady-StateDocument10 pagesImpact of Seed Bioaugmentation On Thermophilic Anaerobic Digesters During Startup and Steady-StateMario WhoeverNo ratings yet

- NIH Public Access: Author ManuscriptDocument9 pagesNIH Public Access: Author ManuscriptSyedFaridAliNo ratings yet

- Continuous Methanolysis of Palm Oil Using A Liquid-Liquid Film ReactorDocument10 pagesContinuous Methanolysis of Palm Oil Using A Liquid-Liquid Film ReactorFelipe JimenezNo ratings yet

- Modeling of Anaerobic Digestion of Canary GrassDocument8 pagesModeling of Anaerobic Digestion of Canary GrassProAkademiaNo ratings yet

- Optimal Engineered Algae Composition For The Integrated Simultaneous Production of Bioethanol and BiodieselDocument29 pagesOptimal Engineered Algae Composition For The Integrated Simultaneous Production of Bioethanol and Biodieselbahtera agungNo ratings yet

- Modeling and Analysis A MethanolDocument10 pagesModeling and Analysis A MethanolVidal TxusNo ratings yet

- Coupling Hydrothermal Liquefaction and Anaerobic Digestion For Energy Valorization From Model Biomass FeedstocksDocument10 pagesCoupling Hydrothermal Liquefaction and Anaerobic Digestion For Energy Valorization From Model Biomass Feedstockstera novaNo ratings yet

- Reaction Mechanisms and Rate Constants of Waste Degradation in Landfill Biorector Systems With Ensymatic EnhancementDocument4 pagesReaction Mechanisms and Rate Constants of Waste Degradation in Landfill Biorector Systems With Ensymatic EnhancementMauricio Gabriel GuzmanNo ratings yet

- Synthesis of Trimethylolpropane Esters of Oleic Acid Using A Multi-SO3H-Functionalized Ionic Liquid As An Efficient CatalystDocument7 pagesSynthesis of Trimethylolpropane Esters of Oleic Acid Using A Multi-SO3H-Functionalized Ionic Liquid As An Efficient CatalystAldi IgnielNo ratings yet

- 2006 - Effects of Temperature and Hydraulic Retention TimeDocument5 pages2006 - Effects of Temperature and Hydraulic Retention TimeAgung Ariefat LubisNo ratings yet

- Effect of Carbon To Nitrogen Ratio On Biogas ProductionDocument10 pagesEffect of Carbon To Nitrogen Ratio On Biogas ProductionLTE002100% (1)

- A Kinetic Model For Methanol-To-Propylene Process in The Presence of Co-FeedDocument50 pagesA Kinetic Model For Methanol-To-Propylene Process in The Presence of Co-FeedAdi permadiNo ratings yet

- Clo3 Reactions in Transesterification Process: E + S ES P + EDocument3 pagesClo3 Reactions in Transesterification Process: E + S ES P + ESyazwani AbdullahNo ratings yet

- Hydrolysis NewDocument45 pagesHydrolysis Newberkofranklin765No ratings yet

- Httpsmdpi Res - Comd Attachmentprocessesprocesses 06 00020article Deployprocesses 06 00020.pdfversion 1519544708Document20 pagesHttpsmdpi Res - Comd Attachmentprocessesprocesses 06 00020article Deployprocesses 06 00020.pdfversion 1519544708anwarabdullah960No ratings yet

- Ethanol 13 AksodkopasdasmlkasmczczxcDocument10 pagesEthanol 13 AksodkopasdasmlkasmczczxcNiko Ava DaaNo ratings yet

- Tesser 2005Document5 pagesTesser 2005Glorie Mae BurerosNo ratings yet

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerFrom EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNo ratings yet

- Chemesthesis: Chemical Touch in Food and EatingFrom EverandChemesthesis: Chemical Touch in Food and EatingShane T. McDonaldNo ratings yet

- Waster Materials ConclusionsDocument3 pagesWaster Materials ConclusionsSohailNo ratings yet

- Waster Materials FinalDocument3 pagesWaster Materials FinalSohailNo ratings yet

- Olives ResearchDocument2 pagesOlives ResearchSohailNo ratings yet

- Anaerobic FormDocument1 pageAnaerobic FormSohailNo ratings yet

- Anaerobic Formula CalcDocument2 pagesAnaerobic Formula CalcSohailNo ratings yet

- Anaerobic Sys 2Document2 pagesAnaerobic Sys 2SohailNo ratings yet

- Olives ReviewDocument2 pagesOlives ReviewSohailNo ratings yet

- Anaerobic System Formulas 2Document2 pagesAnaerobic System Formulas 2SohailNo ratings yet

- Anaerobic System 2Document1 pageAnaerobic System 2SohailNo ratings yet

- Olives Analysis 2Document2 pagesOlives Analysis 2SohailNo ratings yet

- Anaerobic Digestion SystemDocument2 pagesAnaerobic Digestion SystemSohailNo ratings yet

- Netsuite REST Web ServicesDocument81 pagesNetsuite REST Web ServicesSohailNo ratings yet

- Suite Talk Web Services Platform GuideDocument341 pagesSuite Talk Web Services Platform GuideSohailNo ratings yet

- Coordination For Motor Protection: High Performance MCCBDocument0 pagesCoordination For Motor Protection: High Performance MCCBKishore KrishnaNo ratings yet

- The Sine and Cosine Rule QuestionsDocument20 pagesThe Sine and Cosine Rule QuestionsJacob WilliamNo ratings yet

- Accenture AptitudeDocument122 pagesAccenture AptitudeHarshith P.BNo ratings yet

- SSAS HardwareSizingTabularSolutionsDocument33 pagesSSAS HardwareSizingTabularSolutionsm_dreessenNo ratings yet

- Introduction To GNU Radio and Software RadioDocument4 pagesIntroduction To GNU Radio and Software RadioDinesh VermaNo ratings yet

- Universal Pump Cart: No. PC200Document1 pageUniversal Pump Cart: No. PC200herbert madariagaNo ratings yet

- Catálogo de Bombas de Diafragma - ARODocument52 pagesCatálogo de Bombas de Diafragma - AROIvan RodrigoNo ratings yet

- Comparison Between C and C++ and Lisp and PrologDocument18 pagesComparison Between C and C++ and Lisp and PrologAhmed HeshamNo ratings yet

- Percentage Increase and DecreaseDocument3 pagesPercentage Increase and DecreaseLai Kee KongNo ratings yet

- Human Rights Term PaperDocument18 pagesHuman Rights Term Papersanjog DewanNo ratings yet

- ACLU Letter On Riverside County RedistrictingDocument2 pagesACLU Letter On Riverside County RedistrictingThe Press-Enterprise / pressenterprise.comNo ratings yet

- Korando 2012Document1,082 pagesKorando 2012mirrahel paim67% (3)

- Computation of ProfitsDocument4 pagesComputation of ProfitsAngela LozanoNo ratings yet

- Fama French PDFDocument8 pagesFama French PDFMonzer ShkeirNo ratings yet

- In Design: Iman BokhariDocument12 pagesIn Design: Iman Bokharimena_sky11No ratings yet

- Makalah CJR BibDocument9 pagesMakalah CJR BibRyan AlfandiNo ratings yet

- 4183 17321 1 PBDocument12 pages4183 17321 1 PBUmiKulsumNo ratings yet

- Kerala vISION 2025Document57 pagesKerala vISION 2025newvedvyasNo ratings yet

- How To Install A Light FixtureDocument5 pagesHow To Install A Light FixtureMarc RiomalosNo ratings yet

- Benin V NigerDocument9 pagesBenin V NigerRonika ThapaNo ratings yet

- Analysis of Low Cost AirlinesDocument29 pagesAnalysis of Low Cost AirlinesAbhijeet BhattacharyaNo ratings yet

- PF-20T and PF-50T: Bass Guitar AmplifiersDocument16 pagesPF-20T and PF-50T: Bass Guitar AmplifiersGiovanni VirdisNo ratings yet

- PSR I455Document4 pagesPSR I455caronNo ratings yet

- Brian CA March 12Document13 pagesBrian CA March 12scott.maisonNo ratings yet

- Sema V COMELEC DigestDocument5 pagesSema V COMELEC DigestTrizia VeluyaNo ratings yet

- 20 Create Face BlendsDocument11 pages20 Create Face BlendsAlberto CanoNo ratings yet

- Level-3 Answer Keys PDFDocument42 pagesLevel-3 Answer Keys PDFSukhbir GrakNo ratings yet

- Personal MKTG PKG - Part 2 V2Document3 pagesPersonal MKTG PKG - Part 2 V2Lakshya TripathiNo ratings yet

- I LuxDocument24 pagesI LuxNirav M. BhavsarNo ratings yet