Professional Documents

Culture Documents

Hangchacbd15 A2mc1

Hangchacbd15 A2mc1

Uploaded by

VRM - Entrenamiento HCOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hangchacbd15 A2mc1

Hangchacbd15 A2mc1

Uploaded by

VRM - Entrenamiento HCCopyright:

Available Formats

A series Mini Range pallet truck specification

1.1 Manufacturer HANGCHA GROUP CO.,LTD.

1.2 Manufacturer's type designation CBD15-A2MC1

Distinguishing

1.4 Operator type: hand, pedestrian, standing, seated, order-picker Pedestrian

mark

1.5 Rated capacity/rated load Q (kg) 1500

1.6 Load centre distance c (mm) 600

1.8 Load distance, centre of drive axle to fork x (mm) 960

1.9 Wheelbase y (mm) 1285

2.1 Service Weight(Including battery) kg 220

Weight

Battery weight kg 50

3.1 Tyres: solid rubber, superelastic, pneumatic, polyurethane PU

3.2 Tyre size, front Ф210x70

Tyres, chassis

3.3 Tyre size, rear 2×Ф80x64

3.4 Additional wheel (dimensions) Ф70x40

3.5 Wheels, number front / rear (x = driven wheels) 1x+2/4

3.6 Tread, front b10 (mm) 404

3.7 Tread, rear b11 (mm) 400

4.4 Lift h3 (mm) 120

4.15 Fork height,lowered h13 (mm) 80

4.19 Overall length l1 (mm) 1669

4.21 Overall width b1(mm) 568

Dimensions

4.22 Fork dimensions s/e/l (mm) 50/160/1150

4.25 Distance between fork-arms b5 (mm) 560/680

4.32 Ground clearance, centre of wheelbase m2 (mm) 30

4.34.1 Aisle width for pallets 1000 x 1200 crossways Ast (mm) 1850 1)

4.34.2 Aisle width for pallets 800 x 1200 lengthways Ast (mm) 1900 2)

4.35 Turning radius Wa (mm) 1400 3)

5.1 Travel speed,laden/unladen

Electric Performance

km/h 4.5/4.9

5.2 Lift speed,laden/unladen m/s 0.050/0.060

data

5.3 Lowering speed,laden/unladen m/s 0.040/0.045

5.8 Max Gradeability,laden/unladen % 6/15

6.1 Drive motor rating S2 60 min kW 0.65

engine

6.2 Lift motor rating at S3 15% kW 0.8

6.4 Battery voltage,rated capacity V/Ah 2x12/70

8.1 Type of drive control DC

9.1 Manufacturer Curtis

Note:1). VDI 2198:+358mm 2). VDI 2198:+200mm 3). When fork lowered,+60mm

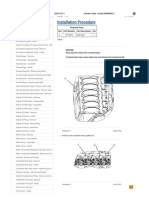

A series pallet truck mini range

h14

with capacities of 1,500kg

h3

h13

m2

y

L1

2018 VERSION 1/COPYRIGHT 2018/08

Follow us on Follow us on Follow us on

ZHEJIANG HANGCHA IMP. &EXP. CO., LTD. Facebook YouTube WeChat

Factory site: 666 Xiangfu Road,

Hangzhou, Zhejiang, China (311305)

b11

b1

b5

HANGCHA trucksconform

Wa to the European Safety

Tel: +86-571-88926735 88926755 ISO14001:2015 ISO9001:2015 Requirements.

Fax: +86-571-88926789 88132890

HANGCHA GROUP CO., LTD. reserves the right to make any changes without

a/2

notice concerning colors, equipment, or specifications detailed in this brochure, or

a/2

sales@hcforklift.com

Ast

www.hcforklift.com

to discontinue individual models. The colors of trucks, delivered may differ slightly

from those in brochures. The World of Hangcha

A series pallet truck mini range High Performance Standard specification Options

/ Rated capacity 1500kg, meet the needs of the majority / Permanent magnet drive motor / Different length of fork

of customers. / CURTIS permanent magnet controller / Different width of outside fork

The A series pallet truck mini range Ⅱ has been engineered / Powered by traction motor not only has good accelera- / Emergency switch / Single load wheel

to be both powerful and flexible to meet the requirements of tion and perfect performance, but also low heat. / Multi-function battery indicator

/ Latest CURTIS control system, precise and smooth. / PU wheel

many demanding applications. Whether it’s supermarket work, / Regenerative braking for battery recovery during travel / 1150mm fork length

speed reduction, anti-slope on gradient. / 560mm outside fork width

delivery service, stock replenishment or heavy manufacturing, / All key parts such as tiller, switches, connectors, battery / Electronic lifting limitation

the A series pallet truck mini range Ⅱ has the strength and indicator and hour meter all adopt the famous brand. /

/

Non-contact proximity switch

Till made by REMA

Rema tiller head

durability to minimise your total cost of ownership. / Horn

/ Maintenance free battery

/ Internal charger

/ Walking upright

/ Guide device

/ Additional wheel

Comfort / Tandem load wheel

/ Simple and beautiful tiller made by REMA designed to

make the operator feel comfortable, all the operation

can be completed by one hand.

/ Optimized designing structure to offer a good visibility

and easy entrance of the pallet.

Auxillary wheels are equipped to have

/ Built-in charger and maintenance free gel battery better stability

adopted to provide convenient usage.

/ The compact body and semicircular design provide an

Easy/ ideal operation in limited space, and the ability of

walking upright greatly increases the convenience in

Efficiency/ the container.

/ Standard fork height 80mm, equipped the guide device

Economy

easy to get in pallets (including sealing pallets).

/ Side battery change is standard feature.

Appearance

/ A series pallet truck mini range Ⅱ applied

professional industrial design, stream lines,

and compact, and fully ergonomic consider- Modern outline design

ation, in line with the latest design trends.

/ Applied steel stamping and injection

Reliability Safety Maintenance

molding processes, which is robust, durable, / 5-pivot design provide longer working life. / Three braking system of regenerative braking, reverse / Built-in charger and maintenance free gel battery, you

and also environmental compliance. / Imported waterproof connectors, all wires and cables current braking, parking brake, insures the safe opera- don’t need to worry about them.

are protected, greatly improve the reliability of the tion. / Integrated battery indicator, hour meter and self-diag-

electric system. / Anti-slope on gradient can keep the safety. nostic instrument.

/ Top quality hydraulic power unit applied to provide low / The emergency button on the tiller head can effectively / Full opened hood, easy accessibility of all components,

noise, low vibration, smooth lifting and landing reliable avoid the harm to the driver. is easy for service.

operation. / The standard equipped electronic lifting limitation / All shafts installed lubricated shaft sleeve and oil cup,

/ Punch formed forks to provide more strength and tip protect the pump motor from damaging dramatically provide convenient maintenance and long service life.

guide to provide higher efficient operation. and more energy saving.

/ Using non-contact proximity switch, improves safety

and reliability.

Tandem load wheel

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Fluid Level Shots To Optimize Chemical Treatment ProgramsDocument15 pagesFluid Level Shots To Optimize Chemical Treatment ProgramsWilliam100% (1)

- Plant Design CP5062 HAZOP Example For Hui BeeDocument22 pagesPlant Design CP5062 HAZOP Example For Hui BeeNoel Kristian0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ficha Tecnica Con Curva Myers Bomba Tipo CampanaDocument4 pagesFicha Tecnica Con Curva Myers Bomba Tipo CampanaRonald FranciaNo ratings yet

- Truck-Mixer Pump "Magnum" MK28L-80/115 RH: Placing Boom Pumping Unit Concrete Mixer Driven by ChassisDocument2 pagesTruck-Mixer Pump "Magnum" MK28L-80/115 RH: Placing Boom Pumping Unit Concrete Mixer Driven by ChassisVasiliy PavliukNo ratings yet

- Water Management Using Ponraja's Guide LinesDocument258 pagesWater Management Using Ponraja's Guide LinesRajeNo ratings yet

- Oil and Gas FacilitiesDocument11 pagesOil and Gas FacilitiesDemzy Adeniyi100% (4)

- Installation Procedure: NoticeDocument2 pagesInstallation Procedure: NoticeEdwin juanito gamarra serranoNo ratings yet

- Instruction Manual: ADONY Series AHDocument47 pagesInstruction Manual: ADONY Series AHHong Trung DuongNo ratings yet

- Troubleshooting Guide, Harvest Right, TSG-DIGITAL-v01-2021Document16 pagesTroubleshooting Guide, Harvest Right, TSG-DIGITAL-v01-2021abattzNo ratings yet

- Fault Code 2215 (ISC/QSC/ISL/QSL Automotive, Industrial, or Marine Application)Document3 pagesFault Code 2215 (ISC/QSC/ISL/QSL Automotive, Industrial, or Marine Application)Ali ArdinNo ratings yet

- Joy CooperDocument23 pagesJoy CooperJayson Alelojo DejesusNo ratings yet

- Cutting LubricantsDocument35 pagesCutting LubricantsMetalloyNo ratings yet

- 5th WeekDocument7 pages5th Weekharish nethaNo ratings yet

- TKF00MEMST0007Rev 2MethodstatementofFlushingandHydrotestingforStationPipingDocument41 pagesTKF00MEMST0007Rev 2MethodstatementofFlushingandHydrotestingforStationPipinghasan_676489616No ratings yet

- Teknofanghi OpManual PolyDilution en 2012-12-05Document89 pagesTeknofanghi OpManual PolyDilution en 2012-12-05Alia NassiriNo ratings yet

- BDT 47 KvaDocument2 pagesBDT 47 KvaAyman EsaNo ratings yet

- Design and Modeling of RC SubmarineDocument5 pagesDesign and Modeling of RC SubmarineMousa AklNo ratings yet

- OISD Standard - 119Document25 pagesOISD Standard - 119Viveka SaravananNo ratings yet

- MVAC Testing & Commissioning Procedure - 2007Document245 pagesMVAC Testing & Commissioning Procedure - 2007spencersiu100% (6)

- Hydrostatic Pump (M46 - Servo Assisted Steering) (Left Half)_(S_N 514418295, 514418706 - 514418710, 514418885 - 514418886, 514418905 - 514424999, 514520063 - 514524999, 514620147 - 514624999)_863 (1)Document5 pagesHydrostatic Pump (M46 - Servo Assisted Steering) (Left Half)_(S_N 514418295, 514418706 - 514418710, 514418885 - 514418886, 514418905 - 514424999, 514520063 - 514524999, 514620147 - 514624999)_863 (1)tatyNo ratings yet

- Kudu Hsu Ps PDFDocument3 pagesKudu Hsu Ps PDFSARALLAHNo ratings yet

- Bomba Bulldog 215-255 - Instrucciones y Lista de Parte-GracoDocument20 pagesBomba Bulldog 215-255 - Instrucciones y Lista de Parte-GracomaraujoNo ratings yet

- HydraulicsDocument8 pagesHydraulicsShaddy GitauNo ratings yet

- Technical Data Sheet: 25cm Single Acting Handpump AssembliesDocument6 pagesTechnical Data Sheet: 25cm Single Acting Handpump AssembliesngazawooNo ratings yet

- Laboratory ExperimentsDocument70 pagesLaboratory ExperimentsKarl TristanNo ratings yet

- Specification of Bulb Turbine(结构说明)- PL1Document8 pagesSpecification of Bulb Turbine(结构说明)- PL1An Nguyen0% (1)

- Release Note Tebodin Process Toolbox Version 4.0Document4 pagesRelease Note Tebodin Process Toolbox Version 4.0Phượng NguyễnNo ratings yet

- Group 4 Disassembly and Assembly: 1. STEERING (+fan Pump)Document68 pagesGroup 4 Disassembly and Assembly: 1. STEERING (+fan Pump)Marco OlivettoNo ratings yet

- Flotec Water Pumps Owner's Manual - Model S183Document39 pagesFlotec Water Pumps Owner's Manual - Model S183WestsideWholesaleNo ratings yet

- Bharat Petroleum Corporation Limited PMC TenderDocument62 pagesBharat Petroleum Corporation Limited PMC TendersubstationloverNo ratings yet