Professional Documents

Culture Documents

WEP For Painting

WEP For Painting

Uploaded by

palashCopyright:

Available Formats

You might also like

- CPCCWHS2001 Assessment WorkbookDocument70 pagesCPCCWHS2001 Assessment Workbookankit33% (3)

- Completed Idp Report PDFDocument117 pagesCompleted Idp Report PDFFarhana Hussin100% (2)

- Assessment Workbook CPC Construction, Plumbing and Services Training PackageDocument94 pagesAssessment Workbook CPC Construction, Plumbing and Services Training PackageKomal SharmaNo ratings yet

- SGSO Regulation EnglishDocument38 pagesSGSO Regulation EnglishCinthia BazethNo ratings yet

- Pamphlet 5 - Edition 9 - January 2017Document30 pagesPamphlet 5 - Edition 9 - January 2017Comercial AySNo ratings yet

- Production Riser Life Extension: Guidance Notes OnDocument24 pagesProduction Riser Life Extension: Guidance Notes OnGopalakrishnanNo ratings yet

- Nine Steps to Success: North American edition: An ISO 27001 Implementation OverviewFrom EverandNine Steps to Success: North American edition: An ISO 27001 Implementation OverviewNo ratings yet

- Flat, Trofoil & TriplexDocument12 pagesFlat, Trofoil & Triplexphanibarama100% (1)

- VV Manual v1.1 PDFDocument111 pagesVV Manual v1.1 PDFHernâniCruzNo ratings yet

- CaseStudy-Ceramic Industry PDFDocument80 pagesCaseStudy-Ceramic Industry PDFMario CoelhoNo ratings yet

- Evaluation of Quality ManagementDocument18 pagesEvaluation of Quality ManagementAlemuNo ratings yet

- RFP - Section - II - Schedule of Requirements - RFP - 2018 - 6100 - Annex A EDD Standards PDFDocument35 pagesRFP - Section - II - Schedule of Requirements - RFP - 2018 - 6100 - Annex A EDD Standards PDFJagna GillNo ratings yet

- 8 - RJN NAD HSE Management PlanDocument45 pages8 - RJN NAD HSE Management PlanMartahanManurung100% (1)

- Ecpn Cs 168 Final For Publication For Moc For B&sDocument63 pagesEcpn Cs 168 Final For Publication For Moc For B&snatanNo ratings yet

- Regulations For Sanitary InstallationsDocument207 pagesRegulations For Sanitary Installationsyusuf100% (1)

- MDOT Procedures For Aggregate Inspection 658850 7Document91 pagesMDOT Procedures For Aggregate Inspection 658850 7Mo YNo ratings yet

- Project Guidelines 2019 Final JUNEDocument59 pagesProject Guidelines 2019 Final JUNENicholas KinotiNo ratings yet

- DINODocument38 pagesDINOCHIDERA ANo ratings yet

- Qam of Mekelle-1Document320 pagesQam of Mekelle-1Daric TesfayeNo ratings yet

- Section 5 - Annex - 3 Standard of Methods and MeasurmentsDocument64 pagesSection 5 - Annex - 3 Standard of Methods and MeasurmentsAshebir AjemaNo ratings yet

- Malaysia StandardDocument5 pagesMalaysia Standards63118No ratings yet

- PROPOSAL FOR YIRGALEM TEXTILE FACTORY Final Last PPPPPPPPPPPDocument51 pagesPROPOSAL FOR YIRGALEM TEXTILE FACTORY Final Last PPPPPPPPPPPsoloNo ratings yet

- Standard Methods of Measurement MUDHC 2014Document71 pagesStandard Methods of Measurement MUDHC 2014Desalegn Melknew90% (10)

- NIST - hb.150!1!2021 Energy Efficient Lighting ProductsDocument22 pagesNIST - hb.150!1!2021 Energy Efficient Lighting ProductsRIYANTO BEBETNo ratings yet

- Petroleum Deport EIA - FinalDocument104 pagesPetroleum Deport EIA - FinalJoey MW100% (1)

- Capstone Project Humidity Test ChamberDocument49 pagesCapstone Project Humidity Test Chamberkhaled hlalahNo ratings yet

- FM 5420 Carbon Dioxide Extinguishing Systems 2018Document59 pagesFM 5420 Carbon Dioxide Extinguishing Systems 2018andy100% (1)

- Composition of Natural-Gas Condensate Types of CondensateDocument35 pagesComposition of Natural-Gas Condensate Types of CondensatePinak Chowdhury100% (1)

- Technical Specification For Road Rail Equipment FSS550Document70 pagesTechnical Specification For Road Rail Equipment FSS550Ion Logofătu AlbertNo ratings yet

- Mac3701 2024 TL103 3 BDocument80 pagesMac3701 2024 TL103 3 BRodney MahlanguNo ratings yet

- 4 - 02. Section II - 4420003405Document137 pages4 - 02. Section II - 4420003405JonesNo ratings yet

- HSE Docs by Hseprof ComDocument51 pagesHSE Docs by Hseprof Comzainjotun406No ratings yet

- RFP Attachment C CSEAS 2.0 PMC Statement of WorkDocument55 pagesRFP Attachment C CSEAS 2.0 PMC Statement of WorkLim Siew LingNo ratings yet

- PWTP2 - QCP 20160908-ADocument35 pagesPWTP2 - QCP 20160908-AgregNo ratings yet

- EACO Indoor Air Quality (IAQ) - Guideline For Non-Industrial WorkplacesDocument54 pagesEACO Indoor Air Quality (IAQ) - Guideline For Non-Industrial WorkplacesM MNo ratings yet

- ABS MArine Management Systems Update 2016Document59 pagesABS MArine Management Systems Update 2016Xmenxs XmenxsNo ratings yet

- Tenant GuidelinesDocument90 pagesTenant Guidelinessheryl himocNo ratings yet

- HSE-ML-002 Tugs Operation HSE ManualDocument22 pagesHSE-ML-002 Tugs Operation HSE ManualRamy AbouquahfNo ratings yet

- Final Gulilat ResearchDocument46 pagesFinal Gulilat ResearchAssebe FeteneNo ratings yet

- Schedule Managment PlanDocument57 pagesSchedule Managment Planridhoni putraNo ratings yet

- (BOOK NO. 14) - (22) - SG-G-04 - Regulatory Inspection & Enforcement - (OTHER)Document73 pages(BOOK NO. 14) - (22) - SG-G-04 - Regulatory Inspection & Enforcement - (OTHER)pratip_bNo ratings yet

- Arkan Building Materials Health, Safety & Environment ManualDocument28 pagesArkan Building Materials Health, Safety & Environment ManualmorisNo ratings yet

- Simple Thesis On PMODocument106 pagesSimple Thesis On PMOMarcia Edwards50% (2)

- FM 1635 Plastic Pipe and Fittings For Automatic Sprinkler Systems 2018Document54 pagesFM 1635 Plastic Pipe and Fittings For Automatic Sprinkler Systems 2018andyNo ratings yet

- An Investigation of Total Quality ManageDocument323 pagesAn Investigation of Total Quality ManageAbate TefferaNo ratings yet

- Quality Assurance Manual: A/FatronicsDocument32 pagesQuality Assurance Manual: A/FatronicsAnand A V MysoreNo ratings yet

- Doe Handbook: Guide To Good Practices For Training of Technical Staff and ManagersDocument46 pagesDoe Handbook: Guide To Good Practices For Training of Technical Staff and ManagersAgustin A.No ratings yet

- Mba Ohalloran B 2014 PDFDocument100 pagesMba Ohalloran B 2014 PDFMsm MahsoomNo ratings yet

- Section 3 - Technical PackageDocument110 pagesSection 3 - Technical Packageرودي رودNo ratings yet

- Rcs Construction Manufacturing Construction Elements Cop 2022Document109 pagesRcs Construction Manufacturing Construction Elements Cop 2022JasonNo ratings yet

- Eia Report For Mpa WebsiteDocument188 pagesEia Report For Mpa WebsiteYen Ling NgNo ratings yet

- Clause-By-Clause Explanation of ISO 9001:2008: White PaperDocument21 pagesClause-By-Clause Explanation of ISO 9001:2008: White PapermardiradNo ratings yet

- ITA Design Guidelines WaterproofingDocument74 pagesITA Design Guidelines WaterproofingTansel YılmazNo ratings yet

- Doe HDBK 1002Document70 pagesDoe HDBK 1002hadiranjiNo ratings yet

- Pengurusan Kewangan (Kumpulan 6)Document42 pagesPengurusan Kewangan (Kumpulan 6)Wai ChongNo ratings yet

- Quality Manual v1.1 PDFDocument45 pagesQuality Manual v1.1 PDFGummalla RajeshNo ratings yet

- Occupational Health and Safety (Ohs) Management Plan ForDocument54 pagesOccupational Health and Safety (Ohs) Management Plan ForJC Dolorito100% (1)

- Heyles Fentoes Trainnig ReportDocument58 pagesHeyles Fentoes Trainnig ReportayeshmanthabroNo ratings yet

- Process Operator Refinery Chemical Liquid Processes 246F en TS3Document31 pagesProcess Operator Refinery Chemical Liquid Processes 246F en TS3shakNo ratings yet

- WQ1454 Project Execution PlanDocument60 pagesWQ1454 Project Execution PlanRAZANo ratings yet

- WEP For Concrete BIGMDocument12 pagesWEP For Concrete BIGMpalashNo ratings yet

- WEP For Gypsum Board False CeilingDocument6 pagesWEP For Gypsum Board False CeilingpalashNo ratings yet

- WEP For Steel Structure WorkDocument8 pagesWEP For Steel Structure WorkpalashNo ratings yet

- WEP For Sheet Pile WorkDocument12 pagesWEP For Sheet Pile WorkpalashNo ratings yet

- Program of Works For DENR Perimeter FenceDocument8 pagesProgram of Works For DENR Perimeter FenceKarl Brian OdonNo ratings yet

- Density 844 (KG/M) Absolute Roughness of Pipe 0.000046 (M) Kinematic Viscosity ( ) 6.643 E-6 (m2/s)Document7 pagesDensity 844 (KG/M) Absolute Roughness of Pipe 0.000046 (M) Kinematic Viscosity ( ) 6.643 E-6 (m2/s)epbamdadNo ratings yet

- BBIA Landside Infrastructure Final Design ReportDocument167 pagesBBIA Landside Infrastructure Final Design ReportTayyabah ZafarNo ratings yet

- Hospital: ServicesDocument60 pagesHospital: ServicesChanpreet SinghNo ratings yet

- Balance Material List 2Document1 pageBalance Material List 2manojkumarmurlidharaNo ratings yet

- Space Attributes: AccessibleDocument56 pagesSpace Attributes: AccessibleStephanie Lynn omegaNo ratings yet

- Pres RateDocument2 pagesPres RatescemanjuNo ratings yet

- RCD - PPT - Part 1Document32 pagesRCD - PPT - Part 1Christian Josh DomingoNo ratings yet

- Chapter 8: Two-Way Slab SystemsDocument53 pagesChapter 8: Two-Way Slab SystemsDavid SanchezNo ratings yet

- Abstract of The BOCW ActDocument4 pagesAbstract of The BOCW ActSaptarshi Dasgupta100% (1)

- Construction and Building Materials: Faiz Uddin Ahmed Shaikh, Salmabanu Luhar, Hasan S SSahan Arel, Ismail LuharDocument28 pagesConstruction and Building Materials: Faiz Uddin Ahmed Shaikh, Salmabanu Luhar, Hasan S SSahan Arel, Ismail LuharChirag N PatelNo ratings yet

- DAFZ RegulationsDocument41 pagesDAFZ RegulationsRoger SchulpNo ratings yet

- Autocalculator v. 16.00 i113001ENDocument53 pagesAutocalculator v. 16.00 i113001ENstikss100% (1)

- Design of Combined FootingDocument6 pagesDesign of Combined FootingEric John PedrosoNo ratings yet

- Curb InletDocument1 pageCurb InletJoseph MathewNo ratings yet

- Louis SullivanDocument20 pagesLouis SullivanMEGHA SHARMANo ratings yet

- For Heavy-Duty Equipment Exposed To Excessive Dirt and DebrisDocument2 pagesFor Heavy-Duty Equipment Exposed To Excessive Dirt and DebrisKarthik YadavNo ratings yet

- Nas1303 Nas1316Document2 pagesNas1303 Nas1316Jean AbelaNo ratings yet

- Case Studt 1Document11 pagesCase Studt 1keerthi R100% (1)

- Air Compressor Overall - Component DiagramDocument18 pagesAir Compressor Overall - Component DiagramHafizuddin RazakNo ratings yet

- Perno de Convergencia P 090.01 Konvergenzmessbolzen KV enDocument4 pagesPerno de Convergencia P 090.01 Konvergenzmessbolzen KV enFreddy Sanchez LuckNo ratings yet

- Aircraft Material & HardwareDocument105 pagesAircraft Material & Hardwarevipin muraliNo ratings yet

- Estonia JobsDocument8 pagesEstonia JobsMd JonayedNo ratings yet

- BP 220 PD957 Planning and Design Standards ComparisonDocument10 pagesBP 220 PD957 Planning and Design Standards ComparisonRandolph AlvarezNo ratings yet

- Nitoflor SL Cond-DissDocument4 pagesNitoflor SL Cond-DissVenkata Raju KalidindiNo ratings yet

- 04 Part 2-Desain Bangunan Sipil Pada PLTADocument30 pages04 Part 2-Desain Bangunan Sipil Pada PLTANovi AndrianyNo ratings yet

- Instruction Manual HL2-105Document20 pagesInstruction Manual HL2-105Станислав Георгиев67% (6)

- ILJIN STEEL Corporation: The First PartnerDocument25 pagesILJIN STEEL Corporation: The First PartnerUB HeavypartsNo ratings yet

- Is Thicker Gasket Material Better Than ThinnerDocument2 pagesIs Thicker Gasket Material Better Than ThinnerSteven LiparotoNo ratings yet

WEP For Painting

WEP For Painting

Uploaded by

palashOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WEP For Painting

WEP For Painting

Uploaded by

palashCopyright:

Available Formats

THE PROJECT FOR THE

IMPROVEMENT OF GOVERNANCE

AND MANAGEMENT RESEARCH AND

TRAINING FACILITIES

Work Execution Plan

FOR

Painting

Document No. TCEL/BIGM/WEP/Sheet pile/REV.00

PREPARED BY:

The Civil Engineers LTD

MAIN CONTRACTOR: TAISEI CORPORATION

CLIENT: BANGLADESH INSTITUTE OF GOVERNANCE AND MANAGEMENT

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

2

Table of Contents

1.0 GENERAL .............................................................................................................................................. 4

2.0 SCOPES .................................................................................................................................................. 4

3.0 REFERENCE DOCUMENTS ................................................................................................................ 4

4.0 METHOD STATEMENT ....................................................................................................................... 4

5.0 MATERIALS .......................................................................................................................................... 4

5.1 Plastic Emulsion and Exterior Weather Coat ................................................................................... 4

5.1.1 Acrylic Putty................................................................................................................................ 4

5.1.2 Primer Coat.................................................................................................................................. 4

5.1.3 Top Coat ...................................................................................................................................... 4

5.2 Epoxy Coat .......................................................................................................................................... 4

5.2.1 Epoxy Putty ................................................................................................................................. 4

5.2.2 Primer Coat.................................................................................................................................. 4

5.2.3 Top Coat ...................................................................................................................................... 4

6.0 RESOURCE, EQUIPMENT AND FACILITIES ................................................................................... 5

7.0 Work Procedures ..................................................................................................................................... 5

7.1 Storage of material .................................................................................................................................... 5

7.2 Plastic Emulsion and Exterior Weather Coat Procedure ........................................................................... 6

7.2.1 Surface Preparation............................................................................................................................. 6

7.2.2 Application Procedure ........................................................................................................................ 7

7.3 Epoxy Paint Procedure .............................................................................................................................. 9

7.3.1 Surface Preparation ............................................................................................................................ 9

7.3.2 Application Epoxy on wall Procedure .............................................................................................. 10

7.3.3 Application Epoxy Paint on Floor Procedure ................................................................................... 11

7.3.4 Epoxy Floor Curing .......................................................................................................................... 12

7.3.5 Epoxy paint anti rust procedure ........................................................................................................ 13

7.4 Textured Coating ..................................................................................................................................... 14

7.4.1 Inspection ........................................................................................................................................ 14

7.4.2 Trenching.......................................................................................................................................... 14

7.4.3. Masking ........................................................................................................................................... 14

7.4.4. Water Blasting ................................................................................................................................. 14

7.4.5. Scraping and sanding ....................................................................................................................... 14

7.4.6. Patch and repair ............................................................................................................................... 14

7.4.7. Elastomeric primer .......................................................................................................................... 14

7.4.8. Textured coating .............................................................................................................................. 14

7.4.9. Trim application .............................................................................................................................. 15

7.4.10. Clean up ......................................................................................................................................... 15

7.5 Lacquer paint ........................................................................................................................................... 15

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

8.0 Inspection .............................................................................................................................................. 15

3

9.0 HEALTH, SAFETY AND ENVIRONMENT ...................................................................................... 16

9.1 Regulations .............................................................................................................................................. 16

9.2 Health ...................................................................................................................................................... 16

9.3 Safety ....................................................................................................................................................... 16

9.4 Environmental issues ............................................................................................................................... 16

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

4

1.0 GENERAL

After completion of preparatory works such as the installation of block, plaster

installation, screed works and then the painting works will then be carried out.

2.0 SCOPES

In this method statement will show the procedure of painting works such as.

• Plastic Emulsion Paint

• Exterior Weather Coat

• Epoxy Paint

• Textured Paint

• Anti-rust paint

• Lacquer paint

3.0 REFERENCE DOCUMENTS

From BID DOCUMENT SECTION 1006- PAINTING

4.0 METHOD STATEMENT

This method statement describes the method and procedures involved in the Painting works.

5.0 MATERIALS

5.1 Plastic Emulsion and Exterior Weather Coat

5.1.1 Acrylic Putty

5.1.2 Primer Coat

5.1.3 Top Coat

5.2 Epoxy Coat

5.2.1 Epoxy Putty

5.2.2 Primer Coat

5.2.3 Top Coat

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

6.0 RESOURCE, EQUIPMENT AND FACILITIES

5

The equipment for this operation is as follows:

a) Paint brushes

b) Paint roller, cover and frame

c) Moisture gauge

d) Scraper

e) Sand paper

f) Steel wire brush

g) Scaffolding

h) Painter’s tape

i) Covering floor

j) Spatula

k) Chemical Gas Mask / Mask

l) Rubber Hand Gloves / Cloth Gloves

m) Safety Equipment

n) Other light equipment’s

o) Heater / Blower

7.0 Work Procedures

7.1 Storage of material

a) Materials shall be delivered to the site in the manufacturer’s original packaging with the

clearly information. The containers that not displaying manufacturer's product

identification will not be acceptable.

b) Materials delivered and stored in tightly covered containers in a well-ventilated area.

c) The latex application shall store in temperature between 5 C ﹾup to 43 Cﹾ

d) The resin application shall store in temperature between 18 C ﹾup to 32 Cﹾ

e) Containers should be maintained in clean condition, free of foreign materials and residue.

f) For the 5 gal. of paint buckets the stacking bearing capacity of slab is 30 buckets per square

meter.

g) The storage should be kept neat & clean. Remove oily rags and waste daily, take

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

6

h) necessary measures to ensure that worker and work areas are protected from fire and

health hazard resulting from handling mixing and application.

i) The Engineer may request to collect random sample for testing.

7.2 Plastic Emulsion and Exterior Weather Coat Procedure

7.2.1 Surface Preparation

j) Remove or protection hardware, accessories, plates Machined surface, lighting fixtures

and similar items already installed that not to be painted.

k) Clean the substances that could impair the bond of various coatings. Remove oil,

efflorescence, chalk, dust, grease and related agent.

l) Cracking and porous surfaces are repaired and make good before starting.

m) Roughen substances by sand paper for best bond of various coatings and sand lightly

between each succeeding coating.

n) Determine moisture content of surface by performing appropriate tests. Do not paint

where moisture content exceeds that permitted in manufacturer's printed directions.

o) Paint shall not be applied in rain, mist or when the relative

p) or to damp or wet surfaces. Use heater to displace the humidity.

q) Do not apply when ambient temperature is less than 3°C or if the temperature might drop

to this level within 4 hrs. of application. Use heater to increase ambient temperature.

r) Painting may continue during inclement weather if spaces in which surfaces to be painted

are enclosed and heated within temperature limits specified by the manufacture application

during application and drying periods

s) Lay drop cloths on the floor within a room to protect from the paint. Using painter's tape

apply tape around the door frame and window frames. Make sure to apply firm pressure

when applying the tape to ensure the paint will not be able to drip under the tape.

t) For materials preparation, maintain containers used in mixing and applying paint in a clean

condition, free of foreign materials and reside. All paint materials shall be mix in according

to manufacturer's directions.

u) Stir all the paint materials need to be done to produce a mixture of uniform density before

application. Do not stir surface film into material, that must be removed out before using.

v) Those hollow plastered should be rectified and adequately be repaired.

w) Surrounding plaster at door opening should be perfectly aligned with the frame/sub frame.

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

7

7.2.2 Application Procedure

x) Apply one coat of high-quality primer, on new drywall will help to hide any small

imperfections on walls. And most important, it improves paint adhesion, which greatly

reduces blisters and peeling.

y) Let the primer dry completely. Give the base coat about 6 to 8 hours to set. It should be

z) the touch before you begin applying subsequent coats of paint. It may be more convenient

to apply the primer in the afternoon or evening, then wait until the following day to tackle

the paint.

aa) Mix the paint thoroughly. Use an electric paint mixer or handheld stirrer to blend the paint

to an even consistency. This will prevent the oils and pigments from separating, result in

better coverage and a smoother finish. Once the paint reaches a uniform texture throughout

the paint area.

bb) Third step, provide finish coating that are compatible with applied primers. To begin

painting at the trim by hand, dip the tip of paintbrush about 2" into the paint, letting the

excess drip off. Then, brush the paint onto the wall with the angled edge of the brush,

starting at one of the room’s upper corners. Follow along the painter’s tape at the window

frames on wall and door frames and work way down using smooth, linear strokes until

completed the outer perimeter of the wall.

cc) Painting the interior of the wall, the best method for painting with a roller is to apply it in

alternating "M" or “W” pattern, working back and forth over the same section until it’s

completely filled in.

dd) When painting near the ceiling use an angled brush as they are narrower and will help

prevent getting paint on the ceiling.

ee) The extended roller handle can help you reach the upper sections of the wall nearest to the

ceiling. Make sure to overlap the edges while painting.

ff) The number of coats and the required film thickness are the same regardless of the

application method. Do not apply succeeding coats until the previous coat has cured as

recommended manufacturer.

gg) Apply additional coats if undercoats, stains, or other condition show through final coat of

paint until paint film is of uniform finish, color, and appearance. Give special attention to

ensure that formed surfaces, including edges, comers, crevices, welds, receive a dry film

thickness equivalent of flat surfaces.

hh) Paint surfaces behind movable equipment and furniture the same as similar exposed

surfaces. Before the final installation of equipment, paint surfaces behind permanently

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

8

ii) fixed equipment or furniture with prime coat only.

jj) After completing painting, clean glass and paint-spattered surfaces. Remove spattered

paint by washing and scraping. Be careful not to scratch or damage adjacent finished

surfaces.

kk) Remove all painters tape and gather drop clothes, making sure any spills or splatters are

dry before moving them.

ll) Remove temporary protective wrappings provided by others to protect after completing

painting operations.

mm) Provide “Wet Paint” signs at the complete painting area to protect newly painted finishes

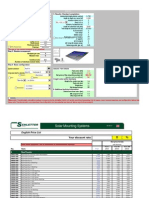

Required Coat Required Paint and Treatment Required Quantity

Under Coat Synthetic resin emulsion sealer 0.07kg/sqm or more

Middle Coat Synthetic Resin Emulsion paint (1-2 coat) .01kg/sqm or more

Top Coat Synthetic Resin Emulsion paint .01kg/sqm or more

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

9

Sl No. Brand or Model

1 SK KAKEN Co. Ltd

2 TOA Paint Co. Ltd

3 KIKUSUI Chemical Industries Co. Ltd.

7.3 Epoxy Paint Procedure

7.3.1 Surface Preparation

a) Remove or protect hardware, accessories, plates, machined surface, lighting fixtures

and similar items already installed that not to be painted.

b) Clean the substances that could impair the bond of various coatings. Remove oil,

efflorescence, chalk, dust, grease and relate agent.

c) Cracking and porous surfaces are repaired and make good before starting.

d) Use a paint tape to prevent to getting paint on ceiling and other areas not to be painted.

e) Roughen substances by sand paper for best bond of various coatings and sand lightly

between each succeeding coating.

f) Determine moisture content of surface by performing appropriate tests. Do not paint

where moisture content exceeds that permitted in manufacturer's printed directions.

g) Paint shall not be applied in rain, mist or when the relative humidity exceeds 85 percent or

to damp or wet surfaces. Use heater to displace the humidity. The temperature shall be in

rank of 10 Cﹾ-50 Cﹾ

h) Painting may continue during inclement weather if spaces in which surfaces to be painted

are enclosed and heated within temperature limits specified by the manufacture application

during application and drying periods

i) Lay drop cloths on the floor within a room to protect from the paint. Using painter's tape

apply tape around the door frame and window frames. Make sure to apply firm pressure

when applying the tape to ensure the paint will not be able to drip under the tape.

j) For materials preparation, maintain containers used in mixing and applying paint in a clean

condition, free of foreign materials and reside. All paint materials shall be mix in according

to manufacturer's directions.

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

10

k) Stir all the paint materials need to be done to produce a mixture of uniform density before

application. Do not stir surface film into material, that must be removed out before using.

l) Those hollow plastered should be rectified and adequately be repaired.

m) Those irregular un-even walls plastered and floor surface (MEP embedded items) cut

portions that were not done simultaneously during applying paints/epoxy.

7.3.2 Application Epoxy on wall Procedure

a) Apply one coat of high-quality primer on new surface will help to hide any small

imperfections. Priming will give the wall surface a longer life and better adhesion to the

substrate. Ensure that the areas are ventilated properly. Use a proper electrical mixer to

mix the component of the primer.

b) Application of the first Top coat of epoxy paint. Topcoat film is prepared by stirring Base

A to disperse any settlement, after which Hardener B is added to Base A and mixed slowly

for about 2 minutes making sure that air does not get into it, after mixing, transfer to another

container and mix again for 30 seconds.

c) Apply the product with a roller. Use a good quality roller, as poor quality rollers may start

to shed. We should be able to re-coat after 24 hours. The next day we may notice various

problems that have appeared such as cracks, holes etc. Make sure that these are sealed-

filled before starting the next coat. If necessary, wait an extra dry for the grout to dry before

re-coating.

d) Apply the final coat. Before placing the final coat make sure all holes and cracks have been

filled, and that all dust has been collected. Otherwise will get an ugly texture on the final

surface. Remember most epoxy products have a pot life of approximately 40 minutes (or

less) so only mix one bucket at a time and get to work immediately.

e) The number of coats and the required film thickness are the same regardless of the

application method. Do not apply succeeding coats until the previous coat has cured as

recommended manufacturer.

f) Once that is completed, we must leave the paint to dry for 24 hours. We will have to ensure

that no-one touches the paint while it is drying. If you do decide to add a second layer, in

order to get a thorough cover of the wall, we will have to make sure that the surface is

completely dry before repainting.

g) The subcontractor should inspect the floor after coating before the main contractor. After

the main contractor’s inspection, the consulting engineers will then perform the final

inspection. All of this is to make sure that the installation meets the requirements.

h) Provide “Wet Paint” signs at the complete painting area to protect newly painted finishes.

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

11

Brand/Model Dry Thickness Ambient Curing

Temperature

Jen. Epilux 4 50 Micron Humidity not 24 Hours

Epoxy Clear exceed 85%

Lacquer Temperature

between 10 C ﹾto

50 Cﹾ

Humidity not

Epilux 950 Super 125 Micron 7 Days

exceed 85%

Hibuild Coating

Temperature

between 10 C ﹾto

50 Cﹾ

Table 3 Epoxy Paint on Wall

7.3.3 Application Epoxy Paint on Floor Procedure

a) Apply one coat of high-quality primer on new surface will help to hide any small

imperfections. Priming will give the floor surface a longer life and better adhesion to the

substrate. Ensure that the areas are ventilated properly. Use a proper electrical mixer to mix

the component of the primer.

b) Application of the first Top coat of epoxy paint. Topcoat film is prepared by stirring Base

A to disperse any settlement, after which Hardener B is added to Base A and mixed slowly

for about 2 minutes making sure that air does not get into it, after mixing, transfer to another

container and mix again for 30 seconds.

c) Apply the product with a roller. Use a good quality roller, as poor quality rollers may start

to shed. We should be able to re-coat after 24 hours. The next day we may notice various

problems that have appeared such as cracks, holes etc. Make sure that these are sealed-

filled before starting the next coat. If necessary, wait an extra dry for the grout to dry before

re-coating.

d) Apply the final coat. Before placing the final coat make sure all holes and cracks have been

filled, and that all dust has been collected. Otherwise will get an ugly texture on the final

surface. Remember most epoxy products have a pot life of approximately 40 minutes (or

less) so only mix one bucket at a time and get to work immediately.

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

12

e) After application, the top coat must be protected using a polyethylene sheet for a period of

24 hours before allowing foot traffic. Vehicle traffic should be allowed five days after

application.

f) The subcontractor should inspect the floor after coating before the main contractor. After the

main contractor’s inspection, the consulting engineers will then perform the final inspection. All

of this is to make sure that the installation meets the requirements.

g) Provide “Wet Paint” signs at the complete painting area to protect newly painted finishes.

Brand/Model Dry Thickness Ambient Curing

Temperature

Jen. Epilux 4 50 Micron Humidity not 24 Hours

Epoxy Clear exceed 85%

Lacquer Temperature

between 10 C ﹾto

50 Cﹾ

Humidity not

Epilux 89 Hibuild 120 Micron exceed 85% 24 Hours

Finish Temperature

between 10 C ﹾto

50 Cﹾ

Humidity not

Epilux 89 Hibuild 120 Micron exceed 85% 7 Days

Finish Temperature

between 10 C ﹾto

50 Cﹾ

Table 4 Epoxy Paint on Floor

7.3.4 Epoxy Floor Curing

a) Once the final top coat is applied, it need to wait a minimum of 18 – 24 hours before the

floor can accept foot traffic. Wait an additional 24 hours before moving things back onto

the floor, and a total of 72 hours before vehicle traffic.

b) Remember that the epoxy floor coating will cure slower when temperatures are cooler than

ideal. It takes approximately 7 days for the floor coating to harden to its full strength.

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

13

7.3.5 Epoxy paint anti rust procedure

Substrate preparation

a) The substrate must be dry, stable and free of anything which would hinder bonding, such

as dust, loose particles, grease, rust or any kind of corrosion.

b) Depending on the nature of the substrate, it should be prepaired by brushing, rubbing down,

sand blasting, etc. and then thoroughly cleaned from dust.

Application of EPOXYCOAT-AC

a) Components A (resin) and B (hardener) are packed in two separate containers, having the

correct predetermined mixing proportion by weight. The whole quantity of component B

is added into component A. Mixing of the 2 components should take place for about 5

minutes, using a low revolution mixer (300 rpm). It is important to stir the mixture

thoroughly near the sides and bottom of the container, to achieve uniform dispersion of the

hardener. To prime the surface, 2 coats of EPOXYCOAT-AC are applied with brush, roller

or spray gun. The second coat is applied once the first one is dry, but within 24 hours.

Consumption: 150-200 g/m2 per coat.

b) Subsequently, in the next 24 hours and after the primer is completely dry, application of

the chosen EPOXYCOAT or DUROFLOOR system can take place. If alternatively,

EPOXYCOAT-AC is to be used as the final finish, 2 more coats of it should be additionally

applied. The second coat follows after the first one is completely dry, but within 24 hours.

Remarks

1) EPOXYCOAT-AC contains solvents. In cases of applications in closed rooms, measures

should be taken for good ventilation.

2) Working time of epoxy systems decreases when ambient temperature rises.

3) Bonding between successive layers may be severely affected by the intervention

moisture or dirt.

4) Epoxy layers should be protected from moisture for 4-6 hours after application. Moisture

may whiten the surface or/and make it sticky. It may also disturb hardening. Faded or

sticky layers in parts of the surface should be removed by grinding or milling and laid

again.

5) In case that longer time than predicted interferes between the application of successive

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

14

layers or in case that old floors are going to be laid again, the surface should be

thoroughly cleaned and ground before application of the new layer.

6) Before application, study the safety advice mentioned on the product’s labels.

7.4 Textured Coating

7.4.1 Inspection

During a thorough inspection, technicians look for chipping, flaking or peeling paint, rotten wood, and

other signs of wall deterioration. Any unsatisfactory conditions must be repaired before the process

can continue.

7.4.2 Trenching

Technicians dig a trench around the exterior walls to prevent moisture intrusion and help eliminate

foundation decay once the texture coating is applied.

7.4.3. Masking

All doors, windows, landscaping and sidewalks are covered to prevent the coating from getting on

these surfaces. This step ensures a professional-looking finished product.

7.4.4. Water Blasting

Workers blast the entire exterior with a high-pressure water spray to remove paint, dirt, stains, mold,

mildew and other foreign substances.

7.4.5. Scraping and sanding

This step removes any residual buildup that withstands the water blast. By removing remaining paint

and debris, damaged areas are revealed.

7.4.6. Patch and repair

Deteriorated areas discovered during the scraping and sanding process are patched and repaired.

Special patching and bonding materials correct defects and establish a smooth, uniform surface for the

texture coating to be applied.

7.4.7. Elastomeric primer

Technicians apply a textured primer to all exterior walls. This provides a protective layer to the

home’s exterior surface so it can endure prolonged exposure to the elements. The primer is carefully

inspected for uniform application before moving on to the next step.

7.4.8. Textured coating

The final coat goes over the primer and chemically bonds to it. This texture coating provides your

home’s final color and helps reflect heat from the sun’s rays. It also acts as a second line of defense

against the elements. In all, the installation supplies a 13- to 18-millimeter-thick, armor-like barrier

around your home.

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

7.4.9. Trim application

15

With the walls completely coated, workers go back and apply a specially formulated trim paint with

highly protective qualities. This contributes to the beauty and durability of your home’s exterior.

7.4.10. Clean up

The workers remove all masking and clean the windows of coating splatters. They also clean up

discarded coating material, rags and other construction waste so you’re left with a beautiful,

professional end product. Pretreatment shall be applied in accordance with manufacture standard

◼ SK KAKEN Co. Ltd.

Under Coat Required Paint &Treatment 0.10-0.13kg/sqm

Top coat 1 Required Paint &Treatment 0.40-0.50 kg/sqm

Top coat 2 Required Paint &Treatment 0.40-0.50 kg/sqm

7.5 Lacquer paint

Pretreatment shall be applied by the method approved by R.E.

Required Coat Required Paint and Treatment Required Quantity

Under Coat Lacquer Wood Sealer 0.10 kg/sq.m

Filler Wood Filler

Middle Coat Lacquer Sanding Sealer 0.12 kg/sq.m

Top Coat (2 coats) Lacquer Clear 0.10 kg/sq.m×2

8.0 Inspection

1) The inspection of quality control painting work, the following properties should be

inspected.

2) Conformance to the approved material.

3) Conformance to coating according to specification.

4) Conformance to the Temperature and humidity for applying condition.

5) Conformance to the adjacent surfaces properly protection.

6) The quality control of painting surfaces.

7) The quality control of painting edges clean and sharp.

WEP for Painting work REV.00 16.02.2023

THE PROJECT FOR THE IMPROVEMENT

OF GOVERNANCE AND MANAGEMENT

RESEARCH AND TRAINING FACILITIES

9.0 HEALTH, SAFETY AND ENVIRONMENT

16

9.1 Regulations

a) Before commencement of painting works, all relevant staffs will be briefed and trained

to comply regulations.

9.2 Health

a) All workers should wear PPE (Personal Protection Equipment).

b) All safety issues will be governed by the Health and Safety plan and strictly adhered.

9.3 Safety

a) While working in the high level, the scaffolding and ladder equipped with platform and hand

rail shall be provided during construction at height. All workers who execute on high level

must wear personal protect equipment (PPE) such as safety helmet, safety belt and etc.

b) Every equipment used must be maintained in accordance with legal requirements.

c) Electrical connections should be handled by qualified and approved electricians.

d) The workplace must be barricaded and well protected to prevent unauthorized personnel.

e) Keep a material safety data sheet to ensure that materials star handled well especially

chemicals. Major spill kit available and personal protective equipment must be made available

to every personnel must be worn at all times.

f) Wear eye protection during application. In case of contact with eyes, rinse immediately with

plenty of water and seek medical advice.

g) As a standard practice in case of skin contact immediately wash skin with soap and plenty of

water.

h) It is recommended to wear suitable nose pad during sanding and surface preparation to avoid

dust inhalation.

i) Do not pour leftover paint down the drain or in water courses.

j) Provide sufficient lighting in working area.

k) Safety Induction Training shall be conducted to new employees by Safety Officer before to

start any work.

9.4 Environmental issues

a) The environmental plan will be strictly adhered on site.

WEP for Painting work REV.00 16.02.2023

You might also like

- CPCCWHS2001 Assessment WorkbookDocument70 pagesCPCCWHS2001 Assessment Workbookankit33% (3)

- Completed Idp Report PDFDocument117 pagesCompleted Idp Report PDFFarhana Hussin100% (2)

- Assessment Workbook CPC Construction, Plumbing and Services Training PackageDocument94 pagesAssessment Workbook CPC Construction, Plumbing and Services Training PackageKomal SharmaNo ratings yet

- SGSO Regulation EnglishDocument38 pagesSGSO Regulation EnglishCinthia BazethNo ratings yet

- Pamphlet 5 - Edition 9 - January 2017Document30 pagesPamphlet 5 - Edition 9 - January 2017Comercial AySNo ratings yet

- Production Riser Life Extension: Guidance Notes OnDocument24 pagesProduction Riser Life Extension: Guidance Notes OnGopalakrishnanNo ratings yet

- Nine Steps to Success: North American edition: An ISO 27001 Implementation OverviewFrom EverandNine Steps to Success: North American edition: An ISO 27001 Implementation OverviewNo ratings yet

- Flat, Trofoil & TriplexDocument12 pagesFlat, Trofoil & Triplexphanibarama100% (1)

- VV Manual v1.1 PDFDocument111 pagesVV Manual v1.1 PDFHernâniCruzNo ratings yet

- CaseStudy-Ceramic Industry PDFDocument80 pagesCaseStudy-Ceramic Industry PDFMario CoelhoNo ratings yet

- Evaluation of Quality ManagementDocument18 pagesEvaluation of Quality ManagementAlemuNo ratings yet

- RFP - Section - II - Schedule of Requirements - RFP - 2018 - 6100 - Annex A EDD Standards PDFDocument35 pagesRFP - Section - II - Schedule of Requirements - RFP - 2018 - 6100 - Annex A EDD Standards PDFJagna GillNo ratings yet

- 8 - RJN NAD HSE Management PlanDocument45 pages8 - RJN NAD HSE Management PlanMartahanManurung100% (1)

- Ecpn Cs 168 Final For Publication For Moc For B&sDocument63 pagesEcpn Cs 168 Final For Publication For Moc For B&snatanNo ratings yet

- Regulations For Sanitary InstallationsDocument207 pagesRegulations For Sanitary Installationsyusuf100% (1)

- MDOT Procedures For Aggregate Inspection 658850 7Document91 pagesMDOT Procedures For Aggregate Inspection 658850 7Mo YNo ratings yet

- Project Guidelines 2019 Final JUNEDocument59 pagesProject Guidelines 2019 Final JUNENicholas KinotiNo ratings yet

- DINODocument38 pagesDINOCHIDERA ANo ratings yet

- Qam of Mekelle-1Document320 pagesQam of Mekelle-1Daric TesfayeNo ratings yet

- Section 5 - Annex - 3 Standard of Methods and MeasurmentsDocument64 pagesSection 5 - Annex - 3 Standard of Methods and MeasurmentsAshebir AjemaNo ratings yet

- Malaysia StandardDocument5 pagesMalaysia Standards63118No ratings yet

- PROPOSAL FOR YIRGALEM TEXTILE FACTORY Final Last PPPPPPPPPPPDocument51 pagesPROPOSAL FOR YIRGALEM TEXTILE FACTORY Final Last PPPPPPPPPPPsoloNo ratings yet

- Standard Methods of Measurement MUDHC 2014Document71 pagesStandard Methods of Measurement MUDHC 2014Desalegn Melknew90% (10)

- NIST - hb.150!1!2021 Energy Efficient Lighting ProductsDocument22 pagesNIST - hb.150!1!2021 Energy Efficient Lighting ProductsRIYANTO BEBETNo ratings yet

- Petroleum Deport EIA - FinalDocument104 pagesPetroleum Deport EIA - FinalJoey MW100% (1)

- Capstone Project Humidity Test ChamberDocument49 pagesCapstone Project Humidity Test Chamberkhaled hlalahNo ratings yet

- FM 5420 Carbon Dioxide Extinguishing Systems 2018Document59 pagesFM 5420 Carbon Dioxide Extinguishing Systems 2018andy100% (1)

- Composition of Natural-Gas Condensate Types of CondensateDocument35 pagesComposition of Natural-Gas Condensate Types of CondensatePinak Chowdhury100% (1)

- Technical Specification For Road Rail Equipment FSS550Document70 pagesTechnical Specification For Road Rail Equipment FSS550Ion Logofătu AlbertNo ratings yet

- Mac3701 2024 TL103 3 BDocument80 pagesMac3701 2024 TL103 3 BRodney MahlanguNo ratings yet

- 4 - 02. Section II - 4420003405Document137 pages4 - 02. Section II - 4420003405JonesNo ratings yet

- HSE Docs by Hseprof ComDocument51 pagesHSE Docs by Hseprof Comzainjotun406No ratings yet

- RFP Attachment C CSEAS 2.0 PMC Statement of WorkDocument55 pagesRFP Attachment C CSEAS 2.0 PMC Statement of WorkLim Siew LingNo ratings yet

- PWTP2 - QCP 20160908-ADocument35 pagesPWTP2 - QCP 20160908-AgregNo ratings yet

- EACO Indoor Air Quality (IAQ) - Guideline For Non-Industrial WorkplacesDocument54 pagesEACO Indoor Air Quality (IAQ) - Guideline For Non-Industrial WorkplacesM MNo ratings yet

- ABS MArine Management Systems Update 2016Document59 pagesABS MArine Management Systems Update 2016Xmenxs XmenxsNo ratings yet

- Tenant GuidelinesDocument90 pagesTenant Guidelinessheryl himocNo ratings yet

- HSE-ML-002 Tugs Operation HSE ManualDocument22 pagesHSE-ML-002 Tugs Operation HSE ManualRamy AbouquahfNo ratings yet

- Final Gulilat ResearchDocument46 pagesFinal Gulilat ResearchAssebe FeteneNo ratings yet

- Schedule Managment PlanDocument57 pagesSchedule Managment Planridhoni putraNo ratings yet

- (BOOK NO. 14) - (22) - SG-G-04 - Regulatory Inspection & Enforcement - (OTHER)Document73 pages(BOOK NO. 14) - (22) - SG-G-04 - Regulatory Inspection & Enforcement - (OTHER)pratip_bNo ratings yet

- Arkan Building Materials Health, Safety & Environment ManualDocument28 pagesArkan Building Materials Health, Safety & Environment ManualmorisNo ratings yet

- Simple Thesis On PMODocument106 pagesSimple Thesis On PMOMarcia Edwards50% (2)

- FM 1635 Plastic Pipe and Fittings For Automatic Sprinkler Systems 2018Document54 pagesFM 1635 Plastic Pipe and Fittings For Automatic Sprinkler Systems 2018andyNo ratings yet

- An Investigation of Total Quality ManageDocument323 pagesAn Investigation of Total Quality ManageAbate TefferaNo ratings yet

- Quality Assurance Manual: A/FatronicsDocument32 pagesQuality Assurance Manual: A/FatronicsAnand A V MysoreNo ratings yet

- Doe Handbook: Guide To Good Practices For Training of Technical Staff and ManagersDocument46 pagesDoe Handbook: Guide To Good Practices For Training of Technical Staff and ManagersAgustin A.No ratings yet

- Mba Ohalloran B 2014 PDFDocument100 pagesMba Ohalloran B 2014 PDFMsm MahsoomNo ratings yet

- Section 3 - Technical PackageDocument110 pagesSection 3 - Technical Packageرودي رودNo ratings yet

- Rcs Construction Manufacturing Construction Elements Cop 2022Document109 pagesRcs Construction Manufacturing Construction Elements Cop 2022JasonNo ratings yet

- Eia Report For Mpa WebsiteDocument188 pagesEia Report For Mpa WebsiteYen Ling NgNo ratings yet

- Clause-By-Clause Explanation of ISO 9001:2008: White PaperDocument21 pagesClause-By-Clause Explanation of ISO 9001:2008: White PapermardiradNo ratings yet

- ITA Design Guidelines WaterproofingDocument74 pagesITA Design Guidelines WaterproofingTansel YılmazNo ratings yet

- Doe HDBK 1002Document70 pagesDoe HDBK 1002hadiranjiNo ratings yet

- Pengurusan Kewangan (Kumpulan 6)Document42 pagesPengurusan Kewangan (Kumpulan 6)Wai ChongNo ratings yet

- Quality Manual v1.1 PDFDocument45 pagesQuality Manual v1.1 PDFGummalla RajeshNo ratings yet

- Occupational Health and Safety (Ohs) Management Plan ForDocument54 pagesOccupational Health and Safety (Ohs) Management Plan ForJC Dolorito100% (1)

- Heyles Fentoes Trainnig ReportDocument58 pagesHeyles Fentoes Trainnig ReportayeshmanthabroNo ratings yet

- Process Operator Refinery Chemical Liquid Processes 246F en TS3Document31 pagesProcess Operator Refinery Chemical Liquid Processes 246F en TS3shakNo ratings yet

- WQ1454 Project Execution PlanDocument60 pagesWQ1454 Project Execution PlanRAZANo ratings yet

- WEP For Concrete BIGMDocument12 pagesWEP For Concrete BIGMpalashNo ratings yet

- WEP For Gypsum Board False CeilingDocument6 pagesWEP For Gypsum Board False CeilingpalashNo ratings yet

- WEP For Steel Structure WorkDocument8 pagesWEP For Steel Structure WorkpalashNo ratings yet

- WEP For Sheet Pile WorkDocument12 pagesWEP For Sheet Pile WorkpalashNo ratings yet

- Program of Works For DENR Perimeter FenceDocument8 pagesProgram of Works For DENR Perimeter FenceKarl Brian OdonNo ratings yet

- Density 844 (KG/M) Absolute Roughness of Pipe 0.000046 (M) Kinematic Viscosity ( ) 6.643 E-6 (m2/s)Document7 pagesDensity 844 (KG/M) Absolute Roughness of Pipe 0.000046 (M) Kinematic Viscosity ( ) 6.643 E-6 (m2/s)epbamdadNo ratings yet

- BBIA Landside Infrastructure Final Design ReportDocument167 pagesBBIA Landside Infrastructure Final Design ReportTayyabah ZafarNo ratings yet

- Hospital: ServicesDocument60 pagesHospital: ServicesChanpreet SinghNo ratings yet

- Balance Material List 2Document1 pageBalance Material List 2manojkumarmurlidharaNo ratings yet

- Space Attributes: AccessibleDocument56 pagesSpace Attributes: AccessibleStephanie Lynn omegaNo ratings yet

- Pres RateDocument2 pagesPres RatescemanjuNo ratings yet

- RCD - PPT - Part 1Document32 pagesRCD - PPT - Part 1Christian Josh DomingoNo ratings yet

- Chapter 8: Two-Way Slab SystemsDocument53 pagesChapter 8: Two-Way Slab SystemsDavid SanchezNo ratings yet

- Abstract of The BOCW ActDocument4 pagesAbstract of The BOCW ActSaptarshi Dasgupta100% (1)

- Construction and Building Materials: Faiz Uddin Ahmed Shaikh, Salmabanu Luhar, Hasan S SSahan Arel, Ismail LuharDocument28 pagesConstruction and Building Materials: Faiz Uddin Ahmed Shaikh, Salmabanu Luhar, Hasan S SSahan Arel, Ismail LuharChirag N PatelNo ratings yet

- DAFZ RegulationsDocument41 pagesDAFZ RegulationsRoger SchulpNo ratings yet

- Autocalculator v. 16.00 i113001ENDocument53 pagesAutocalculator v. 16.00 i113001ENstikss100% (1)

- Design of Combined FootingDocument6 pagesDesign of Combined FootingEric John PedrosoNo ratings yet

- Curb InletDocument1 pageCurb InletJoseph MathewNo ratings yet

- Louis SullivanDocument20 pagesLouis SullivanMEGHA SHARMANo ratings yet

- For Heavy-Duty Equipment Exposed To Excessive Dirt and DebrisDocument2 pagesFor Heavy-Duty Equipment Exposed To Excessive Dirt and DebrisKarthik YadavNo ratings yet

- Nas1303 Nas1316Document2 pagesNas1303 Nas1316Jean AbelaNo ratings yet

- Case Studt 1Document11 pagesCase Studt 1keerthi R100% (1)

- Air Compressor Overall - Component DiagramDocument18 pagesAir Compressor Overall - Component DiagramHafizuddin RazakNo ratings yet

- Perno de Convergencia P 090.01 Konvergenzmessbolzen KV enDocument4 pagesPerno de Convergencia P 090.01 Konvergenzmessbolzen KV enFreddy Sanchez LuckNo ratings yet

- Aircraft Material & HardwareDocument105 pagesAircraft Material & Hardwarevipin muraliNo ratings yet

- Estonia JobsDocument8 pagesEstonia JobsMd JonayedNo ratings yet

- BP 220 PD957 Planning and Design Standards ComparisonDocument10 pagesBP 220 PD957 Planning and Design Standards ComparisonRandolph AlvarezNo ratings yet

- Nitoflor SL Cond-DissDocument4 pagesNitoflor SL Cond-DissVenkata Raju KalidindiNo ratings yet

- 04 Part 2-Desain Bangunan Sipil Pada PLTADocument30 pages04 Part 2-Desain Bangunan Sipil Pada PLTANovi AndrianyNo ratings yet

- Instruction Manual HL2-105Document20 pagesInstruction Manual HL2-105Станислав Георгиев67% (6)

- ILJIN STEEL Corporation: The First PartnerDocument25 pagesILJIN STEEL Corporation: The First PartnerUB HeavypartsNo ratings yet

- Is Thicker Gasket Material Better Than ThinnerDocument2 pagesIs Thicker Gasket Material Better Than ThinnerSteven LiparotoNo ratings yet