Professional Documents

Culture Documents

Danfoss MSV F2 Static Balancing

Danfoss MSV F2 Static Balancing

Uploaded by

Novian Hermawan HOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Danfoss MSV F2 Static Balancing

Danfoss MSV F2 Static Balancing

Uploaded by

Novian Hermawan HCopyright:

Available Formats

Data sheet

Manual presetting valve

MSV-F2, PN 16/25, DN 15-400

Description

MSV-F2 DN 15-150 MSV-F2 DN 200-400

MSV-F2 valves are manual presetting valves with Main data:

flanged connections. They are used for balancing • DN 15-400

the flow in heating and cooling installations. • PN 16:

- Flow temperature: –10°C … 130°C

The valves have a position indicator and stroke • PN 25:

limiter as standard. The hand wheel of the valve - Flow temperature: –10°C … 150°C

is integrated with the stroke limiter. • Valves can be mounted in the supply or return

The setting can be locked. Valve characteristics pipe.

are set up in measuring device PFM 1000/

PFM 100. Valves are free of asbestos.

Shut-off function.

Application

Cooling installation (flow) with manual presetting valves. In order to balance the

cooling installation manual presetting valves should be mounted on each terminal

unit, branch and riser (LENOTM MSV-BD).

© Danfoss | 2022.11 AI144786474818en-010405 | 1

Data sheet Manual presetting valve MSV-F2

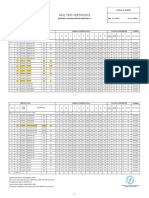

Ordering MSV-F2 valves - PN 16

DN kVS Tmax. PN Code No.

Picture

(mm) (m3/h) (°C) (bar) (with needle test plugs)

15 3.1 003Z1085

20 6.3 003Z1086

25 9.0 003Z1087

32 15.5 003Z1088

40 32.3 003Z1089

50 53.8 003Z1061

65 93.4 003Z1062

80 122.3 003Z1063

130 16

100 200.0 003Z1064

125 304.4 003Z1065

150 400.8 003Z1066

200 872 003Z1140

250 1,238 003Z1141

300 1,662 003Z1142

350 2,359 003Z1143

400 3,516 003Z1144

MSV-F2 valves - PN 25

DN kVS Tmax. PN Code No.

Picture

(mm) (m3/h) (°C) (bar) (with needle test plugs)

15 3.1 003Z1092

20 6.3 003Z1093

25 9.0 003Z1094

32 15.5 003Z1095

40 32.3 003Z1096

50 53.8 003Z1070

65 93.4 003Z1071

80 122.3 003Z1072

150 25

100 200.0 003Z1073

125 304.4 003Z1074

150 400.8 003Z1075

200 872 003Z1145

250 1,238 003Z1146

300 1,662 003Z1147

350 2,359 003Z1148

400 3,516 003Z1149

.

Accessories

Type Code No. Type Code No.

DN 15-50 003Z0179

Standard test plugs with O-ring, 2 pcs. 003Z0104

DN 65-150 003Z0180

Extension piece for test plugs 45 mm, DN 200-250 003Z1180

003Z0103

2 pcs. Hand-wheel

DN 300 003Z1181

Extended test plugs mounted under

003Z3946 DN 350 003Z1182

pressure, 2 pcs.

Flow measuring instrument PFM100 DN 400 003Z1183

003L8260

(10bar)

Flow measuring instrument PFM1000

003Z8260

(10 bar)

Flow measuring instrument PFM1000

003Z8261

(20 bar)

2 | AI144786474818en-010405 © Danfoss | 2022.11

Data sheet Manual presetting valve MSV-F2

Technical data

MSV-F2 valves - PN 16

Nominal diameter DN 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400

kVS m3/h 3.1 6.3 9.0 15.5 32.3 53.8 93.4 122.3 200.0 304.4 400.8 872 1238 1662 2359 3516

Nominal pressure 16

bar

Max. pressure drop 1.5

Leakage rate Grade A; According to ISO5208, Table 5 (No visible leakage)

Flow medium Water and water mixtures with secondary coolants (like glycols 1)) for closed heating and cooling systems

Max. flow temperature °

C 130

Connections Flanges according to EN 1092-2

Weight kg 2.3 2.9 3.8 5.6 7.2 9.4 17 21 32 44 56.5 98 153 247 374 525

Material

Body Cast iron EN-GJL 250 (GG 25)

Seat sealing EPDM

Stainless Stainless steel/

Cone CW602N Casted stainless steel

steel CW602N

1)

Please verefy compability between materials and secondary coolants with supplier.

MSV-F2 valves - PN 25

Nominal diameter DN 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400

kVS m3/h 3.1 6.3 9.0 15.5 32.3 53.8 93.4 122.3 200.0 304.4 400.8 872 1238 1662 2359 3516

Nominal pressure 25

bar

Max. pressure drop 2.0

Leakage rate Grade A; According to ISO5208, Table 5 (No visible leakage)

Flow medium Water and water mixtures with secondary coolants (like glycols 1)) for closed heating and cooling systems

Max. flow temperature °

C 150

Connections Flanges according to EN 1092-2

Weight kg 2.3 3.0 3.8 5.8 7.2 9.4 17 21 33 44 56.5 107 172 278 420 603

Material

Body Ductile iron EN-GJS 400-15 (GGG-40)

Seat sealing EPDM

Stainless Stainless steel

Cone CW602N Casted stainless steel

steel CW602N

1)

Please verefy compability between materials and secondary coolants with supplier.

Pressure-temperature classification (flanges according to EN 1092-2)

Temperature

Material PN

−10 °C 120 °C 130 °C 150 °C

EN-GJL 250 (MSV-F2 DN 15-150) 16 16 16 15.5 -

EN-GJL 250 (MSV-F2 DN 200-400) 16 16 16 15.5 -

bar

EN-GJS 400-15 (MSV-F2 DN 15-150) 25 25 25 - 24.3

EN-GJS 400-15 (MSV-F2 DN 200-400) 25 25 25 - 24.3

Stroke limiter

Valves have built in flow limitation Valves have built in flow limitation

© Danfoss | 2022.11 AI144786474818en-010405 | 3

Data sheet Manual presetting valve MSV-F2

Design

MSV-F2 DN 15-50 MSV-F2 DN 65-80

MSV-F2 DN 100-150

1 Body 8 Fixed screw

2 Plug 9 Spindle

3 Valve cone 10 Stuffing box

3.1 Seat soft sealing 11 Bonnet

4 Rod 12 Allen screw/Hexagon screw

5 Stroke limiter/Allen screw 13 Flat gasket

6 Gasket

7 Handwheel with digital display

- DN 15-150 plastic

4 | AI144786474818en-010405 © Danfoss | 2022.11

Data sheet Manual presetting valve MSV-F2

Design (continued)

1 Handwheel

2 The elastic spring

3 Stuffing box

4 Valve cover

5 Spindle

6 Spindle limiter

7 Cone head

8 Cone attachment

9 O-ring

10 Valve body

11 G¼” screw

12 O-ring

13 O-ring

14 O-ring

15 Gasket Cu

16 Bolt

17 Gasket

18 Nipple

MSV-F2 DN 200-400

Setting Ethylenglycol correction factor

Formula: C2H6O2 Q water

Q corr. =

Density at 20 °C: ρwater = 1 kg/dm3 Share of water × ρ water + Share of glycol × ρ glycol

ρglycol = 1.338 kg/dm3

Ethylenglycol part

0 10 20 30 40 50 60 70 80 90 100

xg (%)

Correction factor 1.0 0.983 0.968 0.953 0.939 0.925 0.912 0.899 0.887 0.876 0.864

MSV-F2 DN 65

∆p = 0.6 bar

Hand wheel setting: 3.0

Flow: 16.8 m3/h

30 % glycol

Qcorr. = 16.8 m3/h × 0.953 = 16.0 m3/h

It refers to all types of valves.

© Danfoss | 2022.11 AI144786474818en-010405 | 5

Data sheet Manual presetting valve MSV-F2

Installation Always install the valve with the arrow on the

body in the same direction as the flow. In order to

avoid turbulence, which will affect the measuring

accuracy, it is recommended to have a straight

length of pipe up and down stream from the

valve as shown (D - diameter of pipe).

The influence of turbulence, if our 5D 2D

recommendations are not adhered to, can

influence the flow up to 20%.

6 | AI144786474818en-010405 © Danfoss | 2022.11

Data sheet Manual presetting valve MSV-F2

Sizing

Example:

MSV-F2 DN 65

Q = 16 m3/h

∆p = 5 kPa

Calculation for the valve setting:

Draw a straight line from the desired flow

(16 m3/h) through the differential pressure

(5 kPA) to k v scale.

From the k v value draw a horizontal line. Where

it intersects the given valve (DN65) you can find

the valve setting.

Result:

presetting 7.0

© Danfoss | 2022.11 AI144786474818en-010405 | 7

Data sheet Manual presetting valve MSV-F2

Flow diagrams DN 15 / PN 16 / PN 25

Setting k v -value

1 0.45

2 1.26

3 2.73

4 3.09

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

DN 20 / PN 16 / PN 25

Setting k v -value

1 0.54

2 2.48

3 5.11

4 6.26

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

8 | AI144786474818en-010405 © Danfoss | 2022.11

Data sheet Manual presetting valve MSV-F2

Flow diagrams (continued) DN 25 / PN 16 / PN 25

Setting k v -value

1 1.61

2 6.0

3 8.38

4 9.01

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

DN 32 / PN 16 / PN 25

Setting k v -value

1 3.53

2 7.56

3 12.32

4 15.54

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

© Danfoss | 2022.11 AI144786474818en-010405 | 9

Data sheet Manual presetting valve MSV-F2

Flow diagrams (continued) DN 40 / PN 16 / PN 25

Setting k v -value

1 4.19

2 9.98

3 16.42

4 22.13

5 28.14

6 32.31

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

DN 50 / PN 16 / PN 25

Setting k v -value

1 7.4

2 15.8

3 26.7

4 36.9

5 46.2

6 53.8

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

10 | AI144786474818en-010405 © Danfoss | 2022.11

Data sheet Manual presetting valve MSV-F2

Flow diagrams (continued) DN 65 / PN 16 / PN 25

Setting k v -value

1 2.6

2 8.8

3 21.6

4 39.0

5 49.8

6 58.5

7 69.3

8 79.0

9 87.8

9.5 93.4

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

DN 80 / PN 16 / PN 25

Setting k v -value

1 5.8

2 9.9

3 24.5

4 48.5

5 71.3

6 87.0

7 96.4

8 109.3

9.5 122.3

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

© Danfoss | 2022.11 AI144786474818en-010405 | 11

Data sheet Manual presetting valve MSV-F2

Flow diagrams (continued) DN 100 / PN 16 / PN 25

Setting k v -value

1 8.3

2 32.4

3 72.9

4 107.2

5 128.2

6 152.8

7 180.0

8 200.0

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

DN 125 / PN 16 / PN 25

Setting k v -value

1 10.3

2 35.4

3 73.0

4 114.9

5 150.5

6 185.2

7 225.1

8 261.1

9 294.2

9.5 304.4

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

12 | AI144786474818en-010405 © Danfoss | 2022.11

Data sheet Manual presetting valve MSV-F2

Flow diagrams (continued) DN 150 / PN 16 / PN 25

Setting k v -value

1 21.4

2 48.5

3 99.8

4 162.0

5 214.0

6 260.9

7 304.1

8 354.6

9.5 400.8

Max. permissible differential pressure

in throttling function 1.5/2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

DN 200 / PN 16 / PN 25

Setting k v -value

1 30.8

2 58.7

3 100

4 170

5 262

6 361

7 423

8 481

9 542

10 597

11 647

12 684

13 722

14 763

15 807

16 850

Max: 16.7 872

Max. permissible differential pressure

in throttling function 1.5 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

© Danfoss | 2022.11 AI144786474818en-010405 | 13

Data sheet Manual presetting valve MSV-F2

Flow diagrams (continued) DN 250 / PN 16 / PN 25

Setting k v -value

1 53.6

2 109

3 207

4 349

5 490

6 580

7 693

8 791

9 877

10 942

11 1012

12 1076

13 1140

14 1211

Max: 14.4 1238

Max. permissible differential pressure

in throttling function 1.5 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

14 | AI144786474818en-010405 © Danfoss | 2022.11

Data sheet Manual presetting valve MSV-F2

Flow diagrams (continued) DN 300 / PN 16 / PN 25

Setting k v-value

1 57.4

2 117

3 208

4 356

5 503

6 683

7 826

8 940

9 1055

10 1161

11 1260

12 1343

13 1423

14 1500

15 1568

16 1643

Max: 16.4 1662

Max. permissible differential pressure

in throttling function 1.5 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

© Danfoss | 2022.11 AI144786474818en-010405 | 15

Data sheet Manual presetting valve MSV-F2

Flow diagrams (continued) DN 350 / PN 16 / PN 25

Setting k v -value Setting k v -value

1 75.1 9 1559

2 154 10 1711

3 300 11 1848

4 498 12 1952

5 768 13 2059

6 991 14 2182

7 1177 15 2305

8 1382 15.4 2359

Max. permissible differential pressure

in throttling function 1.5 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

DN 400 / PN 16 / PN 25

Setting k v -value Setting k v -value

0 0 9 2223

1 124 10 2482

2 292 11 2682

3 533 12 2848

4 819 13 2973

5 1192 14 3093

6 1445 15 3241

7 1720 16 3359

8 1983 Max: 17 3516

Max. permissible differential pressure

in throttling function 1.5 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

16 | AI144786474818en-010405 © Danfoss | 2022.11

Data sheet Manual presetting valve MSV-F2

Dimensions

MSV-F2 DN 15-50

PN 16 PN 25

L ØA H1

DN ØD ØK n × Ød Weight ØD ØK n × Ød Weight

mm kg mm kg

15 130 78 80 95 65 4x14 2.3 95 65 4x14 2.3

20 150 78 90 105 75 4x14 2.9 105 75 4x14 3.0

25 160 78 105 115 85 4x14 3.8 115 85 4x14 3.8

32 180 78 110 140 100 4x19 5.6 140 100 4x19 5.8

40 200 78 125 150 110 4x19 7.2 150 110 4x19 7.2

50 230 78 125 165 125 4x19 9.4 165 125 4x19 9.4

65 290 140 187 185 145 4x19 17 185 145 8x19 17

80 310 140 205 200 160 8x19 21 200 160 8x19 21

Remark: “n” is number of holes in the flange.

ØA

H1

ØK/n-Ød

ØD

DN

MSV-F2 DN 65-80

© Danfoss | 2022.11 AI144786474818en-010405 | 17

Data sheet Manual presetting valve MSV-F2

Dimensions (continued)

ØA

H1

ØK/n-Ød

ØD

DN

L

MSV-F2 DN 100-150

PN 16 PN 25

L ØA H1

DN ØD ØK n × Ød Weight ØD ØK n × Ød Weight

mm kg mm kg

100 350 140 222 220 180 8x19 32 235 190 8x23 33

125 400 140 251 250 210 8x19 44 270 220 8x28 44

150 480 140 247 285 240 8x23 56 300 250 8x28 56

200 600 306 418 340 295 12x23 98 360 310 12x28 107

250 730 306 471 400 355 12x28 153 425 370 12x31 172

300 850 306 525 460 410 12x28 247 485 430 16x31 278

350 980 306 590 520 470 16x28 374 555 490 16x34 420

400 1100 306 684 580 525 16x31 525 620 550 16x37 603

Remark: “n” is number of holes in the flange.

ØA

H1

Ø K/n - Ø d

ØD

DN

MSV-F2 DN 200-400

18 | AI144786474818en-010405 © Danfoss | DCS-SGDPT/SI | 2022.11

You might also like

- Day 2 Math, Distributive PropertyDocument9 pagesDay 2 Math, Distributive PropertyMrPeterson25No ratings yet

- Danfoss MSV-F2Document16 pagesDanfoss MSV-F2Dominik SvigirNo ratings yet

- Esp Calculation Sheet-M2Document36 pagesEsp Calculation Sheet-M2Buraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- PDF fp2Document9 pagesPDF fp2Коресендович ЮрийNo ratings yet

- Stick Magazine CatalogDocument37 pagesStick Magazine CatalogАртемNo ratings yet

- 02CZ10Document8 pages02CZ10A.hNo ratings yet

- Thermo Fuse Varistors PBDocument4 pagesThermo Fuse Varistors PBessen999No ratings yet

- Tev-Cat-Pages 17Document1 pageTev-Cat-Pages 17brunoNo ratings yet

- SM8S10 ShanghaisemitechDocument4 pagesSM8S10 ShanghaisemitechneobelhadjNo ratings yet

- Ps1350027 02 Cylinder SteeringDocument2 pagesPs1350027 02 Cylinder SteeringKaharrNo ratings yet

- Typ 15C01 6 enDocument3 pagesTyp 15C01 6 enLeonardoNo ratings yet

- Siov Metal Oxide Varistors: Leaded Varistors, Superior-Mp, S20 SeriesDocument24 pagesSiov Metal Oxide Varistors: Leaded Varistors, Superior-Mp, S20 SeriesartovolastiNo ratings yet

- TDK Epcos09573-1Document12 pagesTDK Epcos09573-1David VasquezNo ratings yet

- Easy Switch With Sulzer Adapter Brackets E10640Document2 pagesEasy Switch With Sulzer Adapter Brackets E10640Marcos Chaves MagalhãesNo ratings yet

- Datasheet de Un CapacitorDocument1 pageDatasheet de Un CapacitorSantiago Guerrero MartinezNo ratings yet

- 30DF1 30DF6Document2 pages30DF1 30DF6isaiasvaNo ratings yet

- Fiche Technique 500489 Thermistance PTC TDK b59990 c120 A70 55 1 PcsDocument15 pagesFiche Technique 500489 Thermistance PTC TDK b59990 c120 A70 55 1 PcsBelghennou Hadj AliNo ratings yet

- Data PDFDocument4 pagesData PDFPanagiotis PanagosNo ratings yet

- S07K275 EpcosDocument17 pagesS07K275 Epcosvali dNo ratings yet

- ANSI B16.5 Slip-On, Raised Face Flanges - Class 150 or 300: Configuration Sheet Model Precision Tube SeriesDocument2 pagesANSI B16.5 Slip-On, Raised Face Flanges - Class 150 or 300: Configuration Sheet Model Precision Tube SeriesEdisonCorderoNo ratings yet

- Product Data: Immersion Sensor W/ Weatherproof EnclosureDocument2 pagesProduct Data: Immersion Sensor W/ Weatherproof EnclosureRobert UrquiaNo ratings yet

- Tee NPT, Cap NPRDocument2 pagesTee NPT, Cap NPRJonathan Mendez RamosNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- D2n Relay: The Best Rela TionDocument11 pagesD2n Relay: The Best Rela TionИгорьNo ratings yet

- Varistores EpcosDocument47 pagesVaristores EpcosSidimar SotorivaNo ratings yet

- SIOV Leaded StandarD-1317152Document48 pagesSIOV Leaded StandarD-1317152adyro12No ratings yet

- SIOV Leaded StandarDDocument47 pagesSIOV Leaded StandarDMee Plengtham Uu-saNo ratings yet

- Siov SMD Cu Surge Varistors PBDocument4 pagesSiov SMD Cu Surge Varistors PBnsebxxNo ratings yet

- TM ZT824H 1 41057101014a FrameDocument161 pagesTM ZT824H 1 41057101014a FrameMuli adiNo ratings yet

- Siov Leaded Advanced MP 10mmDocument22 pagesSiov Leaded Advanced MP 10mmNorgen QuinteroNo ratings yet

- MOC30X0MDocument11 pagesMOC30X0MmersoigNo ratings yet

- z1047 (TS)Document1 pagez1047 (TS)zero cloudNo ratings yet

- Diodes Inc ZC831ATC95789Document7 pagesDiodes Inc ZC831ATC95789carlosibaNo ratings yet

- SMD Zener Diodes (Three Terminals) - 300mWDocument4 pagesSMD Zener Diodes (Three Terminals) - 300mWMax TeleNo ratings yet

- STP100-101 DatasheetDocument4 pagesSTP100-101 DatasheetNATHANNo ratings yet

- 50 Watt Zener Diode: F A M - RDocument2 pages50 Watt Zener Diode: F A M - RLuís GuerreiroNo ratings yet

- Aquarius+ UPVC Industrial Pipe & FittingsDocument16 pagesAquarius+ UPVC Industrial Pipe & Fittingspanchal harnishNo ratings yet

- RE 25 860/11.11 Replaces: RE 25 860/10.10 Pressure Relief ValvesDocument3 pagesRE 25 860/11.11 Replaces: RE 25 860/10.10 Pressure Relief ValvesflowNo ratings yet

- Modular Lube Lubrication Systems: Divider ValvesDocument6 pagesModular Lube Lubrication Systems: Divider ValvesIbrahimAmroNo ratings yet

- LEO XST DatasheetDocument3 pagesLEO XST DatasheetELBAGHATI MohammadNo ratings yet

- SIOV Leaded StandarD-81501Document37 pagesSIOV Leaded StandarD-81501Nv TháiNo ratings yet

- MF NSMFDocument14 pagesMF NSMFsales6No ratings yet

- Com Varistoren Von Epcos 3 1576 PDFDocument36 pagesCom Varistoren Von Epcos 3 1576 PDFAwadhNo ratings yet

- Lokotrack ST3.8 S N 78316Document378 pagesLokotrack ST3.8 S N 78316miguel. montañoNo ratings yet

- BZX55C: Silicon Planar Zener DiodesDocument4 pagesBZX55C: Silicon Planar Zener DiodesRizky AnandaNo ratings yet

- Tools & Consumables Consumption Report Rev 1Document6 pagesTools & Consumables Consumption Report Rev 1Mihai CozmaNo ratings yet

- Vitrohm Series ZC - 201602Document3 pagesVitrohm Series ZC - 201602Nani VellankiNo ratings yet

- SMD General Purpose TransistorDocument3 pagesSMD General Purpose TransistorcompusoundNo ratings yet

- SMD (ZV)Document15 pagesSMD (ZV)Igor PNo ratings yet

- Esfuerzo TransversalDocument9 pagesEsfuerzo TransversalBRAYHAN RICARDO CABRERA MONTALVONo ratings yet

- Enclosure Heat DissipationDocument4 pagesEnclosure Heat DissipationBlessingNo ratings yet

- Cryogenic Use Specs SheetDocument2 pagesCryogenic Use Specs SheetmbNo ratings yet

- Cu2 Uk Ud Uk CK: CTM yDocument1 pageCu2 Uk Ud Uk CK: CTM yManupriya KapleshNo ratings yet

- MZ816Document2 pagesMZ816Jesús Miguel LemNo ratings yet

- Buckling CalculatorDocument35 pagesBuckling CalculatorMunever Okić0% (1)

- Bs638 (Part 4) 0361Tq Welding Cable Single CoreDocument2 pagesBs638 (Part 4) 0361Tq Welding Cable Single CoreAdnan KhanNo ratings yet

- Zeners BZX85C 3V3 - BZX85C 33: Absolute Maximum RatingsDocument3 pagesZeners BZX85C 3V3 - BZX85C 33: Absolute Maximum RatingsYAKALA RAVIKUMARNo ratings yet

- EDrive Actuators VecTac VT BrochureDocument4 pagesEDrive Actuators VecTac VT BrochureElectromateNo ratings yet

- NIC Components NCC SeriesDocument3 pagesNIC Components NCC SeriesNICCompNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- ImportantquestionDocument2 pagesImportantquestionRitik RajNo ratings yet

- 215MW HFO Power Plant of Dhaka Northern: Manikganj, BangladeshDocument48 pages215MW HFO Power Plant of Dhaka Northern: Manikganj, BangladeshKhan MohhammadNo ratings yet

- STR W6735 DatasheetDocument13 pagesSTR W6735 DatasheetloagerNo ratings yet

- Daily, Weekly and Monthly Responsibilities For Oracle Applications DbasDocument21 pagesDaily, Weekly and Monthly Responsibilities For Oracle Applications DbasVikrant ThapaNo ratings yet

- Komatsu HM400-2RDocument12 pagesKomatsu HM400-2RBarbatose LupusrexNo ratings yet

- Gasoline EngineDocument41 pagesGasoline EngineRalph JaramilloNo ratings yet

- Health Devices IPM System: Inspection and Preventive MaintenanceDocument8 pagesHealth Devices IPM System: Inspection and Preventive MaintenancePradigda Kresna Putra100% (1)

- Sw4548e PDFDocument152 pagesSw4548e PDFGA16DET100% (1)

- Motorcycle Security System Using SMS Warning and GPS TrackingDocument7 pagesMotorcycle Security System Using SMS Warning and GPS TrackingahabbasiNo ratings yet

- Taking Reservation DetailsDocument34 pagesTaking Reservation DetailsCherrielyn LawasNo ratings yet

- Subnetting Assignment #1: Instructions For All ProblemsDocument3 pagesSubnetting Assignment #1: Instructions For All ProblemssugapriyaNo ratings yet

- Virtualized Software Defined Networks and Services by Mehmet Toy and Qiang DuanDocument328 pagesVirtualized Software Defined Networks and Services by Mehmet Toy and Qiang Duancota_carinhasNo ratings yet

- Slide PPT Seminar InternasionalDocument6 pagesSlide PPT Seminar InternasionalFandi AfandiNo ratings yet

- High Energy Ball Mill SpecsDocument10 pagesHigh Energy Ball Mill SpecsRanveer ShekhawatNo ratings yet

- EMC Centera 4.0 GlobalServices Release Notes Rev.a37Document94 pagesEMC Centera 4.0 GlobalServices Release Notes Rev.a37Eero AhoNo ratings yet

- PP 303 To 312 Jordan Peng Horng Tan Final Paper EditedDocument10 pagesPP 303 To 312 Jordan Peng Horng Tan Final Paper EditedjaywarvenNo ratings yet

- Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCDocument1 pageProperties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCsidsaleemNo ratings yet

- How To Walk Bass Lines IV (#35) (Live Transcript)Document9 pagesHow To Walk Bass Lines IV (#35) (Live Transcript)Nicole CremeNo ratings yet

- 1955 Lundstrom Intermaxillary Tooth Width Ratio and Tooth Alignment and OcclusionDocument29 pages1955 Lundstrom Intermaxillary Tooth Width Ratio and Tooth Alignment and OcclusionRockey ShrivastavaNo ratings yet

- 4 - Discs - Chapter 4 - Rotating Discs v. 2014.11 - Lecture NotesDocument115 pages4 - Discs - Chapter 4 - Rotating Discs v. 2014.11 - Lecture NotesMuzio GolaNo ratings yet

- Juno Lighting Architectural Lighting Products Catalog 1996Document88 pagesJuno Lighting Architectural Lighting Products Catalog 1996Alan MastersNo ratings yet

- Caking of Refined SugarDocument3 pagesCaking of Refined Sugarnghi100% (1)

- Control Systems - State Space ModelDocument8 pagesControl Systems - State Space ModelVivek PatilNo ratings yet

- Validation of The Spanish Version of The Children's Self-Perceptions of Adequacy in and Predilection For Physical Activity (CSAPPA) QuestionnaireDocument20 pagesValidation of The Spanish Version of The Children's Self-Perceptions of Adequacy in and Predilection For Physical Activity (CSAPPA) QuestionnaireMaria Paula ClavijoNo ratings yet

- CISCO Built-In Wireshark Capability White Paper c11-554444Document10 pagesCISCO Built-In Wireshark Capability White Paper c11-554444Ramaswamy PeriaswamyNo ratings yet

- International Journal of Mineral ProcessingDocument6 pagesInternational Journal of Mineral ProcessingBoba AngelNo ratings yet

- ST 2702Document1 pageST 2702Harsh MouryNo ratings yet

- The Effect of ORP Pulp Potential On Copper Flotation PDFDocument159 pagesThe Effect of ORP Pulp Potential On Copper Flotation PDFJoe LoraNo ratings yet

- Amino Acid Profile, Physicochemical and Sensory Properties of Noodles Produced From Wheat-Bambara Protein Isolate - ScienceDirectDocument13 pagesAmino Acid Profile, Physicochemical and Sensory Properties of Noodles Produced From Wheat-Bambara Protein Isolate - ScienceDirectHalimat Usman AdemolaNo ratings yet