Professional Documents

Culture Documents

TICSA - Diesel Uno Petroleos Guatemala (13.01.23)

TICSA - Diesel Uno Petroleos Guatemala (13.01.23)

Uploaded by

Luis M LópezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TICSA - Diesel Uno Petroleos Guatemala (13.01.23)

TICSA - Diesel Uno Petroleos Guatemala (13.01.23)

Uploaded by

Luis M LópezCopyright:

Available Formats

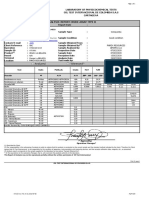

OIL TEST INTERNACIONAL DE GUATEMALA, S.A.

2da. Avenida Lote 79, Zona 0, Col. El Jardín San José, Escuintla

Phone: 7882-9602 - 04 Mail: opsguatemala@otihdl.com;

ANALYSIS REPORT

Our Reference : OTIGT23-0059 Client : UNO PETROLEOS, S.A.

Product(1) : LOW SULFUR DIESEL Contact (s) : MELVIN LEAL

Laboratory Sample Identification : 0054-2023 SJ : ALEXANDER ALEXEEV

11 Calle 2-20 zona 10 Conjunto AVIA, Torre 3, Nivel 19

Seal Number : N/A Address : oficina 1901, Guatemala, Guatemala

Sample Obtained by(2) : OTI GUATEMALA / OPERATIONS

Sample Location : PUERTO SAN JOSE / TICSA Client Ref. : 22P691779 / TBC

SHIP TANKS 3P(24.61%) 3S(25.31%) 5P(24.94%)

5S(25.13%) COMPOSITE SAMPLE BEFORE DISCHARGE MT

Sample Description : YACA Sample Reception Date : JANUARY 10th, 2023

Sample Date : JANUARY 10th, 2023 Analysis Start Date : JANUARY 10th, 2023

Sampling Plan/Method : API chapter 8 Analysis Completion Date : JANUARY 11th, 2023

Sampling Performed by : Vinicio Pereira Analysis Performed at : DUARTE / BARILLAS

Sample Obtained from : SHIP COMPOSITE Analysis Report Issue Date : JANUARY 11th, 2023

Analyzed Witnessed(3) Preliminary Final

Test Unit Method Specifications Results

Appearance N/A ASTM D 4176 Clear and Bright C&B

API Gravity @ 60 °F Degrees ASTM D 287 Report 33.71

Density @ 15 °C Kg/m³ ASTM D 1298 Report 856.02

Color ASTM N/A ASTM D 1500 1.5 max 1.0

Kinematic Viscosity @ 40 °C mm²/s ASTM D 445 1,9 min - 4,1 max 3.143

Sulfur Content Mass % ASTM D 4294 0.05 max 0.0476

Carbon Conradson Residue on 10% Residue Mass % ASTM D 189 0.10 max 0.010

Ash Content Mass % ASTM D 482 0.01 max <0.001

Flash Point °C ASTM D 93 52 min 66.0

Pour Point °C ASTM D 97 Report -22

Cloud Point °C ASTM D 2500 0 max -10

Cetane Index N/A ASTM D 976 45 min 48.10

Water & Sediment vol % ASTM D 2709 0.05 max <0.01

Copper Strip Corrosion, 3h @ 122 ºF N/A ASTM D 130 No. 2 max 1A

Aromatics vol % ASTM D 1319 Report 31.6

Distillation/Manual °C ASTM D 86 --- -----

Initial Boiling Point °C report 174.0

10% Recovered °C Report 218.0

50% Recovered °C Report 282.0

90% Recovered °C 360 max 324.0

Final Boiling Point °C Report 345.0

Recovered vol % report 98.5

Residue vol % Report 1.0

Loss vol % Report 0.5

Lubricity at 60ºC (Wear Scar Diameter) µm ASTM D 6079 520 Max 420

∙Major Axis µm report 460

∙Minor Axis µm Report 380

Electrical Conductivity pS/m ASTM D 2624 50 min 168

Temperatura °C report 27.0

Fatty Acid Methyl Ester mg/kg ASTM D7963 1000 max 0.0

***end of analysis results***

Environmental conditions of the tests:

Julio Escalante

Lab Manager

(1)

As declared by Client.

(2) Analysis report corresponds to the sample as supplied to the laboratory by: OTI GUATEMALA / OPERATIONS ; which was analized upon request to verify compliance acoording to declared ; which was analized upon request to verify compliance acoording to

declared specifications, without any additional responsability on behalf of the laboratory.

(3)

Our responsibility in Analysis Witnessing is limited to witness that the analysis is being carried out to the correct sample and according to the previously established method. Therefore, the customer accepts that Oil Test Internacional de Guatemala, S.A. is

not responsible for the conditions of the measuring equipment, instrument or devices and that accepts the calibration data, reagents and other instruments or materials used as presented.

OTI does not have any liability for information provided by the client, which may affect validity of analysis results.

*Test within the scope of ISO 17025:2017 Lab. Accreditation

**Test outsourced to another laboratory

All results contained within this report correspond exclusively to the sample described.

This Report of Analysis may not be reproduced or partially reproduced without the written permission of Oil Test Internacional de Guatemala, S.A.

End of Report

Emisión: 01/ Rev.#:04 / 2019-08-20 FOTI-008

You might also like

- Quality Certificate Jet FuelDocument2 pagesQuality Certificate Jet FuelLeather BredBoi100% (1)

- Test Reports - NBRDocument105 pagesTest Reports - NBRImtiyaz KhanNo ratings yet

- Importing Ground Grid From AutoCAD PDFDocument7 pagesImporting Ground Grid From AutoCAD PDFVasudevan KunjithapathamNo ratings yet

- Doc-20231030-Wa0009 231031 151223Document3 pagesDoc-20231030-Wa0009 231031 151223Erwanto SENo ratings yet

- ASSAY Crude Type II La Belleza OTI-2020Document1 pageASSAY Crude Type II La Belleza OTI-2020jhon alexander oviedo suarezNo ratings yet

- OTI-039 Report of Analysis ASSAY TIGANA OFICIAL PDFDocument1 pageOTI-039 Report of Analysis ASSAY TIGANA OFICIAL PDFLuis José Valera GonzalezNo ratings yet

- A-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportDocument4 pagesA-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportHari KarthickNo ratings yet

- Roa Nkri AeroDocument2 pagesRoa Nkri AeroAlung EdisonNo ratings yet

- Scan Report of Analysis - PT. RIZKY BARA MANDIRI - 1 Kode Sample - RBM-SD-AGUS SALIM - March 03, 2024Document2 pagesScan Report of Analysis - PT. RIZKY BARA MANDIRI - 1 Kode Sample - RBM-SD-AGUS SALIM - March 03, 2024Alung EdisonNo ratings yet

- Scan Report of Analysis - Pt. Bumi Lestari Wisesa - 1 Kode Sample OrsaDocument2 pagesScan Report of Analysis - Pt. Bumi Lestari Wisesa - 1 Kode Sample Orsasunda.empire1989No ratings yet

- LF642-08 Water Vapor PermeabilityDocument4 pagesLF642-08 Water Vapor PermeabilityDaniel MarinNo ratings yet

- Certificate Test Result NO: SHU/14702/07-20: Analysis Undertaken On Samples As ReceivedDocument3 pagesCertificate Test Result NO: SHU/14702/07-20: Analysis Undertaken On Samples As ReceivedLuqman Cuopreakt'zNo ratings yet

- Ajit Coating 207 InnowhiteDocument1 pageAjit Coating 207 InnowhiteAnand Chavan Projects-QualityNo ratings yet

- Thermal & CASS PDFDocument1 pageThermal & CASS PDFAmandeep SinghNo ratings yet

- Third Party ( ) :: Agq Peru, S.A.CDocument4 pagesThird Party ( ) :: Agq Peru, S.A.CGabriela Salinas ChávezNo ratings yet

- Blade Cut ResistanceDocument3 pagesBlade Cut ResistanceMK WRITESNo ratings yet

- Bureau of Indian Standards BIS, Patna Branch Laboratory (PBL)Document5 pagesBureau of Indian Standards BIS, Patna Branch Laboratory (PBL)sunil kumarNo ratings yet

- 12 MM Aggregate Third Party Test Report PDFDocument3 pages12 MM Aggregate Third Party Test Report PDFsyed sulemanNo ratings yet

- Indian Oil Corporation Limited: ASTM/IP/IS1448)Document3 pagesIndian Oil Corporation Limited: ASTM/IP/IS1448)Arvind DhakaNo ratings yet

- A-Star Testing & Inspection (S) Pte LTD No 5, Soon Lee Street #03-37 - Pioneer Point Singapore 627607 - Tel: +65 62616162 / +65 62616169Document8 pagesA-Star Testing & Inspection (S) Pte LTD No 5, Soon Lee Street #03-37 - Pioneer Point Singapore 627607 - Tel: +65 62616162 / +65 62616169Hari KarthickNo ratings yet

- Sun Flower Oil ReportDocument12 pagesSun Flower Oil Reportwww.pal1793No ratings yet

- 2new Consult Subgrade Quality TestsDocument7 pages2new Consult Subgrade Quality TestsmulNo ratings yet

- 2 Turbin 0511 Ob2123174Document1 page2 Turbin 0511 Ob2123174BennyNo ratings yet

- List of Aggregates TestsDocument30 pagesList of Aggregates TestsGeorges Abi JaoudeNo ratings yet

- Aes Laboratories (P) LTD.: Analyzing Today FR An A.csured TomorrowDocument1 pageAes Laboratories (P) LTD.: Analyzing Today FR An A.csured TomorrowShreyansh SinghNo ratings yet

- Analysis Report: Min Max Units Result Analysis MethodDocument1 pageAnalysis Report: Min Max Units Result Analysis MethodRodolfo de la TorreNo ratings yet

- 568 Reference Item 900 Test Region Bislig Bridge Surigao Coastal RoadDocument11 pages568 Reference Item 900 Test Region Bislig Bridge Surigao Coastal RoadFil Conol iiiNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Laboratory Services: Test ReportDocument1 pageLaboratory Services: Test ReportMechtek LabNo ratings yet

- Analysis Report: Min Max Units Result Method AnalysisDocument1 pageAnalysis Report: Min Max Units Result Method AnalysisRodolfo de la TorreNo ratings yet

- Steel Toe Cap 459 CertificateDocument3 pagesSteel Toe Cap 459 CertificatelufvijpharmaNo ratings yet

- DCL Test-Kimmco - Isover Slab 80-k and R ValuesDocument2 pagesDCL Test-Kimmco - Isover Slab 80-k and R ValuesabuyeheaNo ratings yet

- The Boss COA SG 031719Document4 pagesThe Boss COA SG 031719Daniel VascoNo ratings yet

- Aes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowDocument1 pageAes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowShreyansh SinghNo ratings yet

- LHM68油样分析报告- 载车- 卡特实验室4369390 - AES004 - Q300 - 1Document2 pagesLHM68油样分析报告- 载车- 卡特实验室4369390 - AES004 - Q300 - 1袁焕松No ratings yet

- Kanstin Hollywod (Pasir)Document6 pagesKanstin Hollywod (Pasir)Yuniyhan Surya PrajaNo ratings yet

- Tensile Test Report: S S Nikhil (M-Tech Project) CmritDocument2 pagesTensile Test Report: S S Nikhil (M-Tech Project) CmritESHWAR CHARYNo ratings yet

- Hitachi Oil ReportDocument2 pagesHitachi Oil Reportwww.pal1793No ratings yet

- Receiving Inspection Standard: (Raw Material) GradeDocument2 pagesReceiving Inspection Standard: (Raw Material) Gradea9808755315No ratings yet

- Aes Laboratories (P) LTD.: Analyz:ng Today JR An Assured TomorrowDocument1 pageAes Laboratories (P) LTD.: Analyz:ng Today JR An Assured TomorrowShreyansh SinghNo ratings yet

- Aitex LOI Nomex Test Report - 1Document6 pagesAitex LOI Nomex Test Report - 1Arun Vijayan M VNo ratings yet

- HS Everett-Foam Vluae F0271Document1 pageHS Everett-Foam Vluae F0271Dinesh KhatiNo ratings yet

- KahlWax 7304 - 2020-06-04Document1 pageKahlWax 7304 - 2020-06-04Özlem YılmazNo ratings yet

- Int Aim 231787 PT 14 1302&03Document1 pageInt Aim 231787 PT 14 1302&03Joshua ClaytonNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Electrode Qualification TestDocument5 pagesElectrode Qualification TestAbhishek Kumar VishwakarmaNo ratings yet

- RM Mechanical Report 28.1 MMDocument1 pageRM Mechanical Report 28.1 MMBHUSHANNo ratings yet

- 380 1 PDFDocument7 pages380 1 PDFJimyTeránAgudeloNo ratings yet

- Oil Report MPTPLDocument12 pagesOil Report MPTPLwww.pal1793No ratings yet

- EMC Pro1040 Pro1050 2182013 ODCùl ENDocument75 pagesEMC Pro1040 Pro1050 2182013 ODCùl ENTayfun SezişNo ratings yet

- Pt. Tekenomiks Indonesia: Fuel Analysis ReportDocument1 pagePt. Tekenomiks Indonesia: Fuel Analysis Reportfirman manaluNo ratings yet

- LA Ravi Sir NC 4Document4 pagesLA Ravi Sir NC 4mangalamtestingbureaNo ratings yet

- Coa Kaptan Petrokimia Gresik 2022Document1 pageCoa Kaptan Petrokimia Gresik 2022Tommy HiroNo ratings yet

- Plus en 1728 2012Document3 pagesPlus en 1728 2012Jorge R Andrade SNo ratings yet

- 1 Ipog HardnessDocument1 page1 Ipog HardnessprudvirajsriujjwalaNo ratings yet

- Nanochromatography and Nanocapillary Electrophoresis: Pharmaceutical and Environmental AnalysesFrom EverandNanochromatography and Nanocapillary Electrophoresis: Pharmaceutical and Environmental AnalysesNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- BEF22903 Chapter 2Document35 pagesBEF22903 Chapter 2rajsathia99No ratings yet

- AP Physics C E&M Unit 3 1. Magnetic Field and Force HandoutDocument28 pagesAP Physics C E&M Unit 3 1. Magnetic Field and Force HandoutmoonidiveNo ratings yet

- Prospects of Artificial IntelligenceDocument18 pagesProspects of Artificial IntelligenceSAMEDNo ratings yet

- Protective Relaying - An OverviewDocument59 pagesProtective Relaying - An OverviewGurmeet Singh100% (1)

- Parameter Estimation of Linear Induction Motor Labvolt 8228-02Document7 pagesParameter Estimation of Linear Induction Motor Labvolt 8228-02Mohamed Riyad BoudallaaNo ratings yet

- Elcometer-319 - Instrument Za Merenje Klimatskih Uslova-EDocument3 pagesElcometer-319 - Instrument Za Merenje Klimatskih Uslova-EsambathkrNo ratings yet

- 2016 Catalogue-SpanishDocument101 pages2016 Catalogue-SpanishwgonzalesmNo ratings yet

- IP Lab ExDocument24 pagesIP Lab ExKarthik SNo ratings yet

- Bagging and Boosting: 9.520 Class 10, 13 March 2006 Sasha RakhlinDocument19 pagesBagging and Boosting: 9.520 Class 10, 13 March 2006 Sasha RakhlinAkhi DanuNo ratings yet

- Ase 18 2 GaDocument36 pagesAse 18 2 Gac131508No ratings yet

- Ipay88 Technical Spec V1.6.4Document31 pagesIpay88 Technical Spec V1.6.4Dmytro TsybenkoNo ratings yet

- Maths Class X Sample Paper Test 05 For Board Exam 2024Document6 pagesMaths Class X Sample Paper Test 05 For Board Exam 2024suiiironaldo255No ratings yet

- CBP Math Module1111Document42 pagesCBP Math Module1111Ernest LarotinNo ratings yet

- Chapter 2-4 To 2-6 With AnswersDocument12 pagesChapter 2-4 To 2-6 With Answersapi-235135985No ratings yet

- A Novel Kind of Concrete Superplasticizer Based On LigniteDocument8 pagesA Novel Kind of Concrete Superplasticizer Based On Lignitemoustafa hadj-doulaNo ratings yet

- Chapter 3: Mathematical Modelling Principles: - Formulate Dynamic Models Based OnDocument40 pagesChapter 3: Mathematical Modelling Principles: - Formulate Dynamic Models Based OnJanusNo ratings yet

- AP Biology Diffusion and Osmosis Lab ReportDocument7 pagesAP Biology Diffusion and Osmosis Lab ReportVictor Martin100% (1)

- HHSM ZG513Document3 pagesHHSM ZG513Satain Bhat0% (1)

- AsdxxxxDocument2 pagesAsdxxxxalexyno8No ratings yet

- Intrinsic vs. Extrinsic Motivations To Volunteer and Social Capital FormationDocument13 pagesIntrinsic vs. Extrinsic Motivations To Volunteer and Social Capital FormationShouravpedia™No ratings yet

- Slide Chpt03Document34 pagesSlide Chpt03kt rajaNo ratings yet

- Mantenimiento Periodico F-Series PDFDocument14 pagesMantenimiento Periodico F-Series PDFcristian faundesNo ratings yet

- Lifting Lug AnalysisDocument3 pagesLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Goldengate12 2 X Cert Matrix 2769360Document18 pagesGoldengate12 2 X Cert Matrix 2769360repakulakishoreNo ratings yet

- Screw-Jack - Mechanical Engineering AssignmentDocument25 pagesScrew-Jack - Mechanical Engineering AssignmentMorteza ShakerienNo ratings yet

- Debugger CevaxDocument57 pagesDebugger Cevaxcarver_uaNo ratings yet

- 06-06-1986 at 5-30 AmDocument67 pages06-06-1986 at 5-30 Amrahul106No ratings yet

- Kelompok 9 Nama: Rifa Kamilia (1314618002) Rita Septia NR. (1314618015) Muhammad Amanda. (1314618034)Document4 pagesKelompok 9 Nama: Rifa Kamilia (1314618002) Rita Septia NR. (1314618015) Muhammad Amanda. (1314618034)Rifa KamelliaNo ratings yet

- Epofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregDocument5 pagesEpofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregKarishma PrabhuNo ratings yet